Understanding the key elements that drive a small marine engine can significantly enhance both performance and longevity. Knowing how various components work together within the propulsion system allows boat owners to perform maintenance with confidence, ensuring a smooth and reliable experience on the water.

Engine diagrams are invaluable tools that illustrate the intricate network of mechanical parts that make up a propulsion system. From the fuel delivery to the cooling mechanisms, each component plays a crucial role in maintaining efficiency and ensuring proper function. Identifying and understanding these parts helps to address potential issues before they escalate.

In this guide, we will break down the essential elements of a small watercraft motor, providing a clear view of its structure and function. With the right knowledge and tools, keeping your engine in optimal condition becomes a straightforward task, whether you’re performing regular maintenance or troubleshooting problems.

Overview of the Suzuki 9.9 Outboard Motor

Known for its reliability and efficient performance, this versatile marine engine is a popular choice for various watercraft. It offers a balanced blend of power and fuel efficiency, making it an ideal option for boaters seeking dependable propulsion. Designed with durability in mind, it provides consistent operation even in challenging conditions.

The engine features modern innovations that enhance its ease of use, including intuitive controls and lightweight construction. Its compact design ensures portability while maintaining performance. Additionally, it delivers smooth acceleration and responsive handling, catering to both recreational and professional users.

Another key aspect is its environmental impact. The motor complies with stringent emissions standards, reducing its carbon footprint without sacrificing power. Its maintenance-friendly design also contributes to longevity, with accessible components allowing for easier servicing. Whether for fishing, cruising, or other activities, this engine remains a trusted companion on the water.

Key Components in a Suzuki 9.9 Motor

A small marine engine operates efficiently thanks to the intricate collaboration of its essential elements. Each part plays a crucial role in ensuring smooth performance, reliable operation, and durability over time. Understanding the main sections of the motor will help in maintaining its optimal functionality and addressing potential issues.

- Powerhead: The driving force behind the engine, this section houses the combustion process that generates power. It includes the cylinders, pistons, and crankshaft, all working in harmony to produce energy.

- Cooling System: To prevent overheating during prolonged use, the cooling mechanism circulates water through passages around the engine block, regulating its temperature and ensuring continuous operation.

- Fuel Delivery System: Proper combustion depends on this system, which ensures a consistent and precise flow of fuel into the engine. It typically includes the carburetor or fuel injectors, fuel lines, and fuel pump.

- Ignition System: This critical system initiates the combustion process by creating a spark at the right moment. Key components include the spark plugs, ignition coil, and control module.

- Lower Unit: Located at the base, t

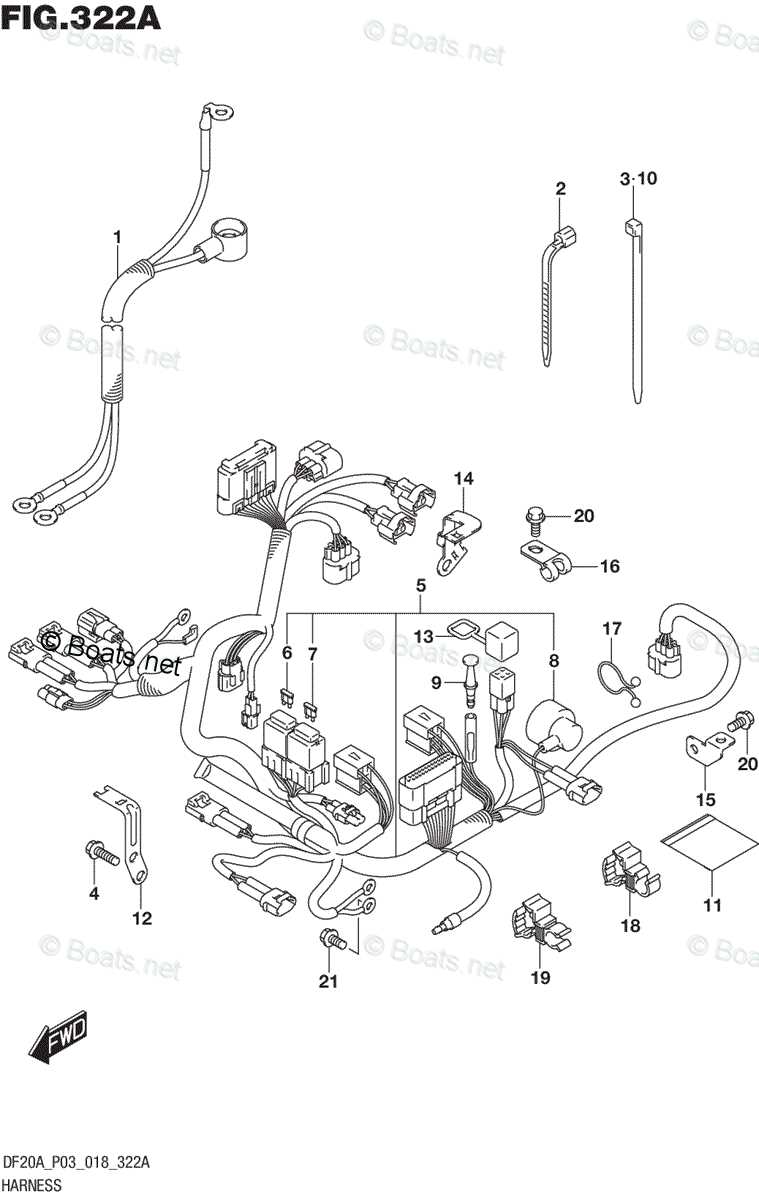

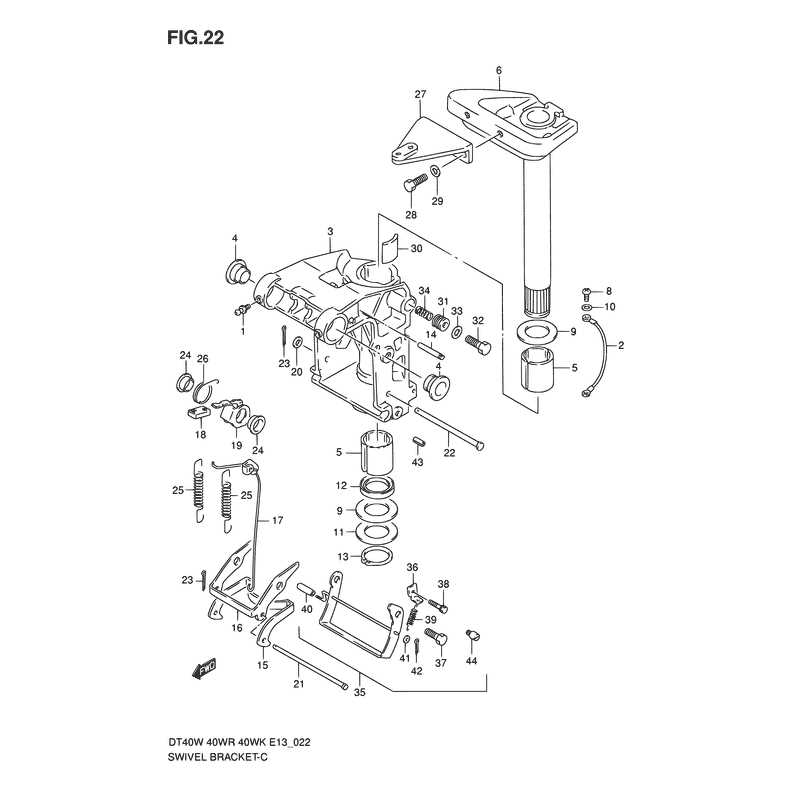

How to Read a Component Layout Diagram

Understanding the layout of a technical schematic is essential for anyone looking to repair or maintain machinery. A detailed illustration serves as a guide to identifying each element and how they fit into the overall system. Proper interpretation ensures that you can order the correct replacement elements and install them accurately, avoiding any mechanical issues in the future.

Identifying Key Sections

Most schematics are divided into sections based on the functionality or location of the elements within the machine. Each section focuses on a specific area, allowing for easier navigation. By familiarizing yourself with the structure of the layout, you’ll be able to locate each part and understand how it interacts with others in the system.

Using the Reference Numbers

Each item on the diagram is typically labeled with a unique reference number. These numbers correspond to a list, which provides more information such as the part name and sometimes its specifications. To successfully use the diagram, match the numbers on the schematic with the reference list, ensuring the accuracy of the information you retrieve.

Reference Number Description Function 1 Fuel System Parts of the Suzuki 9.9

The fuel delivery system plays a vital role in ensuring efficient engine performance. Every component within this system works in unison to transfer fuel from the tank to the combustion chamber, where it powers the motor. These parts must function reliably to maintain optimal engine operation, reduce emissions, and prevent damage due to improper fuel flow. Below is a detailed breakdown of the key elements involved.

Component Description Fuel Pump Transfers fuel from the tank to the engine under the necessary pressure to ensure a steady flow. Fuel Line Connects the fuel tank to the motor, allowing for the transportation of gasoline. Fuel Filter Removes contaminants from the gasoline, protecting the engine from dirt and debris. Carburetor Mixes the fuel with air in the co Ignition and Electrical Components Explained

The ignition and electrical system is crucial for ensuring the engine starts and runs efficiently. These systems are responsible for generating the necessary spark, delivering power, and managing other electrical functions, which together enable smooth and reliable performance. Understanding the various elements involved helps in troubleshooting and maintaining overall functionality.

Key Components of the Ignition System

The ignition system comprises several essential parts that work together to ignite the fuel mixture within the engine. A spark plug generates the spark, while the ignition coil amplifies the voltage required to create that spark. The trigger mechanism or flywheel magneto works by sending signals to the coil, ensuring precise timing for optimal ignition. Each of these components must function correctly for consistent engine operation.

Electrical System Overview

In addition to ignition, the electrical system manages other power requirements. The alternator or stator generates electrical power to charge the battery and supply electricity to various accessories. A voltage regulator ensures that power is distributed at safe levels, preventing damage to other electrical components. These systems work together to provide both the power needed for the engine and additional functionality like lighting and instrumentation.

Understanding the Cooling System in the 9.9 Motor

The cooling mechanism in marine engines plays a crucial role in ensuring smooth and efficient operation. By regulating the engine’s temperature, it prevents overheating and ensures longevity, especially in demanding marine environments. Knowing how this system functions can help in routine maintenance and troubleshooting potential issues.

How the Cooling Mechanism Works

The system typically draws water from the surrounding environment, circulates it through various internal passages, and then expels it. This flow of water absorbs the heat generated by the engine, maintaining an optimal working temperature. Without this process, the engine components could rapidly overheat, leading to serious damage.

Key Components of the Cooling System

Several essential components make up the cooling mechanism. Understanding the role of each part is critical for diagnosing and resolving issues. Below is a table outlining the primary elements involved.

Component Function Water Pump Draws in water from the external environment to circulate through the engine. Thermostat Regulates the engine’s temperature by controlling the flow of cooling water. Impeller Propels the Common Wear and Tear Parts to Replace

Over time, essential components of any mechanical device naturally experience degradation due to regular use. Regular inspection and timely replacement of these critical items can prevent larger issues and extend the lifespan of your equipment. Below is a guide to some of the most commonly affected areas and components that may require attention.

Essential Seals and Gaskets

Seals and gaskets are often subject to significant wear due to their role in preventing leaks and ensuring proper functioning of the engine. With constant exposure to heat, pressure, and friction, they can crack, harden, or lose their effectiveness. Replacing these components at regular intervals helps maintain optimal performance and prevent more serious failures.

Filters and Impellers

Filters, especially those used in fuel and water systems, are vital for ensuring that contaminants do not enter sensitive areas. Over time, these filters can become clogged or less effective, impacting efficiency. Similarly, the impeller, which plays a key role in cooling, should be replaced periodically to avoid overheating and subsequent damage.

Component Expected Lifespan Symptoms of Wear Finding Genuine Suzuki Replacement Parts

When it’s time to replace components for your engine, ensuring the use of authentic parts is critical for maintaining performance and longevity. Original replacements are specifically designed to fit and function perfectly, preserving the integrity of your equipment. Opting for genuine items minimizes risks associated with wear, failure, and inefficiency.

To locate the right replacements, start by identifying the exact model and version of your motor. Manufacturers often provide detailed catalogs or diagrams to assist in pinpointing the correct part numbers. Many authorized dealers also offer support through online platforms, where you can search by model or serial number.

Be cautious of counterfeit or third-party alternatives that might seem appealing due to lower prices. Non-authentic parts can cause significant damage or reduce the efficiency of the machinery, leading to costly repairs down the line. Always verify the source of the components and prioritize certified distributors to ensure reliability and safety.

How to Maintain Your Suzuki Outboard Efficiently

Regular upkeep of your marine engine is crucial for ensuring longevity and optimal performance. A well-maintained unit not only operates more efficiently but also minimizes the risk of breakdowns while enhancing fuel economy. Understanding the fundamentals of care and preventive measures can help you get the most out of your vessel.

Begin with routine inspections to identify any potential issues before they escalate. Check the oil levels and quality regularly, changing it as per the manufacturer’s recommendations to ensure smooth operation. Pay attention to the cooling system, ensuring that water intake is unobstructed and the thermostat functions correctly to prevent overheating.

Next, focus on the fuel system. Using clean, high-quality fuel can prevent clogging and fuel-related issues. Regularly inspect fuel lines for signs of wear or leaks, replacing any damaged components promptly. Consider using a fuel stabilizer to keep the system functioning optimally, especially during off-seasons.

Another critical area is the electrical system. Inspect all connections, wiring, and battery terminals for corrosion or wear. Clean and tighten connections as necessary to ensure reliable starting and operation. Additionally, ensure that all fuses and circuit breakers are in good working order to prevent electrical failures.

Lastly, always refer to the service manual for specific maintenance schedules and procedures. Following these guidelines will help maintain your marine engine’s performance, ensuring many enjoyable trips on the water.

Troubleshooting Tips for Suzuki 9.9 Motor

Addressing issues with small marine engines can be daunting, yet understanding common problems and their solutions can simplify the process. This section offers practical advice for diagnosing and resolving typical malfunctions, ensuring your motor runs smoothly and efficiently.

When encountering difficulties, follow these essential steps:

- Identify Symptoms: Begin by noting the specific problems your engine is exhibiting. Common issues include:

- Difficulty starting

- Unusual noises

- Loss of power

- Excessive vibration

- Fuel leakage

Once you’ve identified the symptoms, proceed with the following troubleshooting tips:

- Check Fuel Supply: Ensure that the tank is filled with fresh fuel and that the fuel lines are clear. Old or contaminated fuel can lead to starting issues.

- Inspect Electrical Connections: Examine the wiring, battery, and ignition system for any loose connections or corrosion. A faulty electrical system can cause the engine to fail to start or run improperly.

- Examine the Propeller: Ensure the propeller is not damaged and is free of debris. A damaged or obstructed propeller can lead to reduced performance and increased strain on the engine.

- Inspect Cooling System: Verify that the cooling system is functioning correctly. Overheating can result from clogged water intake or a malfunctioning pump, leading to engine failure.

- Perform Routine Maintenance: Regularly change the oil, replace filters, and inspect spark plugs. Neglecting maintenance can lead to performance issues over time.

If problems persist after following these steps, consult a qualified technician for further assistance. Proper diagnosis and timely repairs can extend the life of your marine engine and enhance your boating experience.

Benefits of Using OEM Parts for Suzuki 9.9

Utilizing original equipment manufacturer components offers numerous advantages that enhance the performance and longevity of marine engines. These meticulously crafted items are designed to meet the specific requirements of each model, ensuring compatibility and optimal functionality. By choosing these high-quality elements, users can enjoy peace of mind, knowing they are investing in reliability and durability.

Quality Assurance

OEM components are manufactured to the highest standards, ensuring superior performance. Unlike aftermarket alternatives, which may vary in quality, original items undergo rigorous testing to guarantee that they meet exact specifications. This commitment to excellence helps to minimize the risk of malfunctions and extends the lifespan of the engine.

Enhanced Performance

Original components are engineered to work seamlessly with the entire system, enhancing overall performance. These parts ensure that every function operates at peak efficiency, contributing to improved fuel economy and better handling. Investing in original components can lead to a noticeable difference in performance, ultimately providing a better experience on the water.

Advantage OEM Parts Aftermarket Parts Quality High standard, rigorously tested Varies significantly Compatibility Exact fit, designed for specific models May require modifications Warranty Often includes manufacturer’s warranty Limited or no warranty Longevity Typically longer-lasting Shorter lifespan due to variable quality