When it comes to maintaining your lawn care equipment, having a clear understanding of its individual elements is crucial. Each piece plays a vital role in ensuring optimal performance and longevity. By familiarizing yourself with these components, you can make informed decisions regarding repairs and replacements.

Visual representations of these elements can significantly aid in identifying specific parts, their functions, and how they interact within the overall machinery. Whether you are troubleshooting issues or planning upgrades, a detailed overview of each section can enhance your maintenance strategy.

In this article, we will delve into the intricate assembly of your mowing device. We will explore various elements that contribute to its efficient operation, providing insights that will help you navigate the world of lawn care effectively. Understanding these components not only empowers you as an owner but also enhances the overall performance of your equipment.

Overview of John Deere Z225

This section provides a comprehensive look at a popular riding mower model, known for its reliability and efficiency. It is designed for residential use, catering to homeowners seeking a durable solution for lawn maintenance. The machine balances performance with user-friendly features, making it a favored choice among gardening enthusiasts.

Key Features

One of the standout attributes of this mower is its robust engine, which delivers powerful performance for various mowing tasks. Additionally, the cutting deck is engineered to provide a clean and precise cut, ensuring an aesthetically pleasing lawn. The ergonomic design contributes to ease of operation, allowing users to navigate their yards with minimal effort.

Maintenance and Support

Regular upkeep is essential to maximize the longevity of this mower. Routine inspections and servicing help maintain optimal performance levels. Access to quality replacement components ensures that any necessary repairs can be handled efficiently, keeping the mower in top shape for years to come.

Key Features of Z225 Model

This model stands out due to its robust design and user-friendly characteristics, making it ideal for various lawn care needs. The combination of performance and efficiency ensures a seamless mowing experience for users of all skill levels.

Performance and Efficiency

The engine delivers impressive power, enabling quick and thorough grass cutting. Coupled with an innovative cutting system, it guarantees a clean finish with minimal effort.

Comfort and Maneuverability

With an ergonomic seating arrangement and intuitive controls, users can navigate effortlessly. The compact size allows access to tight spaces, enhancing the overall mowing experience.

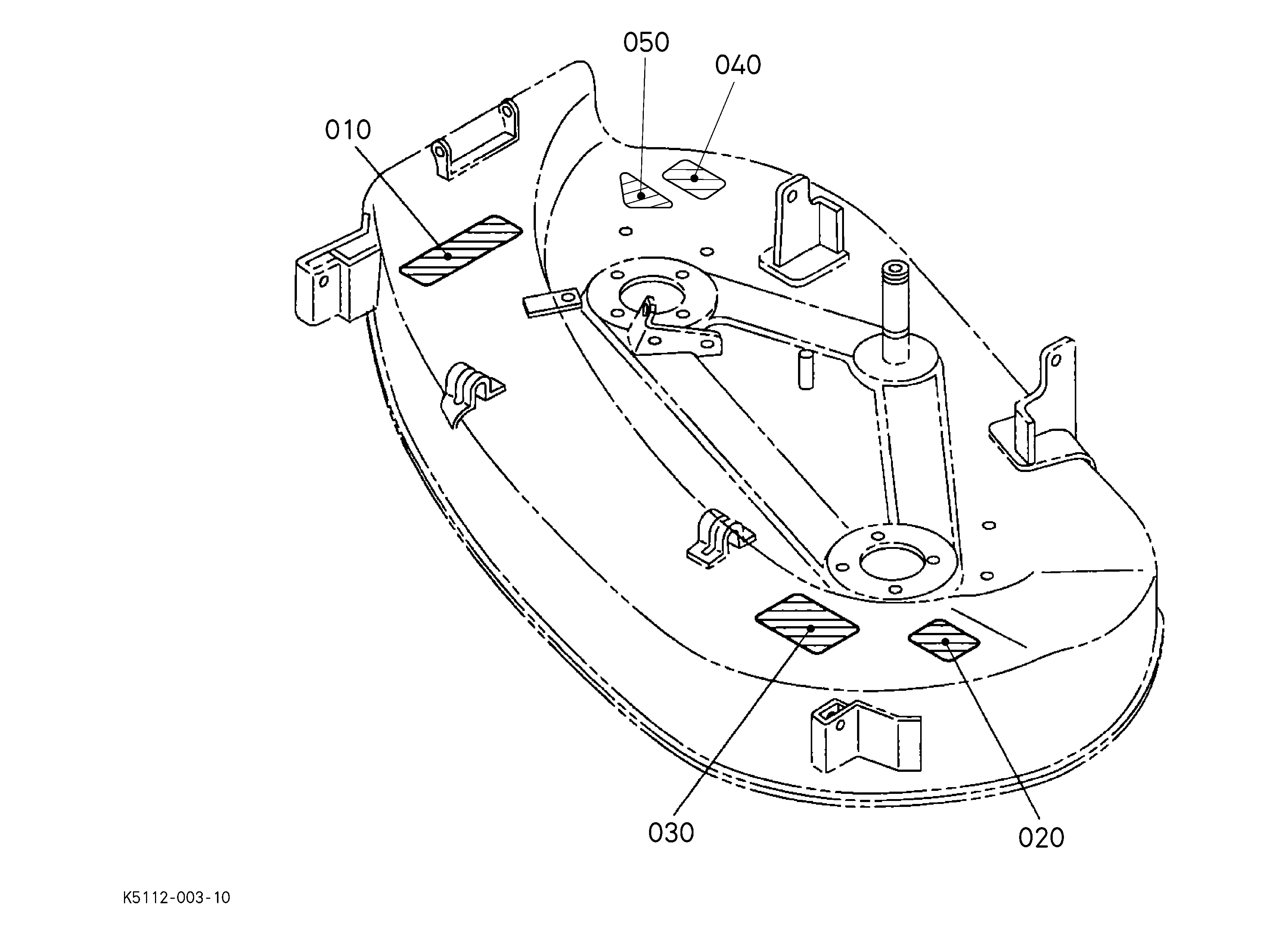

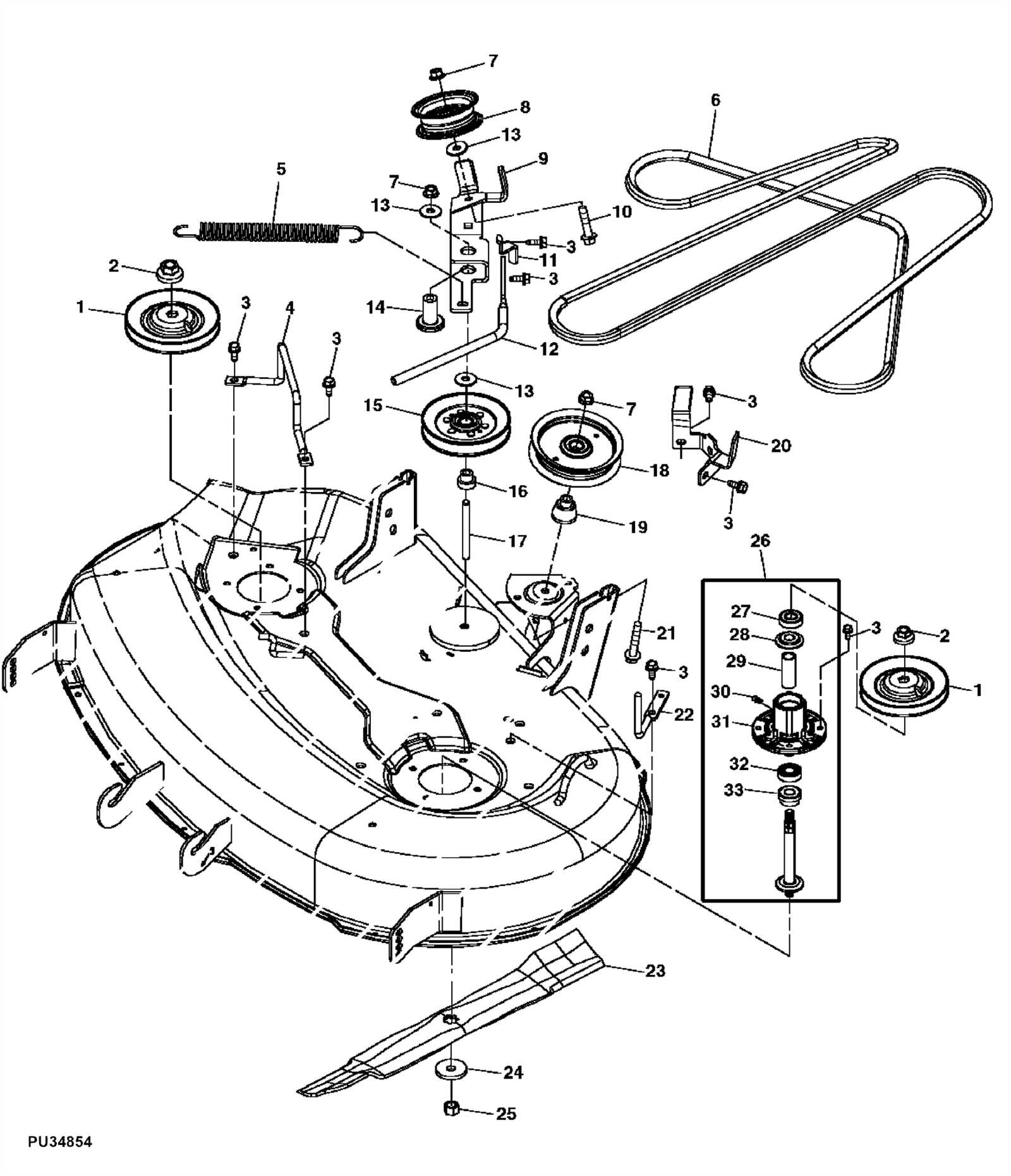

Importance of Parts Diagrams

Visual representations of components play a crucial role in the maintenance and repair of machinery. They serve as a comprehensive guide, helping users identify individual elements and their interconnections. This understanding is essential for efficient troubleshooting and ensuring that repairs are executed accurately.

Enhanced Understanding

Utilizing these visual aids fosters a deeper comprehension of how different elements work together. Users can easily pinpoint where issues may arise, streamlining the repair process and minimizing downtime.

Facilitating Efficient Repairs

Having a clear view of all necessary components enables technicians to gather the right tools and replacements beforehand. This preparation ultimately leads to quicker resolutions and a smoother workflow, enhancing overall productivity.

Understanding the Z225 42C Configuration

This section explores the intricate setup of a specific lawn maintenance machine, focusing on its various components and their functions. By examining the configuration, users can gain insights into the efficient operation and maintenance of this essential equipment.

The configuration includes several key elements that contribute to its overall performance:

- Engine: The powerhouse that drives the machine, impacting speed and cutting efficiency.

- Deck: The area where the cutting action takes place, crucial for achieving an even finish.

- Wheels: Designed for maneuverability, they affect how easily the machine navigates different terrains.

- Control System: The interface that allows the operator to adjust settings for optimal performance.

Each of these components plays a vital role in the overall functionality and effectiveness of the machine. Understanding their configuration not only aids in better operation but also enhances maintenance practices, ensuring longevity and reliability.

For those looking to enhance their knowledge further, consider the following aspects:

- Maintenance Routines: Regular checks on components to prevent wear and tear.

- Adjustment Techniques: Fine-tuning settings for various cutting conditions.

- Replacement Strategies: Knowing when and how to replace worn-out parts.

By delving into these details, users can optimize their experience and ensure their equipment remains in top-notch condition.

Common Issues with Z225 Parts

When operating a particular model of mower, several typical challenges may arise that can affect performance and longevity. Understanding these common problems helps in maintaining optimal functionality and efficiency.

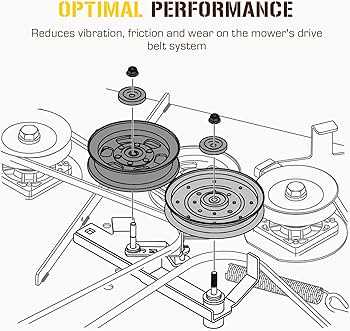

Worn Belts: Over time, drive belts can experience wear and tear, leading to slippage or breakage. Regular inspections are essential to prevent unexpected failures.

Fuel System Blockages: Clogs in the fuel system can hinder engine performance. Keeping the fuel lines and filters clean is crucial for smooth operation.

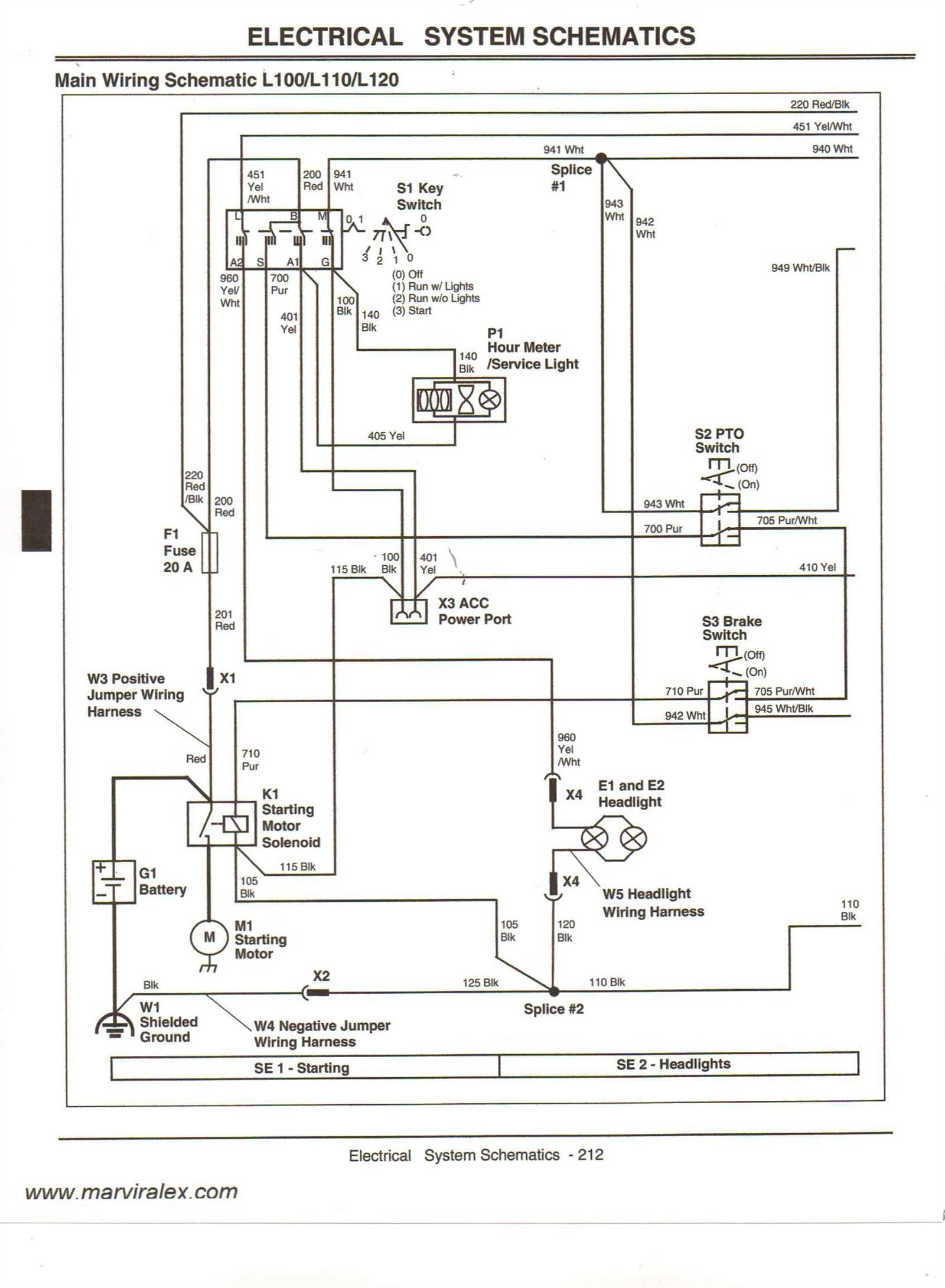

Electrical Failures: Issues with wiring or connectors often lead to starting problems. Ensuring connections are secure and free from corrosion can mitigate these risks.

Blade Deterioration: Blades can dull or become damaged from regular use. Regular sharpening and timely replacement are necessary for effective cutting.

Tire Wear: Tires may show signs of uneven wear due to improper inflation or alignment. Routine checks can help maintain balanced traction and stability.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment. By adhering to a consistent maintenance schedule, you can prevent unexpected issues and enhance overall functionality. This section offers valuable strategies to keep your machinery running smoothly and effectively.

Routine Inspections

Conducting frequent checks is crucial for identifying potential problems early. Examine key components such as the blades, belts, and filters for wear and tear. Keeping an eye on fluid levels, including oil and fuel, will also contribute to optimal performance. Addressing minor issues promptly can save time and costs in the long run.

Cleaning and Lubrication

Maintaining cleanliness is vital for efficient operation. Regularly remove debris from the equipment to prevent clogs and overheating. Additionally, applying the right lubricant to moving parts reduces friction and enhances performance. Following the manufacturer’s guidelines for cleaning and lubrication will help ensure that your machinery remains in top condition.

Where to Find Genuine Parts

Locating authentic components for your equipment is essential for maintaining performance and ensuring longevity. Quality pieces not only guarantee compatibility but also enhance overall reliability. Whether you’re looking for replacement items or upgrades, knowing where to search can save time and money.

Authorized Dealers

One of the most reliable sources for authentic components is authorized dealerships. These establishments are directly connected to the manufacturer and typically stock a comprehensive inventory. They often have knowledgeable staff who can assist with selecting the right components for your specific model.

Online Retailers

Many online platforms specialize in genuine components. Reputable websites offer a wide selection and detailed descriptions to help you make informed choices. Always check for customer reviews and verify that the seller is recognized for dealing in authentic items to avoid counterfeit products.

Comparative Analysis of Similar Models

This section delves into the similarities and differences among various lawn care machines that cater to similar needs. By examining their features, performance, and maintenance aspects, users can make informed decisions tailored to their specific requirements.

Feature Comparison

- Engine Power:

- Model A: 20 HP

- Model B: 22 HP

- Model C: 18 HP

- Cutting Width:

- Model A: 42 inches

- Model B: 48 inches

- Model C: 36 inches

- Deck Material:

- Model A: Steel

- Model B: Fabricated Steel

- Model C: Polypropylene

Maintenance Considerations

Maintenance is crucial for ensuring longevity and optimal performance. Here’s a breakdown of typical upkeep requirements:

- Oil Change Frequency:

- Model A: Every 50 hours

- Model B: Every 75 hours

- Model C: Every 40 hours

- Model A: Annually

- Model B: Biannually

- Model C: Every season

- Model A: Regular checks recommended

- Model B: Seasonal maintenance

- Model C: Monthly inspections

Benefits of Using OEM Components

Utilizing original equipment manufacturer components ensures that your machinery operates at its peak performance. These parts are specifically designed to fit and function seamlessly, providing reliability and longevity.

- Quality Assurance: OEM components meet stringent quality standards, ensuring durability.

- Perfect Fit: These parts are designed for compatibility, minimizing the risk of mechanical issues.

- Warranty Protection: Using original parts often keeps warranties intact, offering peace of mind.

- Performance Optimization: They help maintain the ultimate efficiency of your equipment.

- Long-Term Cost Savings: Investing in quality parts can reduce the need for frequent replacements.

Choosing OEM components is a strategic decision that enhances the functionality and reliability of your machinery over time.

Step-by-Step Repair Guide

This section provides a comprehensive approach to maintaining and fixing your outdoor machinery. By following the outlined steps, you will be equipped to identify issues and perform necessary repairs effectively. Each task is designed to enhance your understanding of the equipment and ensure its optimal performance.

Tools and Materials Needed

Before starting any repair, gather the following tools and materials:

| Tool/Material | Purpose |

|---|---|

| Wrench Set | For loosening and tightening bolts |

| Screwdriver | For removing and installing screws |

| Replacement Parts | To swap out damaged components |

| Safety Gear | To protect yourself during repairs |

Step-by-Step Process

Follow these steps to ensure a successful repair:

- Assess the equipment for any visible issues.

- Refer to the service manual for specific troubleshooting guidelines.

- Gather the necessary tools and materials listed above.

- Begin by disconnecting power sources to ensure safety.

- Carefully remove any covers or guards to access internal components.

- Inspect each part thoroughly for wear or damage.

- Replace any defective parts with new ones as per the manual’s instructions.

- Reassemble the machinery, ensuring all fasteners are securely tightened.

- Reconnect power sources and perform a test run to verify successful repairs.

By adhering to this guide, you can maintain the efficiency and longevity of your machinery with confidence.

Tools Needed for Z225 Maintenance

Maintaining your equipment is essential for optimal performance and longevity. Having the right tools on hand can simplify the process, ensuring that all tasks are completed efficiently and effectively. This section outlines the necessary instruments to keep your machine in excellent condition.

Essential Tools

Here is a list of fundamental tools that are typically required for regular upkeep:

| Tool | Description |

|---|---|

| Wrench Set | For loosening and tightening bolts and nuts. |

| Screwdriver Set | For adjusting and securing screws in various components. |

| Socket Set | To reach fasteners in tight spaces with ease. |

| Oil Can | To lubricate moving parts to prevent wear. |

| Fuel Can | For safely storing and transporting fuel. |

Additional Helpful Tools

While the essential tools will cover most maintenance needs, some additional instruments can enhance your maintenance routine:

| Tool | Description |

|---|---|

| Multimeter | For diagnosing electrical issues and ensuring proper functionality. |

| Tire Pressure Gauge | To check and maintain correct tire pressure for safe operation. |

| Cleaning Brush | For removing dirt and debris from surfaces and components. |

| Safety Gear | Including gloves and goggles to protect yourself during maintenance tasks. |

Customer Reviews and Feedback Insights

Understanding customer opinions is essential for enhancing product quality and user satisfaction. Feedback from users can reveal strengths, weaknesses, and areas for improvement, ultimately guiding manufacturers in their development processes. This section explores the insights gathered from consumer experiences, highlighting key trends and notable comments that shape the perception of the equipment.

Positive Experiences

Many users have expressed satisfaction with the overall performance and reliability of the machinery. Customers frequently commend the ease of use and efficiency, noting that the device meets their expectations in various tasks. Durability and user-friendly design are often highlighted, with numerous reviews mentioning how the product has exceeded their initial expectations.

Areas for Improvement

While feedback is largely positive, some consumers have pointed out specific aspects that could benefit from refinement. Common critiques include the need for better customer support and more comprehensive user manuals. Additionally, a few users suggested enhancements to certain components to improve performance in demanding conditions. These insights provide valuable direction for future upgrades and help ensure continued satisfaction among users.