Modern electrical setups require efficient components to ensure the safety and reliability of power distribution. One of the key mechanisms in these systems is designed to manage and interrupt electrical flow, preventing potential damage from overloading or short circuits. This element plays a crucial role in maintaining system stability and protecting connected devices.

Understanding the structure and internal components of such safety devices is essential for both installation and maintenance. By learning how each part functions, technicians can identify issues more quickly and ensure that the overall system operates smoothly.

In this section, we will delve into the various elements that make up these protection devices, exploring their individual roles and how they interact within the system to provide a seamless flow of electricity while preventing any potential hazards.

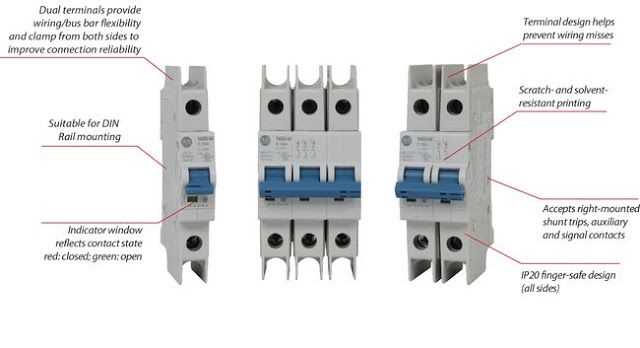

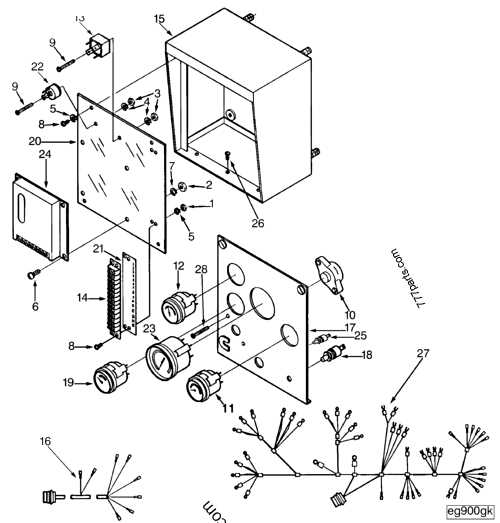

Circuit Breaker Parts Diagram

This section presents an overview of the components found within a protective device used in electrical systems. Understanding the various elements involved is essential for effective maintenance and troubleshooting.

Key components include:

- Enclosure: The outer shell that provides protection against environmental factors.

- Switching Mechanism: The mechanism responsible for opening and closing the circuit.

- Contacts: The conductive elements that make or break the connection.

- Arc Extinguisher: A device that dissipates energy from the arc during operation.

- Thermal Element: A component that responds to heat to prevent overload.

- Magnetic Element: This triggers the mechanism in case of a short circuit.

Each component plays a crucial role in ensuring the reliability and safety of electrical installations.

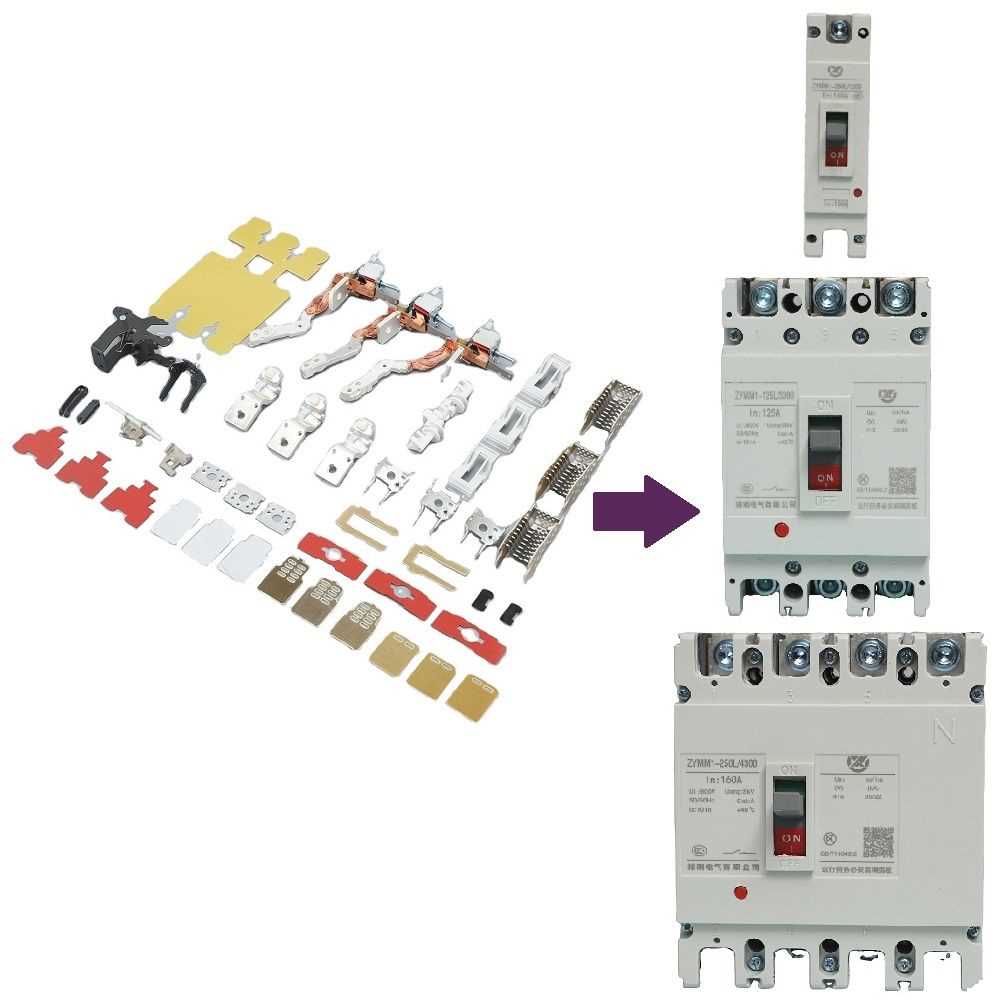

Main Components of a Circuit Breaker

The essential elements of a protective switching device play a crucial role in ensuring safety and reliability in electrical systems. Each component works in harmony to detect faults and interrupt the flow of electricity, preventing potential hazards. Understanding these key features is fundamental for effective maintenance and troubleshooting.

The primary element is the sensing mechanism, which identifies abnormal current levels, triggering the device’s operation. Accompanying this are the interrupting mechanisms that physically open the electrical circuit to halt the flow of current. Additionally, the structure includes various contacts, which facilitate the connection and disconnection process.

Support systems, such as springs and latches, provide the necessary force and ensure the proper functioning of the mechanism. Furthermore, insulation materials are critical for preventing unintended current paths and ensuring safe operation under various conditions. Each of these features contributes to the overall effectiveness of the system in safeguarding electrical circuits.

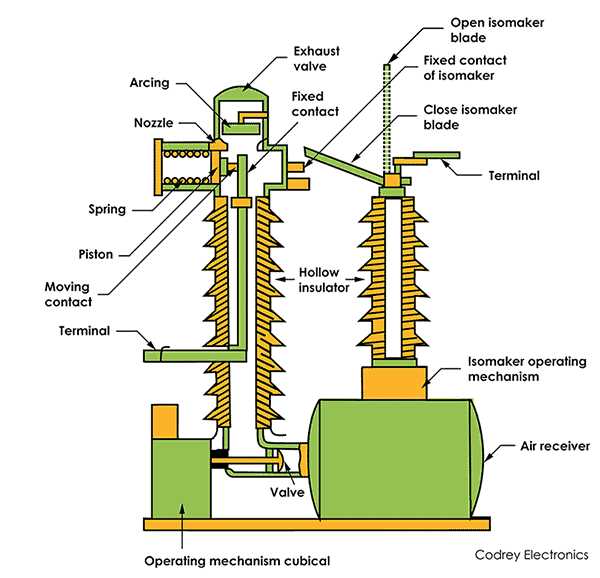

Internal Structure and Key Elements

The internal configuration of an electrical protective device comprises several essential components that work together to ensure safety and functionality. Understanding these elements is crucial for grasping how this mechanism operates effectively in various electrical systems.

Main Components

- Contact System: This element is responsible for establishing and interrupting the electrical connection.

- Arc Extinguishing Mechanism: Designed to quench the arc formed during the interruption process, preventing damage and ensuring reliability.

- Trip Unit: Acts as a control system that detects faults and triggers the interruption process.

- Operating Mechanism: Facilitates the movement of contacts to either connect or disconnect the circuit.

- Frame: The outer structure that houses all internal components, providing mechanical support and protection.

Functional Aspects

- The contact system initiates or terminates the flow of electricity based on the device’s operational state.

- The arc extinguishing mechanism ensures that the electrical arc does not persist, which could lead to dangerous situations.

- The trip unit continuously monitors the electrical flow and responds to anomalies, thereby protecting the connected circuitry.

- The operating mechanism translates the trip unit’s signal into a physical action that alters the connection state.

- The frame not only supports internal elements but also safeguards them from environmental factors.

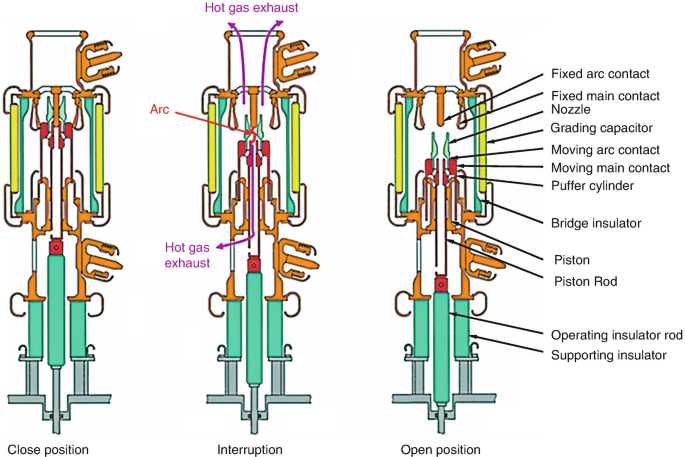

How a Circuit Breaker Operates

The mechanism designed to protect electrical systems functions through a combination of components that monitor and control the flow of electricity. Its primary role is to prevent overloads and short circuits, ensuring safety and reliability in various applications.

When the current exceeds predetermined levels, the internal mechanism responds by interrupting the flow. This action is facilitated by a thermal or magnetic sensor that detects abnormalities. Once the unsafe condition is identified, the device quickly disengages the electrical connection, halting the potential damage.

After a disruption, the system can be reset manually, restoring the connection. This reset capability allows for easy restoration of power without the need for replacement parts, enhancing the efficiency and practicality of the device in everyday use.

Functions of the Trip Mechanism

The trip mechanism plays a crucial role in safeguarding electrical systems by controlling the flow of current. It serves as a critical component designed to detect faults and initiate protective actions, thereby ensuring the safety and reliability of electrical installations.

Fault Detection

The primary function of the trip mechanism is to identify abnormal conditions, such as overloads or short circuits. When these situations arise, the mechanism quickly senses the deviation from normal operating parameters, triggering a response that interrupts the electrical supply.

Current Interruption

Upon detection of a fault, the trip mechanism activates a mechanism that disconnects the electrical circuit, preventing potential damage to equipment and reducing the risk of fire or electric shock. This swift action is vital for maintaining the integrity of the entire electrical system.

Importance of Arc Extinguishing Chamber

The arc extinguishing chamber plays a crucial role in the functionality and safety of electrical switching devices. Its primary purpose is to manage and dissipate the energy released during electrical discharges, thereby preventing damage to the system and ensuring a stable operation.

In the event of an overload or fault, the chamber is designed to contain and extinguish arcs that can occur. This is vital for maintaining the integrity of the equipment and protecting both operators and connected circuits. By effectively quenching these arcs, the chamber minimizes the risk of thermal and mechanical stress that could lead to failures or accidents.

Moreover, the design and efficiency of the arc extinguishing chamber are integral to the overall performance of the device. A well-engineered chamber enhances the reliability of the switching mechanism, contributing to the longevity and efficiency of the entire electrical system. Thus, understanding its importance is essential for anyone involved in the maintenance or design of electrical installations.

Role of the Operating Mechanism

The operating mechanism serves a critical function in the overall performance and reliability of electrical protection devices. It is responsible for initiating actions that safeguard electrical systems from overloads and short circuits. By ensuring timely intervention, this component helps maintain safety and operational integrity within electrical networks.

At its core, the operating mechanism translates the conditions detected within the system into mechanical movements that activate the necessary protective measures. This process involves a series of springs, levers, and other mechanical elements working in unison to deliver precise responses to varying electrical conditions. The efficiency and responsiveness of the mechanism directly impact the effectiveness of the safety measures in place.

Additionally, the design and construction of the operating mechanism influence its durability and maintenance requirements. A well-engineered mechanism can withstand frequent operation and harsh environmental conditions, ensuring long-lasting performance. Regular inspection and maintenance of this vital component are essential to uphold its reliability and prevent potential failures.

In summary, the operating mechanism plays a pivotal role in enhancing the functionality and safety of electrical systems. Its ability to effectively respond to critical conditions underscores its importance in the realm of electrical protection and control.

Types of Contacts in Circuit Breakers

In electrical protection devices, contacts play a vital role in controlling the flow of electricity. These components are essential for ensuring safety and functionality, as they are responsible for opening and closing circuits based on specific conditions. Understanding the various types of contacts is crucial for selecting the appropriate device for different applications.

Fixed Contacts: These contacts remain stationary and provide a stable connection point within the device. They are designed to withstand high currents and are typically made of conductive materials that can endure wear over time.

Moving Contacts: In contrast, moving contacts are designed to change position, either to make or break a connection. They often operate in conjunction with fixed contacts and are engineered to respond quickly to electrical overloads or faults.

Auxiliary Contacts: These are additional contacts that serve secondary functions, such as signaling or indicating the status of the main device. They can be either normally open or normally closed, depending on the specific requirements of the system.

Low-Voltage Contacts: These contacts are specifically designed for applications involving low voltage. They provide reliable operation in scenarios where minimal electrical interference is present, ensuring that devices function properly without risk of failure.

Understanding these types of contacts enhances the ability to make informed decisions regarding electrical protection solutions, ultimately leading to improved safety and efficiency.

Protective Devices and Indicators

Understanding protective mechanisms and indicators is essential for ensuring the safety and efficiency of electrical systems. These components play a crucial role in safeguarding against potential hazards and providing necessary feedback on the system’s status. By monitoring and controlling electrical flow, they help prevent damage and enhance operational reliability.

Among the various elements utilized in these safety measures, fuses, relays, and signaling devices stand out. Each component serves a specific purpose, contributing to the overall integrity of the electrical infrastructure. Below is a summary of common protective devices and their functions:

| Device Type | Function |

|---|---|

| Fuse | Protects against overload by melting and interrupting the circuit when excessive current flows. |

| Relay | Acts as a switch that opens or closes circuits automatically based on specific conditions, providing control and protection. |

| Indicator Light | Signals the operational status of a system, alerting users to normal operation or faults. |

| Surge Protector | Defends against voltage spikes by redirecting excess voltage away from sensitive equipment. |

Incorporating these devices into electrical systems is vital for enhancing safety and ensuring proper functioning. Regular inspections and maintenance of these components can significantly reduce the risk of failures and improve the longevity of the equipment.

Insulating Components and Their Purpose

Insulating elements play a crucial role in ensuring the safety and reliability of electrical systems. These components are designed to prevent unwanted electrical flow, protecting both the equipment and users from potential hazards. By providing a barrier against electrical currents, they help maintain the integrity of the system and reduce the risk of faults.

Functionality of insulating materials is essential in various applications. They are utilized to separate conductive parts, ensuring that electricity flows only through designated pathways. This separation is vital for preventing short circuits and protecting sensitive devices from excessive voltage or current.

In addition to safety, these components contribute to the overall performance of electrical systems. They minimize energy losses by reducing leakage currents and improving efficiency. Furthermore, high-quality insulating materials can withstand extreme temperatures and environmental conditions, ensuring long-term functionality and reliability.

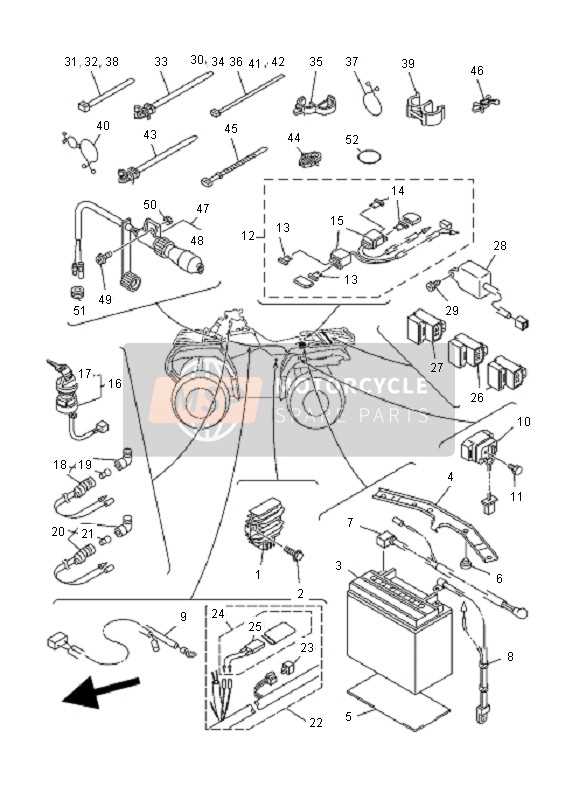

External Connections and Mounting Points

This section outlines the significance of external linkages and the designated locations for installation. Understanding these elements is crucial for ensuring optimal performance and safety of the device in various applications.

Connection Types

Different types of connections serve distinct purposes, facilitating the flow of electricity and control signals. These connections must be properly configured to ensure reliability and efficiency.

| Connection Type | Description |

|---|---|

| Power Input | This is where the primary electrical supply enters the device, providing the necessary energy for operation. |

| Control Signals | These connections allow external control systems to manage the functioning of the device, enabling automation and remote operation. |

| Grounding | Essential for safety, grounding connections minimize the risk of electrical shock by directing excess current to the earth. |

Mounting Locations

Designated mounting points are integral to the stability and accessibility of the unit. Correct placement is vital to ensure that maintenance can be performed easily and that the device operates within its intended parameters.

Maintaining Circuit Breaker Efficiency

Ensuring optimal functionality of electrical protection devices is crucial for reliable system operation. Regular maintenance plays a vital role in preventing potential failures and prolonging the lifespan of these components. By adhering to specific practices, users can enhance performance and ensure safety in their electrical installations.

Regular Inspection

Routine evaluations are essential to identify any signs of wear or damage. Look for discoloration, unusual noises, or irregularities during operation. Addressing these issues promptly can prevent more significant problems in the future.

Cleaning and Dust Removal

Accumulated dust and debris can hinder efficiency. Implementing a regular cleaning schedule helps maintain optimal performance. Use appropriate methods to remove dust without causing damage, ensuring that all surfaces are clear for proper functioning.

Common Issues and Part Replacement

Electrical systems may encounter various challenges that can affect their functionality and efficiency. Recognizing these common problems is essential for maintaining the overall performance of the unit. Timely identification and replacement of faulty components can prevent further damage and ensure safe operation.

- Frequent Tripping: A common issue where the system automatically turns off, indicating an overload or short circuit. This can often be resolved by checking the load capacity and replacing worn-out elements.

- Overheating: Excessive heat can lead to malfunction. This might be due to poor connections or damaged insulation. Replacing these damaged connections can restore optimal function.

- No Power: If there is no power to the system, it may be due to a failed component. Checking the integrity of the internal wiring and replacing any broken connections is vital.

- Unusual Noises: Sounds like buzzing or clicking may indicate mechanical issues. Inspecting the assembly and replacing any damaged or loose elements can alleviate these noises.

Regular maintenance and prompt replacement of defective components not only enhance safety but also prolong the life of the electrical system. It is advisable to consult with a professional for accurate diagnosis and repair.