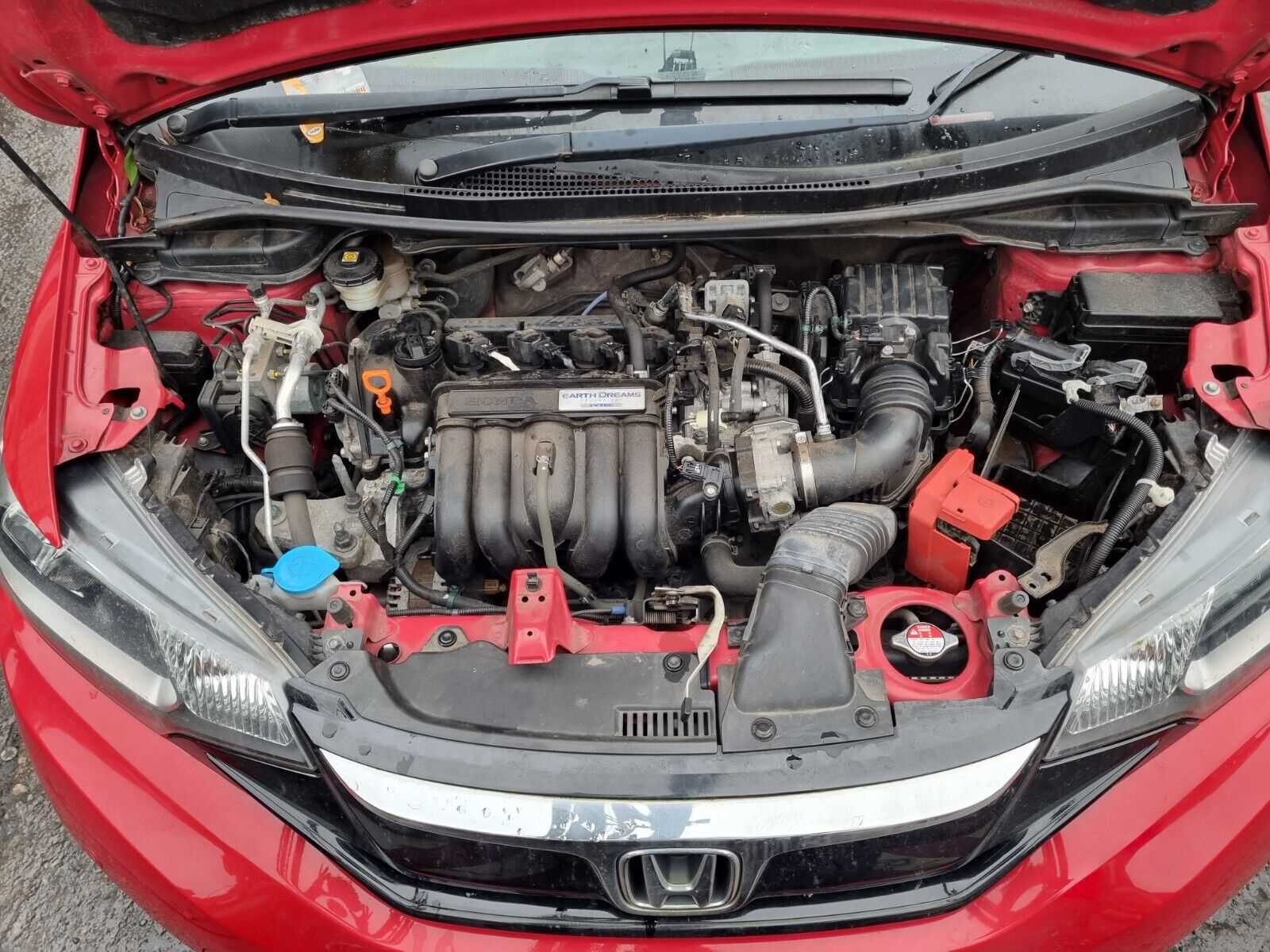

The intricate arrangement of various mechanical elements is crucial for the optimal functioning of any vehicle. A comprehensive illustration can greatly aid in recognizing how these components interact and contribute to the overall performance of the transportation system. By examining these layouts, one can gain insights into the essential functions of each unit and their roles in enhancing efficiency.

Visual representations serve as valuable tools for both enthusiasts and professionals alike. They provide clarity on the positioning and relationships between different components, enabling better troubleshooting and maintenance practices. Understanding this structure can lead to improved diagnostics and informed decisions regarding upgrades or repairs.

In summary, delving into these detailed schematics not only enriches one’s knowledge but also empowers individuals to engage more confidently with their vehicles. Recognizing how various elements fit together fosters a deeper appreciation for automotive engineering and its complexities.

Understanding Honda Fit Engine Components

Comprehending the various elements that make up a vehicle’s power source is essential for effective maintenance and repair. Each component plays a crucial role in ensuring optimal performance and efficiency, contributing to the overall functionality of the machinery.

Key Elements of the Power Source

Familiarity with the primary constituents can enhance troubleshooting efforts and facilitate better decision-making during servicing. Key elements include the fuel delivery system, ignition components, and the cooling apparatus, each working in concert to drive the vehicle forward.

Functionality Overview

Understanding the roles of these constituents allows for a more informed approach to both repairs and upgrades. Regular inspection and awareness of how each element interacts can lead to improved longevity and reliability of the entire system.

| Component | Function |

|---|---|

| Fuel Injector | Delivers fuel to the combustion chamber |

| Ignition Coil | Generates high voltage for spark plugs |

| Cooling Fan | Maintains optimal operating temperature |

| Oil Pump | Circulates lubrication throughout the system |

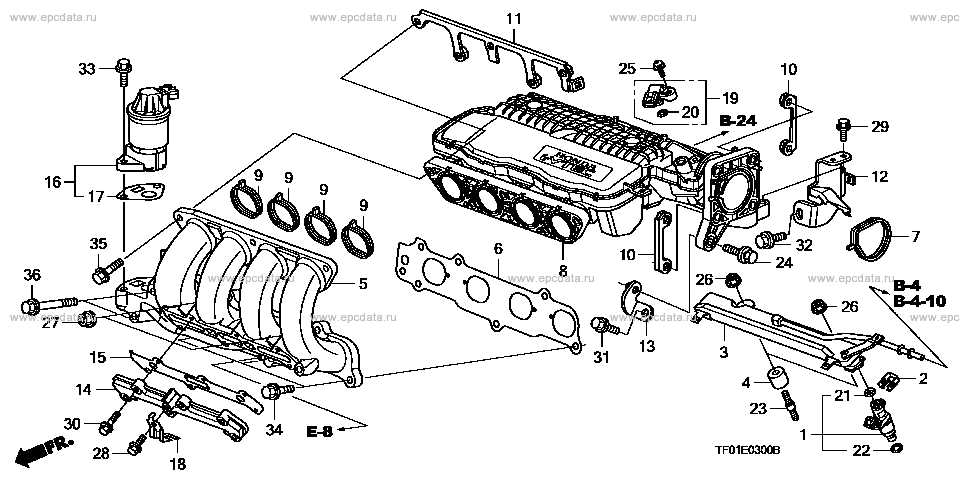

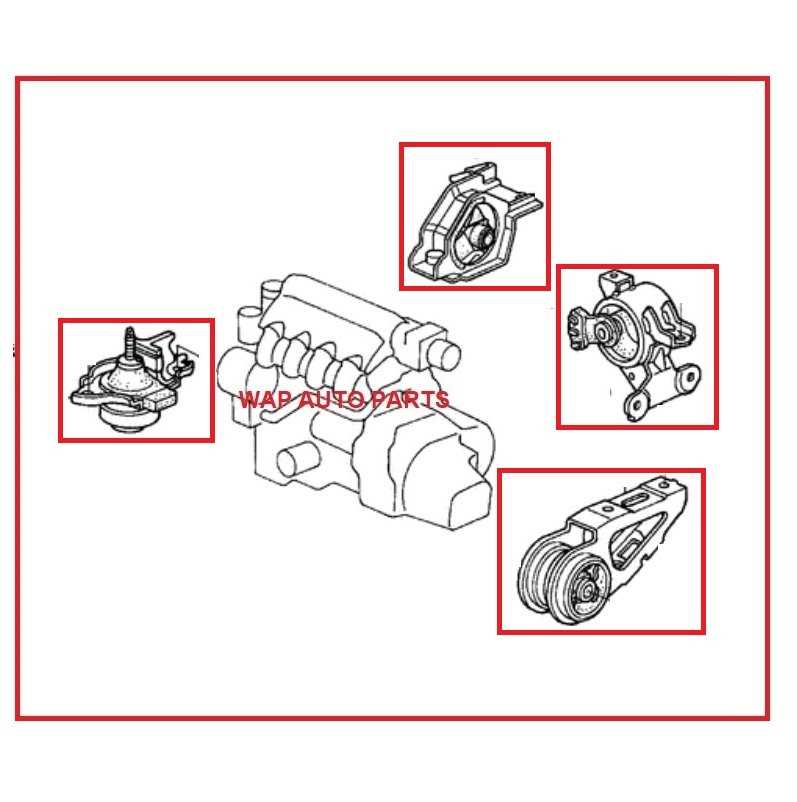

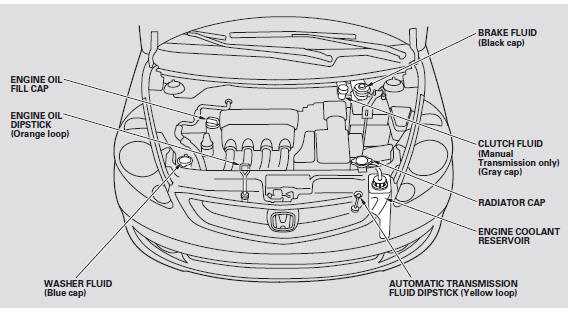

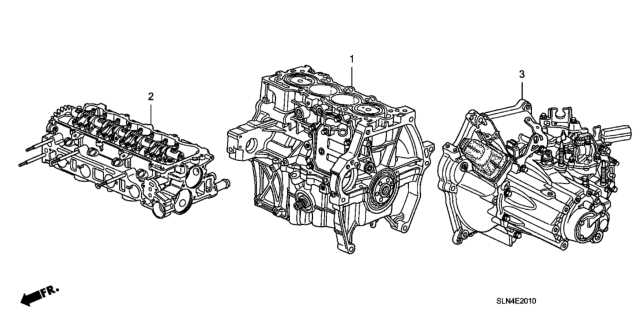

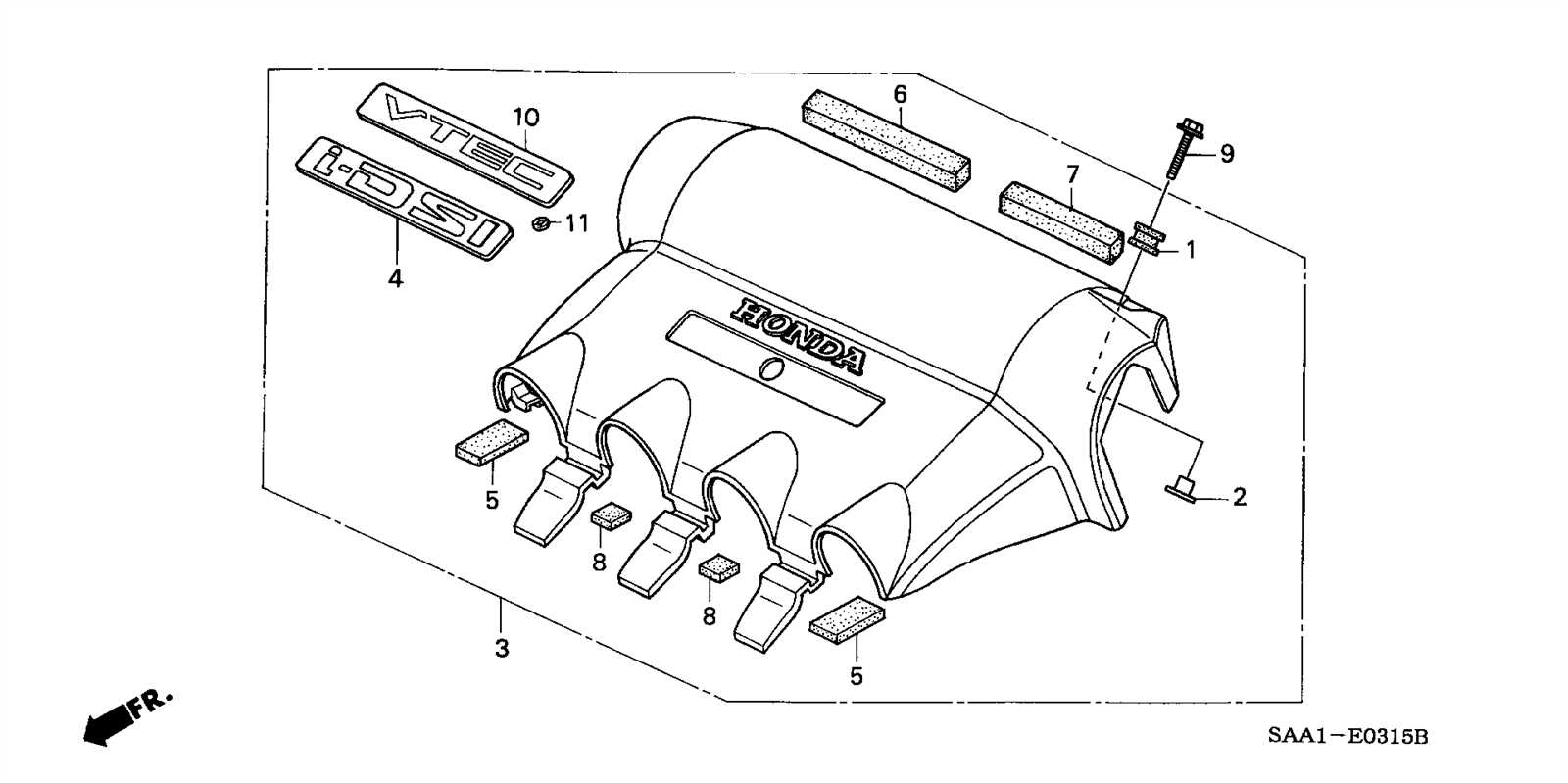

Overview of Engine Parts Layout

This section provides a comprehensive look at the arrangement of critical components within the power unit of a vehicle. Understanding how these elements are organized is essential for effective maintenance and troubleshooting.

The structure typically includes various systems that work in harmony to ensure optimal performance. Key areas to focus on are:

- Fuel System: Responsible for delivering fuel to the combustion chamber.

- Intake System: Facilitates air intake for combustion processes.

- Exhaust System: Manages the expulsion of gases after combustion.

- Cooling System: Maintains appropriate temperatures to prevent overheating.

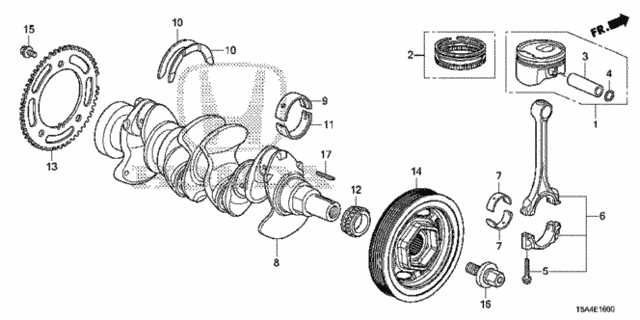

Each section contains numerous elements that contribute to the overall functionality:

- Combustion Chamber

- Pistons

- Cylinders

- Crankshaft

- Camshaft

Recognizing the layout and interrelations of these components aids in diagnosing issues and optimizing performance.

Importance of Each Component Explained

Understanding the significance of each element within a propulsion system is crucial for optimal performance and longevity. Each component plays a vital role, contributing to the overall efficiency and functionality of the vehicle.

Key Roles of Essential Elements

Each part serves specific functions that affect the system’s operation. Here are some critical roles:

- Power Generation: Some components are responsible for creating the necessary force to propel the vehicle forward.

- Fuel Management: Certain elements regulate the flow and mixture of fuel, ensuring efficient combustion.

- Cooling System: Vital parts maintain optimal temperatures, preventing overheating and ensuring reliability.

- Exhaust Handling: Components manage the expulsion of gases, minimizing environmental impact.

Impact on Performance and Maintenance

Each element’s condition directly influences both performance and maintenance requirements:

- Regular checks can prevent costly repairs.

- Understanding functionality aids in troubleshooting issues.

- Efficient components lead to better fuel economy.

Ultimately, knowledge of these components fosters informed decision-making regarding care and upgrades, enhancing the overall driving experience.

Common Issues with Engine Parts

Various components within a vehicle’s power unit can encounter typical challenges that affect performance and reliability. Understanding these frequent issues helps in proactive maintenance and ensures optimal functioning.

- Overheating: Excessive heat can lead to serious damage, often caused by coolant leaks or faulty thermostats.

- Oil Leaks: Seals and gaskets can wear down, resulting in oil seepage, which may affect lubrication and performance.

- Fuel Injector Problems: Clogs or malfunctions in fuel injectors can lead to poor fuel delivery, causing rough idling and decreased efficiency.

Regular inspections can help identify these issues early, preventing costly repairs and enhancing the longevity of the machinery.

Maintenance Tips for Engine Longevity

Regular care and attention are essential for enhancing the lifespan of your vehicle’s core components. Implementing effective practices not only boosts performance but also minimizes the risk of costly repairs. Consistency in maintenance is key to ensuring optimal functionality over time.

Routine Oil Changes

Frequent replacement of lubrication fluid is vital. Clean oil reduces friction, preventing wear and tear on vital components. Adhere to the manufacturer’s recommendations regarding intervals for changes to maximize protection.

Cooling System Checks

Maintaining the cooling apparatus is crucial for avoiding overheating. Inspect coolant levels and hoses regularly. Replace any worn parts to ensure efficient temperature regulation, which contributes to overall durability.

In summary, investing time in maintenance routines will significantly enhance the reliability and longevity of your vehicle’s internal systems. Prioritize care to enjoy a smoother and more efficient driving experience.

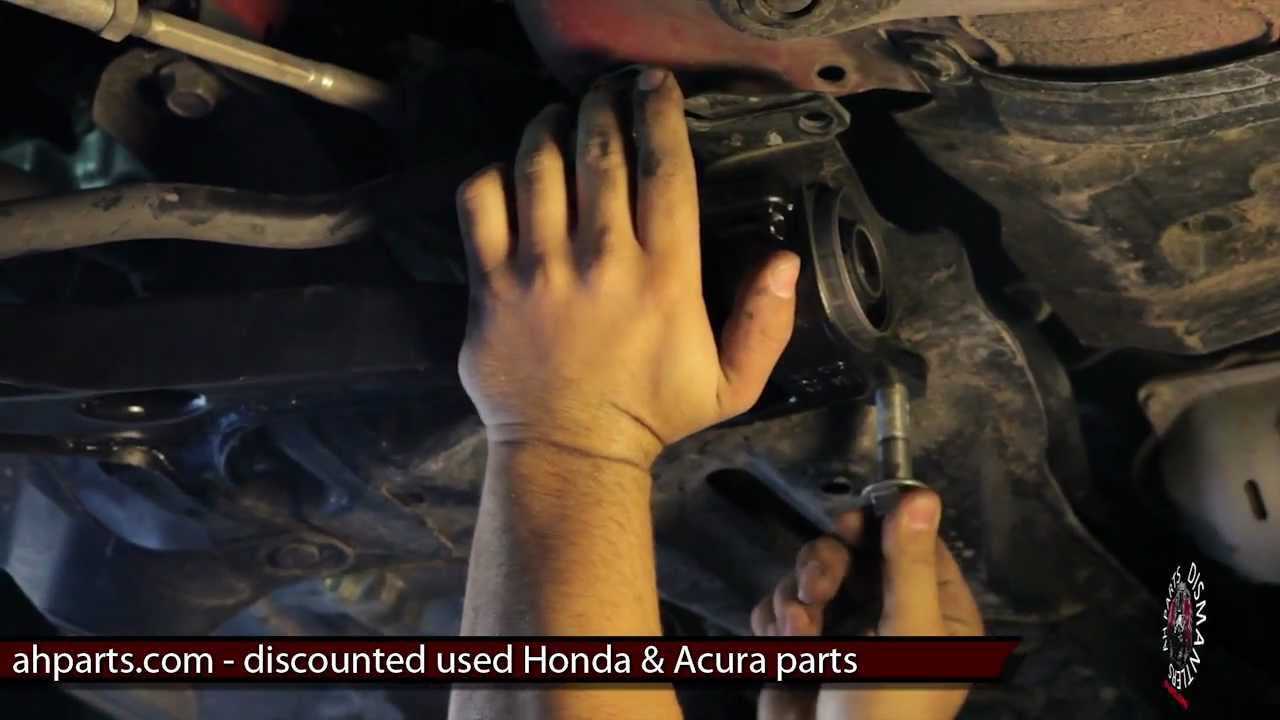

Replacing Engine Components: A Guide

Understanding the intricacies of internal mechanisms is essential for maintaining vehicle performance. This guide offers insights into the process of swapping out various mechanical elements, ensuring optimal functionality and longevity.

Assessing the Need for Replacement is the first step. Regular inspections can reveal wear and tear, helping to identify which components require attention. A proactive approach can prevent more extensive issues down the line.

Gathering Necessary Tools is crucial before starting any task. Ensure you have the right instruments at hand, including wrenches, sockets, and torque specifications, to facilitate a smooth replacement process.

Step-by-Step Replacement should be executed methodically. Begin by disconnecting power sources, followed by removing the affected components. Follow manufacturer guidelines for installation to guarantee a proper fit and functionality.

Final Checks after installation are vital. Double-check connections and fluid levels, then conduct a thorough test drive to confirm that everything operates smoothly. Address any anomalies immediately to maintain reliability.

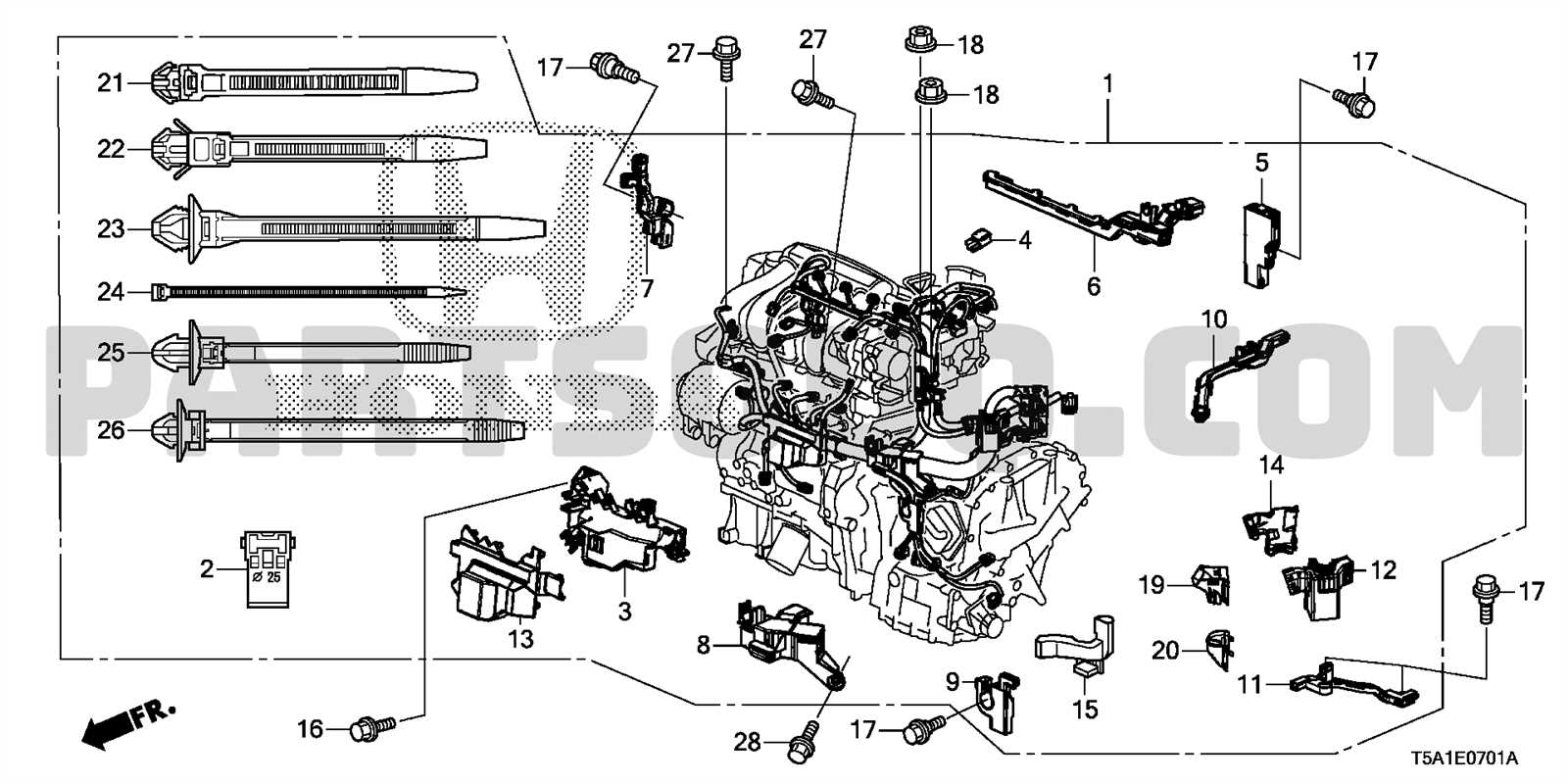

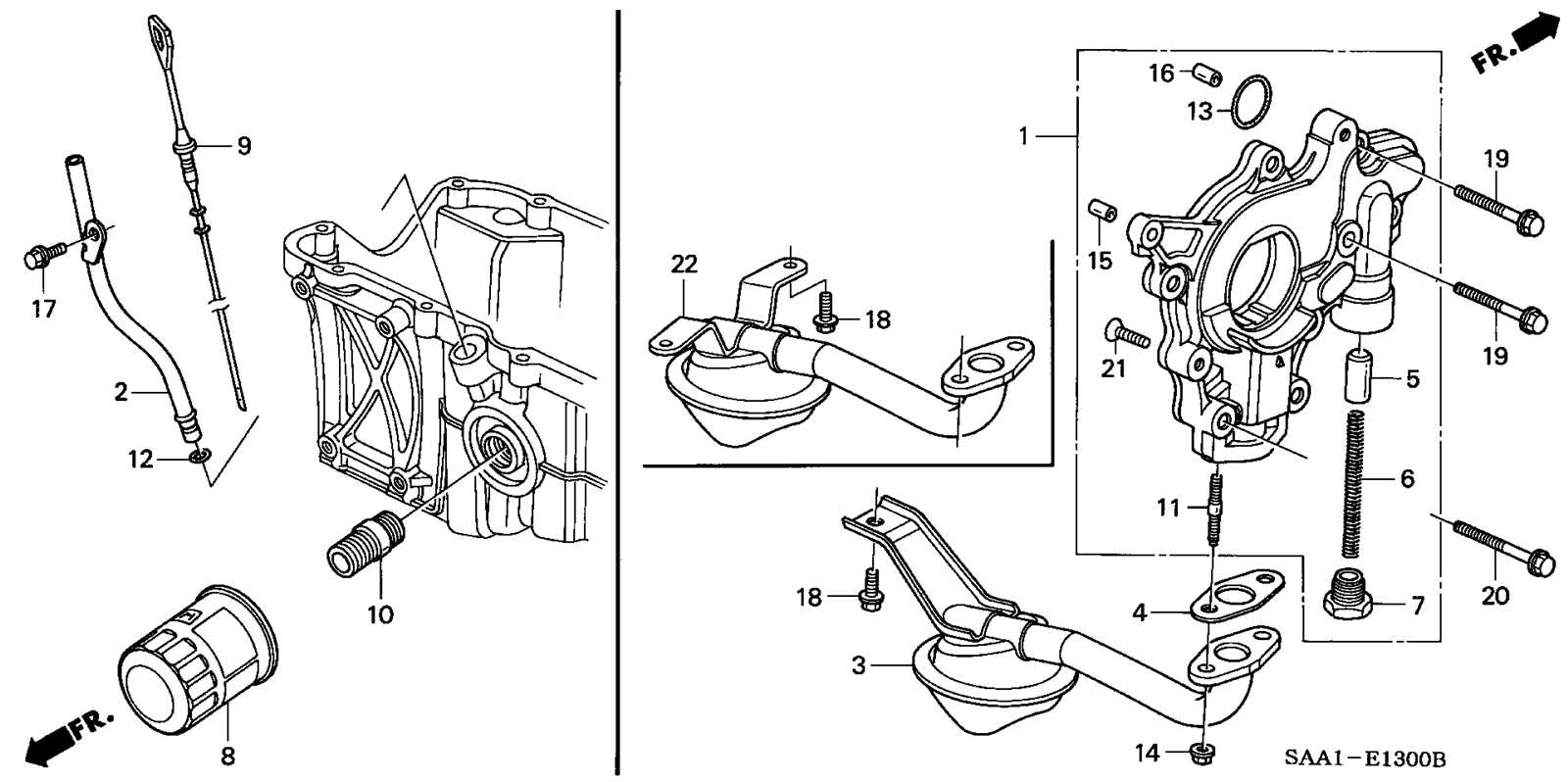

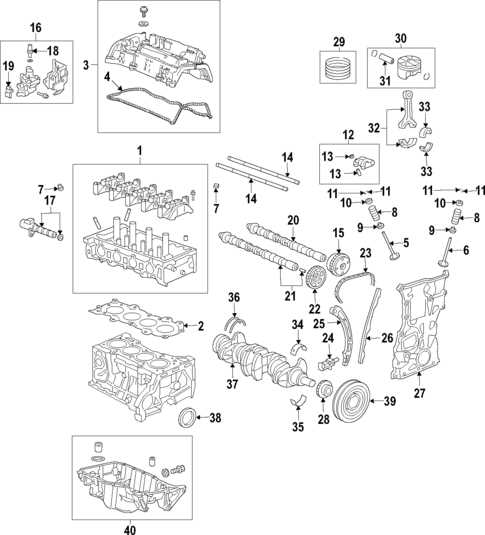

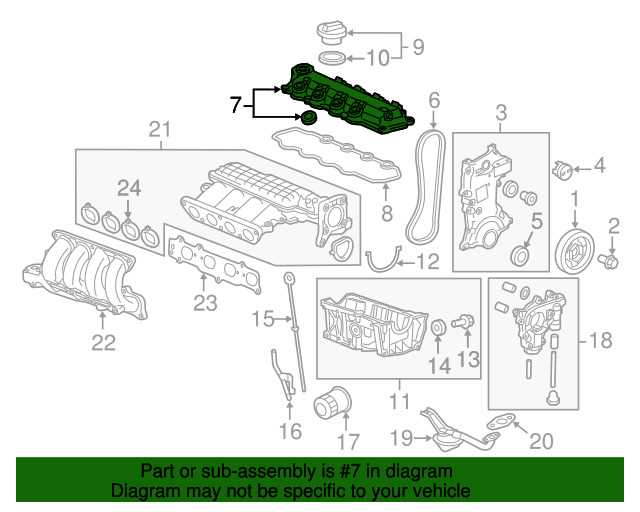

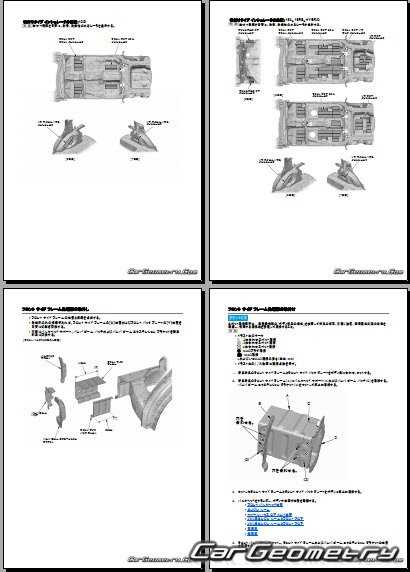

Identifying Parts in the Diagram

Understanding the components of a vehicle’s internal mechanisms is essential for effective maintenance and repair. Recognizing each element within the illustration aids in diagnosing issues and performing accurate replacements. A clear grasp of these components ensures that users can navigate through mechanical challenges with confidence.

To begin with, focus on the main sections depicted, such as the assembly units and their respective functionalities. Familiarize yourself with the names and locations of each item to streamline your approach. Pay attention to the interconnected systems that rely on one another, as this knowledge will enhance your ability to troubleshoot effectively.

Engine Assembly Process Overview

The assembly procedure of a power unit is a critical phase in automotive manufacturing. This intricate process involves the precise arrangement of various components to ensure optimal functionality and performance. Understanding the sequence and interactions of each element is essential for successful integration.

Initially, the base structure is prepared, which serves as the foundation for subsequent components. This includes the installation of the crankcase and the necessary seals. Following this, the pistons and connecting rods are fitted, allowing for the conversion of linear motion into rotational force.

Next, the assembly of the cylinder head takes place, incorporating valves and camshafts that control the intake and exhaust processes. Each component must be aligned accurately to maintain efficiency and minimize wear. The final stages involve attaching ancillary systems, such as the cooling and lubrication setups, which are crucial for maintaining operational temperature and reducing friction.

Throughout this procedure, quality control measures are implemented to ensure that all specifications are met, contributing to the reliability and longevity of the unit. The culmination of this process results in a robust assembly ready for installation in the vehicle.

Tools Needed for Engine Repair

When undertaking repairs on a vehicle’s mechanical components, having the right tools is essential for efficiency and accuracy. Proper equipment not only simplifies the process but also ensures that each task is completed with precision.

Essential Tools

- Socket set

- Wrenches (adjustable and fixed)

- Screwdrivers (various sizes)

- Pliers (needle-nose and slip-joint)

- Torque wrench

- Oil filter wrench

Additional Accessories

- Work light

- Magnetic tray for small parts

- Shop vacuum

- Cleaning supplies (rags, brushes)

- Gloves and safety glasses

How to Read Engine Diagrams

Understanding mechanical illustrations can enhance your comprehension of vehicle mechanics. These visual representations provide crucial insights into various components and their relationships within the system. Familiarizing yourself with the symbols and notations used will facilitate a clearer interpretation of how different elements function together.

Begin by identifying the legend or key, as it often explains the symbols employed in the illustration. Each symbol typically corresponds to a specific component, such as a valve or a sensor. Pay attention to the lines connecting these symbols, as they indicate relationships and interactions. Solid lines usually represent physical connections, while dashed lines may signify electrical or fluid pathways.

Next, note the arrangement and layout of components. Observing how parts are grouped can reveal functional clusters, helping to understand their roles. It is beneficial to cross-reference with a glossary or resource that details each component’s function, enhancing your overall knowledge of the system.

Finally, practice by analyzing various illustrations. With time, your ability to quickly interpret these visuals will improve, allowing for better diagnostics and maintenance of the mechanical systems you encounter.

Visualizing Engine Parts Interaction

Understanding the intricate connections within a power unit enhances the comprehension of its overall functionality. Each component works in harmony, contributing to the seamless operation of the mechanism. By exploring these relationships, one can appreciate how various elements influence performance and efficiency.

In this section, we will examine the interdependence of key components, shedding light on their roles and how they interact to achieve optimal results. A visual representation can serve as a valuable tool for grasping these dynamics, making it easier to identify potential issues and maintenance needs.

| Component | Function | Interaction with Other Elements |

|---|---|---|

| Piston | Converts pressure into mechanical energy | Works with cylinders and crankshaft |

| Crankshaft | Transforms linear motion into rotational motion | Interacts with pistons and flywheel |

| Camshaft | Controls valve timing | Synchronizes with pistons and valves |

| Valves | Regulate air and fuel flow | Dependent on camshaft operation |

Safety Precautions during Engine Work

Ensuring safety while performing maintenance tasks on a vehicle is paramount. Adhering to specific guidelines can prevent accidents and injuries, creating a secure environment for all involved.

- Personal Protective Equipment (PPE): Always wear appropriate gear, including gloves, goggles, and sturdy footwear.

- Work Area Organization: Keep the workspace clean and free of hazards to reduce the risk of slips and falls.

- Ventilation: Ensure proper airflow in the workspace to avoid inhaling harmful fumes.

- Tools Inspection: Check all tools and equipment for damage before use, replacing any faulty items.

- Fire Safety: Keep fire extinguishers accessible and be aware of flammable materials in the vicinity.

- Proper Lifting Techniques: Use correct lifting methods to prevent back injuries when handling heavy components.

By following these precautions, individuals can significantly enhance safety during vehicle maintenance tasks. Prioritizing safety fosters a responsible approach to automotive care.