For anyone looking to maintain or repair their machinery, comprehending the individual elements and their arrangement is crucial. A clear visualization of the various components can greatly enhance the effectiveness of your upkeep efforts. This section aims to provide insights into the intricate network of parts that make up your tool.

By familiarizing yourself with the layout and functionality of each section, you can streamline repairs and ensure optimal performance. Whether you’re tackling routine maintenance or troubleshooting an issue, having access to a comprehensive overview of the structure will empower you to make informed decisions. This understanding not only aids in the immediate task at hand but also fosters long-term care of your equipment.

Overview of Key Components

This section provides an insight into the fundamental elements of a specific engine model, highlighting their functions and significance in the overall operation.

Essential Parts

The following components play a crucial role in the engine’s performance:

- Engine Block: The core structure housing various internal parts.

- Cylinder Head: Contains combustion chambers and valves.

- Piston: Converts fuel energy into mechanical motion.

- Crankshaft: Transforms linear motion of pistons into rotational movement.

- Fuel System: Responsible for delivering fuel to the combustion chambers.

- Ignition System: Initiates the combustion process.

Supporting Elements

In addition to the main components, several supporting parts enhance the functionality:

- Cooling System: Regulates engine temperature to prevent overheating.

- Lubrication System: Ensures smooth operation by reducing friction.

- Exhaust System: Channels gases away from the engine.

- Air Intake System: Supplies the engine with necessary air for combustion.

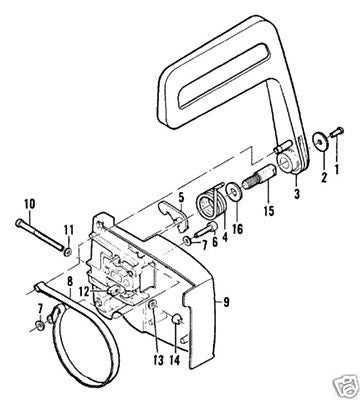

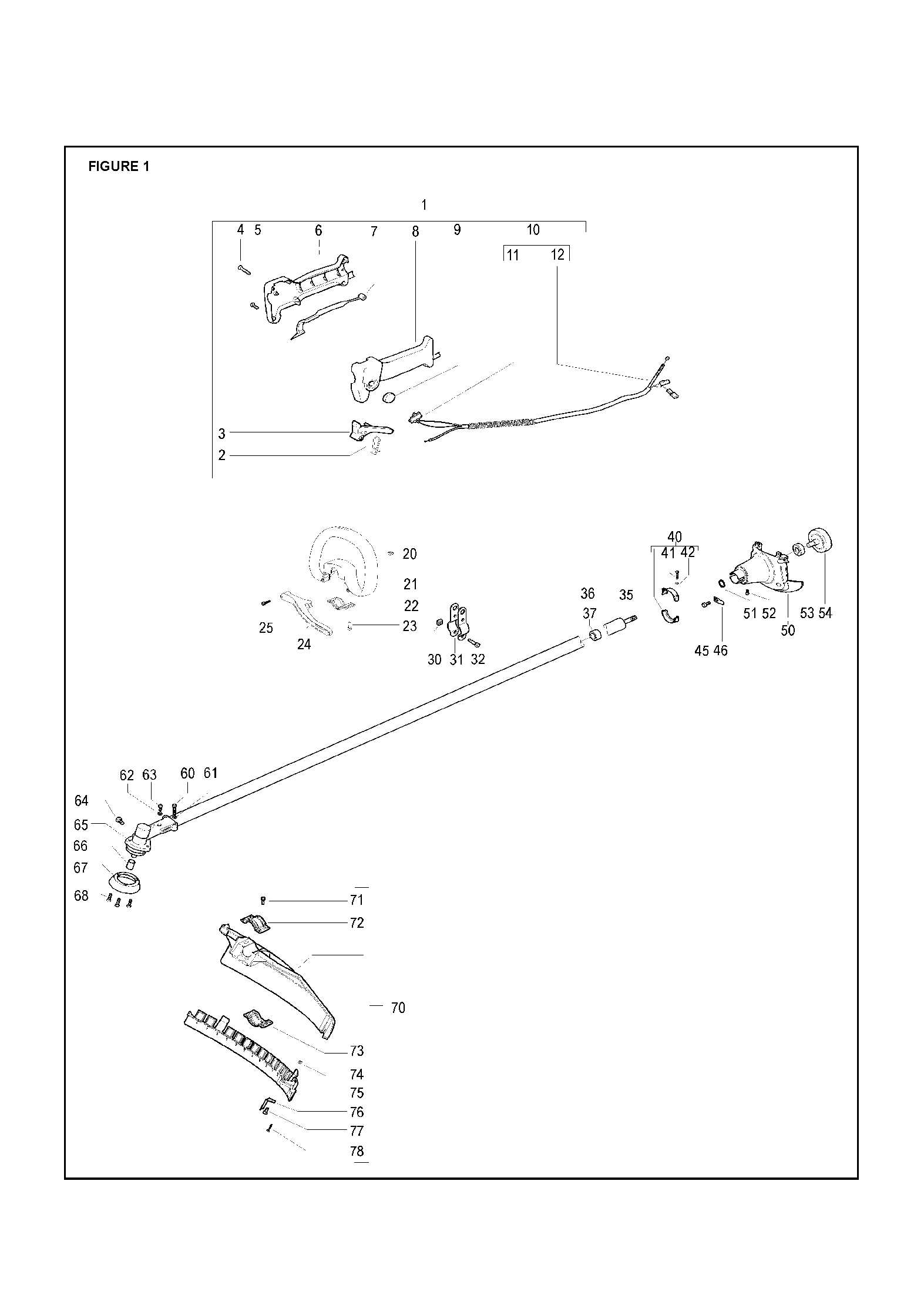

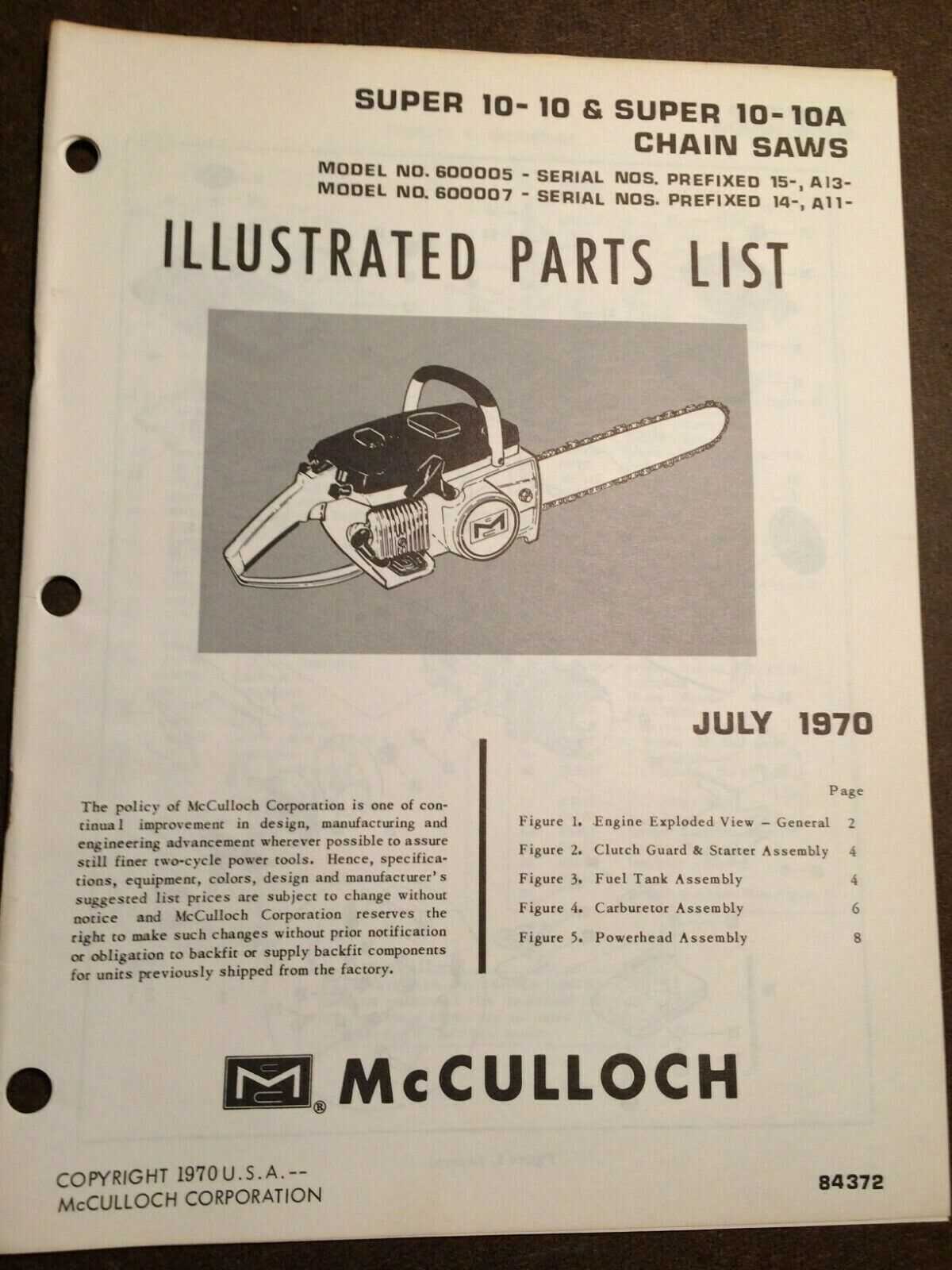

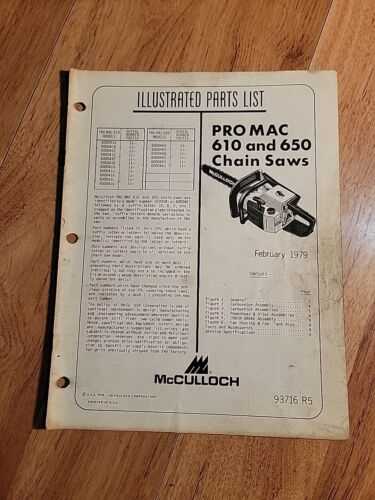

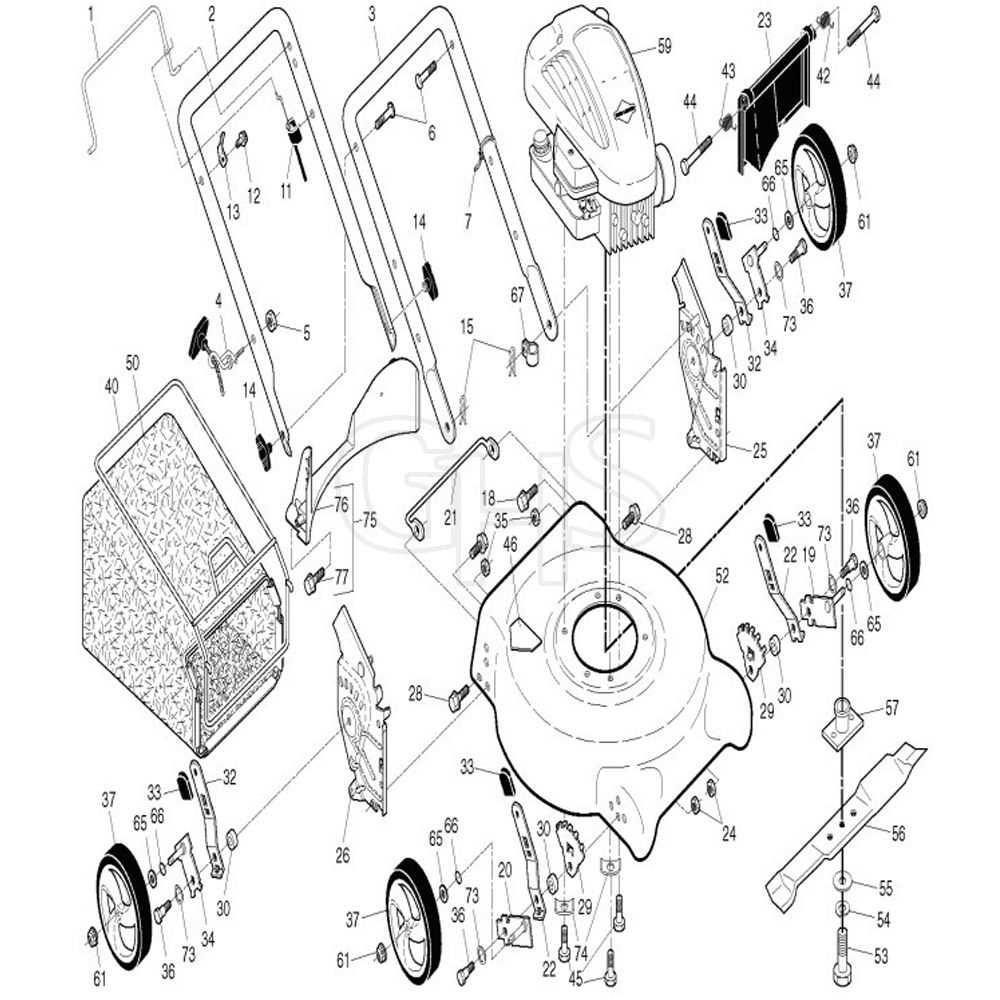

How to Read the Parts Diagram

Understanding an illustration of components is essential for effective maintenance and repair. Such visual guides provide a clear representation of various elements and their relationships within a system. By familiarizing yourself with this visual reference, you can streamline the identification and acquisition of necessary components.

When examining the illustration, start by noting the labeled sections. Each part will typically be assigned a unique identifier, which can correspond to a list or key accompanying the visual. This key offers detailed information regarding specifications and availability.

| Label | Description |

|---|---|

| A | Engine assembly |

| B | Fuel tank |

| C | Handle |

| D | Blade |

Additionally, pay attention to the orientation and layout. Components may be depicted in a way that highlights their functional arrangement. Understanding this spatial relationship can enhance your ability to troubleshoot issues effectively.

Common Replacement Parts Explained

Understanding the essential components of machinery is crucial for maintenance and repair. Certain elements are more frequently replaced due to wear and tear, ensuring optimal performance and longevity of the equipment. This section provides insight into these commonly exchanged items, highlighting their functions and importance.

Filters: Filters play a vital role in keeping the engine clean by trapping debris and contaminants. Regular replacement is necessary to maintain efficiency and prevent damage to internal components.

Blades: The cutting edges are essential for achieving precise results. Over time, they can dull or become damaged, necessitating their replacement to ensure effective operation.

Spark Plugs: These components ignite the fuel-air mixture in the engine. Worn or fouled spark plugs can lead to poor performance, making their timely replacement critical for smooth functioning.

Batteries: A reliable power source is essential for starting the equipment. Batteries degrade over time, and replacing them ensures dependable operation.

Drive Belts: These transfer power from the engine to various components. If they wear out or break, they can cause significant performance issues, making regular inspections and replacements important.

Identifying Wear and Tear Issues

Understanding the signs of deterioration in machinery is crucial for maintaining optimal performance. Regular inspection can help uncover potential problems before they escalate, ensuring longevity and efficiency. Familiarity with common indicators of wear will enable users to take proactive measures.

Visual Inspections: Regularly check for visible cracks, corrosion, or discoloration. These can signal underlying issues that may affect functionality.

Performance Changes: Noticeable declines in performance, such as decreased power or irregular operation, often indicate wear on critical components. Addressing these changes promptly is essential.

Unusual Noises: Listen for unfamiliar sounds during operation. Grinding, squeaking, or rattling can reveal that parts are wearing out and require attention.

Fluid Leaks: Any signs of leakage can point to worn seals or gaskets. It’s important to address these issues quickly to prevent further damage.

By staying vigilant and knowing what to look for, users can effectively identify and manage wear and tear, ultimately extending the life of their equipment.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular upkeep and attention to detail. By following a consistent maintenance routine, you can significantly extend the lifespan of your tools while enhancing their performance. Here are some essential strategies to keep your machinery in optimal condition.

Regular Cleaning

Keeping your devices clean is crucial for preventing wear and tear. Dust, dirt, and debris can accumulate and lead to malfunctions over time. Establish a routine to wipe down surfaces, remove any blockages, and ensure that moving parts are free from obstructions.

Periodic Inspections

Conducting regular inspections allows you to identify potential issues before they become serious problems. Check for signs of wear, loose components, or fluid leaks. Addressing these issues promptly can save you from costly repairs down the line.

| Task | Frequency | Notes |

|---|---|---|

| Clean exterior | After each use | Use a soft cloth to prevent scratches |

| Check fluid levels | Weekly | Maintain optimal levels for performance |

| Tighten bolts and screws | Monthly | Ensure all components are secure |

| Inspect moving parts | Every three months | Look for signs of wear or damage |

Tools Required for Repairs

When undertaking maintenance on outdoor machinery, having the right tools is essential for a successful and efficient repair process. The correct equipment not only simplifies tasks but also enhances safety, allowing for a smooth workflow. Below are key instruments that will prove invaluable during repairs.

Essential Hand Tools

Basic hand tools form the backbone of any repair job. A good selection includes wrenches, screwdrivers, and pliers. Each of these tools serves a unique purpose, enabling you to loosen or tighten various components effectively. Additionally, a socket set can offer versatility for different sizes of bolts, ensuring you have the right fit for your project.

Power Tools and Safety Equipment

For more demanding tasks, power tools can greatly expedite the repair process. Tools like drills and grinders can be particularly useful. Don’t forget to equip yourself with protective gear such as gloves, goggles, and ear protection to ensure safety while working. Having the appropriate tools and safety measures will ultimately lead to a more effective and secure repair experience.

Step-by-Step Disassembly Guide

This section provides a detailed approach to dismantling the equipment safely and efficiently. Following these instructions will help ensure that all components are handled correctly, minimizing the risk of damage.

- Gather necessary tools:

- Screwdrivers (flathead and Phillips)

- Wrenches

- Pliers

- Tweezers

- Container for small parts

- Ensure the equipment is turned off and disconnected from any power source.

- Start with external components:

- Remove any covers or shields.

- Take out screws and bolts securing the outer parts.

- Proceed to internal mechanisms:

- Carefully detach any visible components.

- Document each step for reassembly.

- Keep small parts organized to avoid loss.

- Consult the user manual for specific instructions on tricky sections.

Following this guide will facilitate a smooth disassembly process, allowing for maintenance or repair as needed.

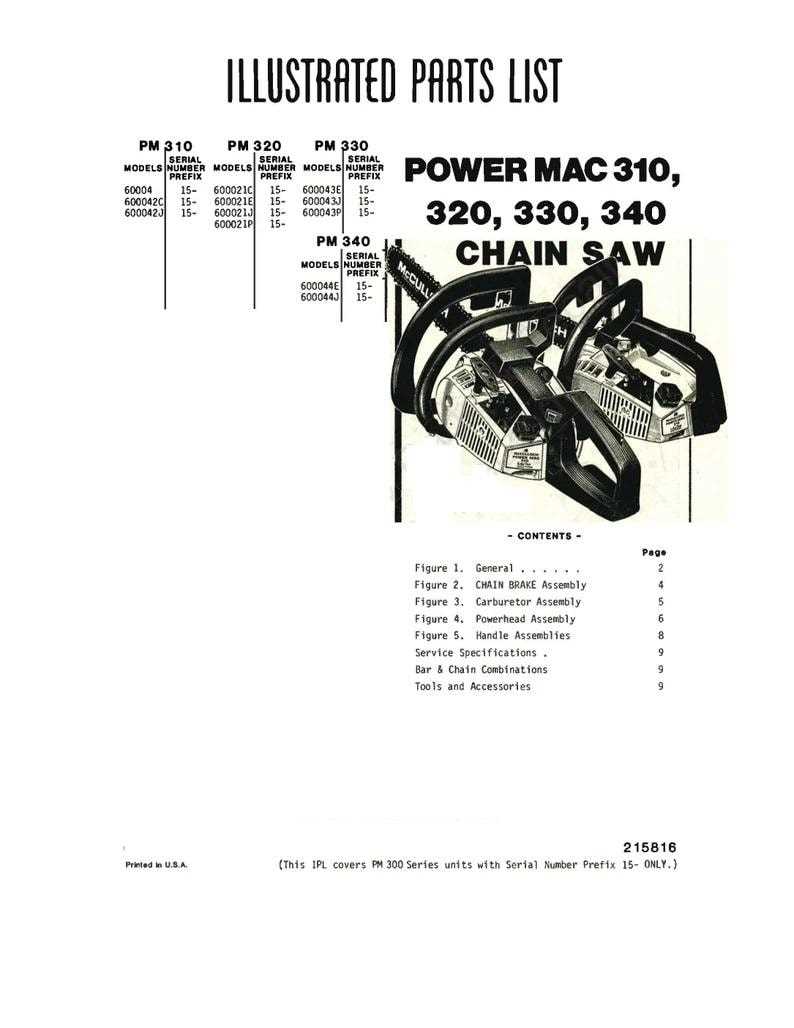

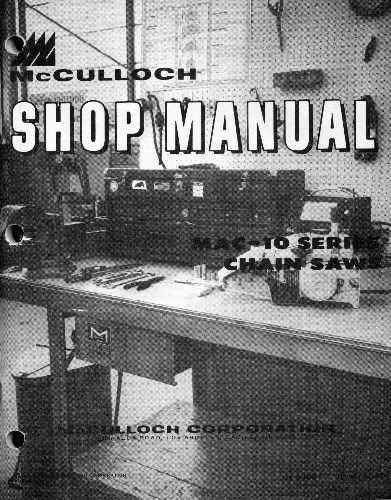

Reassembly Instructions for Mcculloch 610

This section provides essential guidance for the careful reconstruction of your equipment after disassembly. Following these steps ensures proper functionality and longevity, allowing you to maximize performance.

Preparation Steps

Before starting the reassembly process, gather all components and tools. Ensure a clean workspace to avoid losing any small parts. Review the original configuration to facilitate accurate reassembly.

Reassembly Process

| Step | Description |

|---|---|

| 1 | Begin by positioning the main body securely. |

| 2 | Attach the internal mechanisms, ensuring each component clicks into place. |

| 3 | Secure the outer casing, aligning it with the designated fasteners. |

| 4 | Double-check connections and tighten any loose parts. |

Once completed, conduct a thorough inspection to ensure everything is assembled correctly. This will provide the ultimate assurance of reliable operation.

Where to Find Genuine Parts

Locating authentic components for your equipment is essential to maintain its performance and longevity. Reliable sources ensure that you receive high-quality items that fit perfectly and operate effectively.

| Source | Description |

|---|---|

| Authorized Dealers | Official retailers provide a guarantee of authenticity and may offer expert advice. |

| Manufacturer’s Website | The best place for genuine items directly from the source, often featuring comprehensive catalogs. |

| Specialized Online Retailers | These platforms often focus on specific brands and can offer a wide range of components. |

| Local Repair Shops | Local technicians may have access to genuine components and can provide installation services. |

Comparative Analysis with Other Models

This section delves into the comparative aspects of various models within the same category, focusing on key features, performance metrics, and user feedback. By examining these factors, we can better understand how different designs meet the needs of users and how they stack up against each other in practical applications.

When evaluating alternative options, several important criteria emerge:

- Performance:

- Power output and efficiency

- Speed and operational capacity

- Durability under continuous use

- Design Features:

- Weight and portability

- Ergonomics and user comfort

- Innovative technology integration

- Maintenance:

- Ease of access to components

- Frequency and cost of servicing

- Availability of replacement components

- Cost-Effectiveness:

- Initial purchase price

- Long-term operational costs

- Resale value

In comparing these elements, we find that while some models excel in performance, others may offer superior design or lower maintenance costs. Understanding these distinctions helps consumers make informed decisions based on their specific needs and preferences.

Frequently Asked Questions

This section addresses common inquiries related to maintenance and components of outdoor power equipment. Here, you can find concise answers to help clarify various aspects of upkeep and troubleshooting.

| Question | Answer |

|---|---|

| What are the essential components for regular maintenance? | Key components include the air filter, spark plug, and fuel filter. Regular checks can enhance performance. |

| How can I identify parts that need replacement? | Look for wear signs like cracks or corrosion, and consult the manual for guidance on specific elements. |

| Is it necessary to use original equipment manufacturer parts? | While aftermarket parts may work, OEM parts ensure optimal performance and compatibility. |

| How often should I perform maintenance? | Routine checks are recommended after every 20-25 hours of use, or at the beginning of each season. |

| Where can I find replacement components? | Authorized dealers and online retailers typically stock a wide range of compatible elements for your equipment. |