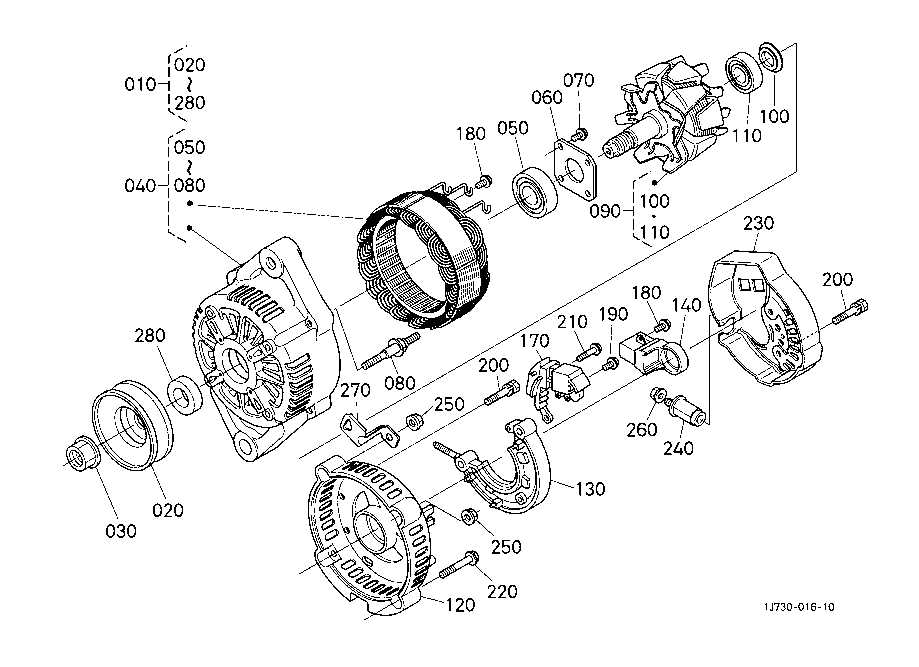

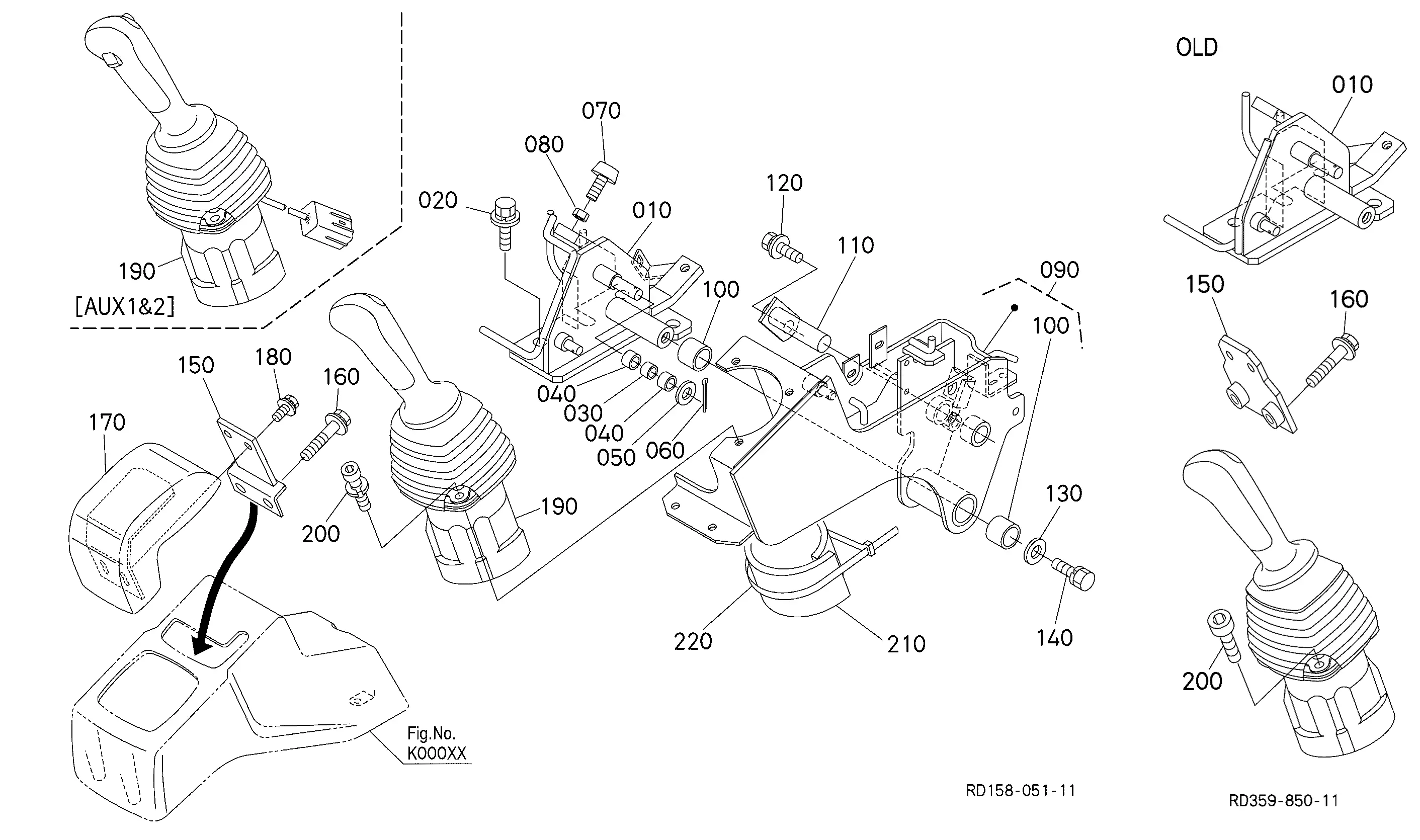

The efficient functioning of heavy machinery relies on a well-organized structure of various elements that work in harmony. A clear visual representation of these components is essential for operators and technicians, allowing for quick identification and troubleshooting. By grasping the arrangement of parts, users can enhance maintenance practices and ensure optimal performance.

Having a comprehensive overview of the machinery’s configuration helps in understanding how each segment contributes to the overall operation. This knowledge is invaluable for anyone involved in the upkeep or operation of the equipment, providing insights that lead to informed decision-making. Familiarity with the arrangement can also facilitate easier repairs and replacements, minimizing downtime and maximizing productivity.

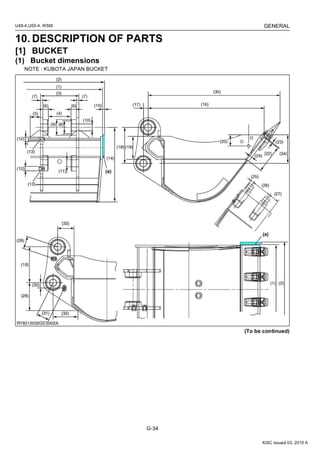

This section aims to provide a comprehensive understanding of a specific compact excavator model, focusing on its key features, components, and functionalities. By exploring its essential elements, users can gain valuable insights into its design and operational efficiency.

- Machine Specifications: Outline the technical details and capabilities of the equipment, including its weight, dimensions, and engine specifications.

- Key Features: Highlight unique characteristics that set this machine apart from its competitors, such as advanced hydraulic systems or enhanced operator comfort.

- Functional Components: Discuss the various parts that contribute to the machine’s performance, including the undercarriage, cab, and boom.

- Hydraulic System Overview: Explain how the hydraulic system operates, detailing its significance in powering the machine’s movements.

- Maintenance Recommendations: Provide guidelines on regular upkeep to ensure optimal performance and longevity.

- Common Issues: Identify frequent problems users may encounter and offer potential solutions.

- Attachment Compatibility: Discuss available attachments that enhance the versatility of the machine, enabling various applications.

- Operational Guidelines: Provide tips on effective usage to maximize efficiency and safety during operation.

- Safety Features: Highlight built-in safety mechanisms that protect the operator and bystanders.

- Aftermarket Support: Discuss the availability of additional services and components that can be accessed post-purchase.

- User Testimonials: Include feedback from users to give prospective buyers insights into real-world performance and reliability.

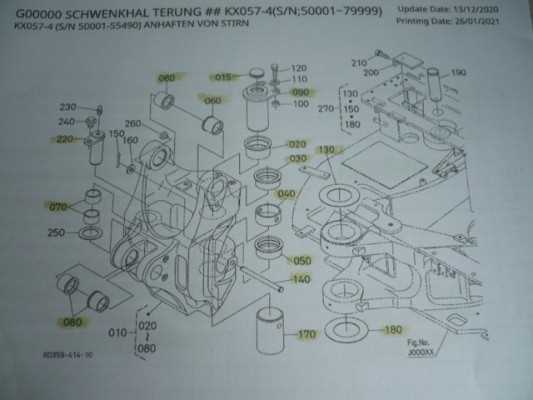

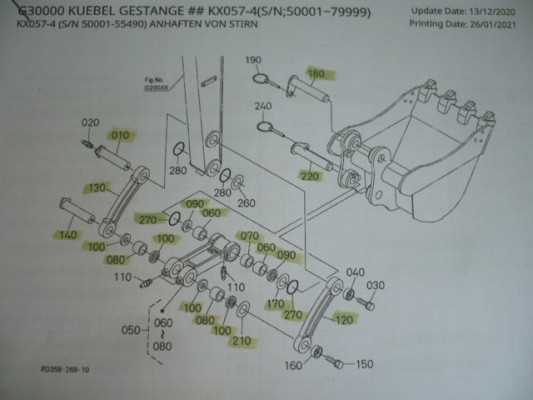

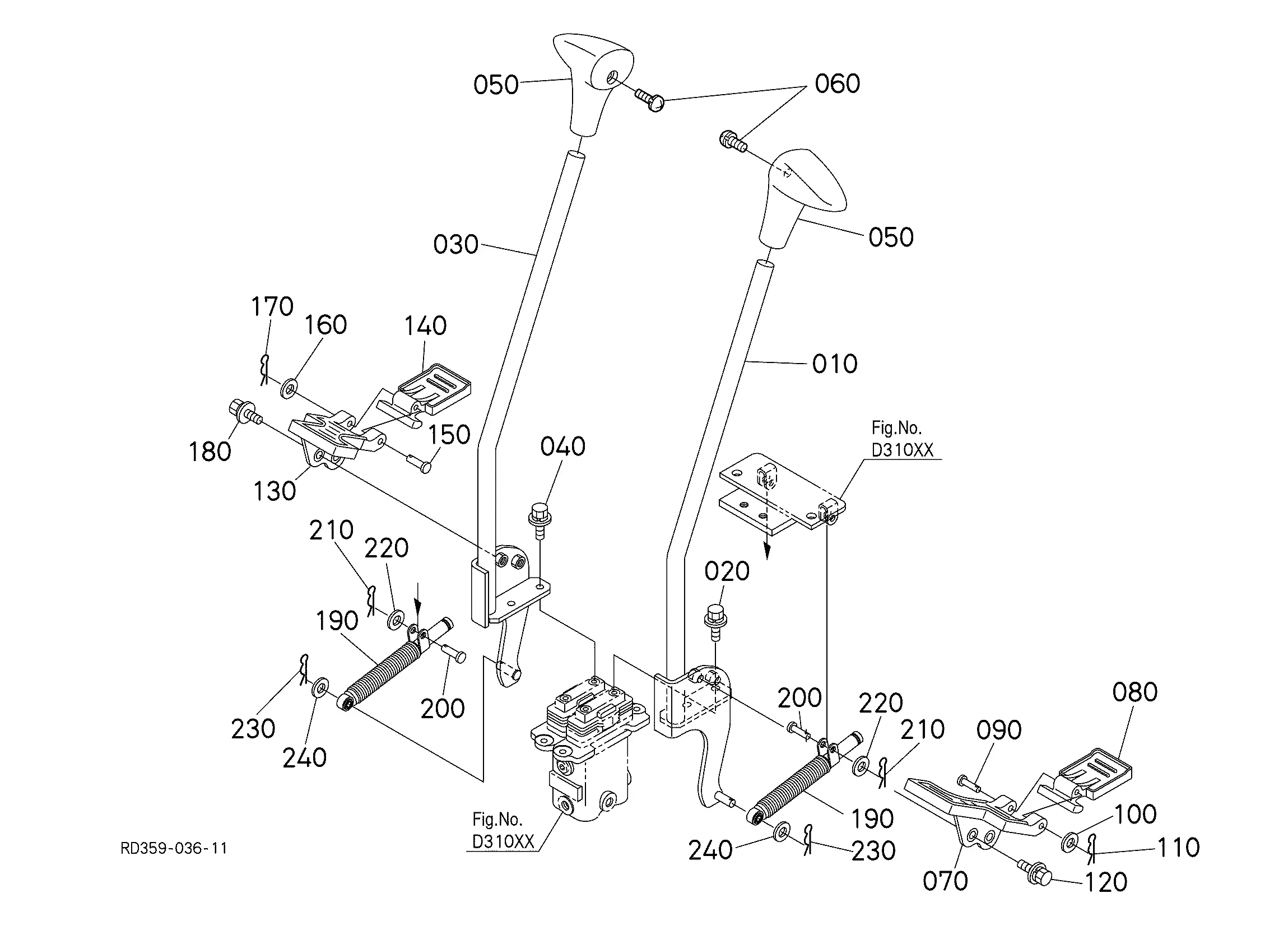

Importance of Parts Diagrams

Visual representations of components are essential for understanding the assembly and functionality of machinery. They serve as valuable tools for operators and technicians, facilitating efficient maintenance and repairs.

One key advantage of these visual aids is their ability to enhance communication. When discussing repairs or modifications, referring to illustrations can significantly reduce misunderstandings. This is particularly useful in a collaborative environment, where multiple individuals may be involved in the servicing process.

- Efficiency in Repairs: Accurate visuals enable quicker identification of components, allowing for faster diagnostics and repairs.

- Training and Education: These illustrations serve as effective teaching tools for new personnel, helping them familiarize themselves with equipment.

- Inventory Management: Detailed representations assist in tracking and ordering necessary items, ensuring that maintenance can proceed without delays.

- Preventative Maintenance: Regular reference to these visuals can promote proactive servicing, ultimately extending the lifespan of the machinery.

In conclusion, utilizing visual references enhances operational efficiency and promotes effective communication among team members, contributing to better overall performance in machinery management.

Main Components Explained

Understanding the essential elements of a mini-excavator is crucial for efficient operation and maintenance. Each component plays a significant role in the machine’s overall functionality, ensuring optimal performance in various tasks. This section delves into the key parts that make up this powerful equipment.

1. Engine and Power System

The engine serves as the heart of the machine, providing the necessary power for various operations. Its efficiency directly impacts the performance and fuel consumption.

- Type: Diesel engines are commonly used due to their reliability and power output.

- Cooling System: Ensures the engine operates within a safe temperature range.

- Fuel System: Delivers fuel efficiently to maintain performance.

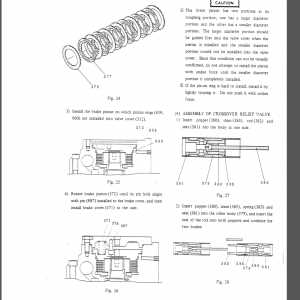

2. Hydraulic System

The hydraulic system is vital for the movement and operation of attachments. It converts the engine’s power into hydraulic energy.

- Pumps: Generate hydraulic pressure needed for various functions.

- Valves: Control the flow and direction of hydraulic fluid.

- Cylinders: Facilitate the movement of the boom, arm, and bucket.

How to Use the Diagram

Understanding the visual representation of a machinery assembly is crucial for effective maintenance and repairs. This section provides guidance on how to effectively interpret the schematic to facilitate troubleshooting and part replacement.

Follow these steps to make the most of the illustration:

- Familiarize yourself with the layout:

- Examine the overall structure to identify major components.

- Note the arrangement of different sections for a better understanding of connectivity.

- Use the labels and markings to pinpoint particular components.

- Cross-reference with your repair manual for precise specifications.

- List the necessary parts you need to replace or repair based on your findings.

- Organize your tools and workspace for efficiency.

- Keep the illustration handy while working to avoid mistakes.

- Update your understanding as you progress through the maintenance process.

By utilizing this schematic effectively, you can enhance your efficiency and accuracy during repair and maintenance tasks.

Common Replacement Parts

In the maintenance of heavy machinery, certain components often require substitution due to wear and tear. Understanding which elements are typically replaced can enhance the longevity and efficiency of equipment. This section outlines frequently needed items for upkeep and repair, ensuring optimal performance.

Hydraulic Components

Hydraulic elements are crucial for the functionality of excavators and similar machinery. Commonly replaced items include hydraulic hoses and seals, which can wear out due to pressure and exposure to various elements. Regular checks and timely replacements can prevent leaks and maintain system efficiency.

Tracks and Undercarriage Parts

The undercarriage is subjected to significant stress, especially in challenging terrains. Track links and rollers often need replacement to ensure smooth operation and stability. Investing in high-quality replacements can drastically reduce maintenance costs over time and improve the machine’s overall performance.

Maintenance Tips for Durability

Ensuring the longevity and reliable performance of machinery requires consistent and thoughtful upkeep. Regular maintenance not only helps to prevent unexpected breakdowns but also enhances efficiency and extends the lifespan of the equipment. Implementing a few key strategies can make a significant difference in maintaining operational excellence.

- Regular Inspections: Conduct frequent checks on all components to identify any signs of wear or damage early. This proactive approach allows for timely repairs.

- Fluid Checks: Monitor and replace hydraulic fluid, engine oil, and other essential fluids as recommended by the manufacturer. Proper lubrication is crucial for optimal functioning.

- Cleaning: Keep all parts clean and free from debris. Accumulated dirt can lead to overheating and reduced efficiency.

- Adjustments: Regularly adjust belts, chains, and other movable parts to ensure they are functioning correctly. Proper tension and alignment are vital for performance.

- Component Replacement: Replace worn or damaged parts promptly. Using high-quality replacement parts can significantly enhance durability.

By following these maintenance tips, users can enhance the performance and lifespan of their machinery, ensuring that it remains a reliable asset for years to come.

Identifying Parts in the Diagram

Understanding the layout of a machinery illustration is crucial for effective maintenance and repairs. This section aims to guide users in recognizing various components represented within the schematic. Each element serves a specific function, and knowing how they interrelate enhances overall efficiency and performance.

Understanding Component Functions

Every segment of the visual representation corresponds to a particular unit, ranging from mechanical elements to hydraulic systems. Familiarity with these components aids in diagnosing issues and determining necessary replacements or adjustments. Pay close attention to labels and numbering, which provide vital information about each section’s role.

Using Reference Manuals

Consulting reference guides can significantly assist in interpreting the illustration accurately. These manuals typically contain detailed descriptions of each component’s specifications and maintenance requirements. They also offer insights into troubleshooting common problems, ensuring that operators can address challenges effectively.

Finding OEM Parts Easily

Locating original equipment manufacturer components can be a straightforward process with the right approach. Many enthusiasts and professionals seek high-quality replacements to ensure their machinery operates efficiently. Understanding how to navigate available resources will save time and enhance productivity.

Utilizing Authorized Dealers

One of the most reliable methods for acquiring genuine components is through authorized dealerships. These establishments typically have extensive inventories and can provide expert advice. When visiting a dealer, it’s helpful to have the model number and specifications on hand to facilitate the search.

Exploring Online Resources

The internet offers a wealth of platforms for sourcing quality replacements. Various websites specialize in connecting users with manufacturers and suppliers. Here is a table of popular online sources:

| Website | Description |

|---|---|

| OEMParts.com | A comprehensive site featuring a wide range of authentic components for various machinery. |

| PartsCatalog.com | An online catalog that allows users to search for specific models and find compatible items. |

| EquipmentFinder.com | A platform that connects users with local and online suppliers for machinery parts. |

Aftermarket vs. Original Parts

When maintaining heavy machinery, one crucial decision is whether to opt for original components or aftermarket alternatives. Each choice comes with its advantages and disadvantages, impacting performance, reliability, and cost. Understanding these differences can aid in making informed decisions for equipment upkeep.

Original components are designed and manufactured by the original equipment manufacturer (OEM). These items often ensure a perfect fit and optimal performance due to their tailored design. On the other hand, aftermarket alternatives are produced by third-party manufacturers and can offer a range of options and pricing structures. Below are some key points to consider when evaluating these two types:

- Quality: OEM items generally adhere to strict quality standards, while aftermarket products may vary in quality. It’s essential to research the reputation of aftermarket brands.

- Cost: Aftermarket options are typically more affordable, making them an attractive choice for budget-conscious operators. However, potential trade-offs in quality may lead to increased long-term costs.

- Availability: Aftermarket components are often more readily available from various suppliers, which can facilitate quicker repairs.

- Warranty: OEM components usually come with warranties that guarantee their performance. In contrast, the warranty coverage for aftermarket items can be inconsistent, so it’s important to verify the terms.

Ultimately, the choice between original and aftermarket alternatives will depend on specific needs, preferences, and financial considerations. Assessing the pros and cons of each can lead to a more effective maintenance strategy.

Repair Techniques and Best Practices

Effective maintenance and repair of machinery require a thorough understanding of both the equipment and the appropriate methods to ensure longevity and optimal performance. Implementing the right techniques not only enhances efficiency but also minimizes downtime and costs associated with repairs.

Regular Inspections: Conducting frequent evaluations of the equipment helps in identifying potential issues before they escalate. It is crucial to check key components for wear and tear, ensuring that any necessary adjustments or replacements are made promptly.

Use of Quality Materials: When performing repairs, utilizing high-quality materials is essential. This guarantees durability and reliability in the long run. Always opt for trusted suppliers to source your components, as this can significantly impact the performance of the machinery.

Following Manufacturer Guidelines: Adhering to the manufacturer’s recommendations is critical in the repair process. These guidelines provide detailed instructions on assembly, disassembly, and maintenance practices, ensuring that the work is completed correctly and safely.

Documentation: Keeping detailed records of all maintenance activities and repairs is a best practice that should not be overlooked. This documentation aids in tracking the history of the machinery and can be invaluable for future reference or when troubleshooting issues.

Training and Knowledge: Continuous education and training for those involved in the repair process are vital. Staying updated on the latest techniques and technologies can lead to improved methods and better outcomes in maintenance practices.

Resources for Further Information

For individuals seeking to enhance their understanding of machinery components and maintenance, a variety of resources are available. These materials can assist users in navigating technical specifications and gaining insights into the functionality and repair of equipment.

Several online platforms, forums, and reference books provide valuable information. Below is a table that highlights some of these resources:

| Resource Type | Description | Link |

|---|---|---|

| Manufacturer Website | Official site offering detailed specifications and manuals. | Visit |

| Online Forums | Community discussions for troubleshooting and advice from experienced users. | Visit |

| Technical Manuals | Comprehensive guides available in print or digital format. | Visit |

| Video Tutorials | Visual guides demonstrating repairs and maintenance procedures. | Visit |

Customer Reviews and Experiences

Feedback from users provides valuable insights into the functionality and reliability of machinery. Customers often share their thoughts regarding their interactions with equipment, focusing on performance, durability, and overall satisfaction. Understanding these experiences can assist potential buyers in making informed decisions and highlight areas for improvement.

User Satisfaction

Many individuals express high levels of contentment with their recent purchases, emphasizing how these machines have enhanced their productivity. Reviews frequently mention ease of operation and the intuitive design, allowing even novice operators to handle tasks efficiently. Users appreciate the robust construction, which stands up to rigorous use in various conditions.

Areas for Improvement

While numerous reviews are positive, some customers identify specific aspects that could benefit from enhancements. Common critiques include the need for improved customer support and more accessible replacement components. Feedback suggests that addressing these concerns could elevate user experience even further.