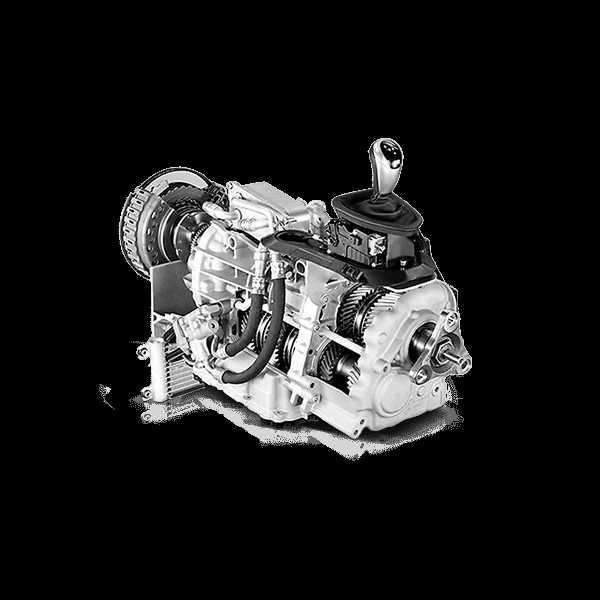

In the world of automotive engineering, the intricate systems that facilitate movement play a crucial role in vehicle performance. A detailed exploration of these mechanisms provides valuable insights into their functionality and design. This section delves into the essential elements that contribute to the smooth operation of a vehicle’s powertrain.

Understanding the inner workings of a vehicle’s gear mechanism is vital for both enthusiasts and professionals alike. Each component is meticulously crafted to work in harmony, ensuring optimal efficiency and reliability. A comprehensive look at these components allows for a better grasp of how they interact and contribute to the overall effectiveness of the driving experience.

The relationship between various elements within the system highlights the importance of maintenance and knowledge. Proper awareness of these components can assist in diagnosing issues and making informed decisions regarding repairs or upgrades. By familiarizing oneself with the individual parts, one can appreciate the complexity and engineering prowess that goes into crafting these vital automotive systems.

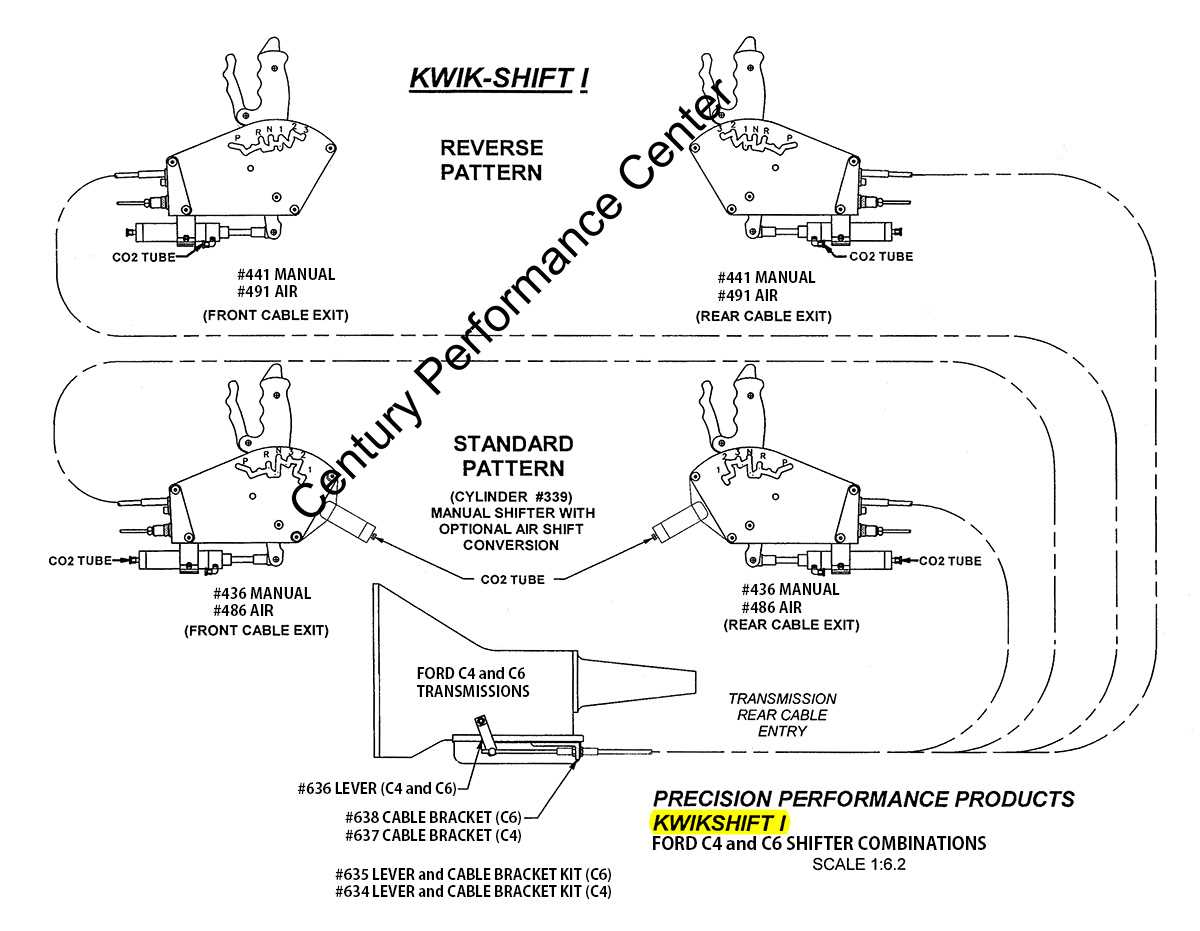

Ford C4 Transmission Overview

The C4 model is a well-known automatic gearbox that has been widely used in various vehicles. Its design focuses on efficiency and reliability, making it a popular choice among automotive enthusiasts and manufacturers. Understanding its components and functionality can provide insights into its performance and maintenance requirements.

Key Features

- Compact design that allows for easier installation.

- Hydraulic operation for smooth gear shifting.

- Durable materials that enhance longevity.

Functionality

This gearbox operates using a series of hydraulic mechanisms to facilitate gear changes based on driving conditions. The system’s simplicity contributes to its effectiveness and ease of use, ensuring a seamless driving experience.

- Input shaft receives power from the engine.

- Fluid coupling transfers power to the gear sets.

- Output shaft delivers power to the wheels.

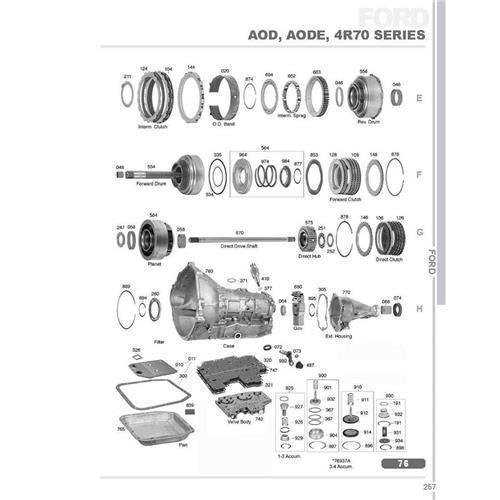

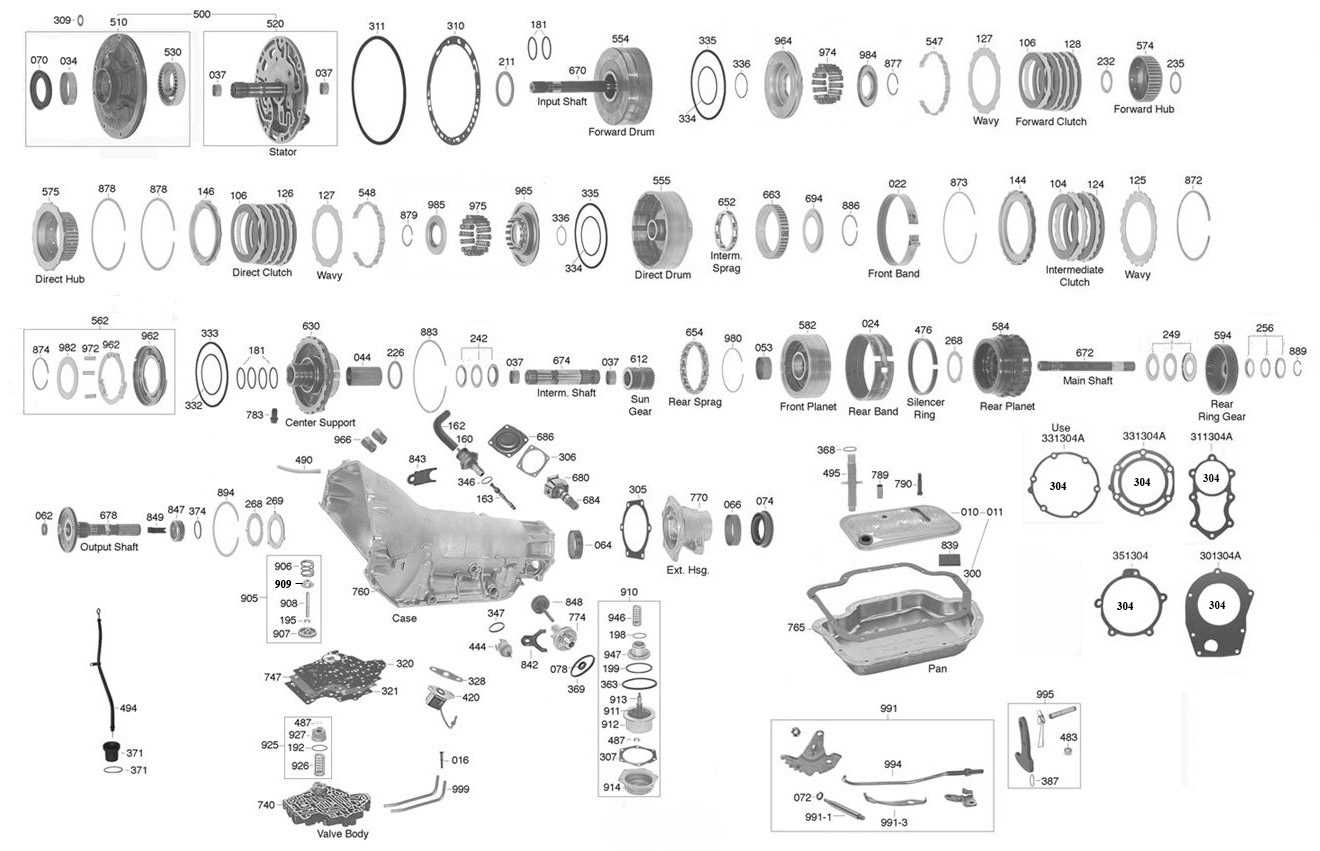

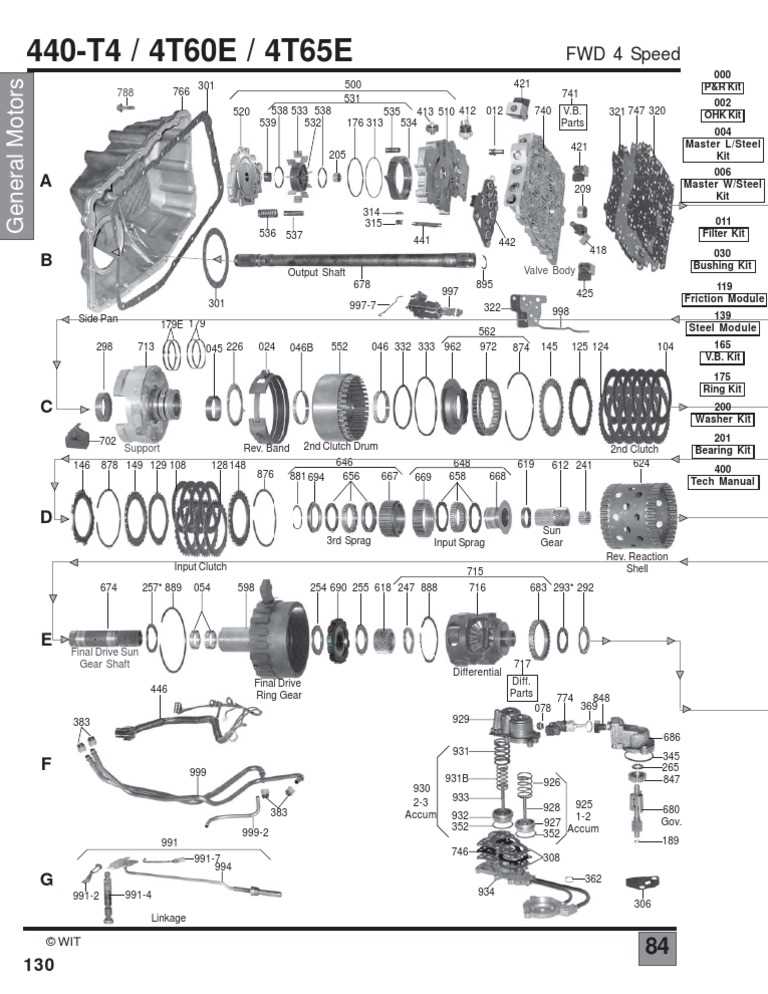

Key Components of C4 Transmission

The C4 system is a complex mechanism that plays a vital role in the overall performance of a vehicle. Understanding its essential elements is crucial for maintenance and repair. Each component contributes to the functionality and efficiency of the assembly, ensuring smooth operation under various conditions.

Core Elements

Several key components work together to create the desired functionality. These elements include clutches, bands, valves, and pumps, each playing a distinct role in the assembly’s operation.

Component Overview

| Component | Function |

|---|---|

| Clutches | Engage and disengage gears to manage power transfer. |

| Bands | Control the movement of components, ensuring smooth shifting. |

| Valves | Regulate fluid flow, directing hydraulic pressure where needed. |

| Pumps | Circulate fluid throughout the assembly, maintaining pressure and lubrication. |

Common Issues with C4 Transmissions

The C4 system is known for its durability, but like any mechanical assembly, it can experience various challenges over time. Understanding these issues can help owners recognize symptoms early and take appropriate action to prevent further complications.

One prevalent concern is slipping, where the unit may struggle to engage or maintain gear ratios. This often leads to reduced performance and can be indicative of low fluid levels or worn components.

Another frequent issue is overheating. Excessive temperatures can damage seals and gaskets, causing leaks and further impairing functionality. Regular maintenance, including fluid changes, is crucial to mitigate this risk.

Delayed engagement is also a common symptom, where there is a noticeable pause before the system responds to input. This can stem from issues with the hydraulic system or internal wear, requiring careful diagnosis to determine the exact cause.

Lastly, unusual noises during operation, such as grinding or clunking sounds, may indicate internal damage or misalignment. Timely inspection and repairs can prevent more severe failures and extend the lifespan of the assembly.

Benefits of C4 Transmission Parts

The components of a specific automatic shifting system offer several advantages that enhance vehicle performance and reliability. These benefits contribute to smoother operation, improved fuel efficiency, and a more enjoyable driving experience. Understanding the significance of these elements can help owners make informed decisions regarding maintenance and upgrades.

Enhanced Performance

One of the key advantages of these essential components is their role in optimizing the overall functionality of the shifting system. High-quality elements ensure precise gear changes, resulting in quicker acceleration and improved responsiveness. This leads to a more dynamic driving experience, especially in demanding conditions.

Improved Durability

Investing in premium components increases the longevity of the entire shifting mechanism. Superior materials and craftsmanship can withstand high levels of stress and heat, reducing the likelihood of premature failure. This durability translates into lower maintenance costs and fewer unexpected repairs, providing peace of mind for vehicle owners.

| Benefit | Description |

|---|---|

| Enhanced Performance | Optimizes gear shifts for quicker acceleration. |

| Improved Durability | Reduces the likelihood of premature failure. |

| Cost-Effectiveness | Lower maintenance costs due to higher reliability. |

Understanding C4 Gear Ratios

Gear ratios play a crucial role in the performance and efficiency of an automotive system. They determine how power is transmitted from the engine to the wheels, affecting acceleration, speed, and overall driving experience. Understanding these ratios can help enthusiasts optimize their vehicles for various driving conditions and preferences.

Importance of Gear Ratios

The selection of appropriate gear ratios influences several aspects of vehicle operation:

- Acceleration: Lower ratios provide quicker acceleration by allowing the engine to reach its power band more rapidly.

- Fuel Efficiency: Higher ratios can enhance fuel efficiency during highway cruising by reducing engine RPM.

- Torque Distribution: Different ratios help distribute torque effectively, improving traction and stability.

Common Gear Ratios

Various gear ratios are commonly used in automotive systems:

- Numerical Ratios: These ratios, such as 2.73:1 or 3.55:1, indicate the number of rotations of the input shaft required to achieve one rotation of the output shaft.

- First Gear Ratio: This ratio affects the initial acceleration and is typically lower for better off-the-line performance.

- Overdrive Ratio: Found in higher gears, this ratio allows for lower engine RPM at cruising speeds, enhancing fuel economy.

How to Maintain C4 Transmission

Proper upkeep of your vehicle’s gear mechanism is essential for optimal performance and longevity. Regular care ensures smooth shifting and helps prevent potential issues that could lead to costly repairs. This guide outlines key practices for maintaining your C4 system effectively.

Regular Fluid Checks

Fluid quality plays a critical role in the overall function of your gear system. It’s important to check the fluid level and condition periodically. If the fluid appears dark or has a burnt smell, it may need to be replaced. Aim to change the fluid according to the manufacturer’s recommendations to keep the internal components lubricated.

Routine Inspection of Components

By following these guidelines and staying proactive about care, you can enhance the performance and durability of your gear mechanism.

Replacing C4 Transmission Filters

Regular maintenance is essential for ensuring optimal performance of your vehicle’s system. One key aspect of this upkeep involves changing the filters, which play a crucial role in keeping the fluid clean and preventing debris from causing damage. This process can enhance the longevity and efficiency of your setup.

Here’s a step-by-step guide to assist you in replacing the filters:

- Gather Necessary Tools:

- New filters

- Fluid

- Socket set

- Wrench

- Drain pan

- Clean rags

- Prepare the Vehicle:

- Park on a level surface.

- Engage the parking brake.

- Allow the system to cool down.

- Drain Fluid:

Position the drain pan beneath the vehicle and remove the drain plug to let the fluid flow out completely.

- Remove the Old Filters:

Locate the filters and carefully detach them using the appropriate socket or wrench. Ensure that no debris enters the fluid system during this process.

- Install New Filters:

Position the new filters in place and secure them firmly to prevent leaks. Follow any specific torque specifications provided by the manufacturer.

- Refill Fluid:

Replace the drain plug and refill with the appropriate fluid through the fill opening, following the manufacturer’s recommendations for type and quantity.

- Check for Leaks:

Start the vehicle and let it run for a few minutes. Inspect the area around the new filters for any signs of leakage.

Replacing the filters regularly is vital for maintaining system health. By following these steps, you can ensure a smoother operation and extend the lifespan of your vehicle’s components.

Identifying C4 Transmission Symptoms

Recognizing issues within a vehicle’s power transfer system is crucial for ensuring optimal performance and longevity. Various indicators may signal the need for attention, and understanding these signs can help prevent further complications. Common manifestations include unusual noises, performance lags, or fluid leaks, all of which warrant careful examination.

One of the most prevalent symptoms is slipping, where the engine revs but the vehicle does not accelerate as expected. This can lead to a noticeable decrease in power delivery. Additionally, delayed engagement when shifting from park to drive or reverse can indicate underlying problems. Strange sounds, such as grinding or whining, may also suggest internal wear or damage that requires immediate inspection.

Fluid leaks beneath the vehicle can be an alarming sign, especially if the fluid is red or brown, indicating possible leaks in the hydraulic system. Overheating is another critical symptom, often associated with insufficient lubrication or clogged passages. Monitoring these indicators closely can aid in diagnosing potential issues early, ensuring a smoother and more reliable driving experience.

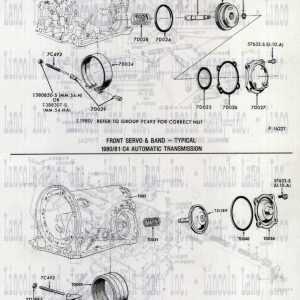

C4 Transmission Rebuild Process

Rebuilding an automatic gearbox involves several critical steps that ensure its optimal performance and longevity. The process typically requires a thorough examination of each component, followed by careful reassembly with fresh components as needed.

Here is a general outline of the steps involved:

- Disassembly: Begin by removing the unit from the vehicle and carefully disassembling it. Take notes or pictures to remember the order of components.

- Inspection: Examine all components for wear and damage. Look for signs of overheating, scoring, or any other issues that may affect performance.

- Cleaning: Clean all parts thoroughly to remove old fluids, dirt, and debris. This ensures that new seals and gaskets can be installed without contamination.

- Replacement: Replace any worn or damaged components, including seals, gaskets, and clutches. It’s essential to use high-quality replacements to maintain reliability.

- Reassembly: Carefully reassemble the unit, ensuring all components are properly aligned and torqued to specifications. Follow the original assembly order for accuracy.

- Testing: After reassembly, conduct tests to verify the functionality of the rebuilt unit. Check for leaks and ensure smooth operation.

This entire process requires patience, precision, and attention to detail to achieve successful results. Properly rebuilding the gearbox can restore it to its original performance level, enhancing the overall driving experience.

Tools Needed for C4 Repairs

Repairing the C4 requires a variety of essential instruments to ensure a smooth and efficient process. Having the right tools not only simplifies the task but also enhances precision and safety during maintenance activities.

Basic Hand Tools

- Wrenches

- Screwdrivers

- Pliers

- Ratchet and socket set

Specialized Equipment

- Torque wrench

- Snap ring pliers

- Fluid pump

- Gauge for measuring clearances

Utilizing these tools will facilitate the repair process and contribute to the longevity of the assembly.

Aftermarket Parts for C4 Transmission

When it comes to enhancing vehicle performance, the availability of replacement components can significantly impact the overall functionality and longevity of your system. Many enthusiasts turn to alternative solutions to achieve better efficiency, durability, and customizability. These options often provide the opportunity to upgrade or replace specific elements to suit individual driving styles and needs.

Aftermarket options encompass a wide range of components that can improve the operational characteristics of the assembly. From enhanced clutches to upgraded bands, these selections can lead to improved responsiveness and reliability. Understanding the various offerings can help owners make informed decisions when considering modifications or repairs.

| Component | Description | Benefits |

|---|---|---|

| Performance Clutches | Higher friction materials designed for increased grip. | Improved power transfer and quicker shifts. |

| Upgraded Bands | Stronger bands that provide better holding capacity. | Enhanced durability and reduced slippage. |

| High-Quality Seals | Superior sealing materials to prevent leaks. | Longer lifespan and better reliability. |

| Cooler Kits | External coolers to regulate temperature effectively. | Improved thermal management for extended performance. |

| Torque Converters | Modified converters for better stall speed. | Enhanced acceleration and responsiveness. |

Wiring Diagram for C4 Transmission

This section aims to provide a comprehensive overview of the electrical schematics associated with the C4 system. Understanding the layout and connections can greatly aid in troubleshooting and enhancing performance. A clear representation of the wiring helps in identifying the various components and their relationships within the assembly.

Key Components

- Solenoids

- Connectors

- Wiring Harness

- Control Module

- Switches

Wiring Connections

- Start with the solenoids, ensuring each is connected to the correct terminal.

- Trace the wiring harness to confirm there are no breaks or frayed sections.

- Check the connectors for secure fittings and clean contacts.

- Inspect the control module for any error codes or malfunctions.

- Verify switch functionality and their integration into the overall system.

Maintaining accurate wiring can prevent issues and ensure optimal operation. Regular checks and updates to the schematics are essential for longevity and reliability.

Upgrades for Enhanced C4 Performance

Improving the efficiency and reliability of your vehicle’s automatic gearbox can significantly enhance its overall performance. Various modifications and enhancements can be made to achieve smoother shifting, better torque handling, and increased durability. Here are several effective upgrades that can help optimize your system.

- High-Performance Clutches: Upgrading to heavy-duty clutches can provide better grip and withstand higher torque levels, resulting in improved shifting response.

- Improved Valve Body: A high-performance valve body can enhance fluid flow and pressure control, leading to quicker and firmer shifts.

- Torque Converter Upgrade: A more efficient torque converter can increase stall speed, improving acceleration and overall power transfer.

- External Cooler: Installing an external cooling unit can help maintain optimal fluid temperatures, prolonging the life of internal components.

- Performance Bands: Upgrading to reinforced bands can enhance the holding capacity, providing better engagement during operation.

- Better Gaskets and Seals: Using high-quality gaskets and seals can prevent leaks and ensure a consistent pressure environment within the system.

Implementing these modifications can lead to a more robust and responsive setup, ultimately elevating the driving experience. Each enhancement offers unique benefits, and selecting the right combination tailored to your needs can yield substantial improvements.