In the realm of outdoor machinery, comprehending the intricate relationships between various elements is crucial for optimal performance and maintenance. This section delves into the essential components of a specific mowing apparatus, offering insights into its functionality and interconnections.

Every piece of machinery consists of numerous interconnected parts that work harmoniously to achieve efficiency. By examining these components, users can gain a deeper appreciation of how each element contributes to the overall operation, ensuring that the equipment runs smoothly and effectively.

Furthermore, familiarizing oneself with these elements can facilitate troubleshooting and repair processes. With a clear understanding of the individual parts, operators can identify potential issues and make informed decisions regarding maintenance, ultimately extending the lifespan of their machinery.

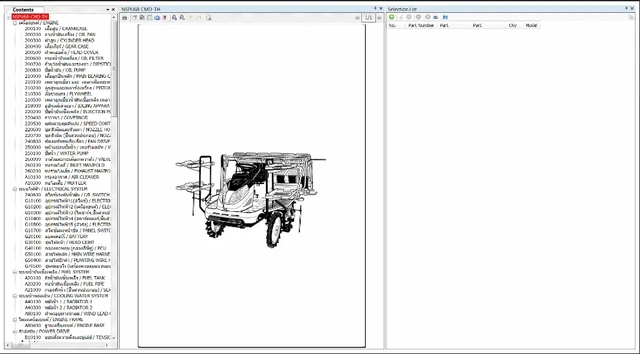

This section provides a structured outline for a detailed article focused on a specific model of lawn care equipment, detailing its various components and their functionalities. The purpose is to enhance understanding for both novice and experienced users, offering insights into maintenance and repair strategies.

- Introduction to the Equipment

An overview of the machinery, including its primary functions and uses in landscaping and agriculture.

- Key Features and Specifications

A breakdown of the essential characteristics, including engine power, cutting width, and design elements.

- Understanding the Structure

A comprehensive look at the main assemblies that constitute the machinery, emphasizing their roles.

- Essential Components and Their Functions

A detailed examination of crucial elements, including blades, chassis, and wheels, highlighting their individual purposes.

- Maintenance Guidelines

Recommendations for regular upkeep, including lubrication, cleaning, and inspection tips to ensure optimal performance.

- Troubleshooting Common Issues

Strategies for diagnosing frequent problems, with practical solutions to enhance user experience.

- Replacement Parts and Accessories

A guide to available accessories and components that can enhance functionality and efficiency.

- Safety Precautions

Important safety measures to follow while operating and maintaining the machinery to prevent accidents.

- User Reviews and Feedback

An analysis of user experiences and testimonials that provide insights into the equipment’s reliability and performance.

- Conclusion and Recommendations

A summary of key points discussed in the article, along with final thoughts on the best practices for users.

Key Features of RCK72P-28Z

This section highlights the standout characteristics of a specific model in the mower category, focusing on its exceptional performance, durability, and user-friendly design. Understanding these attributes can greatly enhance the mowing experience, making it efficient and enjoyable for operators.

Durability and Build Quality

The equipment is designed with high-quality materials that ensure longevity and resilience under various working conditions. Its robust construction minimizes wear and tear, providing users with a reliable tool that can handle tough tasks with ease. The superior craftsmanship contributes to an overall lifespan that outlasts many alternatives on the market.

User-Centric Features

Incorporating ergonomic designs, this model allows for comfortable operation over extended periods. The intuitive controls and adjustable components enhance usability, making it accessible for both novice and experienced users. Features such as easy maintenance and efficient operation further contribute to a seamless mowing experience, reducing downtime and increasing productivity.

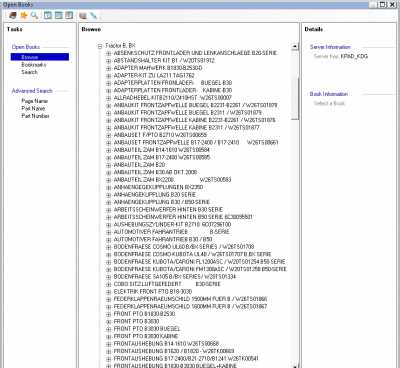

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the structure and functionality of machinery. They provide a clear overview, enabling users to identify individual elements and their interconnections. This clarity is essential for effective maintenance and repair, ensuring that each piece operates in harmony with the others.

Facilitating Maintenance and Repair

One of the primary advantages of these visual aids is their ability to simplify the maintenance process. Technicians can quickly locate specific items that require attention, reducing the time spent troubleshooting. Additionally, having a clear visual guide minimizes the risk of overlooking critical elements, thus enhancing overall efficiency.

Enhancing Communication

Such representations also serve as valuable tools for communication among team members. They provide a common language, ensuring that everyone involved understands the components in the same way. This shared understanding fosters collaboration and promotes a more organized approach to problem-solving.

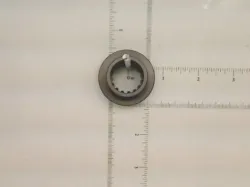

Common Parts in RCK72P-28Z

This section delves into essential components commonly found in lawn maintenance equipment. Understanding these elements is crucial for effective operation and maintenance, ensuring optimal performance throughout the mowing season.

Key Components Overview

The machinery is equipped with various vital elements that contribute to its functionality. Among these are the cutting blades, which are pivotal for achieving a clean and precise cut. Regular inspection and replacement of these blades are necessary to maintain efficiency and prevent damage to the grass.

Transmission and Drive System

A reliable drive system is fundamental for the smooth operation of the equipment. It includes gears and belts that facilitate the transfer of power from the engine to the cutting mechanism. Ensuring these components are in good condition is essential for preventing operational failures.

Regular maintenance of these key components is vital for longevity and performance. Familiarizing oneself with these crucial parts will enhance the understanding of the overall machinery and its operational needs.

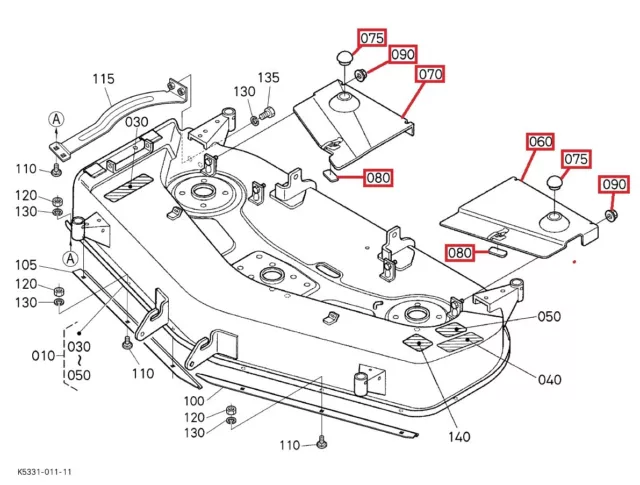

Identifying Components and Functions

Understanding the various elements and their roles is crucial for effective maintenance and operation of lawn care equipment. Each component plays a significant part in ensuring optimal performance, and recognizing their functions can greatly enhance troubleshooting and repairs.

Key Elements

- Blade Assembly: Responsible for cutting grass to the desired length.

- Deck: The housing that contains the blades, providing protection and support.

- Spindle: Connects the blades to the drive system, allowing for rotation.

- Height Adjustment Mechanism: Enables users to modify the cutting height for different types of grass.

- Drive System: Transfers power from the engine to the blades and wheels, facilitating movement and cutting action.

Functions of Major Components

- Blade Assembly: Engages with the grass, cutting it efficiently.

- Deck: Provides a sturdy structure that houses the cutting elements while ensuring safety.

- Spindle: Facilitates the motion of the blades through its connection to the engine.

- Height Adjustment Mechanism: Allows for customization based on user preferences and grass conditions.

- Drive System: Ensures the machine operates smoothly, allowing for effective maneuvering across various terrains.

Maintenance Tips for Lawn Mowers

Regular upkeep is essential for ensuring that your grass-cutting equipment operates efficiently and has a long lifespan. Following simple maintenance practices can enhance performance, minimize the risk of breakdowns, and improve the quality of your lawn care. Here are some valuable tips to help you maintain your mower effectively.

- Clean the Deck: After each use, remove grass clippings and debris from the underside of the mower deck to prevent rust and improve cutting efficiency.

- Check the Blades: Inspect the cutting blades regularly for dullness or damage. Sharpen or replace them as needed to ensure a clean cut.

- Change the Oil: Follow the manufacturer’s recommendations for oil changes. Regularly changing the oil keeps the engine running smoothly and extends its life.

- Inspect Air Filters: Clean or replace the air filter periodically to ensure proper airflow to the engine. A clean filter helps maintain optimal performance.

- Fuel System Maintenance: Use fresh fuel and consider adding a fuel stabilizer if the mower will be stored for an extended period. This prevents fuel degradation and engine problems.

- Check Cables and Belts: Regularly inspect throttle cables and drive belts for wear and tear. Replace them if they show signs of damage or fraying.

- Battery Care: For electric-start models, check the battery condition regularly. Clean terminals and ensure a secure connection.

- Store Properly: At the end of the mowing season, clean the mower thoroughly and store it in a dry place. Consider using a cover to protect it from dust and moisture.

Implementing these maintenance practices will help keep your grass-trimming equipment in top condition, ensuring that your lawn remains well-groomed and healthy.

Where to Find Replacement Parts

When it comes to maintaining your equipment, sourcing the right components is essential for ensuring optimal performance and longevity. Whether you’re looking for specific items or a general supply, there are several avenues you can explore to locate suitable replacements.

One of the most reliable options is to visit authorized dealerships or service centers. These establishments often carry an extensive inventory and can provide expert guidance on compatible components. In addition, many online retailers specialize in aftermarket supplies, offering competitive prices and a wide selection.

Another useful strategy is to connect with online forums and community groups. Engaging with other enthusiasts can lead to valuable recommendations and even direct sales from fellow users. Additionally, many platforms provide useful insights into the latest trends and products available in the market.

| Source | Description |

|---|---|

| Authorized Dealers | Official service centers that offer genuine components and professional advice. |

| Online Retailers | Websites specializing in aftermarket supplies with a wide range of options. |

| Community Forums | Platforms for enthusiasts to share information, recommendations, and sales. |

| Local Shops | Nearby stores that may have an assortment of items suitable for your equipment. |

Assembly Instructions for Components

Proper assembly of individual elements is crucial for the effective operation of your equipment. Following a systematic approach ensures that each part fits correctly, leading to optimal performance and longevity. This section outlines the key steps and considerations when assembling various components.

Preparation: Before beginning the assembly process, ensure that you have all necessary components and tools on hand. Review the component list and verify that everything is in good condition. Lay out the parts in an organized manner to facilitate a smooth assembly process.

Step-by-step Assembly: Start by connecting the larger components first. Align them carefully and use the appropriate fasteners to secure each piece. Ensure that all connections are tight and that there are no gaps between parts. As you progress, refer to the assembly guide to confirm the correct sequence of operations.

Final Checks: Once all components are assembled, conduct a thorough inspection. Check for any loose fittings, signs of misalignment, or other issues. Properly secured and aligned components will enhance the functionality and durability of the equipment.

Following these instructions will help achieve a successful assembly, ensuring that your equipment operates smoothly and efficiently for years to come.

Understanding the Parts Warranty

When investing in equipment components, it’s essential to grasp the terms and conditions of the warranty that accompanies them. A warranty serves as a safeguard, providing assurance that the items are free from defects in materials and workmanship. This coverage typically spans a specified duration, offering peace of mind to the user while ensuring reliable performance over time.

Key Features of Warranty Coverage

Warranties often encompass various aspects, including the duration of coverage, conditions for claims, and any limitations that may apply. It’s crucial to understand what is included, such as repairs, replacements, or refunds, as well as any exclusions that might void the warranty. Manufacturers usually outline these terms clearly, allowing users to know their rights and responsibilities.

Importance of Keeping Records

Maintaining accurate documentation is vital for a successful warranty claim. Users should retain receipts, invoices, and any relevant communication regarding the purchase. This information serves as proof of ownership and eligibility, streamlining the process should issues arise. Being proactive about record-keeping can significantly enhance the warranty experience.

Safety Precautions During Repairs

When undertaking maintenance tasks, ensuring a safe working environment is paramount. Implementing appropriate safety measures helps prevent accidents and injuries, protecting both the individual and the equipment being serviced. It is essential to be aware of potential hazards and take proactive steps to mitigate risks.

Personal Protective Equipment (PPE)

Utilizing the right personal protective gear is critical for maintaining safety during repair activities. This equipment serves as a barrier against various risks associated with machinery maintenance.

| PPE Item | Description |

|---|---|

| Safety Glasses | Protects eyes from flying debris and harmful chemicals. |

| Gloves | Prevents cuts and abrasions, while offering grip and protection from chemicals. |

| Steel-Toed Boots | Offers foot protection against heavy items and sharp objects. |

| Ear Protection | Reduces noise exposure from machinery and tools. |

General Safety Tips

Adhering to established safety protocols can significantly reduce the likelihood of incidents. Here are some important guidelines to follow:

- Ensure the work area is well-lit and free from clutter.

- Disconnect power sources before starting any maintenance work.

- Use tools and equipment as intended, following manufacturer instructions.

- Keep a first aid kit readily available and familiarize yourself with its contents.

- Always work with a partner when handling heavy or awkward components.

Frequently Asked Questions

This section addresses common inquiries related to the maintenance and components of lawn care machinery. It aims to provide helpful insights for users seeking clarity on various aspects of their equipment.

What should I do if I can’t find a specific component?

If a particular part is elusive, it’s advisable to consult the equipment’s manual or reach out to authorized dealers for assistance. They can provide guidance on identifying and sourcing the necessary item.

How can I ensure that I purchase the correct replacement?

To guarantee the right replacement, cross-reference the model number and specifications in the manual. Additionally, verifying compatibility with your equipment before purchasing is crucial.

Are there any maintenance tips to prolong the lifespan of my machinery?

Regular cleaning, timely oil changes, and inspecting for wear can significantly extend the lifespan of your equipment. Following the manufacturer’s recommendations is essential for optimal performance.

What do I do if a part breaks unexpectedly?

In the event of an unexpected failure, cease operation immediately to prevent further damage. Assess the situation, consult the manual for troubleshooting advice, and consider seeking professional help if needed.

Where can I find technical support for my equipment?

Technical support can often be found through the manufacturer’s official website, where they may offer resources such as manuals, FAQs, and contact information for customer service.