In the realm of machinery maintenance and repair, visual representations serve as indispensable tools for both professionals and enthusiasts. These illustrations provide a clear and comprehensive overview of various components, enabling users to identify and understand the intricate relationships between different elements. By utilizing these resources, individuals can enhance their knowledge and efficiency when tackling repair tasks.

Whether one is navigating through complex machinery or performing routine maintenance, having access to detailed visual aids can significantly streamline the process. Such guides empower users to pinpoint specific items swiftly, ensuring that they can efficiently locate what they need without unnecessary confusion. This not only saves time but also reduces the risk of errors during repairs.

Moreover, these resources foster a deeper understanding of the equipment’s functionality. By breaking down the intricate systems into easily digestible visuals, users can better grasp how each component interacts within the larger assembly. This insight is invaluable for troubleshooting and enhancing overall performance, ultimately contributing to the longevity and reliability of the machinery.

Understanding Messicks Parts Diagrams

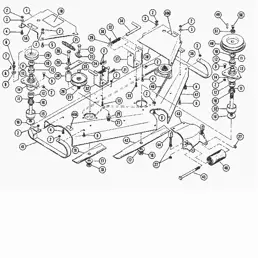

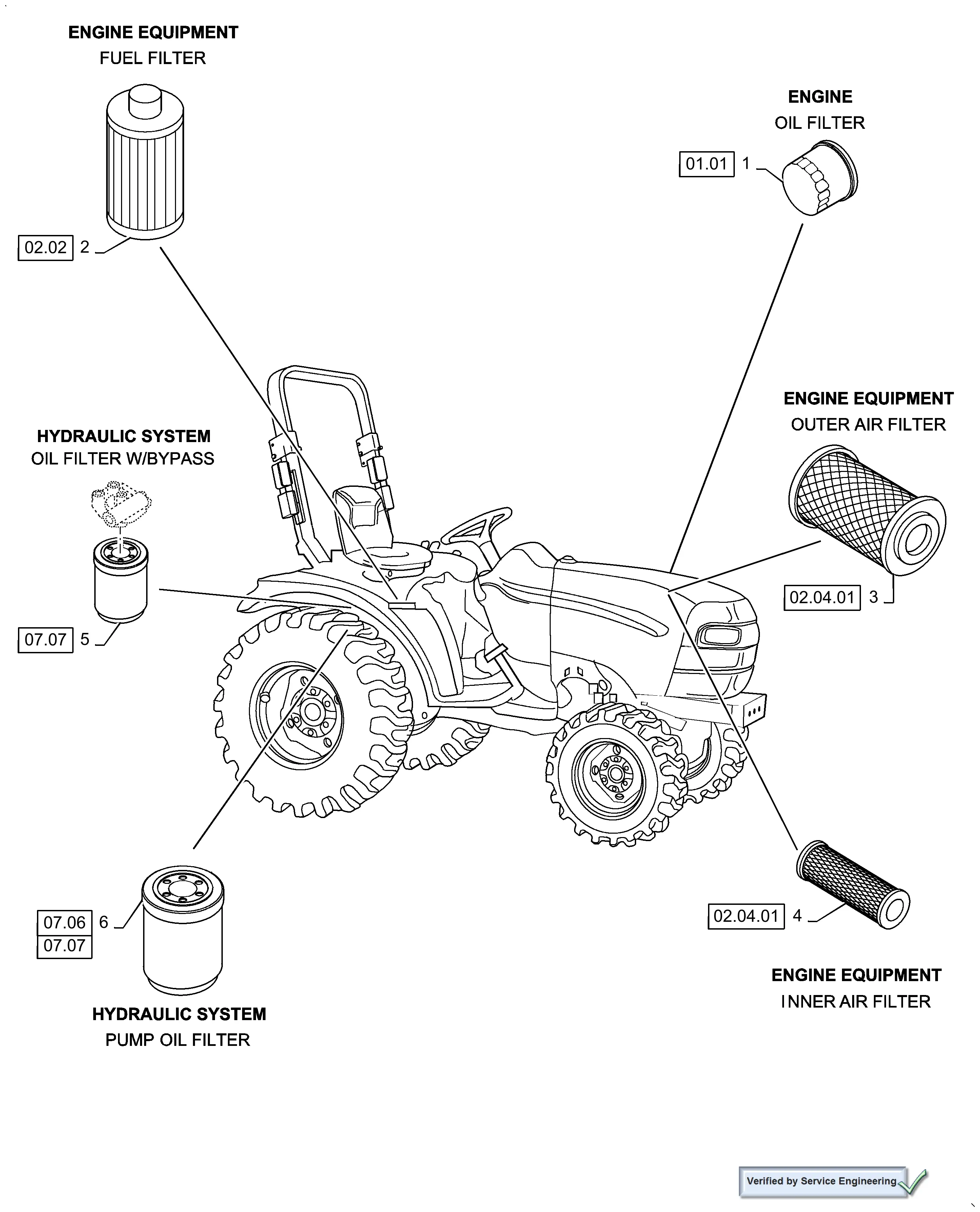

Comprehending visual aids related to machinery components is essential for effective maintenance and repairs. These illustrations provide a clear representation of various elements, helping users identify parts and their specific functions within a system.

These visual guides typically include:

- Detailed representations of individual components

- Labels for easy identification

- Connections between various elements

Utilizing these resources can enhance your understanding of the machinery you work with. Here are some benefits of engaging with these visuals:

- Improved Clarity: Visual aids simplify complex systems, making it easier to grasp how everything fits together.

- Enhanced Accuracy: Knowing the exact components can prevent errors during repairs.

- Time Efficiency: Quickly locating necessary parts speeds up the maintenance process.

To make the most of these tools, consider the following tips:

- Familiarize yourself with the layout of the illustrations.

- Use the labels to cross-reference with physical components.

- Refer to these resources regularly for training and refreshers.

By engaging with these visual references, you can boost your proficiency and confidence in handling equipment, ultimately leading to more effective operations.

Benefits of Using Parts Diagrams

Utilizing visual representations of components offers numerous advantages, enhancing efficiency and understanding in various contexts. These illustrations serve as essential tools for identifying elements, streamlining assembly processes, and facilitating repairs. By breaking down complex machinery or systems into manageable sections, users can easily navigate through the necessary components.

Enhanced Clarity and Understanding

One of the primary benefits of visual representations is their ability to convey information clearly. When users can see a detailed illustration, they can:

- Quickly locate specific items.

- Comprehend relationships between different parts.

- Visualize assembly sequences more effectively.

Improved Efficiency in Repairs and Maintenance

These visual aids significantly boost productivity during maintenance tasks. They allow technicians to:

- Identify worn or damaged components with ease.

- Gather required items before starting repairs.

- Follow step-by-step procedures to avoid errors.

In conclusion, leveraging visual guides can greatly enhance both understanding and operational efficiency, ultimately leading to more effective management of complex systems.

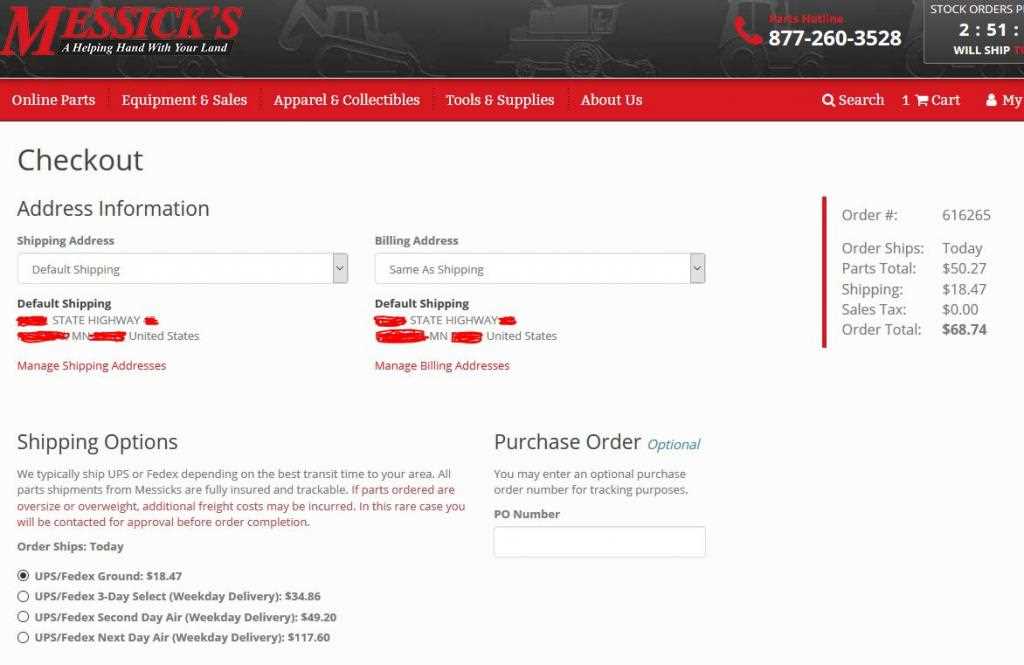

How to Access Messicks Resources

Gaining entry to valuable tools and information can greatly enhance your experience and understanding of machinery maintenance and repairs. This section outlines effective methods for navigating and utilizing these resources to optimize your workflow and decision-making processes.

Online Access

The digital platform offers a user-friendly interface, making it easy to locate necessary information. Follow these steps to access the online resources:

| Step | Description |

|---|---|

| 1 | Visit the official website and navigate to the resources section. |

| 2 | Utilize the search function to find specific items or categories. |

| 3 | Review available materials, ensuring you select the correct model and year. |

| 4 | Download or print the documents for offline use. |

Customer Support

If you encounter difficulties or have specific queries, reaching out to customer support can be immensely helpful. Here are the best practices for effective communication:

- Prepare a clear description of your inquiry.

- Have model numbers and relevant details at hand.

- Utilize available chat options for immediate assistance.

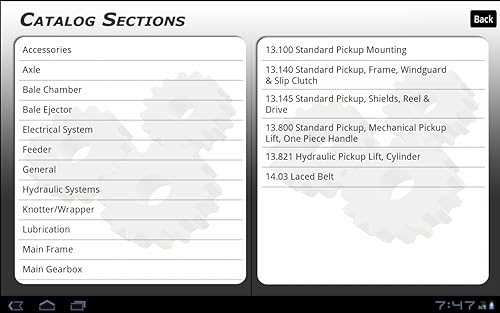

Navigating the Diagram Interface

Understanding the layout and features of an illustration interface is essential for efficient exploration and identification of components. This section will guide you through the elements that facilitate user interaction and streamline the process of locating specific items.

Upon entering the interface, users are greeted with a comprehensive visual representation that allows for easy navigation. The main sections typically include an interactive map and a list of categories, enabling swift access to various groups of items. Hovering over each segment often reveals additional details, enhancing clarity and aiding decision-making.

Furthermore, utilizing the search function can significantly expedite the journey. By entering keywords or item numbers, you can quickly filter through extensive options, saving valuable time. Additionally, the zoom feature enables a closer examination of intricate details, which can be particularly useful when identifying small parts or complex assemblies.

As you explore the interface, take advantage of any available filters or sorting options. These tools can help refine your search based on criteria such as size, type, or compatibility, making it easier to find precisely what you need. Familiarizing yourself with these functionalities will enhance your overall experience and efficiency in navigating the platform.

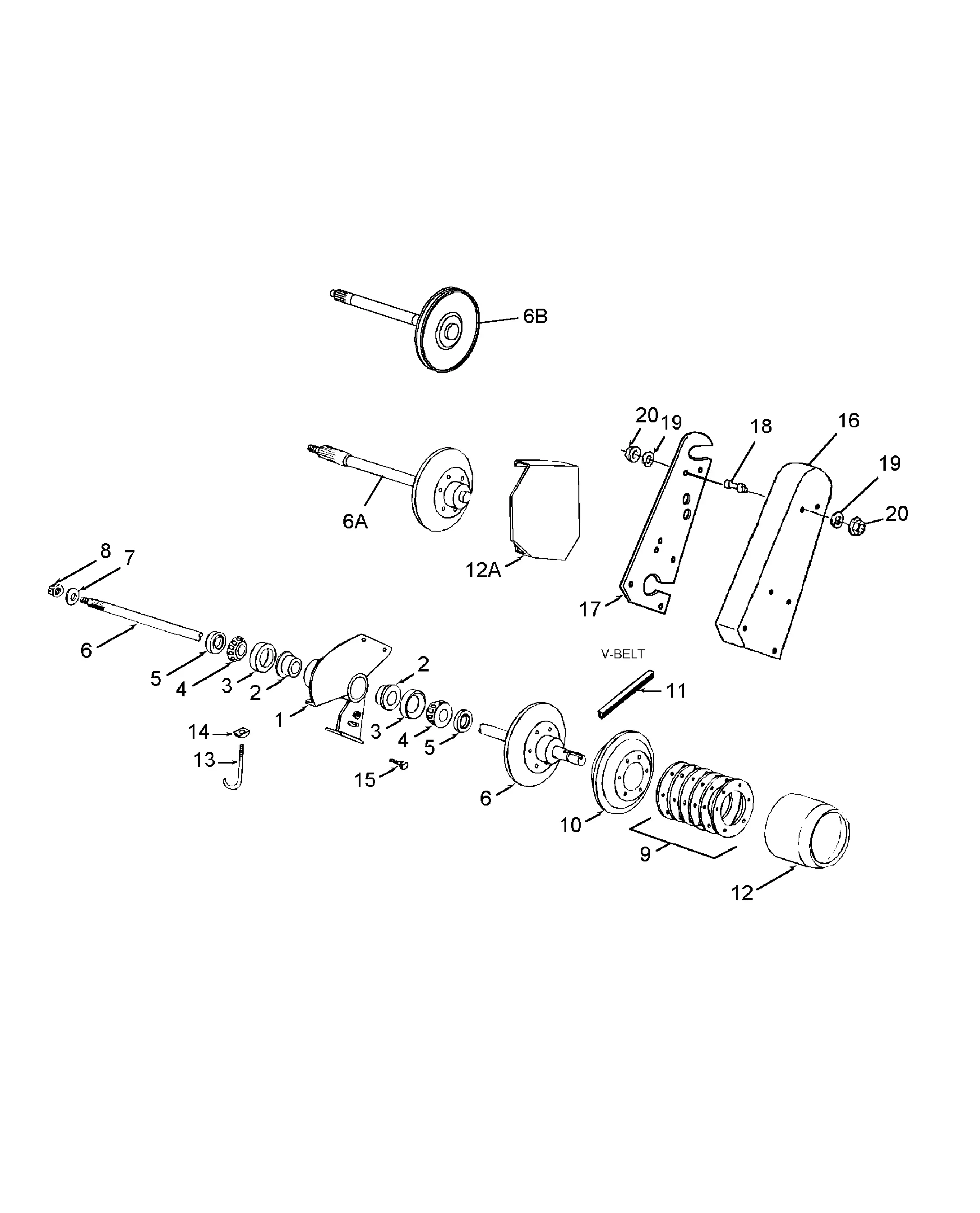

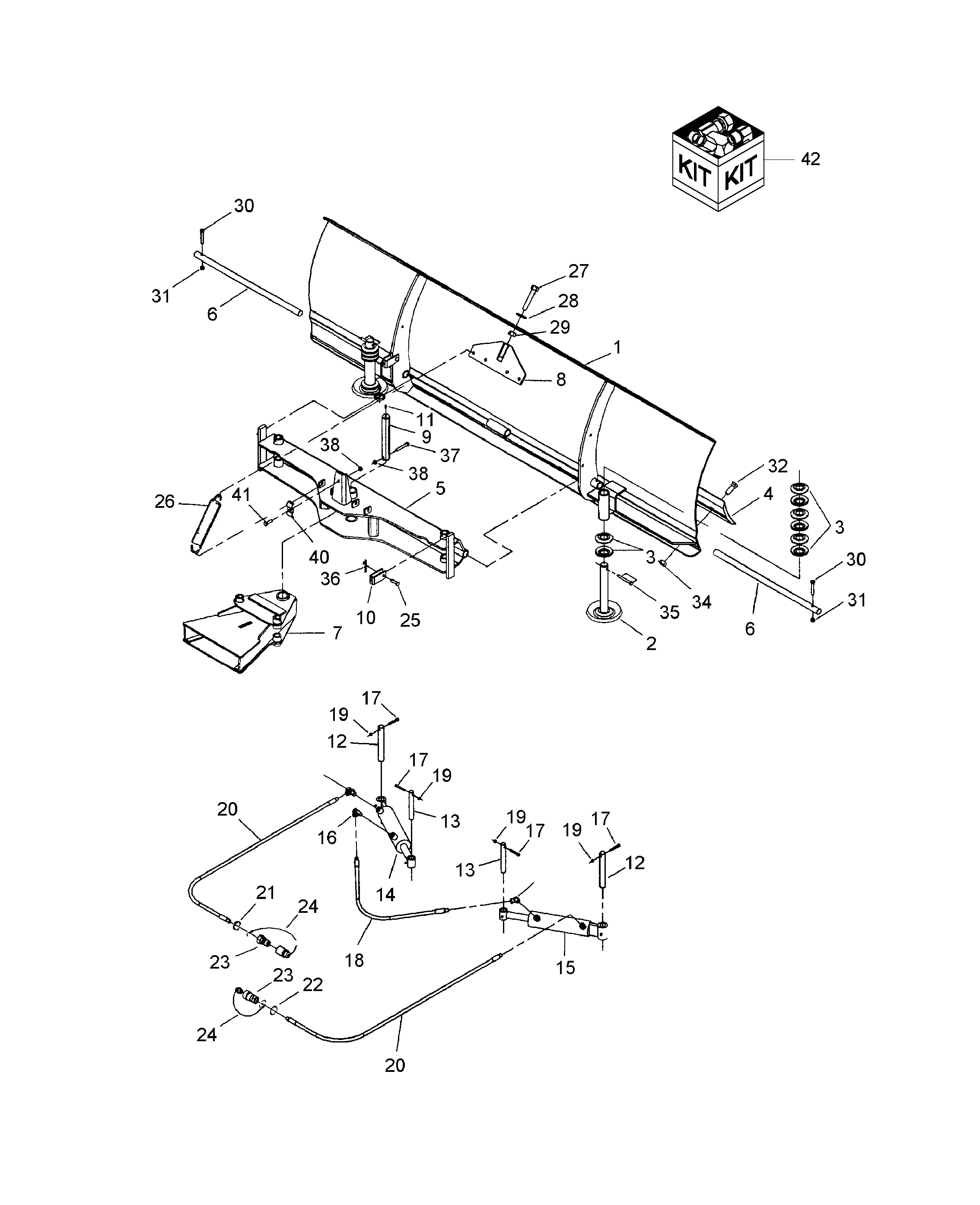

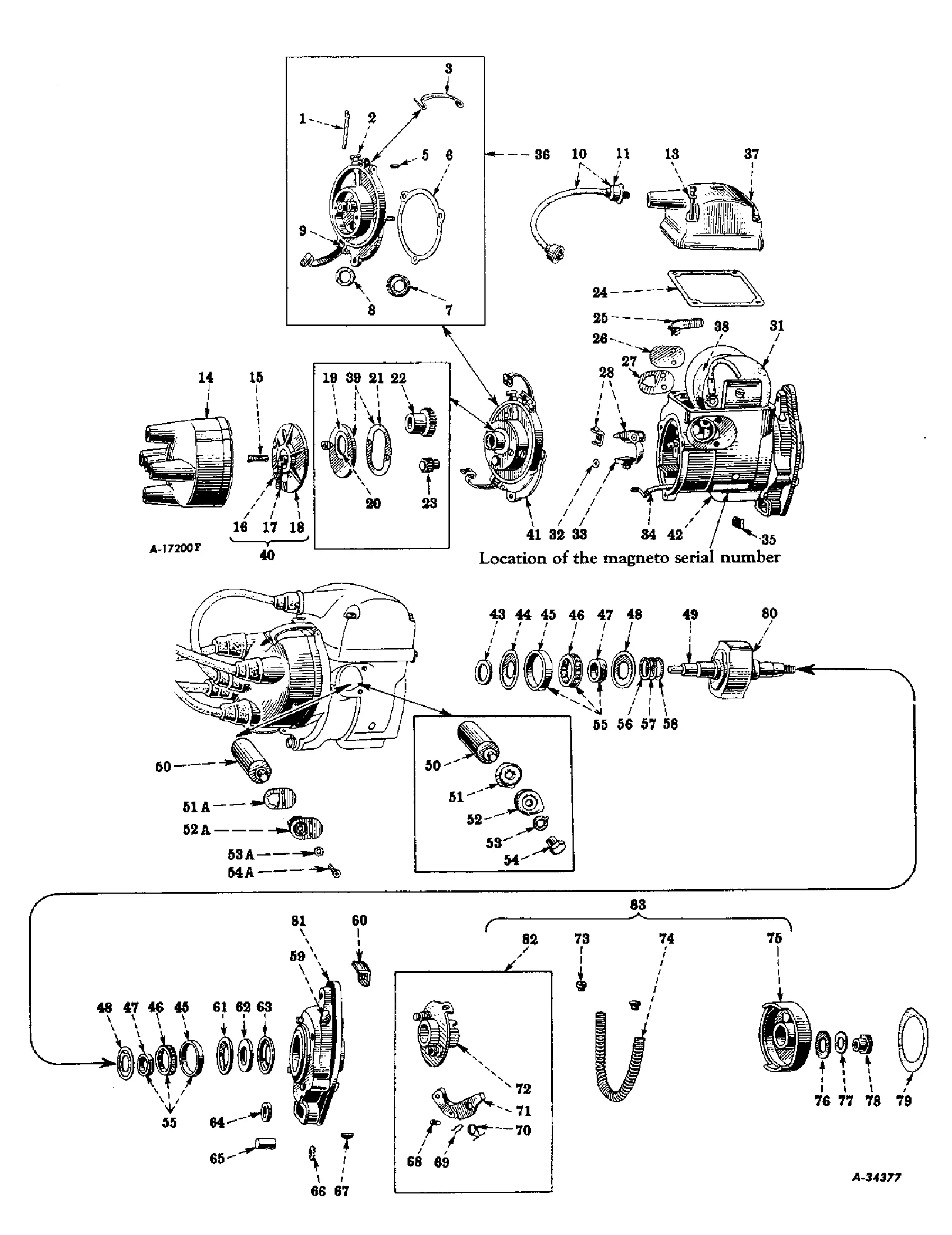

Identifying Components in Diagrams

Understanding the various elements illustrated in technical schematics is crucial for effective maintenance and repairs. Each symbol or representation serves a specific function, contributing to a comprehensive understanding of the system as a whole. By familiarizing oneself with these representations, one can streamline troubleshooting processes and enhance efficiency in identifying necessary actions.

Common Symbols and Their Meanings

Each representation in a technical schematic typically follows established conventions. For instance, certain shapes might denote specific types of machinery or components. Recognizing these common symbols allows for quicker interpretation and aids in the overall comprehension of the layout. Always consult a reference guide for clarification on less familiar symbols to avoid confusion.

Color Coding and Annotations

In addition to shapes, color plays a vital role in the identification of components. Different hues can indicate various statuses, such as operational readiness or maintenance needs. Annotations often accompany these representations, providing additional context or instructions. Paying attention to these details ensures a more thorough understanding of the schematic and facilitates accurate assessment of the system.

Common Issues with Parts Diagrams

Understanding the intricacies of technical illustrations can often present challenges for users seeking to identify components for maintenance or replacement. Misinterpretations can arise from unclear representations, leading to confusion and potential errors in assembly or procurement.

One prevalent issue is the lack of detailed annotations. When visuals do not provide sufficient context or labels, it becomes difficult for individuals to discern specific items, especially if they are unfamiliar with the machinery or equipment. This ambiguity can result in selecting incorrect pieces, causing delays and increased costs.

Additionally, discrepancies between different versions of these visual aids can confuse users. Updates or modifications to equipment may not always be reflected in the available illustrations, leading to reliance on outdated information. Such inconsistencies can hinder effective repairs and maintenance, making it essential for users to cross-reference multiple sources.

Another common concern is the scale of the illustrations. If the sizing is not accurately depicted, users may struggle to gauge the dimensions of components, which can affect compatibility with existing machinery. Clear scaling is crucial for ensuring proper fit and function.

Finally, the overall organization of visual materials can impact usability. A disorganized presentation may require users to sift through unnecessary information, which detracts from the efficiency of the process. Well-structured content enhances the experience, allowing for quicker identification and resolution of issues.

Tips for Accurate Parts Ordering

Ensuring the correct acquisition of components is essential for maintaining efficiency and minimizing downtime. By following a few strategic steps, you can enhance the accuracy of your orders and streamline the procurement process.

- Verify Model Numbers: Always double-check the model numbers of the equipment to ensure compatibility.

- Consult Documentation: Refer to user manuals or service guides that specify the required components.

- Utilize Online Resources: Access reputable online platforms for additional information and insights into specific items.

- Contact Experts: Don’t hesitate to reach out to knowledgeable professionals who can provide guidance on selections.

Implementing these strategies can significantly reduce the chances of errors during the ordering process.

- Cross-Check Part Descriptions: Ensure that the description matches what you need, paying close attention to details.

- Keep a Record: Maintain a log of previously ordered items to simplify future requests.

- Order in Advance: Anticipate needs by placing orders well before they are critically required to allow for unexpected delays.

By being diligent and organized, you can enhance your ordering process, saving both time and resources.

Understanding Part Numbering Systems

The system of identifying components through unique codes is essential for efficient management and organization. These codes serve as a language that helps users, manufacturers, and suppliers communicate effectively regarding specific items. A well-structured identification system enhances clarity and minimizes errors in transactions and inventory management.

Components of Numbering Systems

Various elements contribute to the design of a robust identification framework. Here are some key components:

- Prefix: Often denotes the category or type of item.

- Numerical Sequence: Provides a unique identifier, usually sequential or based on certain criteria.

- Suffix: Can indicate variations such as size, color, or specific features.

Benefits of a Structured System

A well-defined identification framework offers several advantages:

- Improved efficiency in locating and ordering items.

- Reduction in miscommunication between stakeholders.

- Streamlined inventory management processes.

By understanding the principles behind numbering conventions, users can navigate the complexities of product identification more effectively, ensuring a smoother operational flow.

Comparing OEM vs Aftermarket Parts

When it comes to replacement components for machinery, the choice between original equipment manufacturer (OEM) and alternative options can significantly impact performance and longevity. Understanding the nuances of each type can help users make informed decisions tailored to their specific needs and preferences.

Quality and Reliability

OEM items are typically synonymous with high quality, as they are produced to the exact specifications set by the original maker. This often translates into better compatibility and longer-lasting performance. On the other hand, alternative solutions can vary widely in quality. While some aftermarket options may meet or even exceed the standards of their OEM counterparts, others may fall short, leading to potential issues down the line.

Cost Considerations

One of the most compelling reasons to explore alternative solutions is cost savings. Generally, aftermarket items tend to be more affordable, which can be attractive for budget-conscious consumers. However, it is essential to weigh the initial savings against the potential for increased maintenance costs or reduced efficiency over time. Investing in quality, whether OEM or alternative, often pays off in the long run.

Maintenance and Repair Insights

Effective upkeep and restoration of machinery is crucial for ensuring longevity and optimal performance. Understanding the components and their functions plays a vital role in addressing issues promptly and efficiently. This section delves into practical strategies and considerations for maintaining your equipment in peak condition.

Regular Inspections: Conducting routine examinations allows for the early detection of potential problems. By closely monitoring wear and tear, you can mitigate costly repairs and extend the life of your machinery.

Preventive Measures: Implementing scheduled maintenance activities is essential. These proactive steps can include oil changes, filter replacements, and system calibrations. Establishing a timetable ensures that tasks are performed consistently, reducing the likelihood of unexpected breakdowns.

Documentation: Keeping accurate records of all maintenance and repairs helps track the history of your equipment. This information is invaluable for identifying recurring issues and planning future servicing needs.

Resources and Support: Accessing reliable sources for guidance can significantly enhance your maintenance efforts. Whether through manuals, expert consultations, or community forums, having the right information readily available is crucial for troubleshooting and effective repairs.

In conclusion, a well-structured approach to maintenance and repair not only safeguards your investment but also enhances productivity. By prioritizing careful oversight and utilizing available resources, you can ensure your machinery operates smoothly for years to come.

Frequently Asked Questions about Diagrams

This section aims to address common inquiries regarding visual representations used in various contexts. Understanding these illustrations can greatly enhance comprehension and usability, allowing users to effectively navigate and utilize the information presented.

What are the benefits of using visual representations?

Visual aids simplify complex information, making it easier to grasp intricate systems or components. They provide a clear, organized way to present data, reducing the time needed for analysis and decision-making. Additionally, they can enhance communication by offering a universal language that transcends text barriers.

How can I interpret these illustrations effectively?

To interpret these visuals accurately, familiarize yourself with the symbols and legends used. Take time to review the layout and structure, which often highlight relationships and functions. Engaging with accompanying descriptions or guides can also provide valuable context, helping you make informed conclusions based on the visuals.