For enthusiasts and professionals alike, comprehending the intricacies of machinery is essential for efficient maintenance and operation. Each model comes with its unique configuration, presenting challenges and opportunities for users. A thorough grasp of how various components interact can significantly enhance performance and prolong lifespan.

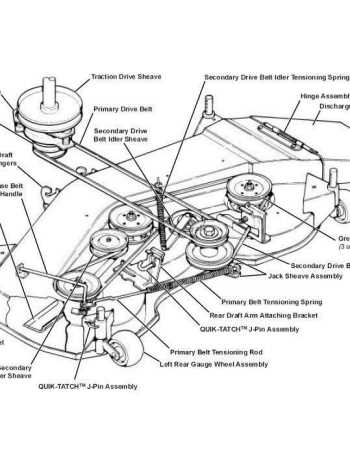

In this exploration, we delve into the specific layout of essential elements for a well-known model. By examining the assembly, one can identify vital sections and their respective roles. This knowledge not only aids in troubleshooting but also empowers users to make informed decisions regarding upgrades and replacements.

Furthermore, having access to clear representations of these assemblies can streamline repair processes, ensuring that even novice users can navigate their way through maintenance tasks with confidence. Understanding this layout ultimately leads to a more satisfying and productive experience with lawn care equipment.

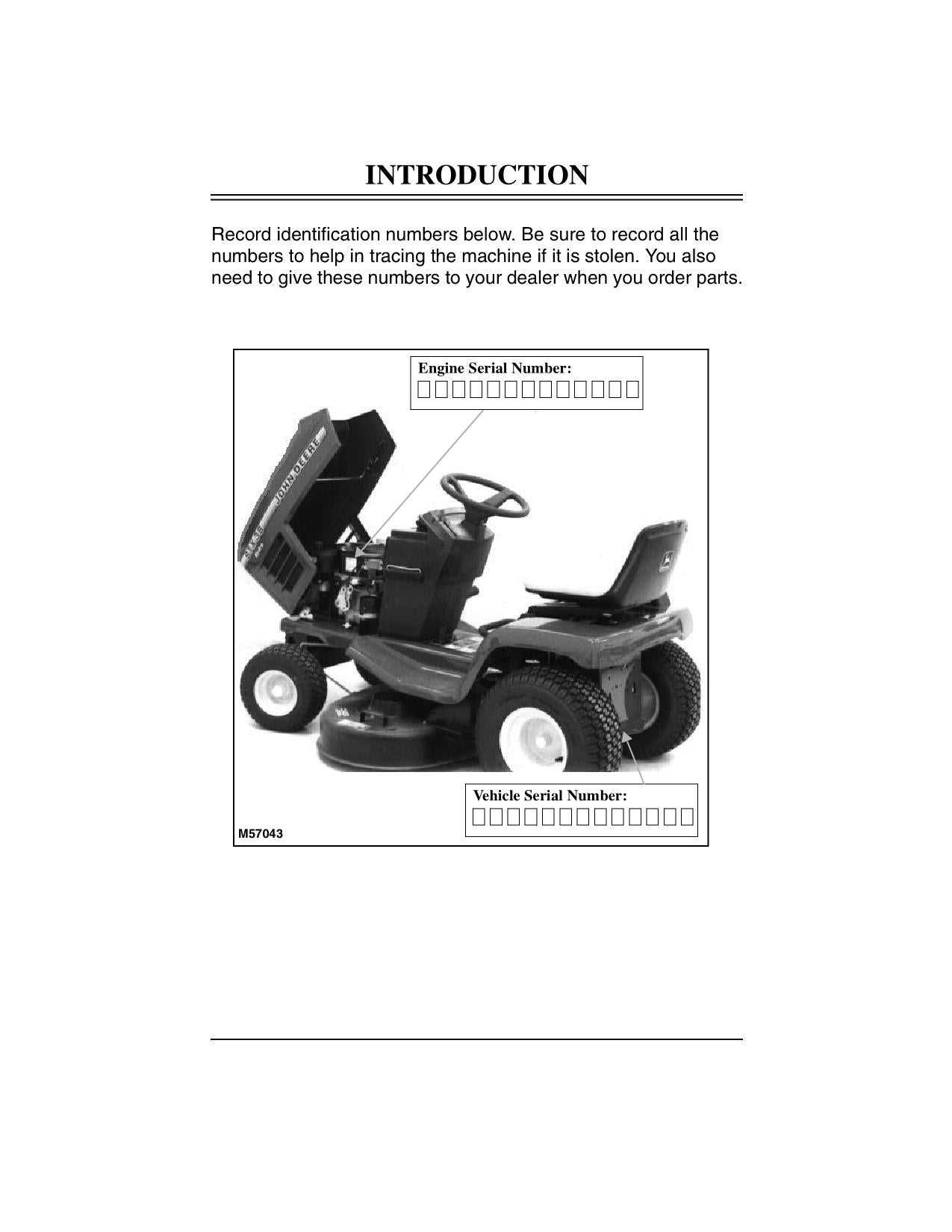

Understanding John Deere STX38

This section delves into the intricacies of a well-regarded lawn maintenance machine known for its efficiency and durability. By exploring its design, functionality, and various components, users can gain valuable insights into optimal operation and maintenance practices.

The model in focus is characterized by a robust build and user-friendly features, making it a popular choice among homeowners and landscaping professionals alike. Here are some key aspects to consider:

- Engine Performance: The power unit is engineered for reliable performance, ensuring a smooth cutting experience.

- Cutting Mechanism: An efficient cutting system allows for a clean finish, adapting to different grass types and lengths.

- Comfort Features: Ergonomically designed controls and seating enhance user experience during extended periods of use.

- Maintenance Ease: Accessibility to components simplifies routine servicing, promoting longevity and reliability.

Understanding the various elements that contribute to this machine’s effectiveness can significantly improve user familiarity and operational efficiency. Regular maintenance and attentiveness to its needs will ensure that this lawn care equipment continues to perform at its best.

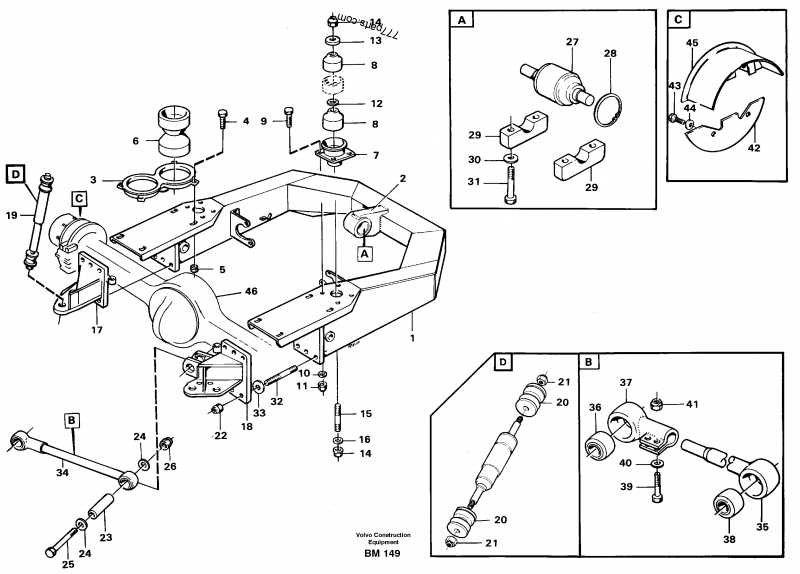

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repairs. Visual representations play a significant role in identifying each element, facilitating smoother workflows and reducing errors. By having a clear overview, users can more easily pinpoint issues and locate necessary components.

| Benefit | Description |

|---|---|

| Enhanced Clarity | Visual aids simplify complex assemblies. |

| Efficiency | Reduces time spent searching for components. |

| Improved Accuracy | Minimizes mistakes during repairs and replacements. |

| Better Communication | Facilitates discussions among technicians. |

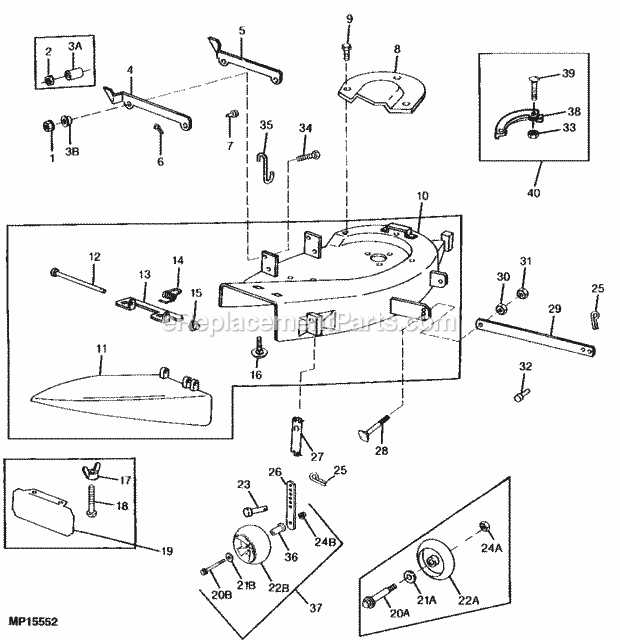

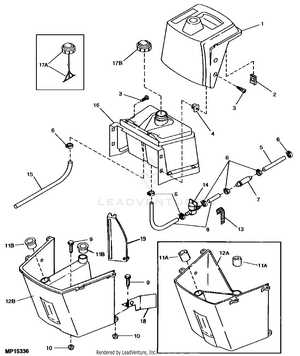

Overview of Black Deck Features

This section explores the key attributes and functionalities of a specific mower component designed for optimal performance and durability. Understanding these features enhances maintenance and operation efficiency.

- Durability: Constructed from high-quality materials to withstand wear and tear.

- Design: Streamlined shape for improved aerodynamics and cutting efficiency.

- Compatibility: Engineered to fit a variety of models, ensuring versatility.

- Maintenance: Features that facilitate easy cleaning and servicing, prolonging lifespan.

- Cutting Performance: Innovative design that enhances grass cutting and collection.

These aspects contribute significantly to the overall functionality, ensuring a reliable experience for users.

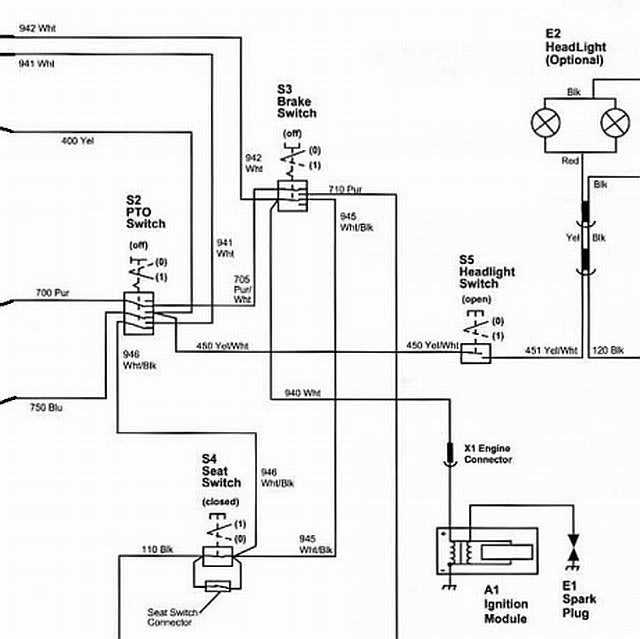

Common Issues with STX38 Models

The machines in this series are known for their reliability and efficiency, yet users may encounter several recurring challenges. Understanding these issues can aid in effective maintenance and prolong the lifespan of the equipment.

Frequent Problems

Owners often report specific difficulties that can affect performance and usability. Awareness of these can help in prompt troubleshooting.

| Issue | Description | Possible Solutions |

|---|---|---|

| Engine Starting | Difficulty in starting the engine can be caused by various factors such as battery failure or fuel issues. | Check battery charge, fuel levels, and ignition components. |

| Uneven Cutting | This may arise from dull blades or incorrect tire pressure, affecting the quality of the cut. | Sharpen or replace blades and check tire inflation. |

| Transmission Issues | Gear shifting problems can occur due to worn components or low fluid levels. | Inspect fluid levels and replace any damaged parts. |

| Electrical Failures | Electrical components can malfunction, leading to operational failures. | Examine wiring and connections for damage or corrosion. |

Maintenance Tips

Regular upkeep is essential to mitigate these common issues. Routine checks and timely replacements can greatly enhance performance and reliability.

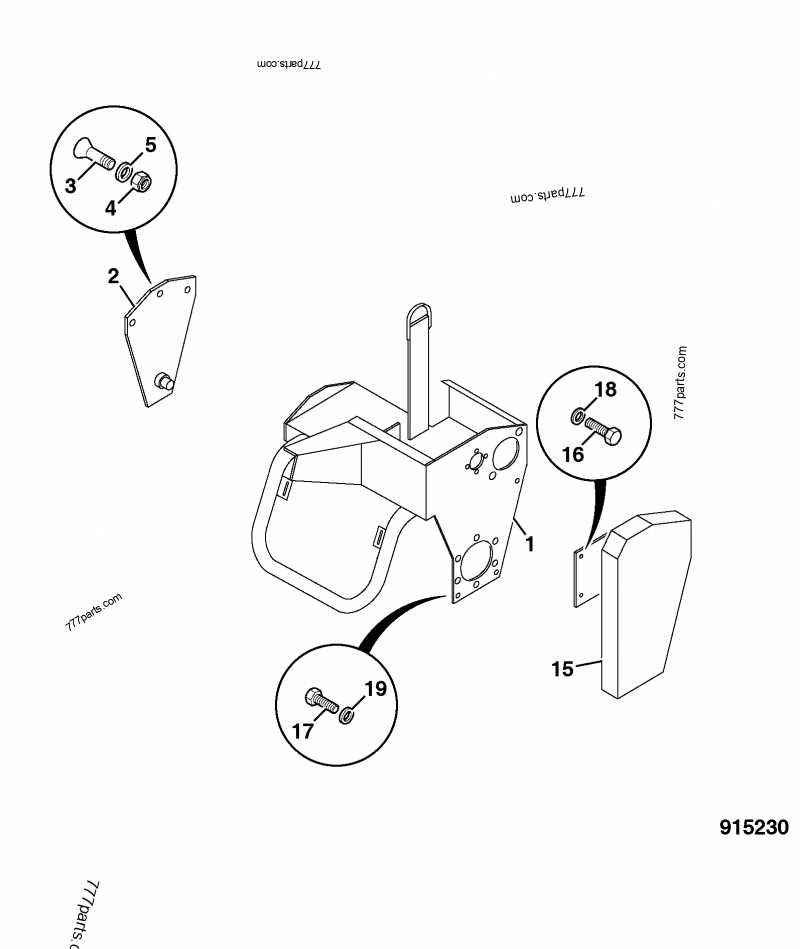

Essential Components of Black Deck

The functionality and performance of any machinery rely heavily on its critical elements. Each component plays a vital role, contributing to the overall efficiency and effectiveness of the system. Understanding these essential parts is crucial for maintenance and troubleshooting.

Engine Assembly: At the heart of the system, this assembly provides the necessary power. Its reliability is paramount for optimal operation.

Chassis Structure: The framework supports various components, ensuring stability during use. A robust chassis enhances durability and performance.

Transmission System: This part transfers power from the engine to the wheels, allowing for smooth movement. Proper functioning is essential for maneuverability.

Cutting Mechanism: Designed for efficiency, this mechanism ensures precise cutting and handling of the terrain. Regular checks are important to maintain sharpness and effectiveness.

Control Panel: The interface allows the operator to manage functions easily. A user-friendly design enhances the overall experience.

Each of these components must work in harmony for peak performance. Regular maintenance and understanding of their functions can prevent potential issues and extend the lifespan of the equipment.

Where to Find Parts Diagrams

Locating schematics for machinery can be essential for maintenance and repair tasks. Various resources offer access to detailed illustrations that can aid in understanding the components and their arrangement. Knowing where to search can streamline the process and ensure that you obtain accurate information.

Online Resources

The internet is a treasure trove for those seeking technical drawings. Manufacturer websites often provide downloadable manuals, while specialized forums and community sites can offer user-shared files and insights. Be sure to verify the credibility of the sources to ensure accuracy.

Local Dealerships and Service Centers

Another effective method is to visit local dealerships or authorized service centers. These establishments typically have access to official resources and can provide assistance in obtaining the necessary illustrations. Consulting with knowledgeable staff can also enhance your understanding of the machinery.

How to Read Parts Diagrams

Understanding the visual representation of components is essential for efficient maintenance and repair. By familiarizing yourself with these illustrations, you can easily identify individual elements and their functions, streamlining the process of restoration and replacement.

Identifying Components

The first step in interpreting these visuals is recognizing the various elements depicted. Each symbol or illustration corresponds to a specific item, often accompanied by a label or code.

| Symbol | Description |

|---|---|

| A | Gear assembly |

| B | Drive belt |

| C | Blade unit |

Understanding Notations

Many illustrations include additional notes or references. Pay attention to these details, as they provide crucial information regarding assembly, orientation, and compatibility of the components.

Replacement Parts for STX38

Maintaining your machinery is essential for optimal performance and longevity. When components wear out or fail, knowing where to find suitable alternatives can save time and ensure smooth operation. This section focuses on the various options available for restoring functionality and enhancing the efficiency of your equipment.

Finding Suitable Alternatives

When seeking replacements, it is important to explore a range of suppliers and manufacturers. Quality alternatives can often be sourced from authorized dealers, online retailers, or specialized workshops. Ensuring compatibility with your specific model is crucial for seamless integration and performance.

Maintenance Tips

Maintenance Tips for Black Deck

Regular upkeep of your outdoor machinery ensures optimal performance and longevity. Implementing systematic care not only enhances efficiency but also minimizes the risk of unexpected failures.

Routine Checks

Conducting periodic inspections is crucial. Look for wear and tear, lubricate moving parts, and ensure that all components are securely fastened. Addressing minor issues early can prevent more significant problems down the line.

Cleaning Procedures

Keep your equipment clean to avoid debris buildup. A simple wash with water and a gentle detergent will suffice. Make sure to dry all areas thoroughly to prevent rust.

| Task | Frequency |

|---|---|

| Inspect belts and cables | Every month |

| Clean exterior | After each use |

| Change oil | Every season |

| Sharpen blades | Every 20 hours |

Upgrading Your John Deere STX38

Enhancing the performance and aesthetics of your lawn machine can significantly improve its functionality and lifespan. By exploring various upgrades, you can tailor your equipment to better meet your needs while ensuring it runs efficiently.

Consider these key modifications:

| Upgrade Type | Description |

|---|---|

| Engine Tune-Up | Improving the engine’s performance through routine maintenance and better components. |

| Blade Replacement | Installing high-quality blades for a cleaner cut and improved efficiency. |

| Enhanced Tires | Switching to durable tires for better traction and stability on various terrains. |

| Upgraded Seat | Replacing the seat with a more comfortable option to enhance user experience. |

By carefully selecting upgrades, you can achieve the ultimate performance from your machine, ensuring it serves you well for years to come.

Tools Required for Repairs

Having the right instruments at your disposal is crucial for effective maintenance and repair tasks. Whether you are addressing minor adjustments or significant overhauls, the appropriate tools enhance efficiency and ensure quality outcomes.

Essential Instruments

Basic tools like wrenches, screwdrivers, and pliers form the foundation of any repair kit. Additionally, specialized equipment such as torque wrenches and diagnostic devices may be necessary for more complex tasks.

Safety Gear

Incorporating safety gear is paramount. Always wear gloves and protective eyewear to safeguard against injuries. Ensuring a safe working environment is the ultimate priority for successful repairs.

Frequently Asked Questions

This section aims to address common inquiries related to maintenance and repair of outdoor equipment. Here, we provide answers to the most pressing questions that users often have, ensuring a better understanding of the components and their functionality.

What should I do if I can’t find a specific component?

If you’re having trouble locating a particular piece, check with authorized dealers or online retailers that specialize in similar machinery. They often have comprehensive catalogs that can assist in your search.

How can I identify the right replacement for my equipment?

To find the appropriate substitute, consult the owner’s manual or the manufacturer’s website for specifications. You can also compare the dimensions and features of the existing component with potential replacements.

Are there any tips for regular maintenance?

Regular upkeep is essential for optimal performance. Clean the equipment frequently, check for wear and tear, and replace any damaged parts promptly to avoid further issues.

What tools are necessary for basic repairs?

A standard toolkit including wrenches, screwdrivers, and pliers is generally sufficient for most minor repairs. Specialized tools may be required for specific tasks, so refer to the manual for guidance.

Where can I find repair manuals or guides?

Repair manuals can often be found on the manufacturer’s website or through various online forums dedicated to equipment maintenance. These resources provide valuable information for troubleshooting and repairs.

Expert Resources for STX38 Owners

For enthusiasts and operators of this particular equipment, having access to reliable resources is essential for optimal maintenance and performance. Whether seeking troubleshooting tips or upgrade suggestions, numerous avenues can be explored to enhance the ownership experience.

- Online Forums: Join communities where fellow users share experiences and solutions.

- Manufacturer Websites: Explore official sites for guides, specifications, and service recommendations.

- YouTube Tutorials: Visual aids can provide step-by-step instructions for repairs and maintenance.

- Local Dealers: Consult experts who can offer personalized advice and genuine components.

- Repair Manuals: Invest in comprehensive manuals that outline procedures and best practices.

By leveraging these resources, owners can delve deeper into the nuances of their machinery, ensuring longevity and efficiency in operation.