In the world of heavy machinery, every piece of equipment is built from a complex network of individual elements working together seamlessly. Knowing how each component functions and interacts is critical for maintenance and repairs. Whether you’re dealing with hydraulic systems, mechanical parts, or electrical setups, understanding the layout of these features allows for more efficient troubleshooting and upkeep.

For those who manage or work with compact machines, it’s essential to have a clear visual representation of how the different systems integrate. This helps in recognizing where problems might arise and how to address them effectively. Each part plays a crucial role, and the efficiency of the entire machine depends on its proper functioning.

With a detailed overview, operators and technicians can confidently identify the necessary adjustments or replacements. This level of understanding also promotes a more informed approach when it comes to selecting the right tools and procedures for repairs or upgrades. Proper knowledge is the foundation of a productive and safe work environment.

Understanding the Components of Case 60XT

When exploring the mechanics of a powerful machine, it’s essential to understand its key elements that work together seamlessly to deliver optimal performance. These crucial systems and subsystems, each designed for a specific function, contribute to the overall efficiency of the vehicle. Knowledge of these components ensures better maintenance and more effective troubleshooting when issues arise.

Among the primary systems, there are numerous modules that interact, ranging from engine elements to structural frameworks. It’s important to break these down into manageable sections for a clearer understanding of how they contribute to functionality.

- Hydraulic System: This is one of the central mechanisms responsible for powering various attachments and lifting mechanisms, allowing the vehicle to perform heavy-duty tasks.

- Drive Train: This system transfers power from the engine to the wheels, enabling movement and traction. Its components are vital for both speed and stability.

- Chassis and Frame: These parts provide the structural integrity required to support the vehicle’s weight, ensuring safety and durability during operation.

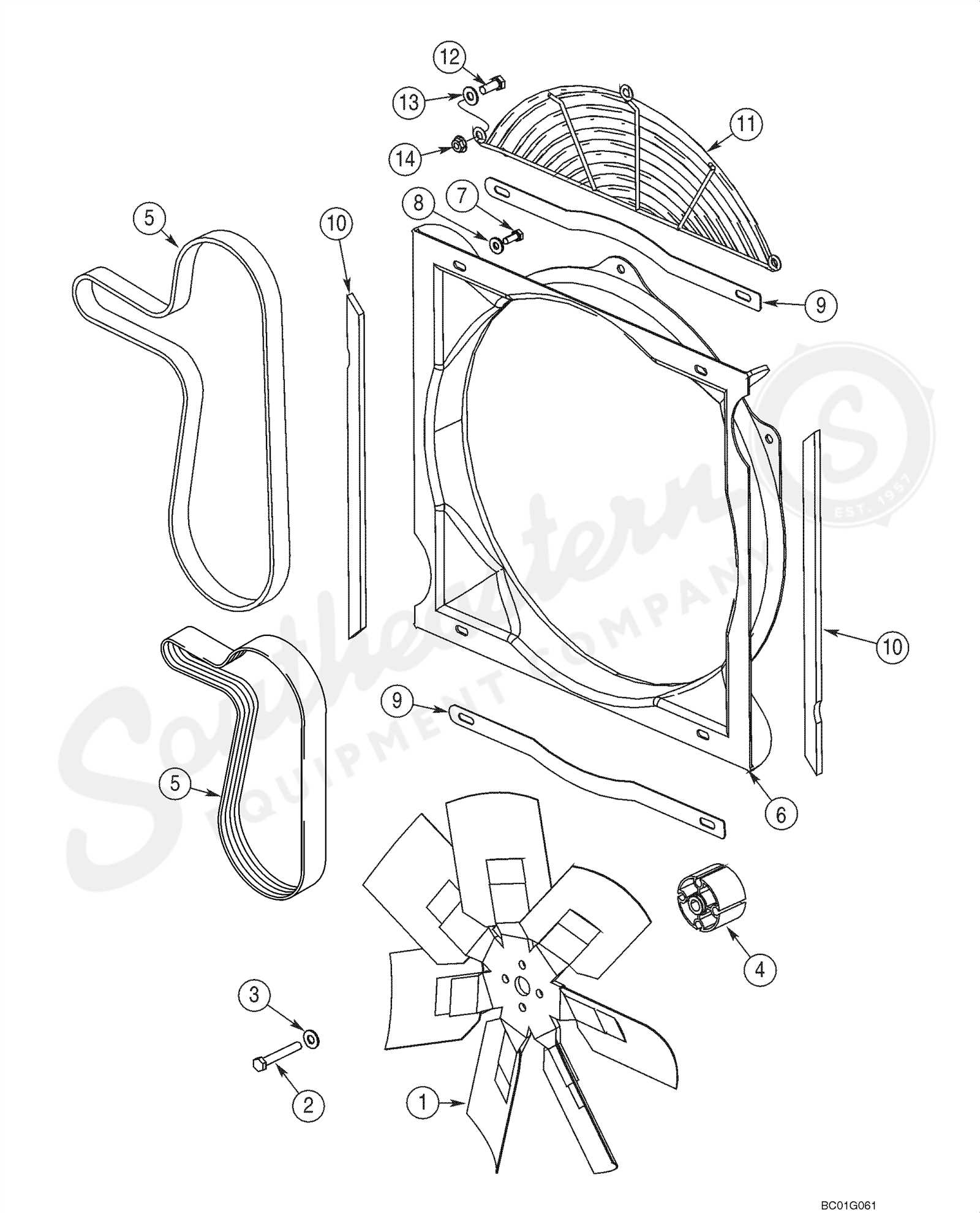

- Cooling System: The engine cooling system is designed to regulate temperature, preventing overheating and ensuring smooth operation even in challenging environments.

- Electrical System: This network controls various components, including lighting, sensors, and control panels, facilitating user interaction with the machine.

Each of these critical systems is made up of various individual elements, all working in harmony to maintain the overall health of the vehicle. Proper care and familiarity with these components help extend the life of the machine and optimize its functionality on the job site.

Key Features of Case 60XT Parts

The components of a compact construction machine are designed to ensure efficiency, reliability, and maximum functionality in various tasks. These elements are engineered to work harmoniously, providing high performance and long-term durability in challenging environments. Understanding the distinct characteristics of these parts can greatly assist in optimizing maintenance and operation. Below are the key aspects that contribute to the overall effectiveness of this machinery.

Durability and Strength

- Robust construction for extended machine life.

- High-quality materials used to withstand heavy loads and extreme conditions.

- Resistance to wear and tear, even in demanding work environments.

Efficiency and Functionality

- Components engineered for optimal power transmission and energy use.

- Precision manufacturing for seamless performance during operation.

- Efficient design contributes to faster and more effective task completion.

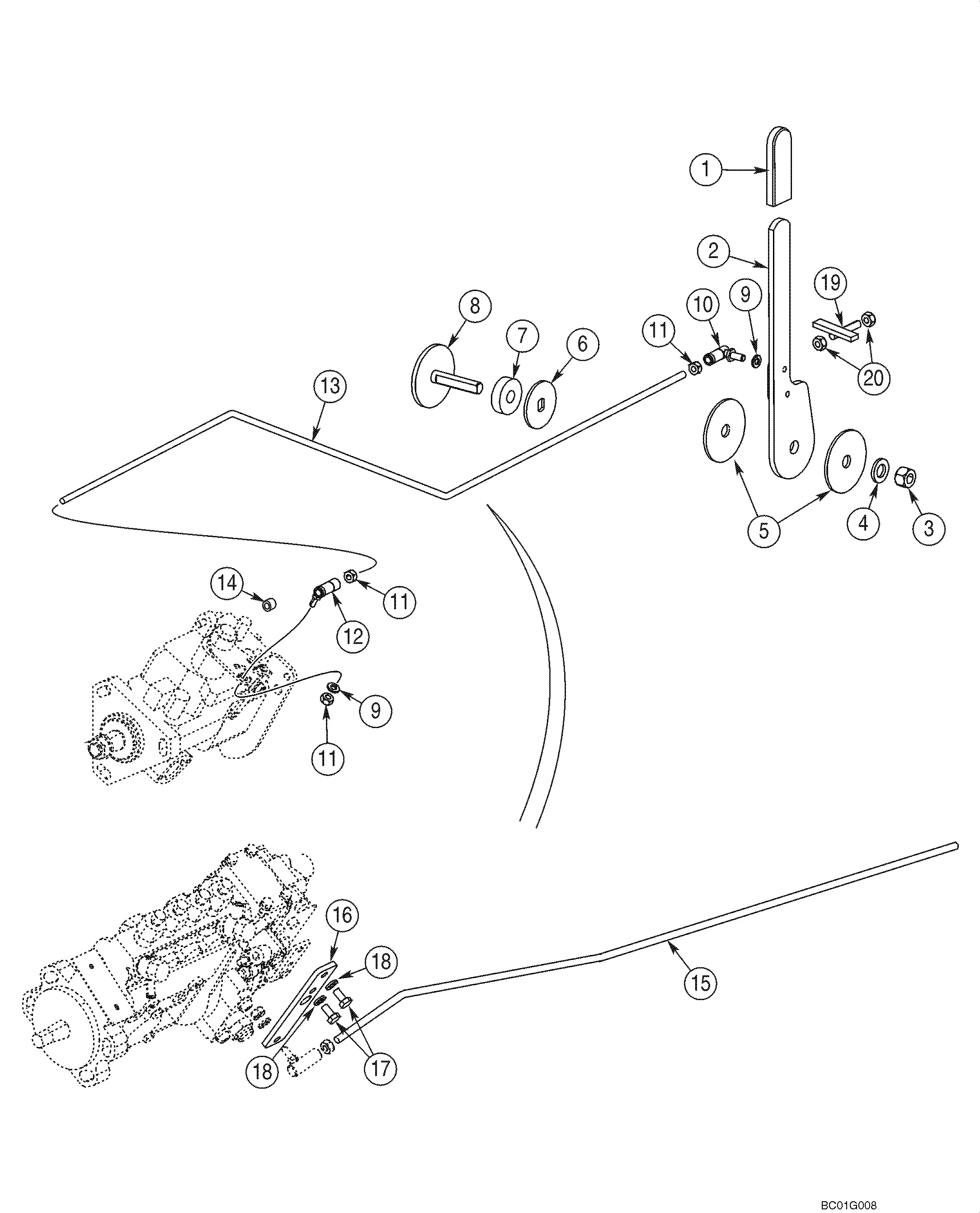

How to Read a Parts Diagram

Understanding how to interpret technical illustrations can significantly enhance your ability to identify and work with machine components. These visuals are essential tools that provide a clear representation of various mechanical assemblies, making it easier to pinpoint the exact location and function of each element. Familiarizing yourself with these drawings is a key step in performing maintenance or repairs on complex equipment.

Here are some steps to help you effectively interpret these visuals:

- Identify the Title and Reference Information: Begin by looking for the title at the top or side of the image. This section usually includes vital details such as the equipment model, type of system, and possibly the version or year of the illustration.

- Understand the Legend or Key: Many diagrams feature a legend or key that explains symbols, numbers, or color codes used throughout the drawing. Make sure to review this section to understand the notation used.

- Locate the Major Assemblies: Look for large groupings or clusters of parts, often indicated by brackets or lines, which represent the main components or sections of the system. These groups help break down the complexity of the system into manageable portions.

- Follow the Numbering System: Each element within the illustration is typically labeled with a unique identifier. These numbers correspond to a list of parts that provide additional details such as part numbers, descriptions, or specific instructions for assembly or disassembly.

- Examine the Directional Indicators: Arrows or lines may indicate the orientation or placement of specific parts. Pay close attention to these markers as they show how the components should be positioned relative to each other.

- Consult the Notes and Instructions: Diagrams often include small text boxes or notes offering further instructions, warnings, or assembly tips. Be sure to review these areas carefully, as they provide crucial information that could prevent errors during work.

By breaking down each section of the visual in a systematic manner, you can gain a clearer understanding of how the machine is structured and how each element functions within the overall system.

Essential Tools for Maintenance

Performing regular upkeep on heavy machinery requires a well-prepared toolkit. Proper tools ensure efficient handling of repairs and servicing, extending the lifespan of the equipment. From basic hand tools to specialized devices, each item plays a crucial role in maintaining operational efficiency and preventing downtime.

Among the must-have tools for machine maintenance are wrenches, screwdrivers, and hydraulic jacks. These essentials are the foundation for most mechanical adjustments and replacements. However, additional instruments such as torque wrenches, impact drivers, and diagnostic meters may also be necessary for more advanced tasks.

| Tool | Purpose |

|---|---|

| Wrenches | For loosening or tightening bolts and nuts |

| Screwdrivers | To fasten or remove screws |

| Hydraulic Jack | For lifting heavy machinery for inspections or repairs |

| Torque Wrench | Ensures correct tightness of fasteners |

| Impact Driver | For driving fasteners with higher torque |

| Diagnostic Meter | For assessing electrical components and systems |

Maintaining a proper set of tools tailored to specific maintenance tasks will greatly improve the efficiency of service operations and minimize unexpected breakdowns.

Identifying Critical Mechanical Parts

Understanding the essential components of any machinery is vital for efficient operation and maintenance. These key elements ensure smooth functionality and longevity of the equipment. Identifying the core mechanical elements allows operators and technicians to focus on regular inspections, proper lubrication, and timely replacements, thus minimizing downtime and maximizing performance.

Some parts play a more significant role in the overall mechanics of the machine, requiring closer attention. These components are typically subject to higher wear and tear, demanding frequent checks for signs of damage or degradation. Without proper care, these crucial elements can lead to operational failures, which may result in costly repairs or even a complete breakdown.

| Component | Function | Signs of Wear |

|---|---|---|

| Hydraulic Pump | Transfers hydraulic fluid to various systems | Low fluid pressure, abnormal noise |

| Drive Chain | Transfers power from the engine to the wheels | Slipping, irregular movement |

| Hydraulic Cylinders | Provide motion and force for lifting and pushing | Leaking fluid, reduced lifting capacity |

| Engine Components | Power source for all operations | Overheating, difficulty starting |

| Tracks | Provide mobility across different terrains | Cracks, uneven wear |

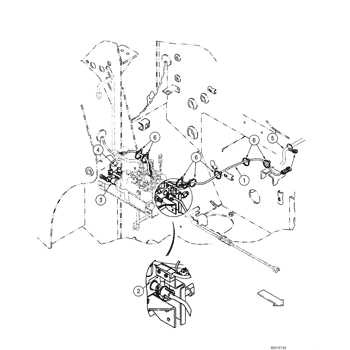

Exploring Hydraulic System Components

Hydraulic systems are integral to the functionality of many heavy machinery machines, allowing them to perform powerful tasks with precision. These systems rely on fluid pressure to transfer energy and operate various functions, such as lifting, tilting, and steering. Understanding the key elements that make up this complex system is essential for ensuring optimal performance and troubleshooting any potential issues.

Key Elements of the Hydraulic System

The heart of any hydraulic system is its pump, which generates the necessary pressure to push fluid through the network. The pump converts mechanical energy into hydraulic energy, enabling movement and power transfer. Along with the pump, control valves play a pivotal role in directing the flow of fluid to different actuators and cylinders, regulating the motion and force applied to various machine components. Together, these elements ensure the smooth operation of hydraulic machinery.

Maintaining Hydraulic Efficiency

Efficiency in hydraulic systems depends on proper maintenance and regular checks. Fluid quality, hose integrity, and component alignment are all critical for smooth operation. Any inefficiencies or leaks in the system can lead to performance degradation or even complete system failure. Regular maintenance and attention to detail are key to ensuring that each component functions at its best.

Electrical System Layout Overview

The electrical architecture of a heavy machinery unit plays a critical role in ensuring smooth and efficient operation. It is responsible for powering essential components such as sensors, motors, lights, and control panels. Understanding the arrangement of wires, connections, and power distribution is essential for troubleshooting and maintaining the overall system integrity.

Detailed knowledge of this configuration can assist technicians in identifying faulty components and streamlining the repair process. An efficient system ensures that power is delivered without interruptions, promoting safety and prolonging the lifespan of the machine.

Replacing Common Wearable Parts

Maintaining the functionality of heavy machinery often requires replacing components that are subject to regular wear and tear. These parts typically endure significant stress during operation, leading to eventual degradation. Timely replacement of these elements helps in preserving optimal performance and preventing more severe damage to the equipment.

Hydraulic hoses and seals are two of the most commonly replaced components. They are exposed to high pressure and constant motion, making them prone to wear over time. Failing to replace damaged hoses or seals can lead to leaks and hydraulic failures, reducing the machine’s efficiency.

Another crucial element is the tracks. The constant friction and impact from terrain can cause significant wear, leading to less traction and efficiency. Regular inspection and timely replacement of worn tracks are essential to avoid costly repairs and downtime.

Maintaining operational efficiency involves regularly checking these components and replacing them before they cause more extensive issues. The task may seem simple, but using high-quality replacements and following manufacturer guidelines is essential to ensure the longevity and reliability of the equipment.

Maintenance Tips for Case 60XT

Regular upkeep of your equipment ensures longevity and optimal performance. Proper servicing helps to avoid downtime and costly repairs by addressing small issues before they escalate. Following a structured maintenance routine is crucial for keeping the machinery in good working condition, reducing wear and tear over time.

Key areas to focus on include fluid levels, filter maintenance, and overall cleanliness. Proper lubrication and timely replacement of components can significantly impact the efficiency and safety of the machine. Below is a table outlining essential maintenance tasks and their recommended intervals.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Engine oil check | Every 50 hours | Ensure proper oil levels and cleanliness to prevent overheating. |

| Hydraulic fluid level | Every 100 hours | Check for leaks and top up fluid as necessary to maintain system pressure. |

| Filter replacement | Every 200 hours | Replace air, oil, and fuel filters to avoid clogging and inefficiency. |

| Check tire pressure | Weekly | Maintain recommended tire pressure for better traction and longer life. |

| Cleaning and inspection | Every 50 hours | Remove dirt and debris from key components to prevent damage. |

Adhering to these practices can greatly extend the lifespan of your machine, improving both performance and reliability. Regular inspection and timely care reduce the chances of unexpected malfunctions, ensuring that your equipment remains ready for the toughest tasks.

Where to Find Genuine Replacement Parts

For any machinery owner, maintaining the integrity and functionality of your equipment is crucial. When a component wears out or breaks, using authentic replacements ensures that your machine continues to operate smoothly and efficiently. Finding reliable sources for these high-quality components is essential for long-term performance and durability.

Official Manufacturers

- Most manufacturers offer a direct sales channel for authentic components. This is often the most reliable source for ensuring the quality and compatibility of the replacement item.

- Official websites and authorized distributors often have online catalogs where you can search for specific components tailored to your equipment.

- By purchasing directly from the source, you can also benefit from warranty protection and support services that might not be available from third-party sellers.

Authorized Dealerships and Service Centers

- Many dealerships specialize in selling high-quality machinery parts. These businesses often maintain relationships with the original equipment manufacturers (OEMs) and can provide the exact components needed for repairs.

- Service centers affiliated with the manufacturer are also ideal places to source authentic replacements, as they are well-versed in the specifications and requirements of your machinery.

While third-party vendors may offer alternatives at a lower cost, it’s important to weigh the risks of using non-authentic items that might compromise performance or safety. Opting for trusted sources guarantees that each replacement fulfills the original equipment’s standards and maintains optimal efficiency.