The world of compact machinery is intricate, filled with various elements that work together to achieve optimal performance. Each component plays a crucial role in ensuring that the equipment operates smoothly and efficiently, enabling users to tackle a wide range of tasks.

To fully appreciate these mechanisms, it’s essential to explore the individual parts and their functions. By examining these elements closely, operators can gain insights into maintenance practices and troubleshooting methods, leading to enhanced productivity.

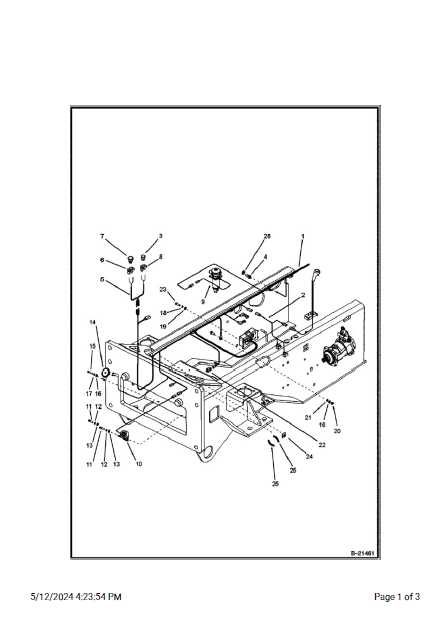

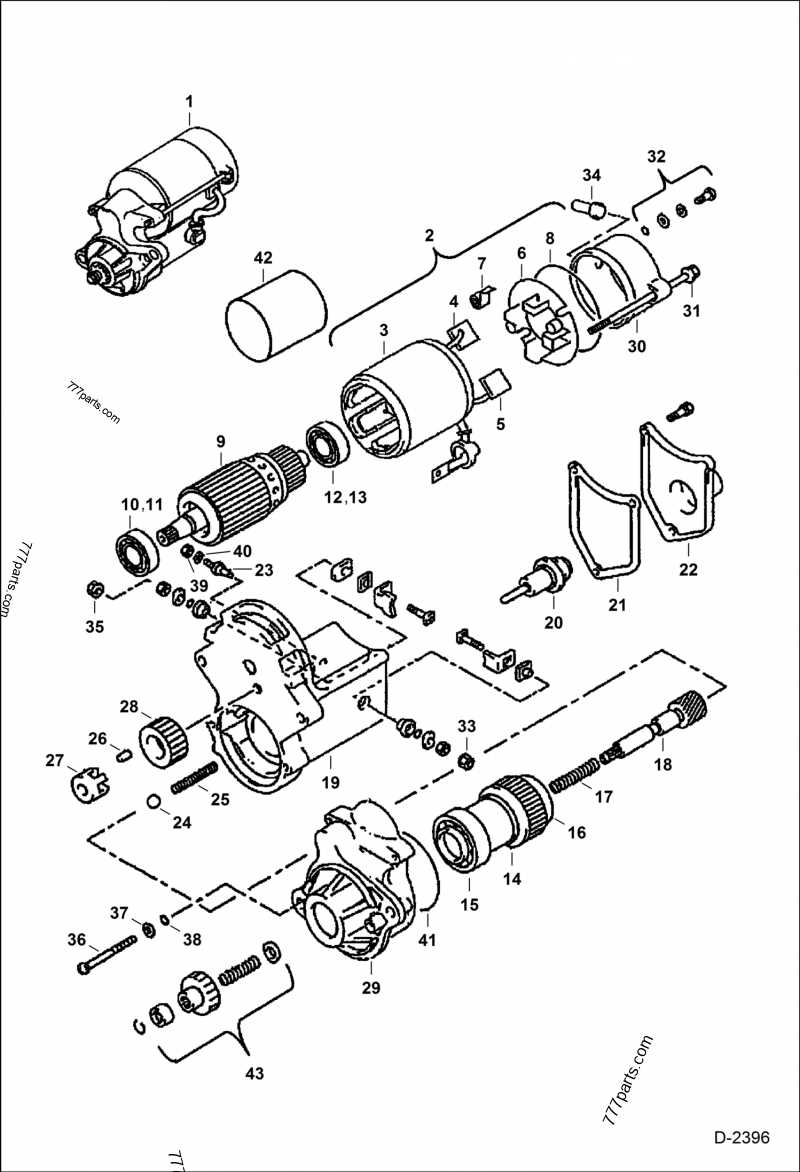

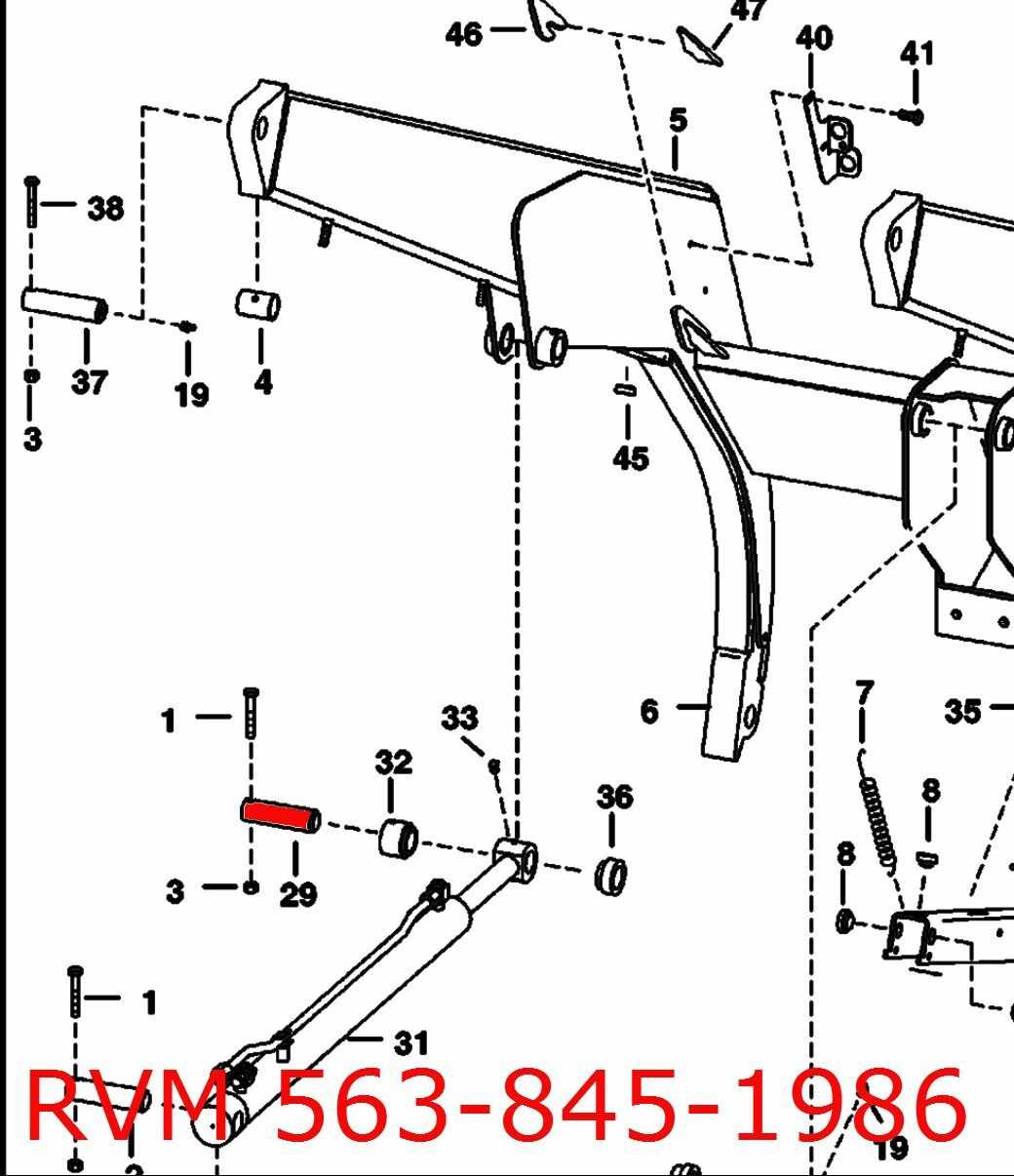

For those looking to deepen their knowledge, a visual representation of these components can be invaluable. Such resources provide clarity and a better understanding of how each part fits into the larger picture, ultimately empowering users to make informed decisions regarding repairs and upgrades.

Understanding Bobcat MT55 Components

When exploring the intricacies of compact machinery, it is essential to grasp the various elements that contribute to its functionality and efficiency. Each component plays a vital role in ensuring optimal performance, making it crucial to familiarize oneself with their structure and purpose.

Framework: The foundational structure provides stability and supports all other parts. Its robust design is essential for handling rigorous tasks.

Hydraulic System: This system is responsible for powering the machine’s movements, utilizing fluid dynamics to facilitate lifting and digging operations.

Engine: The heart of the equipment, delivering the necessary power for operation. Understanding its specifications is key for maintenance and performance optimization.

Attachments: Various tools can be connected to the machinery, enhancing its versatility. Each attachment serves a specific function, allowing users to tackle diverse tasks.

Control System: This component enables the operator to maneuver the machine with precision, showcasing the importance of user interface in heavy equipment.

Delving into these elements offers insights into the overall operation and maintenance of compact machinery, ultimately ensuring prolonged longevity and effective use.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the intricacies of machinery. They serve as invaluable resources for identifying individual elements, facilitating maintenance, and streamlining repair processes. Clear illustrations enhance communication among technicians, ensuring that everyone involved is aligned in their tasks.

Facilitating Maintenance

Detailed visuals allow for quick identification of parts, which is essential during routine checks. This efficiency helps in minimizing downtime and extending the life of the equipment.

Streamlining Repairs

Access to well-organized visuals can significantly reduce confusion during repairs. Technicians can easily reference each component, making the process more efficient and effective.

| Benefit | Description |

|---|---|

| Efficiency | Quick identification of elements saves time. |

| Clarity | Reduces confusion in communication. |

| Accuracy | Helps ensure correct assembly and disassembly. |

Common Issues with MT55 Parts

When dealing with compact equipment, several recurring challenges can arise, impacting performance and efficiency. Understanding these issues can help in maintaining optimal operation and extending the lifespan of the machinery.

Frequent Problems

- Wear and Tear: Components often experience deterioration over time, leading to decreased functionality.

- Hydraulic Leaks: Fluid leaks can occur, compromising system pressure and causing operational failures.

- Electrical Failures: Wiring and connectors may become damaged, resulting in erratic behavior or complete shutdowns.

Preventive Measures

- Regular Inspections: Conduct frequent check-ups to identify wear before it escalates.

- Proper Maintenance: Follow recommended service schedules to keep components in top condition.

- Use Quality Parts: Always opt for high-quality replacements to ensure compatibility and durability.

How to Identify Part Numbers

Understanding how to locate and recognize component identifiers is essential for effective maintenance and repair of machinery. Whether you are replacing a worn-out piece or upgrading equipment, knowing the correct identifiers ensures compatibility and functionality.

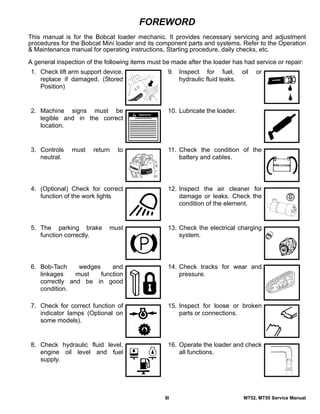

Consulting Manufacturer Documentation

One of the most reliable methods for identifying component identifiers is to refer to the manufacturer’s official documentation. This includes user manuals, maintenance guides, and online resources. These documents typically provide detailed information on components, including diagrams and specific identifiers, making it easier to locate what you need.

Using Online Resources and Forums

The internet is a valuable tool for gathering information. Many online platforms, including forums and dedicated websites, allow users to share insights and experiences. Engaging with these communities can provide additional context and guidance in identifying the correct component identifiers. Always verify the information with reliable sources to ensure accuracy.

Tip: When searching for identifiers, consider variations in naming conventions, as different manufacturers may use unique terms for similar components. Familiarizing yourself with these variations can streamline your search process.

Maintenance Tips for Bobcat MT55

Proper upkeep of your compact utility machine ensures optimal performance and longevity. Regular attention to various components can prevent costly repairs and enhance efficiency, making maintenance a crucial aspect of ownership.

Routine Inspections

Conduct frequent checks on fluid levels, filters, and belts. Hydraulic fluid should be clean and at the appropriate level to avoid operational issues. Inspect air filters for dirt accumulation, as clean filters ensure better engine performance.

Cleaning and Lubrication

Keep the exterior free of debris and dirt to prevent corrosion and mechanical failures. Regularly lubricate moving parts to reduce friction and wear, which will extend the lifespan of your machine.

Finding Replacement Parts Online

Locating components for machinery can be a straightforward process if approached correctly. With the rise of e-commerce, numerous platforms offer a variety of options to ensure you find exactly what you need. Whether you’re looking for specific items or general supplies, understanding where to search and how to evaluate your options can save both time and money.

Where to Look

- Manufacturer Websites: Often the best place to start, as they provide detailed catalogs and authentic products.

- Specialty Retailers: Online stores that focus on heavy equipment components typically have extensive inventories and knowledgeable customer service.

- Marketplaces: Platforms like eBay or Amazon can offer competitive pricing and user reviews, but ensure to check the seller’s credibility.

- Forums and Community Groups: Online communities related to equipment maintenance can provide leads on reliable sources and user experiences.

Evaluating Options

- Check Compatibility: Always verify that the item matches your machine’s specifications.

- Read Reviews: User feedback can give insights into the quality and reliability of the components.

- Compare Prices: Don’t settle for the first option; comparing prices can lead to better deals.

- Return Policy: Ensure the seller has a reasonable return policy in case the item doesn’t meet your needs.

By utilizing these resources and strategies, finding suitable replacements online can become a more efficient and rewarding experience.

Comparing OEM and Aftermarket Options

When it comes to choosing replacement components for machinery, the decision often lies between original equipment manufacturer (OEM) offerings and alternative solutions. Each option presents distinct advantages and disadvantages that can significantly impact performance, longevity, and cost-effectiveness.

Advantages of OEM Components

OEM parts are specifically designed for compatibility with the equipment, ensuring reliable performance and adherence to the manufacturer’s standards. Users often find that these components provide optimal durability and warranty protection.

Benefits of Aftermarket Solutions

Aftermarket components frequently come at a lower price point, offering an economical choice for users. Additionally, some alternatives can provide enhanced features or improved performance, appealing to those looking for upgrades.

| Criteria | OEM | Aftermarket |

|---|---|---|

| Cost | Higher | Lower |

| Compatibility | Guaranteed | Variable |

| Warranty | Often included | Limited |

| Performance | Reliable | Variable |

Step-by-Step Repair Process

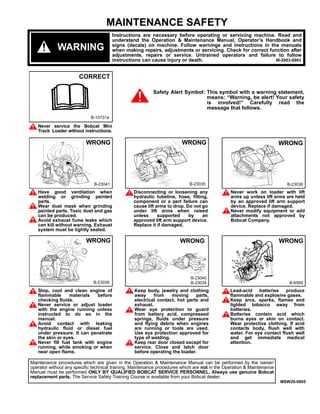

Embarking on a repair journey requires a clear plan and methodical approach to ensure success. Understanding the structure of the machinery and its components is essential for effective troubleshooting and restoration. This section outlines a comprehensive guide that can assist in addressing common issues, facilitating a smoother repair experience.

Preparation and Tools

Before initiating the repair, gather all necessary tools and materials. A well-organized workspace will enhance efficiency. Ensure you have basic hand tools, safety equipment, and any specific components that may need replacement. Reviewing the user manual or technical documentation can provide valuable insights into the machinery’s layout and functions.

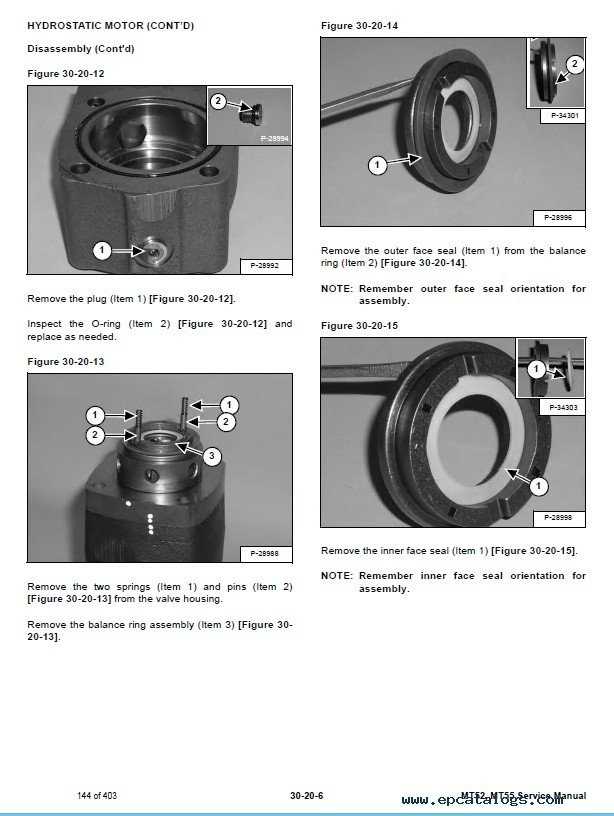

Repair Steps

Start by disconnecting power sources to prevent accidents. Carefully assess the problematic area, identifying any visible wear or damage. Remove components methodically, labeling each part for easier reassembly. Once repairs or replacements are made, double-check connections and reassemble the machine following the reverse order of disassembly. Finally, perform a thorough inspection and test the equipment to ensure it operates as intended.

Tools Needed for MT55 Maintenance

Proper upkeep of your compact loader requires a selection of essential instruments and equipment. These tools ensure that you can efficiently perform routine checks and repairs, helping to extend the lifespan of the machine and maintain optimal performance. Whether you are a seasoned operator or a newcomer, having the right gear is crucial for effective maintenance tasks.

Basic Hand Tools

Start with a standard set of hand tools, including wrenches, ratchets, and screwdrivers. These are vital for loosening and tightening bolts and screws during inspections. A reliable multimeter can also be invaluable for electrical diagnostics, allowing you to troubleshoot any potential issues.

Specialized Equipment

For more intricate maintenance, consider investing in specialized equipment such as a hydraulic jack for lifting, torque wrenches for precise tightening, and oil change kits to facilitate fluid replacement. Additionally, having a set of filter wrenches will help in removing and installing filters effortlessly, ensuring that your machine runs smoothly.

Expert Advice on Repairs

When it comes to maintaining and fixing compact machinery, having the right knowledge and approach is crucial for longevity and optimal performance. Whether you’re dealing with routine maintenance or complex issues, understanding the intricacies of your equipment can save time and money. This section provides insights into effective repair strategies and best practices that will enhance your machinery’s lifespan.

Key Considerations for Effective Maintenance

Before diving into repairs, it’s essential to identify common problem areas and ensure that all necessary tools and resources are readily available. Regular inspections can prevent minor issues from escalating into major failures. Here are some considerations to keep in mind:

| Consideration | Description |

|---|---|

| Routine Checks | Schedule consistent inspections to identify wear and tear. |

| Quality Parts | Use high-quality components to ensure compatibility and durability. |

| Professional Guidance | Consult with experienced technicians for complex repairs. |

Troubleshooting Common Issues

Addressing frequent malfunctions can significantly improve your equipment’s performance. Familiarizing yourself with troubleshooting techniques is beneficial for quick diagnostics. Here are some typical problems and their solutions:

| Issue | Possible Solution |

|---|---|

| Engine Failure | Check fuel levels and replace filters as needed. |

| Hydraulic Leaks | Inspect hoses and fittings for signs of damage. |

| Electrical Problems | Examine wiring and connections for integrity. |

Maximizing MT55 Performance with Upgrades

Enhancing the capabilities of compact machinery can significantly improve productivity and efficiency on the job site. By investing in strategic modifications and high-quality components, operators can unlock new potential and extend the lifespan of their equipment. This section explores various upgrade options that can elevate performance and ensure optimal operation.

Upgrades can range from simple enhancements to more complex modifications. Each option can contribute to improved functionality, reduced downtime, and increased comfort for the operator. Below is a table summarizing some effective upgrades and their benefits:

| Upgrade Type | Description | Benefits |

|---|---|---|

| Engine Tune-Up | Adjustments to engine parameters for optimal performance | Increased power and fuel efficiency |

| Hydraulic Enhancements | Upgrading hydraulic components for better lifting capacity | Improved load handling and stability |

| Attachment Options | Adding specialized tools for specific tasks | Versatility and improved job efficiency |

| Operator Comfort Upgrades | Improving seating and control systems | Enhanced ergonomics and reduced fatigue |

| Maintenance Kits | Comprehensive kits for regular upkeep | Prolonged equipment life and reliability |

By carefully selecting and implementing these enhancements, operators can significantly improve the effectiveness of their machinery, leading to better performance and higher satisfaction in various applications.