In the realm of fluid management, the intricate assembly of various elements plays a crucial role in ensuring efficient operation. Grasping how these components interact can lead to improved functionality and longevity of the system. By examining these mechanisms, one can uncover the essential relationships that drive performance.

Exploring the intricacies of these systems allows users to identify critical functions and troubleshoot effectively. Each element serves a unique purpose, contributing to the overall efficacy of the fluid transfer process. A comprehensive understanding empowers individuals to make informed decisions regarding maintenance and upgrades.

Whether you’re a novice or an experienced technician, delving into the anatomy of these systems provides valuable insights. Knowledge of each component not only enhances operational awareness but also fosters a deeper appreciation for the engineering behind fluid dynamics. Embrace the opportunity to unravel the mysteries of these essential assemblies.

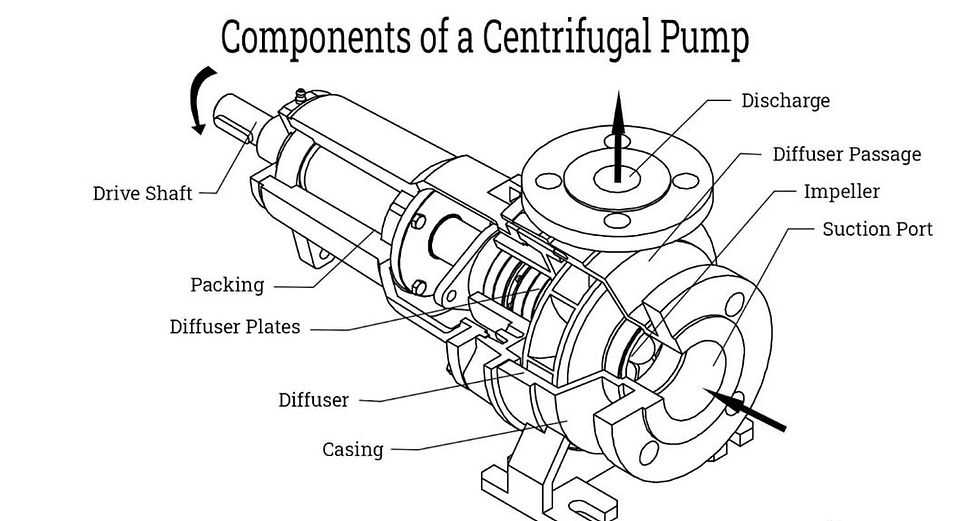

Understanding Water Pump Components

Comprehending the various elements that facilitate fluid movement is crucial for effective operation and maintenance. Each component plays a specific role in ensuring efficiency and reliability. Familiarity with these elements allows for better troubleshooting and optimization of performance.

The central unit, often referred to as the driving force, converts energy into mechanical motion, enabling the transfer of liquids. Coupled with this are various connectors and seals that ensure integrity and prevent leaks. Additionally, there are devices designed to regulate flow and maintain optimal pressure, enhancing overall functionality.

Understanding the intricate relationships between these components aids in identifying potential issues and making informed decisions during repairs or upgrades. Proper knowledge not only extends the lifespan of the system but also improves its overall effectiveness in delivering fluids where needed.

Basic Functions of a Water Pump

In fluid management systems, the essential mechanisms play a crucial role in facilitating the movement of liquids from one location to another. These mechanisms not only enable circulation but also ensure efficiency in various applications, ranging from industrial operations to agricultural practices.

Primarily, these devices are designed to create a difference in pressure, allowing fluids to flow through pipes and reach desired destinations. This process is vital for maintaining consistent supply and preventing stagnation in systems.

Additionally, they contribute to the regulation of fluid levels, which is essential for avoiding overflow or depletion. This function is particularly significant in environments where precise control over liquid quantities is necessary for optimal performance.

Moreover, these mechanisms enhance the overall efficiency of systems by minimizing energy loss and maximizing fluid transfer rates. As a result, users can expect improved productivity and reduced operational costs.

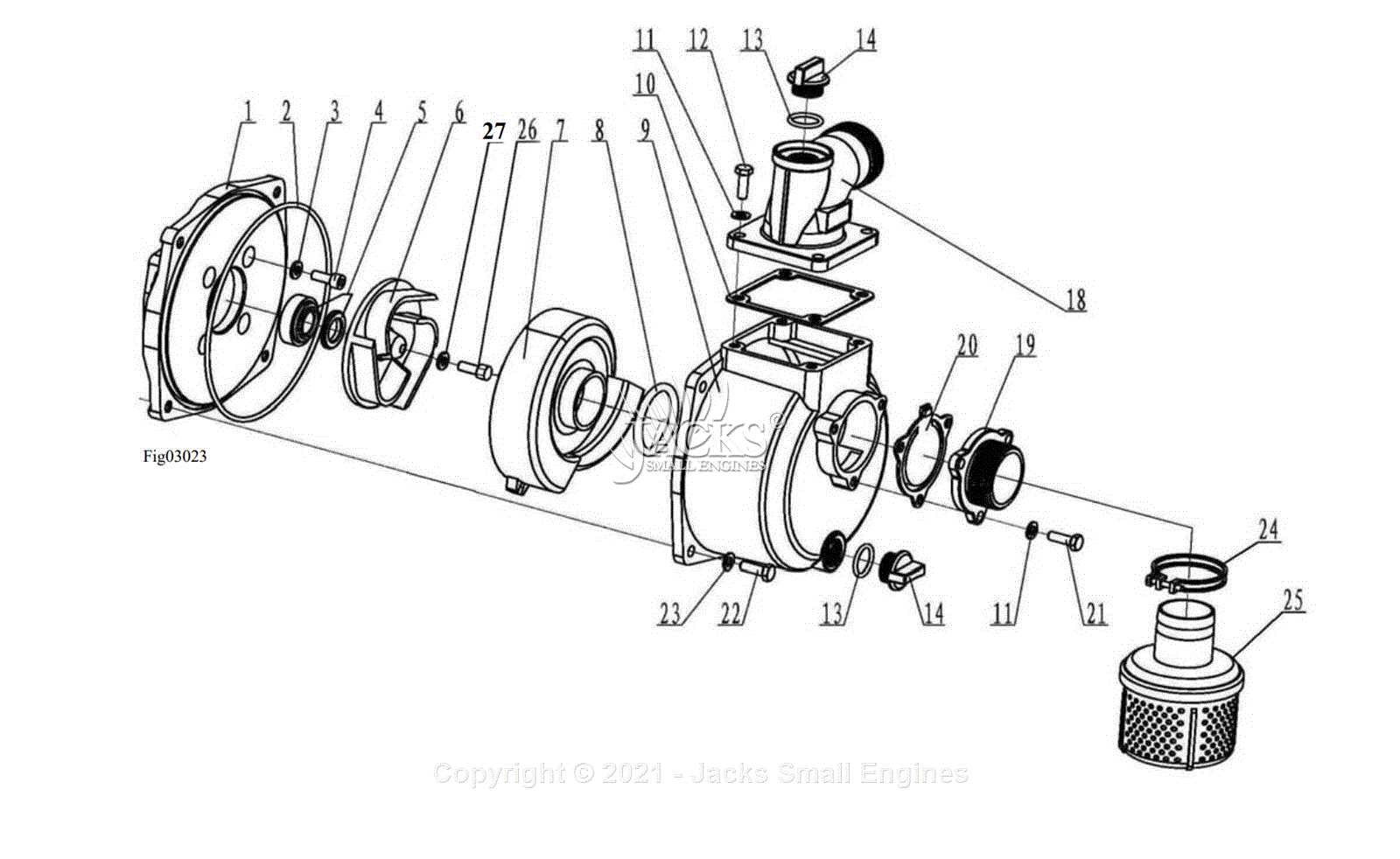

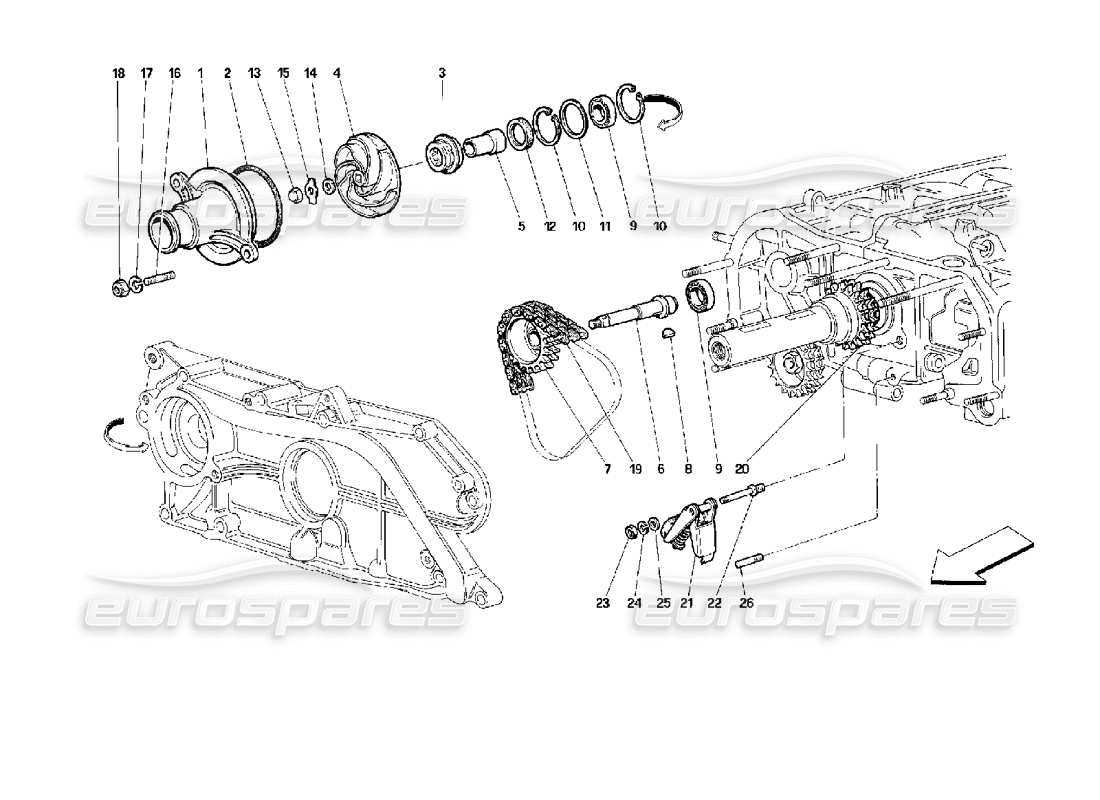

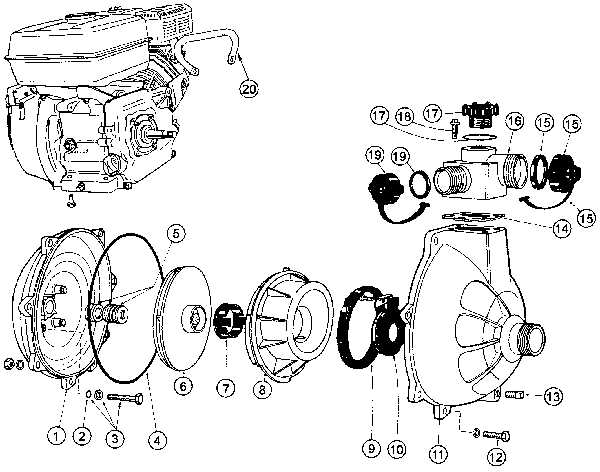

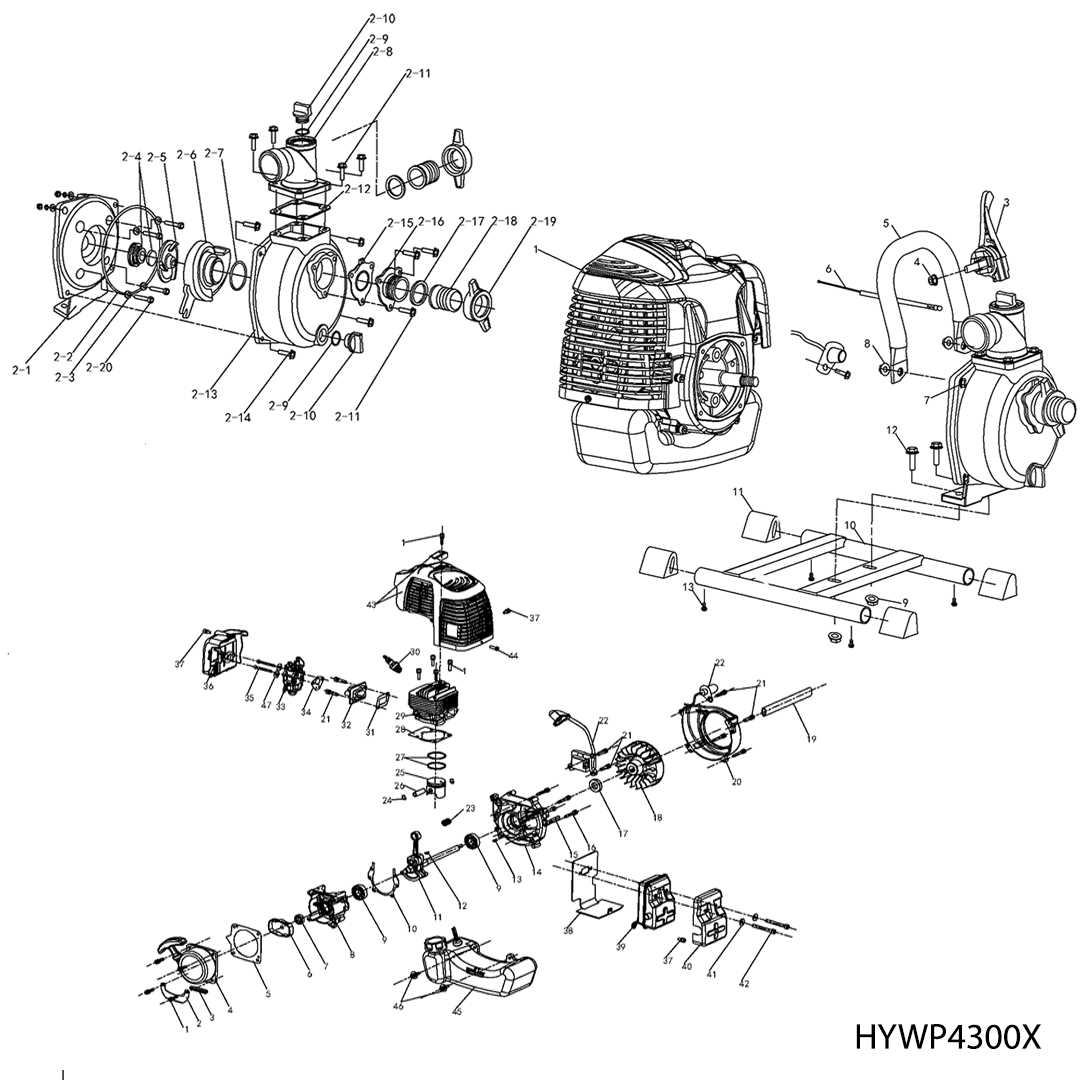

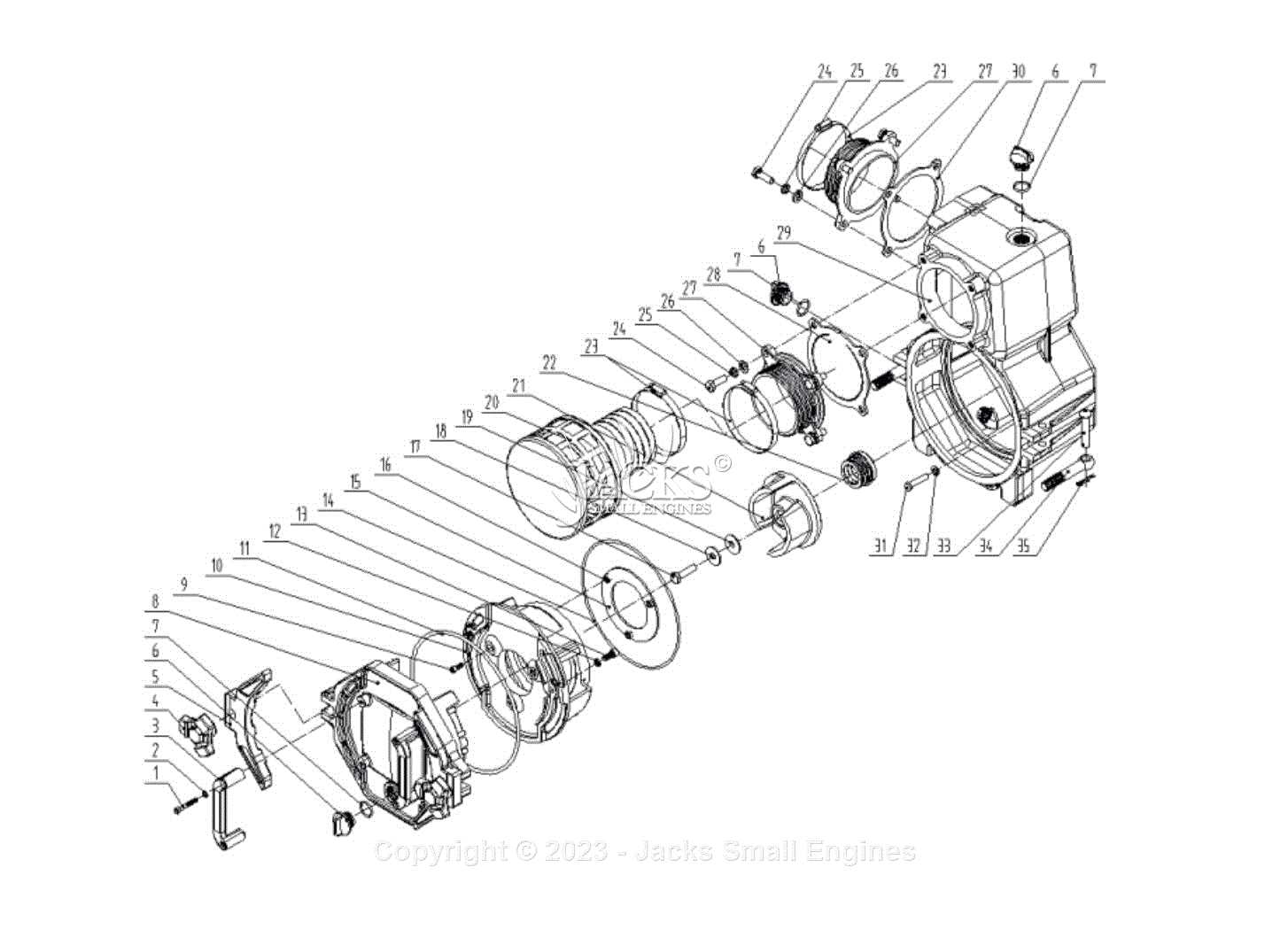

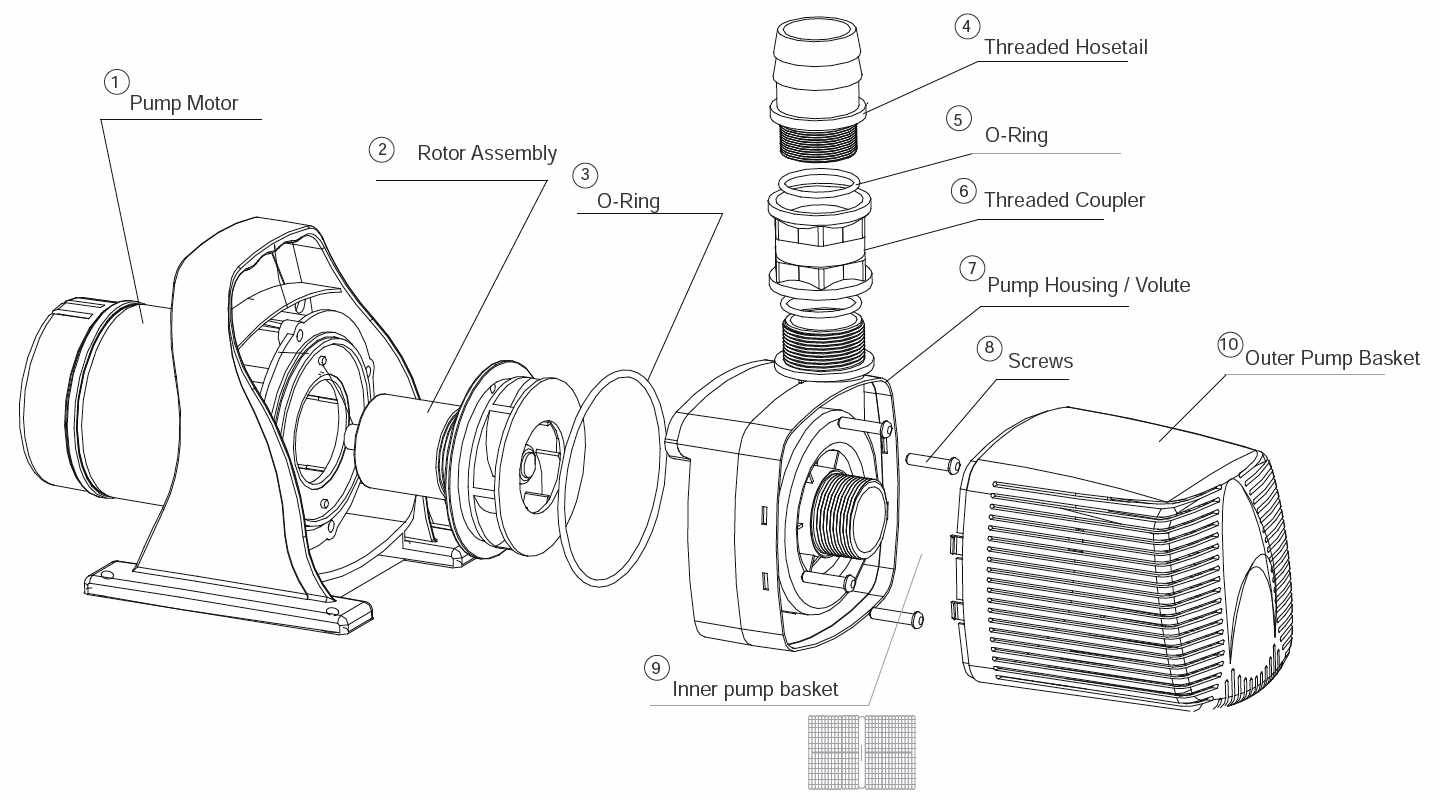

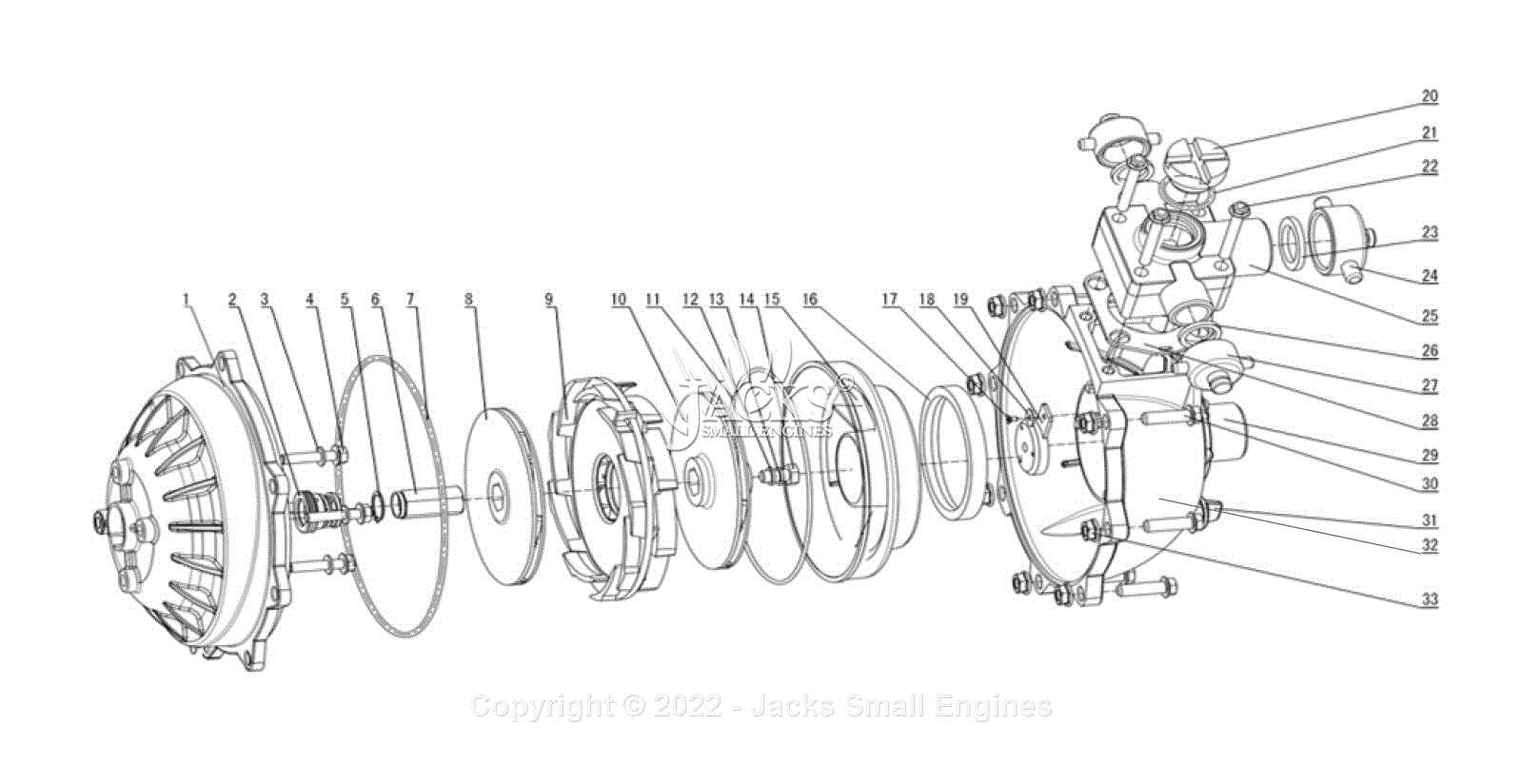

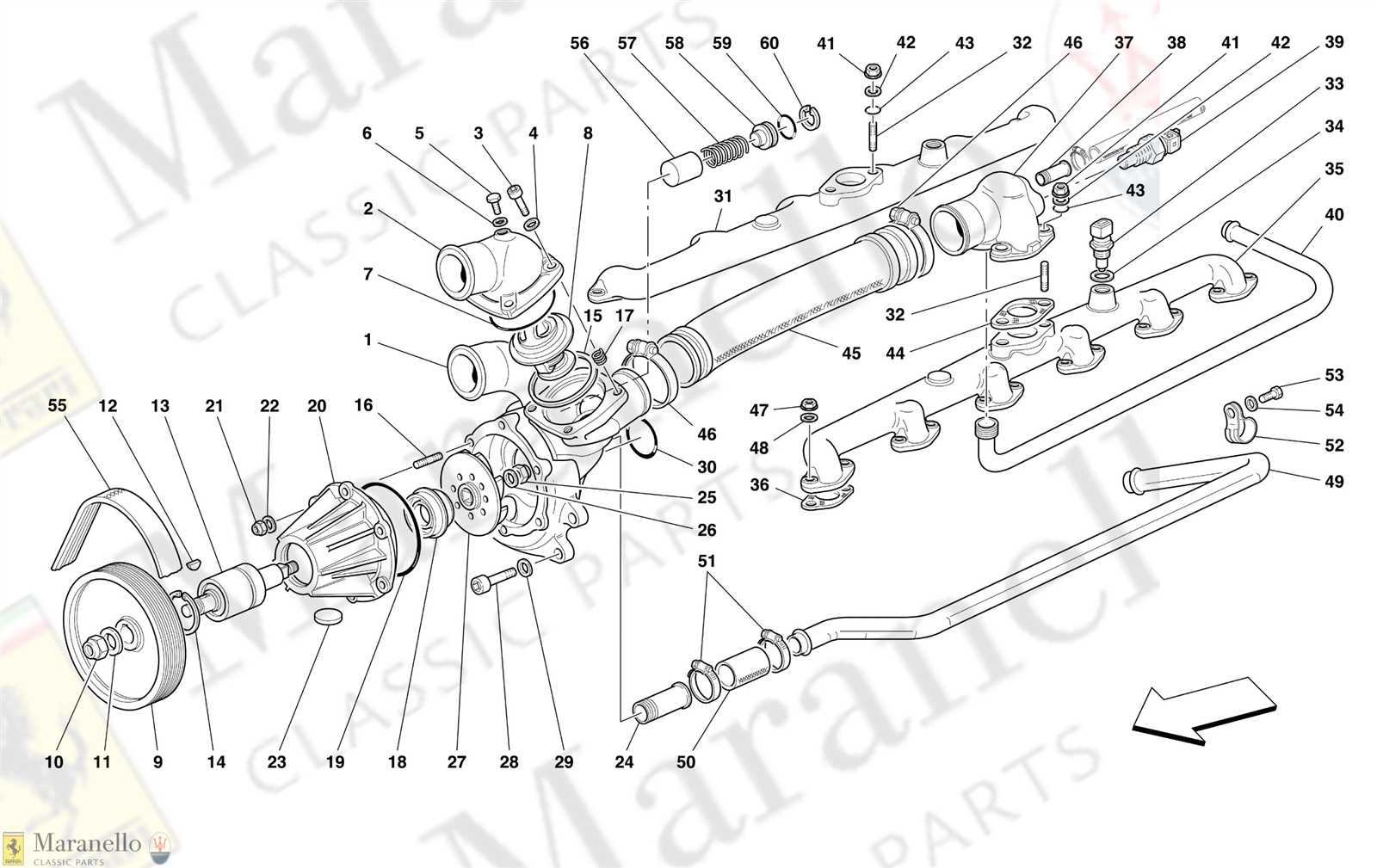

Key Parts of a Pump Assembly

Understanding the essential components of a fluid transfer system is crucial for optimal performance and maintenance. Each element plays a vital role in ensuring efficiency and longevity, contributing to the overall functionality of the mechanism.

Primary Components

The main elements include the casing, which houses the inner workings, and the rotor that facilitates movement. Additionally, seals and bearings are crucial for minimizing friction and preventing leaks, ensuring a seamless operation.

Supporting Elements

In addition to the core components, various supporting elements such as connectors and mounting brackets provide stability and secure integration within a larger system. Proper attention to these components is necessary for achieving the ultimate performance and reliability.

How Diagrams Enhance Understanding

Visual representations play a crucial role in facilitating comprehension of complex systems. They allow individuals to grasp intricate relationships and functions at a glance, simplifying the learning process. By translating abstract concepts into visual formats, these tools bridge the gap between theory and practical application.

Benefits of Visual Representations

- Clarity: Visual aids clarify intricate components and interactions.

- Retention: Images enhance memory recall more effectively than text alone.

- Engagement: Engaging visuals stimulate interest and encourage deeper exploration.

Applications in Various Fields

- Engineering: Simplifies the understanding of machinery and systems.

- Education: Aids students in grasping scientific concepts through clear illustrations.

- Healthcare: Helps professionals visualize anatomy and procedures for better training.

Common Types of Water Pumps

In various applications, different devices are utilized to facilitate the movement of fluids. Each type serves specific needs, ensuring efficiency and effectiveness across industries. Understanding these varieties helps in selecting the right solution for particular tasks.

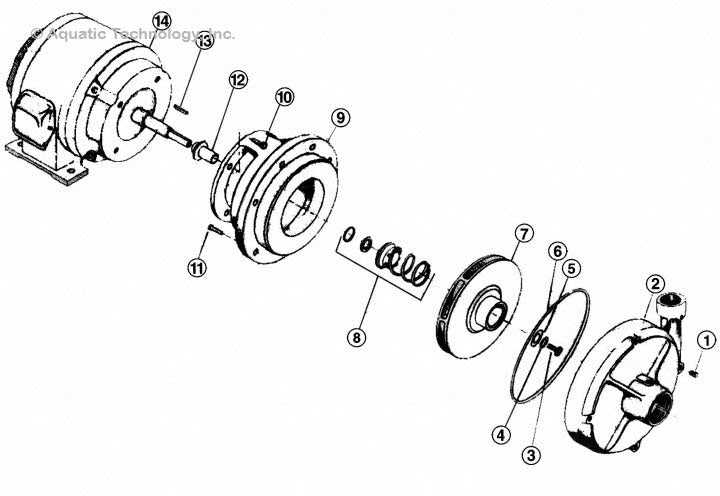

Centrifugal Devices

These machines operate on the principle of centrifugal force, drawing in liquid and expelling it through a discharge outlet. They are widely used in both residential and industrial settings due to their simplicity and reliability.

Positive Displacement Machines

In contrast, these units move fluid by trapping a fixed amount and forcing it through the system. They excel in applications requiring high pressure and are often found in specialized industries.

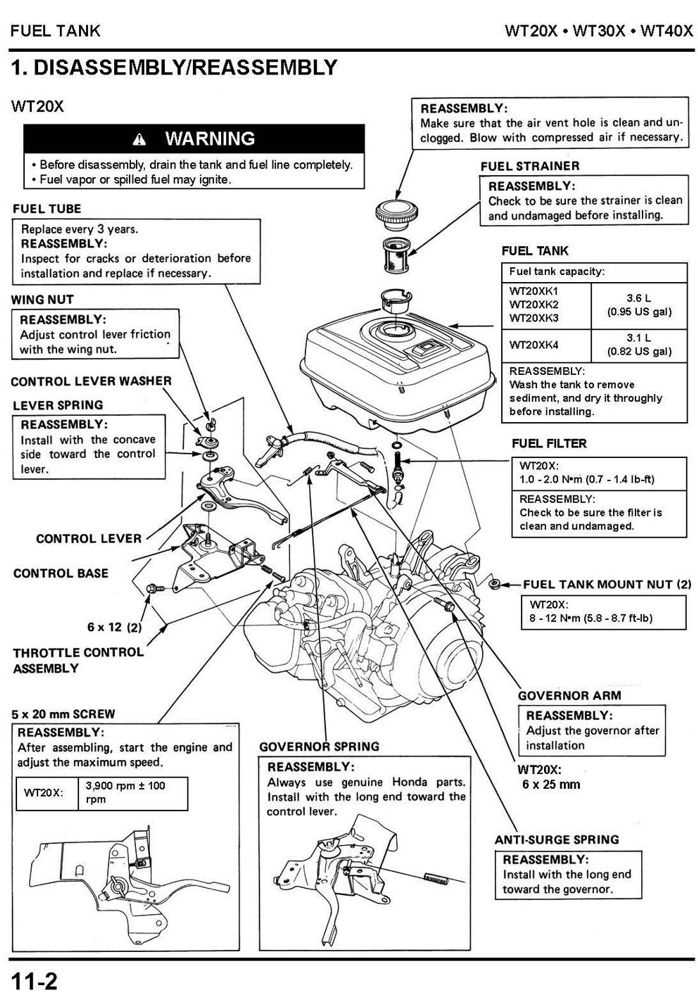

Maintenance Tips for Pump Longevity

Ensuring the durability of essential machinery requires regular care and attention. By following specific guidelines, users can significantly extend the lifespan of their equipment and minimize the need for costly repairs or replacements.

Regular Inspection: Frequent examinations can help identify wear and tear before they escalate into serious issues. Look for signs of leaks, unusual noises, or vibrations that may indicate a problem.

Lubrication: Keeping moving components well-lubricated is crucial for smooth operation. Use the recommended lubricant and apply it at intervals specified in the user manual to prevent friction and overheating.

Cleaning: Dust and debris can accumulate and hinder performance. Schedule routine cleaning to remove buildup from filters and surrounding areas, ensuring optimal function.

Monitor Performance: Keep an eye on the efficiency of the machinery. Sudden changes in output may signal underlying issues that need to be addressed promptly.

Follow Manufacturer Guidelines: Adhering to the manufacturer’s instructions for maintenance can prevent missteps that could lead to premature failure. Always refer to the provided documentation for specific recommendations.

Timely Replacement: Components that are showing signs of deterioration should be replaced as soon as possible. Proactive replacement can prevent larger problems and keep operations running smoothly.

Identifying Wear and Tear in Parts

Understanding the signs of deterioration in mechanical components is essential for maintaining optimal functionality. Regular inspection allows for the early detection of issues, ensuring efficiency and longevity of the system.

Common Indicators of Deterioration

Visual cues such as cracks, discoloration, or unusual wear patterns can signal the need for closer examination. Additionally, abnormal noises during operation often indicate underlying problems that require immediate attention.

Maintenance Strategies

Implementing a routine check-up schedule can help identify issues before they escalate. Regular cleaning and lubrication can also prevent excessive wear and prolong the lifespan of critical components.

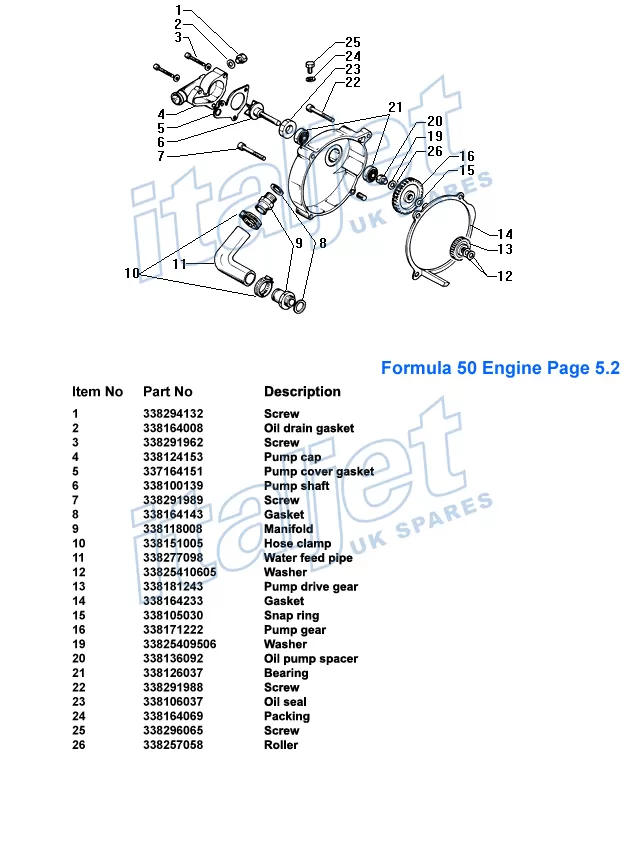

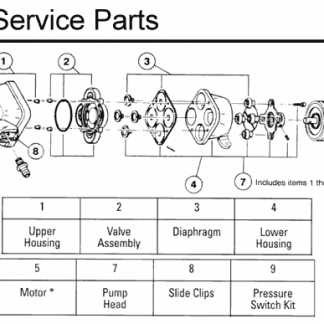

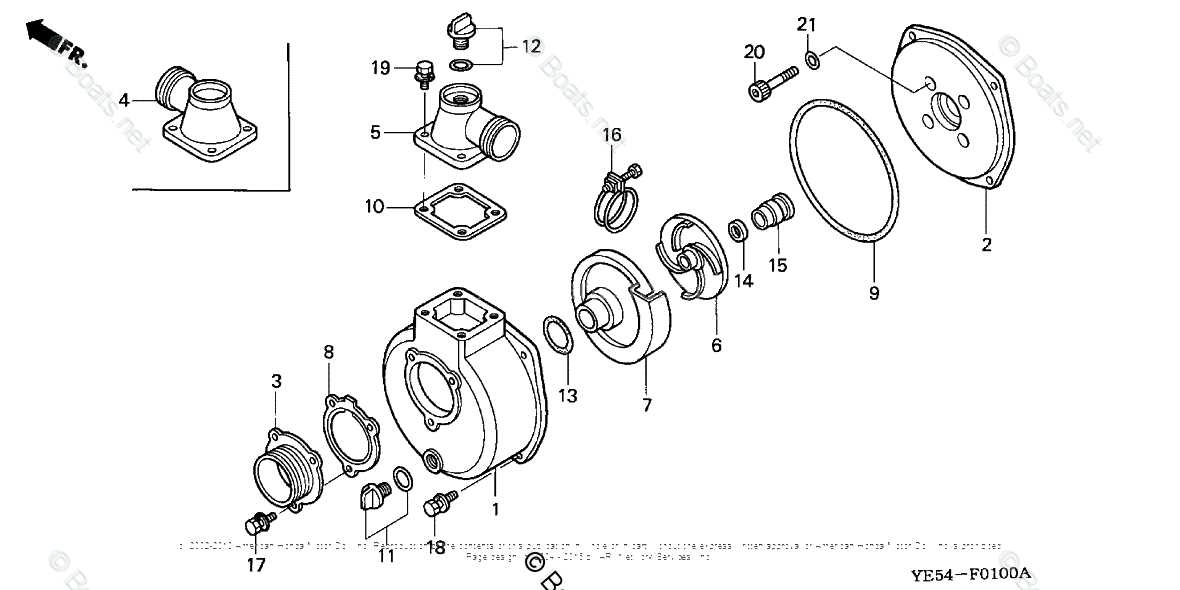

How to Read a Pump Diagram

Understanding a schematic representation of a fluid movement mechanism can greatly enhance your maintenance and troubleshooting skills. Familiarity with the symbols and layout used in such illustrations allows for effective interpretation of the components and their functions.

Identify Key Symbols

Each illustration employs specific symbols to represent different components. Familiarize yourself with these icons, as they often follow industry standards. This knowledge is crucial for grasping the overall setup and operation.

Follow the Flow

Pay attention to the direction of flow indicated in the schematic. Understanding the path that the fluid takes through the system can help you identify potential issues or inefficiencies in the mechanism.

Tools for Water Pump Repair

Repairing a fluid-moving device requires specific instruments to ensure efficiency and effectiveness. Having the right tools not only simplifies the process but also enhances safety and precision during maintenance and fixes. Below are essential tools that every technician should consider when working on such machinery.

Essential Tools

- Wrenches: A set of adjustable wrenches is crucial for loosening and tightening various components.

- Screwdrivers: Both flathead and Phillips screwdrivers are needed for different screws.

- Pliers: Needle-nose and slip-joint pliers can assist with gripping and bending tasks.

- Socket Set: A complete socket set helps in removing nuts and bolts efficiently.

- Sealant: A good sealant is necessary for ensuring leak-proof assembly.

Safety Gear

- Gloves: Protective gloves safeguard hands from sharp edges and chemicals.

- Goggles: Eye protection is essential to prevent injury from debris or splashes.

- Ear Protection: Earplugs or earmuffs help reduce noise exposure when working with loud machinery.

Equipping oneself with these tools and safety gear will ensure a successful and safe maintenance experience for any fluid-moving device.

Safety Precautions During Maintenance

Ensuring a secure environment while performing maintenance tasks is crucial to prevent accidents and injuries. Proper precautions must be taken to safeguard both the individual and the equipment involved in the process. Awareness of potential hazards and adherence to safety guidelines can significantly reduce risks associated with these activities.

Personal Protective Equipment (PPE) is essential. Always wear appropriate gear, including gloves, goggles, and hard hats, to shield against possible dangers. This protective attire minimizes exposure to harmful substances and physical threats during maintenance operations.

Training and Knowledge play a vital role. Individuals should be well-informed about the equipment and its operational protocols. Familiarity with safety procedures and emergency response strategies can enhance preparedness and effectiveness in handling unforeseen situations.

Work Environment should be kept tidy and well-lit. Clutter can lead to accidents, so maintaining an organized workspace is key. Adequate lighting ensures that all components are visible, allowing for careful inspections and adjustments.

Proper Tools must be used to avoid mishaps. Ensure that all instruments are in good condition and suitable for the task at hand. Utilizing the right equipment helps prevent injuries and equipment damage.

By observing these safety measures, individuals can create a safer atmosphere during maintenance activities, thereby promoting efficiency and well-being throughout the process.

Choosing the Right Replacement Parts

Selecting the appropriate components for your machinery is crucial for ensuring optimal functionality and longevity. Making informed choices can prevent future issues and enhance overall performance.

Factors to Consider

- Compatibility with existing systems

- Quality and durability of materials

- Manufacturer’s reputation

- Cost-effectiveness

Where to Find Quality Components

- Authorized dealers

- Reputable online retailers

- Specialty shops focusing on machinery

- Local repair services with strong recommendations

Resources for Further Learning

Enhancing your understanding of mechanical systems can significantly benefit from a variety of educational materials. This section provides a curated selection of resources that cater to different learning preferences, whether you prefer books, online courses, or hands-on experience.

Books and Manuals

- Technical Manuals: Comprehensive guides that cover specific equipment and their operational principles.

- Reference Books: Texts that delve into mechanical engineering concepts, providing foundational knowledge and advanced techniques.

- DIY Handbooks: Practical guides that offer step-by-step instructions for building and maintaining systems.

Online Resources

- Webinars and Tutorials: Interactive sessions led by experts that cover various topics related to system mechanics.

- Online Courses: Platforms such as Coursera and Udemy offer structured courses focusing on engineering principles and maintenance strategies.

- YouTube Channels: Educational channels that provide visual demonstrations and troubleshooting tips.

By exploring these resources, you can deepen your knowledge and improve your skills in the field, ensuring a well-rounded understanding of the intricate mechanisms at play.