Every intricate mechanical setup relies on a series of elements working in harmony to ensure smooth operation. The system in focus here has a variety of critical parts, each playing a unique role. Recognizing how these components interact is essential for anyone seeking to repair, maintain, or modify such machinery.

From the intricate inner mechanisms to the outer elements responsible for durability and performance, every detail contributes to the overall functionality. Gaining insight into these components can greatly improve one’s ability to troubleshoot and enhance the efficiency of the system.

Understanding the structure and placement of each component helps identify potential areas for improvement or maintenance. Whether you’re a seasoned expert or a beginner, learning about the layout and function of these parts can make a significant difference in managing mechanical projects.

Understanding the 727 Transmission Mechanism

At the heart of every vehicle’s movement lies a complex system designed to transfer power from the engine to the wheels. This intricate mechanism is responsible for ensuring that the vehicle moves smoothly through various speeds and conditions, making it an essential component of any automotive system.

Main Functional Components

The core elements of this power-transferring system include several key components that work in harmony. These elements control the flow of energy, allowing for efficient acceleration, deceleration, and maintaining steady speeds. Each element plays a vital role in adjusting power output based on the vehicle’s needs.

Operational Dynamics

The system operates through a series of carefully timed actions that respond to changes in the vehicle’s speed and load. As the engine’s output increases or decreases, the mechanism adjusts accordingly, optimizing performance for both high and low speeds. This seamless adjustment is what enables a smooth driving experience across different terrains.

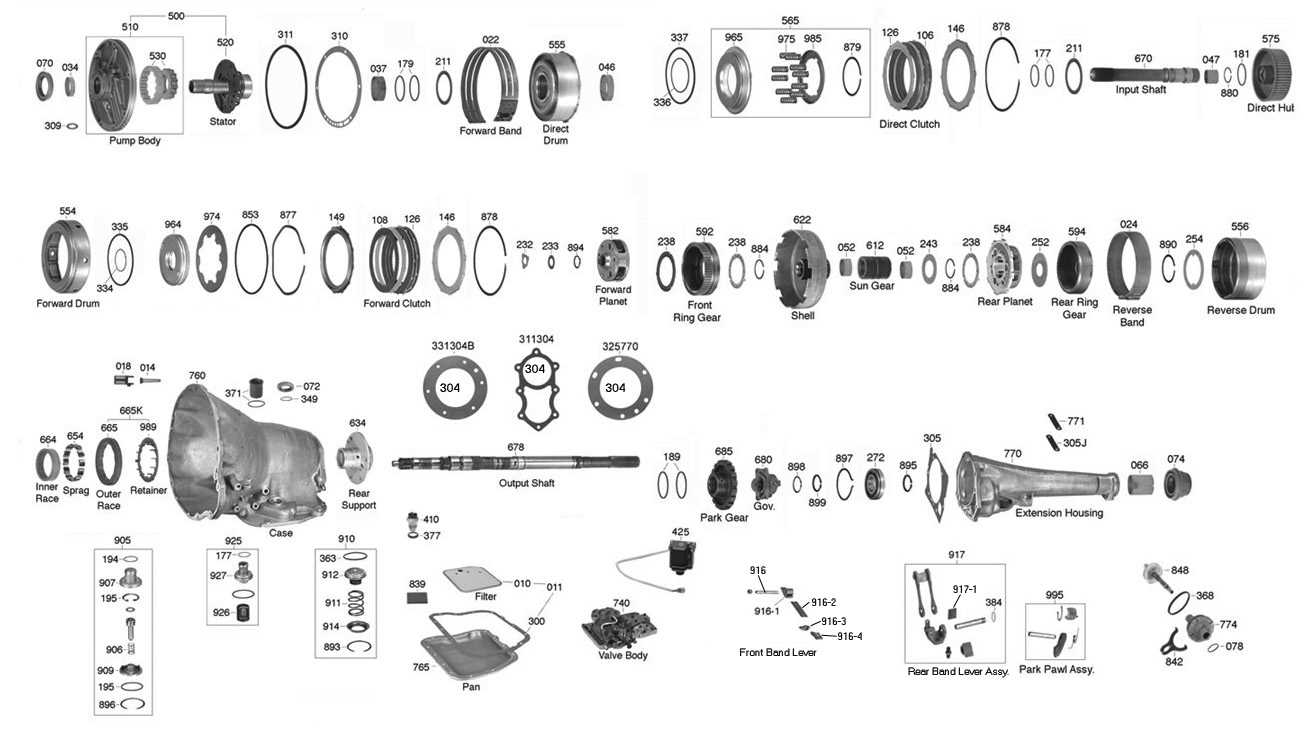

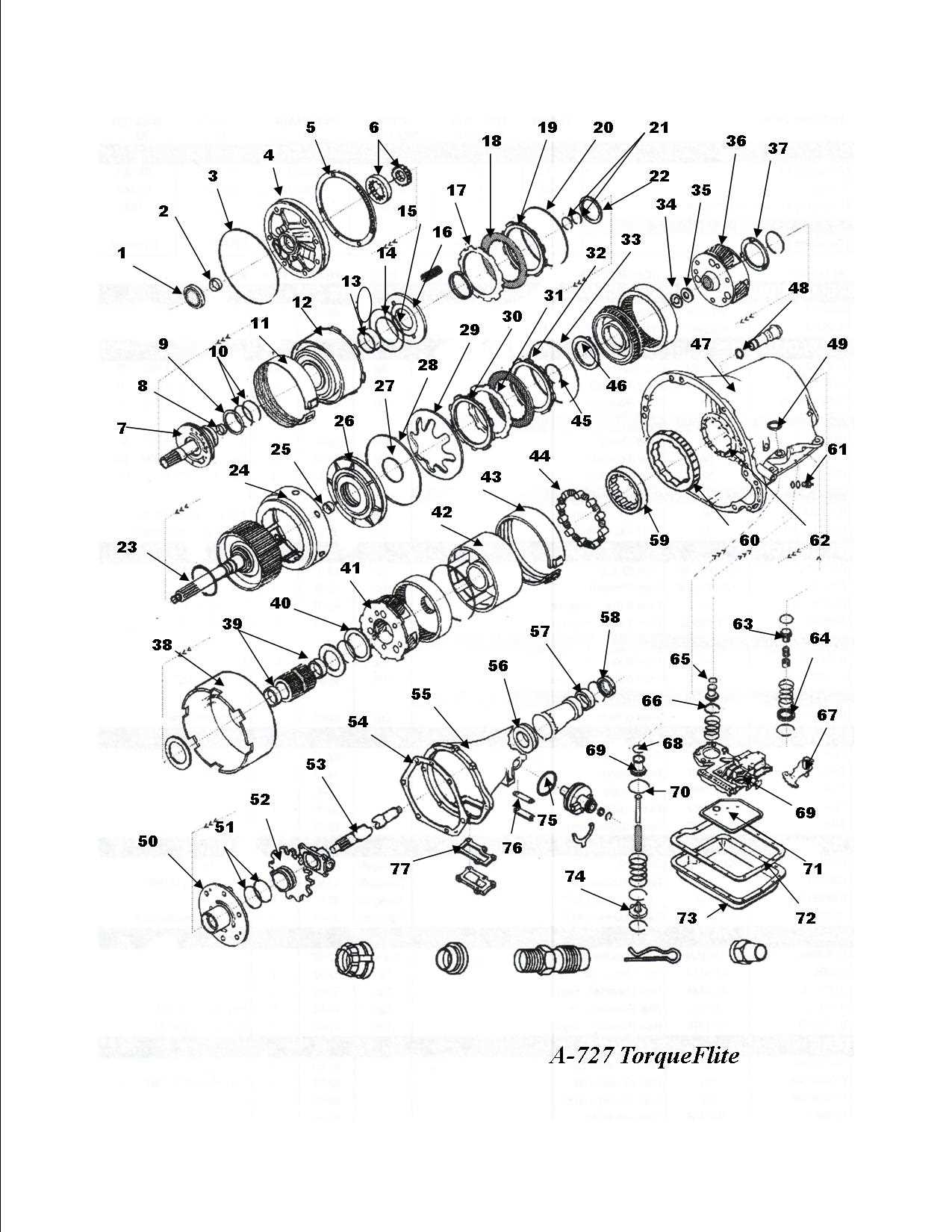

Main Components of the 727 Transmission

The system in question is built with a range of essential mechanisms that work together to ensure smooth operation and efficient power transfer. Each element is designed to perform specific functions, contributing to the overall performance of the unit.

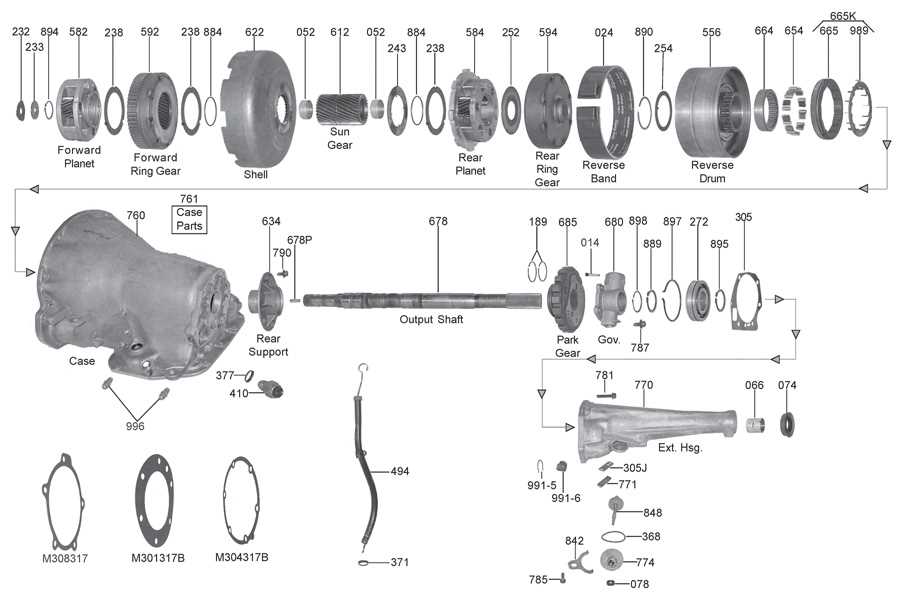

Torque converter plays a crucial role in managing the power between the engine and the unit. It allows the vehicle to remain stationary without stalling the engine while still maintaining proper power flow when accelerating.

The planetary gear set is another key feature, offering different gear ratios for varying speeds and driving conditions. It helps in controlling the power distribution for optimal vehicle performance.

Clutch assemblies and bands work together to engage and disengage gears. These elements are responsible for ensuring that shifts happen smoothly and efficiently, preventing jerks or delays during acceleration.

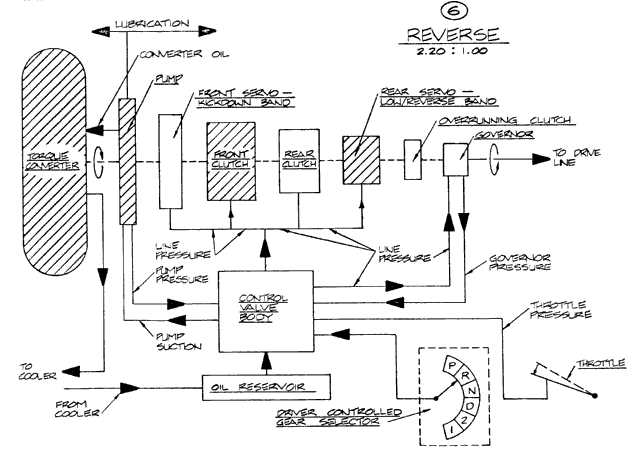

Finally, the valve body acts as the control center, regulating the flow of hydraulic fluid to the correct channels, determining when gears should shift based on the driving conditions.

How the Torque Converter Functions

The torque converter is a vital component in automatic systems, ensuring smooth transfer of energy between the engine and the drive system. Its purpose is to manage and optimize the distribution of power, allowing the vehicle to perform efficiently without manual intervention. This device plays a crucial role in maintaining fluid movement and ensuring that the engine remains engaged, even at lower speeds.

- Power transfer: The converter allows the engine’s power to be smoothly transferred to the rest of the drivetrain, especially when the vehicle is stationary or moving at lower speeds.

- Fluid dynamics: Inside the converter, a special fluid is used to transmit rotational force, reducing the need for direct mechanical connection between components.

- Flexibility: The converter enables smooth acceleration and deceleration by adjusting to the varying speed and load conditions of the vehicle.

This system ensures a balance between performance and energy efficiency, adapting to the vehicle’s speed and demand for power in real time.

Clutch Assembly in the 727 Transmission

The clutch mechanism plays a crucial role in regulating the connection between different components within an automatic gearbox. It ensures smooth transitions and efficient power delivery, contributing to the overall functionality of the vehicle. Proper engagement and release of this system are key to optimal performance.

Main Components of the Clutch System

This assembly consists of several elements that work in unison to control the flow of power. These include friction plates, steel plates, and a pressure plate. Each part is designed to withstand significant stress while maintaining smooth operation under varying conditions.

Clutch Operation

During operation, the clutch engages to transmit power and disengages to allow shifts. Hydraulic pressure facilitates this process, ensuring that power is either transferred smoothly or interrupted when necessary. Over time, these elements may wear down, requiring proper maintenance.

| Component | Function |

|---|---|

| Friction Plates | Transmit power by engaging with other parts |

| Steel Plates | Provide support and help dissipate heat |

| Pressure Plate | Applies force to engage the clutch |

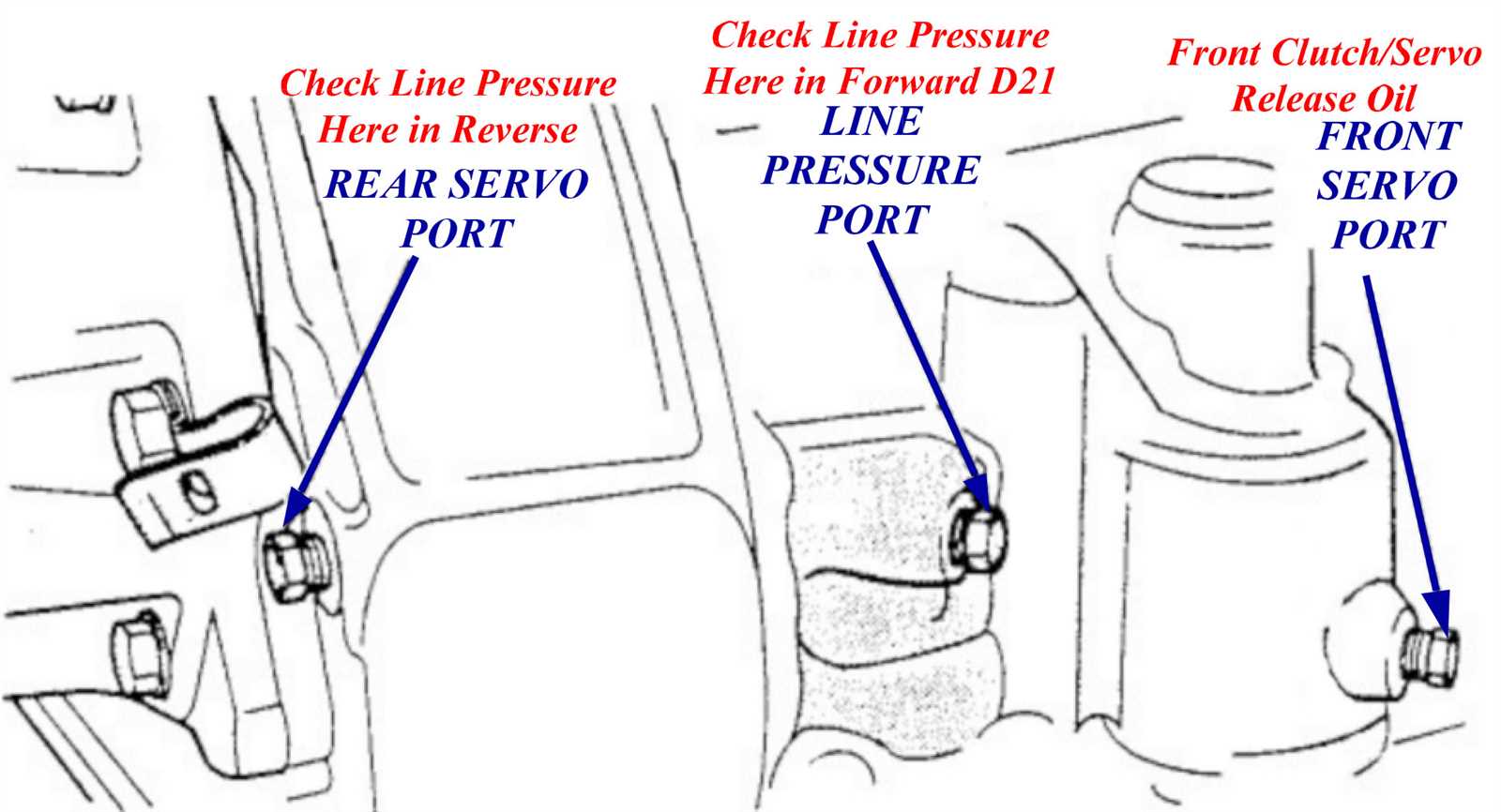

Valve Body: Role and Importance

The valve body serves as the central component that directs hydraulic fluid throughout the system. It ensures that the right flow and pressure are maintained to control various mechanisms within the unit. Without this intricate network of channels and valves, the system would fail to function effectively.

Importance of the valve body lies in its ability to manage the smooth operation of gear shifts and overall performance. By carefully regulating fluid movement, it plays a critical role in ensuring the seamless engagement of different mechanisms, which leads to optimal operation.

Planetary Gear Set Overview

The planetary gear assembly is a fundamental component within various mechanical systems, renowned for its efficiency and compact design. This innovative arrangement consists of multiple gears that work together to provide a range of gear ratios, enabling the desired torque and speed transformations.

Components of the Planetary Gear Assembly

At its core, this assembly typically includes a sun gear, planet gears, and a ring gear. The sun gear, located at the center, serves as the input, while the ring gear encircles the planet gears, which revolve around the sun gear. This unique configuration allows for smooth operation and effective load distribution.

Advantages of Planetary Gear Mechanisms

One of the primary benefits of using this type of gearing is its ability to transmit power in a compact form. The design allows for higher torque capacity while maintaining a smaller footprint compared to traditional gear systems. Additionally, the balanced nature of the assembly results in reduced vibrations and enhanced durability.

Band Adjustments for Optimal Performance

Proper calibration of the bands is crucial for achieving peak functionality in automatic gear systems. Adjustments play a significant role in ensuring smooth operation, enhancing shifting response, and prolonging the lifespan of the components. By fine-tuning these settings, one can achieve a balanced performance that meets the demands of various driving conditions.

| Adjustment Type | Description | Recommended Procedure |

|---|---|---|

| Initial Setup | Setting the initial tension for optimal engagement. | Loosen the adjustment bolt, apply tension, and retighten according to specifications. |

| Fine Tuning | Making minor adjustments to improve responsiveness. | Incrementally adjust the tension while testing performance on the road. |

| Regular Maintenance | Periodic checks to maintain ideal settings. | Inspect and adjust every few thousand miles to ensure consistent performance. |

The Role of the Governor in Shifting

The governor plays a crucial function in the process of gear changes, acting as a regulator that influences how smoothly and efficiently the shifting occurs. This component ensures that the vehicle operates optimally under varying driving conditions.

One of the primary responsibilities of the governor is to monitor the speed of the vehicle. It utilizes this information to adjust the timing of the shifts. Here are some key aspects of its operation:

- Speed Regulation: The governor assesses the vehicle’s speed and communicates necessary adjustments to facilitate appropriate gear selection.

- Shift Timing: By managing when shifts occur, it enhances the driving experience, promoting smoother transitions between gears.

- Load Adaptation: It adjusts shifts based on the load conditions, ensuring that performance is maintained even when carrying heavier weights.

Overall, the governor’s role is integral to maintaining performance and efficiency, contributing significantly to the overall functionality of the system.

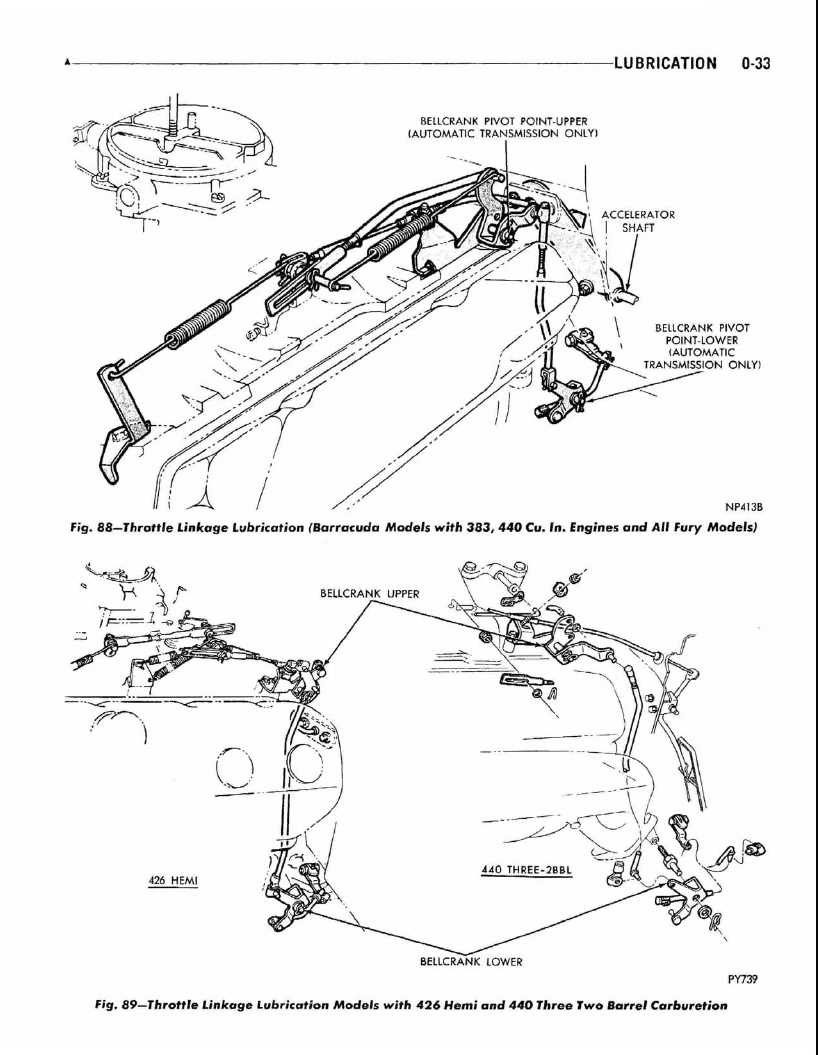

Kickdown Linkage and Its Adjustments

The kickdown linkage plays a crucial role in the functionality of automatic shifting systems. This mechanism allows for a swift downshift in response to increased throttle input, enhancing performance during acceleration. Proper adjustment of this component is essential to ensure optimal responsiveness and drivability.

Understanding the Kickdown Mechanism

The kickdown mechanism consists of various components that work together to facilitate smooth transitions between gears. Here are the key elements:

- Lever Assembly

- Connecting Rod

- Adjustable Link

- Throttle Position Sensor

Adjustment Process

To achieve the desired performance, the kickdown linkage must be adjusted accurately. Follow these steps:

- Locate the linkage assembly connected to the throttle.

- Check the clearance between the lever and the throttle arm.

- Loosen the adjustment nuts and reposition the linkage.

- Tighten the nuts and ensure everything is securely in place.

- Test the vehicle to confirm the adjustments enhance responsiveness.

Regular checks and adjustments can significantly improve the driving experience, providing better acceleration and smoother gear changes.

Signs of Wear in Transmission Seals

Identifying the signs of deterioration in sealing components is crucial for maintaining the overall efficiency of a vehicle’s system. These crucial elements prevent fluid leaks and ensure proper operation, and their failure can lead to serious issues. Understanding the common indicators of wear can help in taking timely actions to avoid extensive damage.

Fluid Leaks

One of the most noticeable signs of compromised seals is the presence of fluid leaks beneath the vehicle. When the seals begin to wear down, they may fail to contain the necessary fluids, leading to puddles or spots on the ground. Regularly inspecting for these leaks can save drivers from potential problems down the line.

Unusual Noise and Vibration

Another sign to watch for is the occurrence of unusual sounds or vibrations while operating the vehicle. When seals are worn, they may not perform optimally, causing components to grind against each other. This can lead to noticeable noise or vibration that was not present before, indicating that an inspection may be necessary.

Addressing these symptoms promptly can help maintain the integrity of the vehicle and prolong its lifespan.

Maintenance Tips for Long Transmission Life

Ensuring the longevity of your vehicle’s shifting system requires regular care and attention. By following a few simple practices, you can significantly enhance its durability and performance over time. Here are essential recommendations to keep in mind.

Regular Fluid Checks

Maintaining optimal fluid levels is crucial for the efficient operation of your vehicle’s components. Consider the following steps:

- Check the fluid level monthly to ensure it meets the recommended specifications.

- Look for any signs of leaks beneath the vehicle.

- Replace the fluid according to the manufacturer’s schedule to maintain performance.

Timely Servicing

Scheduled maintenance plays a vital role in prolonging the lifespan of your vehicle’s systems. Adhere to these practices:

- Follow the service intervals outlined in the owner’s manual.

- Seek professional inspections at least once a year.

- Address any unusual noises or performance issues immediately to prevent further damage.