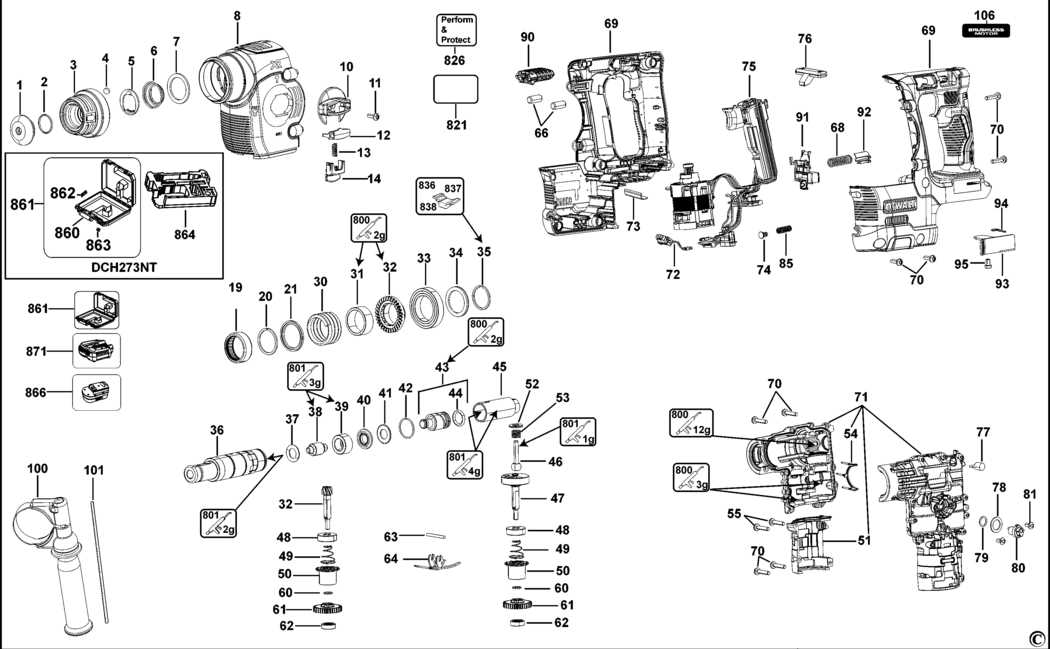

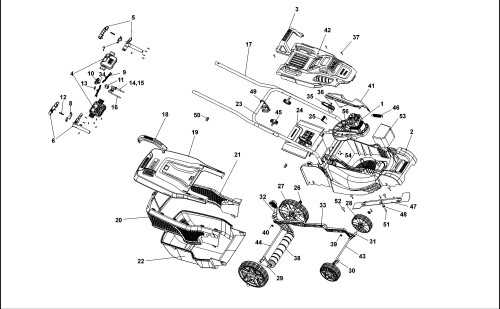

In the realm of power tools, comprehending the intricate layout of components is essential for maintenance and troubleshooting. Each element plays a pivotal role in the overall functionality, ensuring that users can achieve optimal performance during their tasks. By familiarizing oneself with the arrangement and purpose of various elements, one can enhance their knowledge and ability to handle repairs effectively.

Whether you are a seasoned professional or a DIY enthusiast, knowing how the components interact can significantly impact the efficiency and longevity of your equipment. The intricate relationship between different sections can often determine how well a tool operates under various conditions. Understanding these relationships fosters better care practices and more informed decisions when it comes to upgrades or replacements.

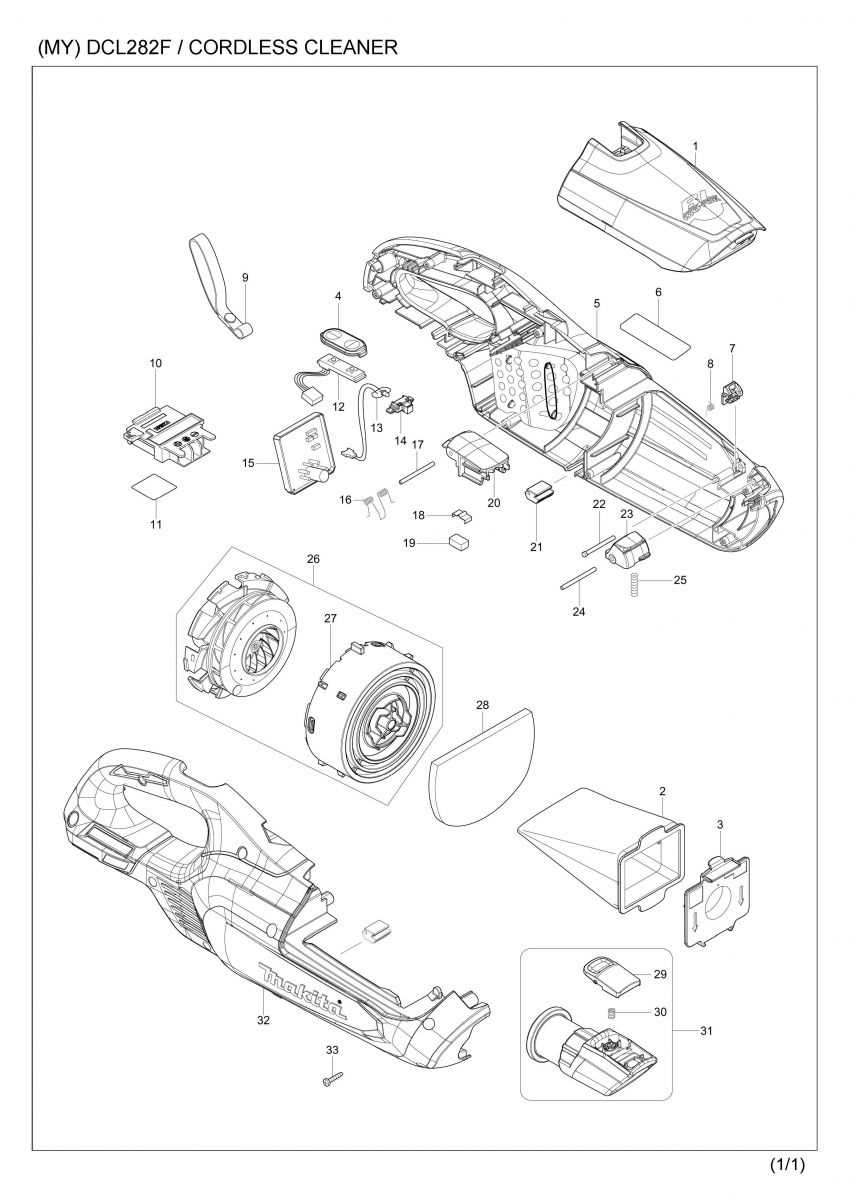

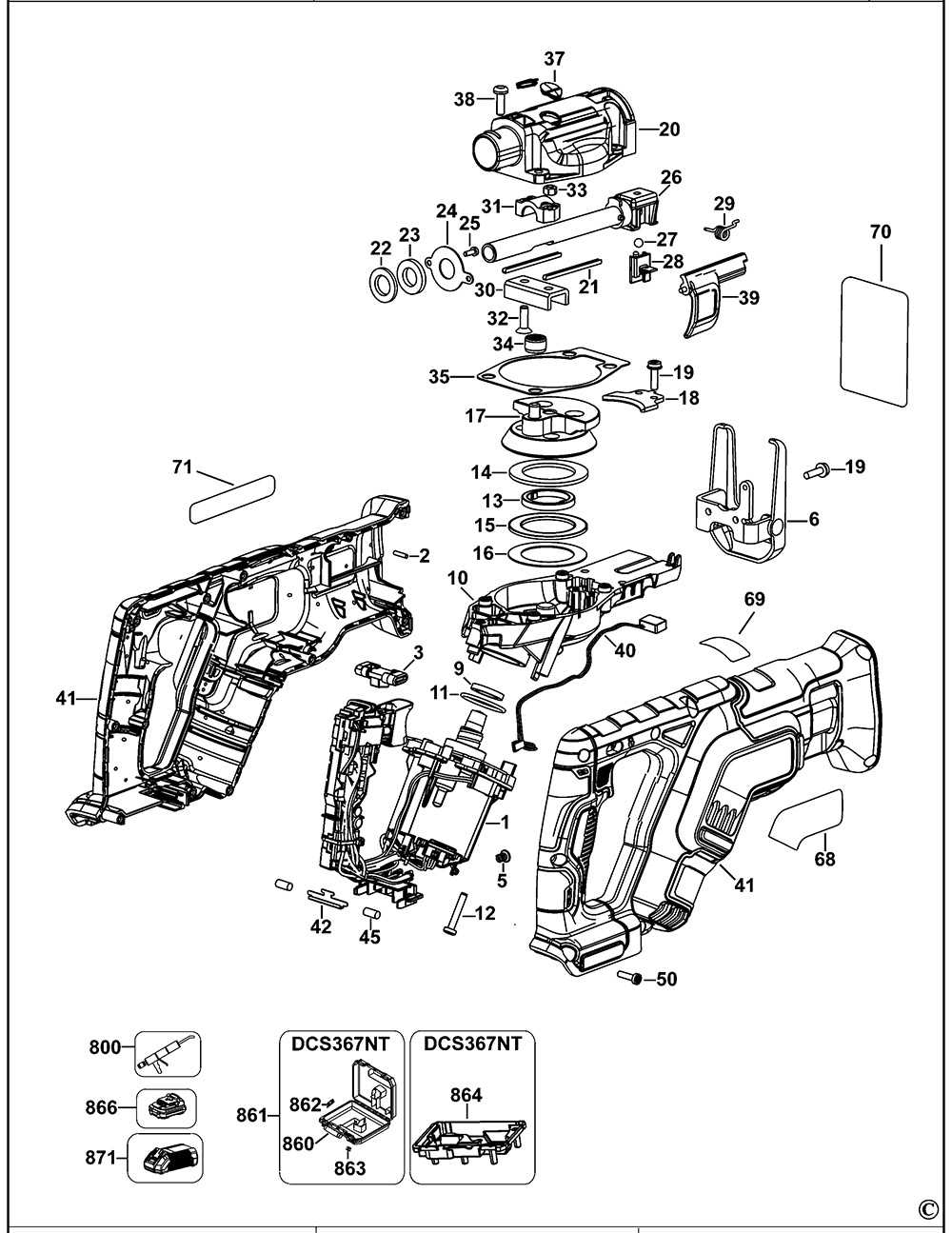

Additionally, having a clear visual representation of the assembly can aid in identifying specific issues that may arise during use. Such insight can simplify the repair process and empower users to tackle challenges confidently. Embracing this knowledge not only contributes to a smoother experience but also promotes a deeper appreciation for the engineering behind these powerful devices.

In any mechanical assembly, a comprehensive listing of components is crucial for efficient maintenance and repairs. This section explores the significance of recognizing each element, facilitating informed decisions during service tasks. Grasping the nuances of each component enhances the understanding of the overall functionality and ensures seamless operations.

| Component Name | Description | Function |

|---|---|---|

| Blade | High-quality cutting tool | Enables precise cutting of various materials |

| Motor | Powerful electric engine | Drives the cutting action with high efficiency |

| Battery | Rechargeable energy source | Powers the device for cordless operation |

| Handle | Ergonomically designed grip | Provides comfort and control during use |

| Base Plate | Sturdy support structure | Ensures stability and alignment during cutting |

Key Components of the Tool

Understanding the essential elements of this power tool is crucial for both effective operation and maintenance. Each component plays a vital role in the overall functionality, contributing to the efficiency and performance of the equipment. Familiarizing oneself with these parts not only aids in optimal usage but also enhances troubleshooting capabilities.

- Motor: The driving force behind the tool, responsible for converting electrical energy into mechanical motion.

- Blade: A critical attachment for cutting, available in various sizes and materials to suit different tasks.

- Trigger: The mechanism that allows users to start and stop the tool, offering control over the cutting speed.

- Guard: A safety feature designed to protect users from accidental contact with the blade during operation.

- Base Plate: The foundation of the tool, providing stability and support while in use.

- Battery: Powers the tool, with options for various voltages to accommodate different levels of demand.

- Housing: The outer shell that encases the internal components, ensuring durability and protection from external elements.

Each of these components contributes to the overall effectiveness and safety of the equipment, making it essential for users to understand their functions and maintenance requirements.

Assembly and Disassembly Guide

This section provides essential information for effectively putting together and taking apart the tool. Understanding the correct procedures is vital for maintenance, repair, and ensuring optimal performance. Following the outlined steps will help prevent damage and enhance the longevity of the equipment.

Tools Required

Before beginning, ensure you have the necessary tools on hand. A Phillips screwdriver, wrench set, and allen keys are typically required. Having these items readily available will facilitate a smoother assembly and disassembly process.

Step-by-Step Instructions

To disassemble the equipment, start by disconnecting it from any power source. Carefully remove the screws and fasteners holding the housing together, taking note of their locations for reassembly. Once the outer casing is removed, you can access internal components. When reassembling, reverse the process, ensuring that all parts fit snugly and are securely fastened. Pay attention to any specific alignment requirements to guarantee proper functionality.

Maintenance Tips for Longevity

Ensuring the extended life of your equipment requires regular upkeep and attention to detail. Implementing a few simple practices can significantly enhance performance and durability, allowing tools to operate efficiently for years.

Regular Cleaning

Maintaining cleanliness is crucial for optimal functionality. Dust and debris can accumulate and lead to overheating or malfunction. Follow these steps:

- Disconnect the tool from the power source.

- Use a soft brush or compressed air to remove dust from vents and moving parts.

- Wipe down surfaces with a damp cloth to eliminate grime.

Routine Inspections

Conducting frequent checks on your equipment can help identify potential issues before they escalate. Pay attention to the following:

- Examine all components for signs of wear or damage.

- Ensure all fasteners are tight and secure.

- Test all features to confirm they are functioning properly.

By adhering to these maintenance strategies, users can significantly extend the lifespan and reliability of their tools, ultimately saving time and resources.

Identifying Replacement Parts

Understanding how to locate the necessary components for repair or maintenance is essential for ensuring optimal performance and longevity of your tools. By familiarizing yourself with the key elements, you can efficiently replace any worn or damaged items, thereby enhancing the overall functionality.

To effectively identify the components needed, follow these guidelines:

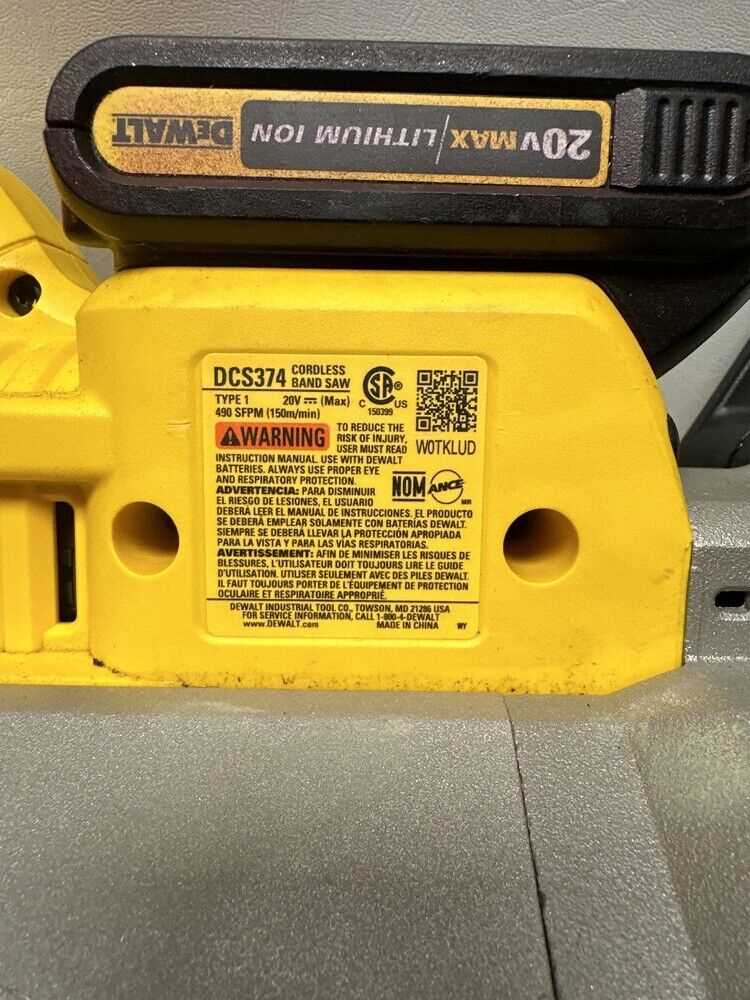

- Consult the user manual for a comprehensive list of components specific to your tool.

- Utilize online resources and forums where other users share insights and experiences regarding replacements.

- Examine the tool closely, noting any labels or markings that indicate part numbers or specifications.

Additionally, consider the following tips when searching for suitable replacements:

- Make a list of all items that require replacement to streamline your search.

- Check with authorized retailers or online platforms that specialize in tool components.

- Cross-reference part numbers to ensure compatibility with your specific model.

By following these steps, you can ensure that you acquire the correct components to maintain the efficiency and reliability of your equipment.

Tools Required for Repairs

To ensure efficient and effective maintenance of your equipment, it is crucial to have the right tools at your disposal. A well-equipped toolkit not only speeds up the repair process but also enhances the quality of the work performed. Understanding which instruments are necessary can save time and reduce the likelihood of damage during repairs.

Essential Hand Tools

Start with basic hand tools that are indispensable for any repair task. These typically include screwdrivers, pliers, wrenches, and a variety of socket sets. A good selection of these items allows for tackling various fasteners and components with ease. Additionally, a utility knife and a set of hex keys can be beneficial for more specialized tasks.

Power Tools and Accessories

Incorporating power tools into your repair toolkit can significantly enhance efficiency. Drills and impact drivers are commonly used for removing stubborn screws and bolts, while saws are useful for any cutting needs. Don’t forget to include the necessary accessories, such as drill bits and blades, to ensure versatility in your repairs.

Common Issues and Solutions

This section addresses frequent challenges faced by users of this power tool and offers practical solutions to enhance its performance and longevity. Understanding these common difficulties can help prevent downtime and ensure efficient operation.

Overheating Problems

One of the most prevalent issues is overheating, which can occur due to prolonged use or lack of proper maintenance. To mitigate this problem, consider the following:

- Allow the tool to cool down after extended usage.

- Ensure the ventilation openings are clear of debris.

- Regularly check and clean the internal components.

Battery Malfunctions

Battery issues can lead to reduced performance or complete failure. To resolve these complications, follow these steps:

- Inspect the battery terminals for corrosion and clean them if necessary.

- Ensure the battery is charged according to the manufacturer’s specifications.

- Replace old or damaged batteries to maintain optimal performance.

By addressing these common problems with appropriate solutions, users can significantly improve the reliability and efficiency of their power equipment.

Upgrades and Accessories Available

Enhancing your tool’s capabilities can significantly improve efficiency and performance. Various modifications and supplementary items are accessible to ensure optimal operation and versatility for a range of tasks. By exploring these enhancements, users can tailor their equipment to meet specific needs and preferences.

Popular Upgrades

- High-capacity batteries for extended runtime.

- Brushless motors to increase efficiency and decrease maintenance.

- Variable speed controls for greater precision.

- Advanced blade options designed for specific materials.

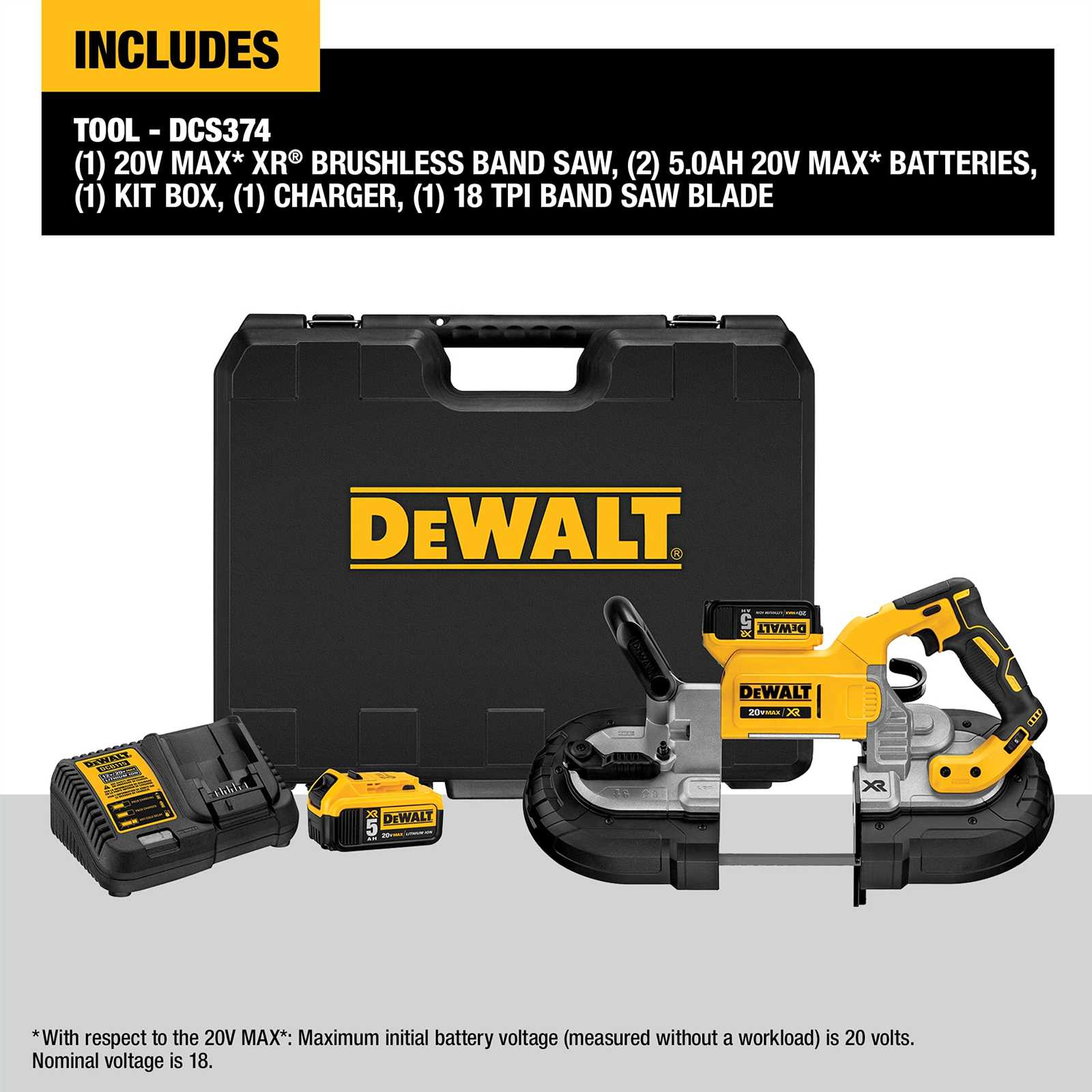

Essential Accessories

- Carrying cases for easy transportation and storage.

- Replacement parts to maintain functionality and safety.

- Charging docks for quick and convenient power replenishment.

- Protective gear to ensure user safety during operation.

Safety Precautions During Use

Ensuring a secure working environment is crucial when operating power tools. Adhering to specific safety measures not only protects the user but also prolongs the lifespan of the equipment. Awareness and preparation are key to minimizing risks and enhancing overall performance.

General Safety Guidelines

- Always wear appropriate personal protective equipment, including goggles, gloves, and ear protection.

- Ensure the workspace is free from clutter and any potential hazards that could cause accidents.

- Keep bystanders, especially children and pets, at a safe distance while operating machinery.

- Read the user manual thoroughly before use to familiarize yourself with the tool’s features and functions.

Operational Precautions

- Inspect the tool for any damage or wear before each use, ensuring all components are functioning correctly.

- Use the appropriate attachment or accessory for the specific task to avoid malfunction.

- Maintain a firm grip on the tool and a stable stance to enhance control during operation.

- Never override safety features, as they are designed to prevent injuries.

Comparing Models in the Series

When exploring various options within a particular lineup, it’s essential to analyze the differences and similarities among them. Each variant may offer unique features and specifications that cater to different user needs, enhancing the overall performance and usability of the tools. Understanding these distinctions can help consumers make informed decisions based on their requirements.

In this series, several models stand out due to their innovative characteristics. Below is a summary of key aspects that differentiate them:

- Power Source: Evaluate the type of battery or power supply each model utilizes, as this affects runtime and efficiency.

- Cutting Capacity: Look at the maximum cutting thickness and width to determine suitability for various tasks.

- Weight and Ergonomics: Consider how the weight and design influence handling and comfort during prolonged use.

- Speed Settings: Some models offer adjustable speed settings, allowing for greater control based on the material being cut.

- Additional Features: Note any special functionalities, such as integrated lights, dust blowers, or blade guides, that enhance user experience.

By examining these factors, users can identify which model aligns best with their specific needs, whether for professional applications or DIY projects. Each version is designed with particular functionalities, making it crucial to assess them according to individual requirements.