In the realm of automotive engineering, a thorough comprehension of gearbox elements is essential for effective maintenance and repair. This section aims to provide insights into the intricate structure of these mechanisms, highlighting the various components that contribute to their functionality. By familiarizing oneself with these elements, one can enhance their ability to diagnose issues and ensure optimal performance.

The complexity of these assemblies can be daunting, yet a detailed breakdown reveals how each individual piece plays a critical role in the overall operation. Understanding the interrelation of these components is vital for anyone looking to engage with the intricacies of automatic shifting systems. From the crucial connections to the smaller, yet significant, elements, every part has its purpose in achieving seamless gear transitions.

Moreover, having a visual representation of these elements can significantly aid in grasping their arrangement and functionality. This visual aid not only simplifies the learning process but also serves as a reference point for mechanics and enthusiasts alike. In this discussion, we will explore the various segments that constitute the system, enabling a clearer perspective on how they collaborate to deliver smooth driving experiences.

Understanding 4L60E Transmission Basics

This section explores the fundamental concepts behind a widely used automatic shifting mechanism, focusing on its structure and functionality. By gaining insight into its components and operations, users can better appreciate how this system enhances vehicle performance and reliability.

Key Components

The essential elements of this shifting mechanism work together to ensure smooth operation. Understanding these components allows for more effective maintenance and troubleshooting.

| Component | Function |

|---|---|

| Clutch Packs | Engage and disengage gears for shifting |

| Valve Body | Directs hydraulic fluid to control gear selection |

| Planetary Gear Set | Provides different gear ratios for speed and torque |

| Torque Converter | Facilitates smooth acceleration by transferring power |

Operational Principles

The operation of this mechanism relies on hydraulic pressure to engage various elements, allowing for efficient gear changes. By understanding the dynamics of these processes, users can better troubleshoot and optimize their systems.

Key Components of 4L60E Assembly

This section explores the essential elements that contribute to the functionality of a particular automotive gearbox. Understanding these critical components helps in grasping how they work together to ensure smooth operation and reliability.

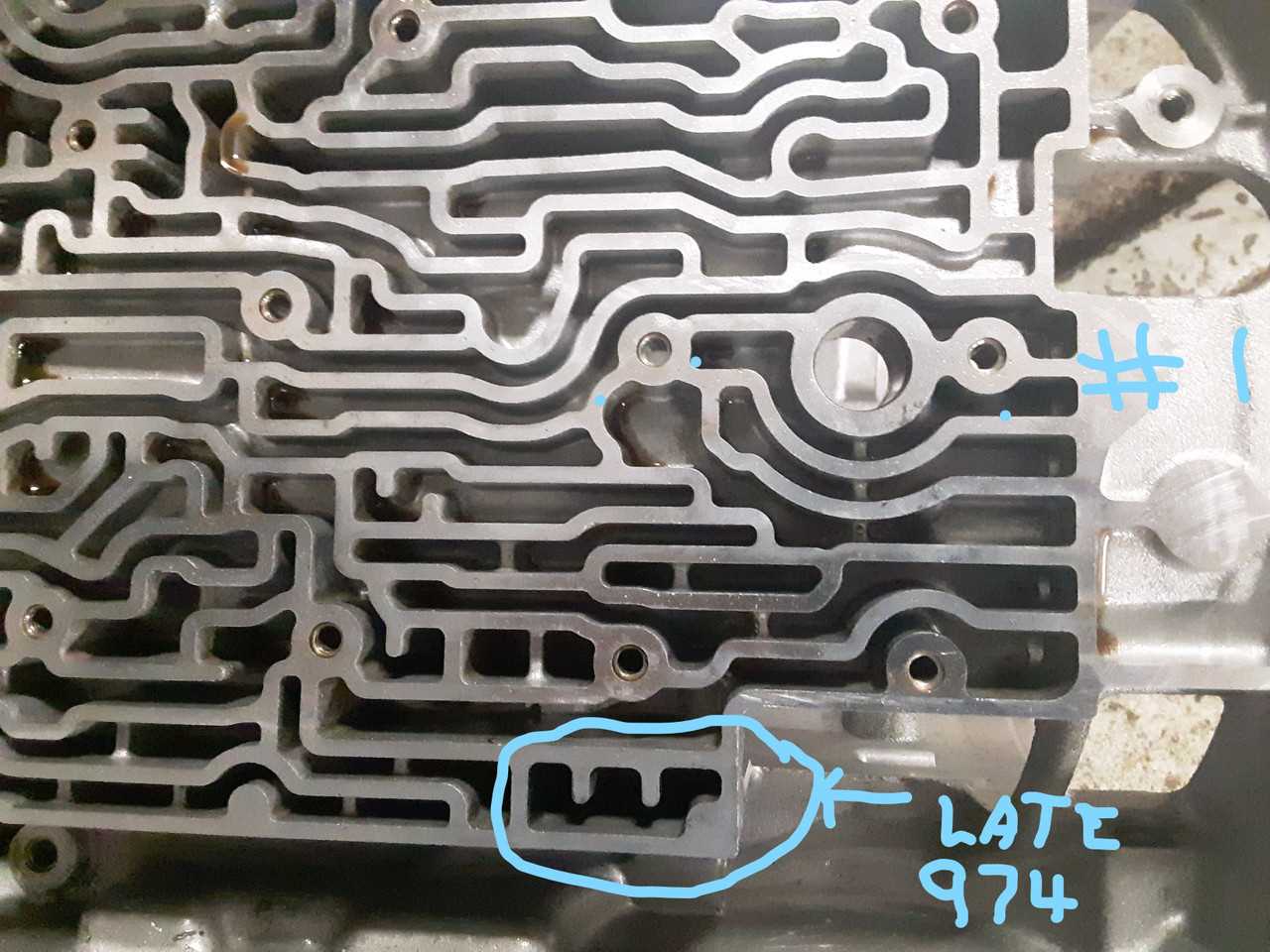

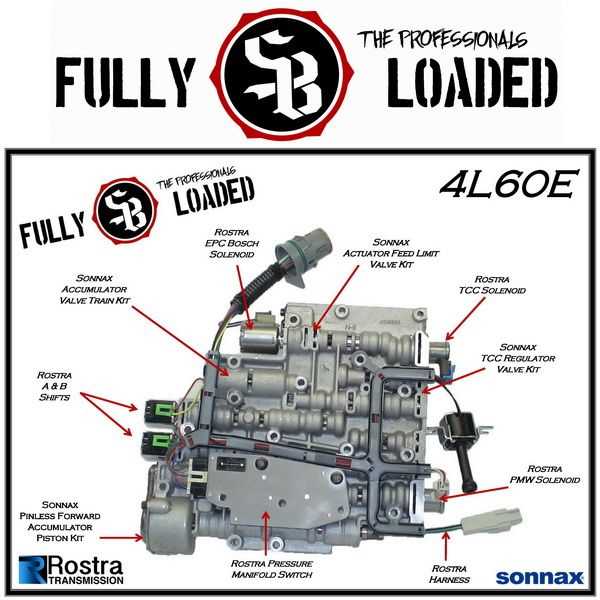

Valve Body: This component is crucial as it controls the flow of hydraulic fluid, directing it to various parts of the system based on the driver’s input and conditions.

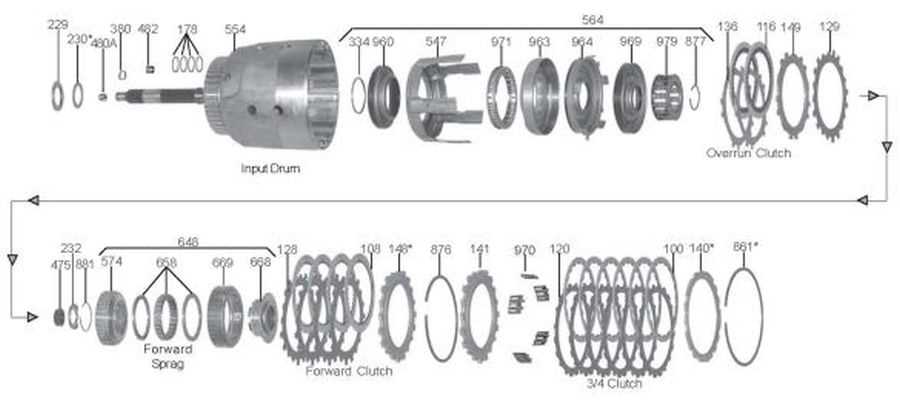

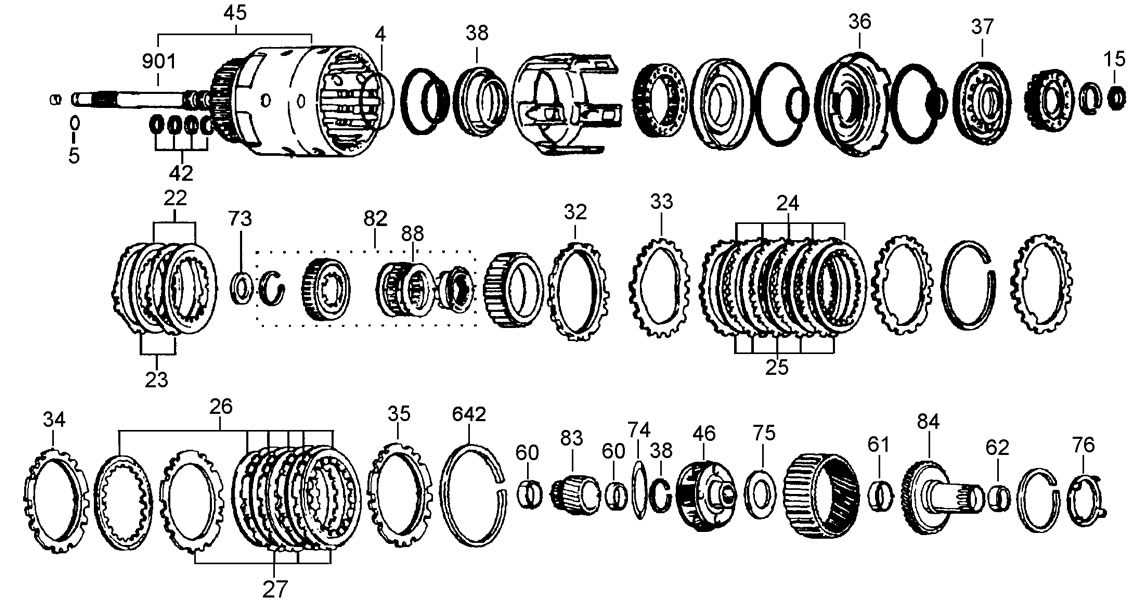

Clutch Packs: These are responsible for engaging and disengaging gears, allowing for smooth transitions during shifting. They utilize friction materials to achieve the necessary grip.

Planetary Gear Set: This assembly consists of multiple gears that work in harmony to provide different gear ratios, significantly impacting acceleration and speed.

Torque Converter: This component transfers power from the engine to the gearbox, allowing for smooth starts and efficient performance under varying loads.

Governor: This device regulates fluid pressure based on vehicle speed, ensuring optimal shifting performance as the vehicle accelerates or decelerates.

Understanding these key elements provides a comprehensive insight into the intricate workings of this type of gearbox, emphasizing the importance of each component in overall performance.

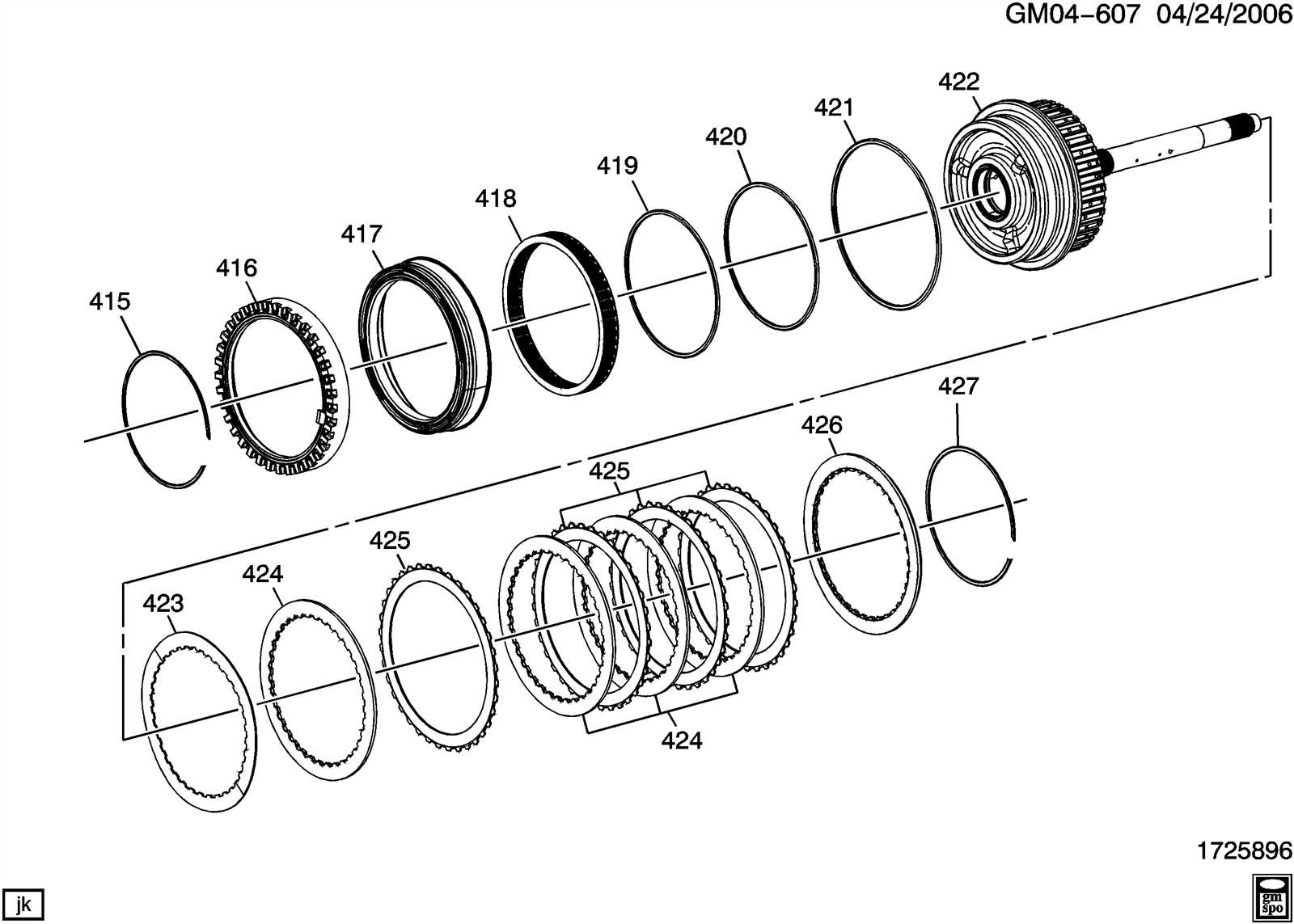

Transmission Parts Diagram Overview

This section provides a comprehensive look at the various components within a specific automotive system, highlighting their roles and interactions. Understanding these elements is essential for effective maintenance and repair, ensuring optimal performance.

Key Components

The essential elements include gears, clutches, and valves, each contributing to the overall functionality. Gears facilitate power transfer, while clutches enable smooth engagement and disengagement. Valves regulate fluid flow, ensuring that the system operates efficiently.

Visual Representation

A visual representation aids in identifying each component’s location and function. By examining these visuals, one can better appreciate the intricate design and how each part works together to achieve seamless operation.

Importance of Proper Assembly Techniques

Accurate assembly methods play a critical role in ensuring the longevity and efficiency of mechanical systems. Proper techniques help in minimizing wear and tear, enhancing performance, and reducing the likelihood of future repairs. When components are put together with precision, the overall functionality is greatly improved, leading to smoother operations and better reliability.

Benefits of Accurate Techniques

Utilizing correct methods during the integration of components provides several advantages. It ensures that each piece interacts smoothly, preventing friction and unnecessary strain. This not only extends the lifespan of the system but also optimizes performance.

Common Mistakes to Avoid

Many issues arise from improper methods, such as misalignment or inadequate fastening. These mistakes can lead to significant failures, causing costly repairs and downtime. Being aware of potential pitfalls is essential for maintaining system integrity.

| Common Mistakes | Consequences |

|---|---|

| Misalignment | Poor performance and increased wear |

| Inadequate Fastening | Loosening and potential failure |

| Ignoring Specifications | Improper fit and function |

Common Issues with 4L60E Assemblies

When dealing with automatic gear systems, several recurring problems can arise, affecting performance and reliability. Understanding these issues can help in maintaining efficiency and prolonging the lifespan of the unit.

Frequent Problems

- Overheating: Excessive heat can lead to component failure, often caused by low fluid levels or clogged coolers.

- Slipping Gears: This may occur due to worn clutches or low hydraulic pressure, resulting in difficulty shifting.

- Fluid Leaks: Commonly found around seals and gaskets, leaks can compromise system integrity and lead to performance issues.

- Erratic Shifting: Inconsistent gear changes might indicate issues with sensors or solenoids.

Prevention Tips

- Regularly check and maintain fluid levels.

- Inspect seals and gaskets for signs of wear.

- Consider routine system flushes to remove debris.

- Monitor temperature closely to avoid overheating.

Tools Needed for Assembly Process

When embarking on the task of reassembling complex mechanical systems, having the right instruments at hand is essential for efficiency and accuracy. Proper tools not only streamline the process but also ensure that each component is correctly fitted and functioning optimally.

Essential Tools

- Torque wrench

- Socket set

- Ratchet and extensions

- Flathead and Phillips screwdrivers

- Pliers and wire cutters

- Gasket scraper

Additional Accessories

- Magnetic tray for small parts

- Oil and grease for lubrication

- Cleaning supplies such as rags and solvent

- Measuring tools for precision

- Safety gear, including gloves and goggles

Step-by-Step Assembly Instructions

This section provides detailed guidance on how to correctly piece together the components of an automatic gear system. Following these instructions will help ensure optimal functionality and performance of the entire mechanism.

Preparation and Tools

Before starting, gather all necessary tools, including a torque wrench, socket set, and screwdrivers. Make sure you have a clean workspace to avoid any contamination of the elements.

Assembly Process

Begin by aligning the main casing and securing it with bolts. Ensure each component fits snugly, as any gaps can lead to malfunction. Carefully install the internal mechanisms, following the sequence outlined in your reference materials. Double-check each connection before tightening to prevent any future issues.

Tips for Troubleshooting Problems

When dealing with automotive systems, identifying issues can be a challenging yet essential task. Understanding common signs and symptoms can help in diagnosing underlying problems effectively.

Common Symptoms

Look for indicators such as unusual noises, fluid leaks, or changes in performance. Recognizing these signs early can save time and effort during the troubleshooting process.

Diagnostic Steps

Follow a systematic approach to isolate issues. Start with visual inspections, then proceed to functional tests. This structured method ensures no detail is overlooked.

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| Unusual noises | Worn components | Inspect and replace affected parts |

| Fluid leaks | Damaged seals | Identify leak source and repair |

| Poor performance | Contaminated fluid | Flush and refill with fresh fluid |

Maintenance Practices for Longevity

Ensuring the durability and efficient performance of automotive systems requires consistent upkeep and attention. Regular maintenance not only enhances functionality but also extends the lifespan of components, reducing the need for costly repairs and replacements.

Regular Fluid Checks

Monitoring fluid levels is crucial for optimal operation. Regularly checking and replacing fluids can prevent damage and maintain performance.

- Check for leaks frequently.

- Replace old fluid with high-quality alternatives.

- Follow manufacturer guidelines for fluid change intervals.

Component Inspection

Routine inspection of individual elements can help identify potential issues before they escalate. Paying attention to wear and tear can save time and resources.

- Inspect seals and gaskets for deterioration.

- Examine mechanical components for signs of wear.

- Ensure connections and fasteners are secure.

By adhering to these practices, one can significantly enhance the longevity and reliability of their automotive systems.

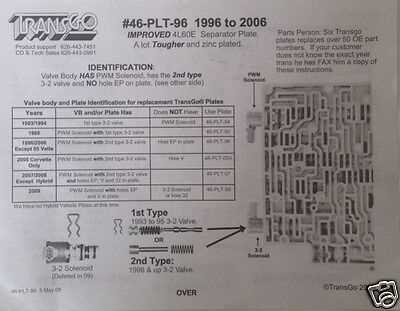

Performance Upgrades for 4L60E

Enhancing the efficiency and capability of your automatic gearbox can significantly improve your vehicle’s overall performance. With various modifications available, you can tailor the unit to better handle increased power levels and improve shift responsiveness. This section delves into several popular upgrades that can transform your driving experience.

High-Performance Torque Converter

Upgrading to a high-performance torque converter can greatly enhance the vehicle’s acceleration and responsiveness. These converters are designed to provide better lock-up characteristics and stall speeds, allowing for optimal power transfer during acceleration.

Improved Valve Body Kit

Installing an upgraded valve body kit can improve shift quality and speed. These kits typically feature enhanced fluid pathways and upgraded components that allow for quicker and firmer shifts, resulting in a more engaging driving experience.

Consider these upgrades to maximize the potential of your gearbox and enjoy a significant boost in performance and reliability.

Understanding Gear Ratios

Gear ratios play a crucial role in the performance and efficiency of various mechanical systems. They determine how rotational speed and torque are transferred between different components, influencing how effectively a machine operates under various conditions.

A gear ratio is defined as the relationship between the number of teeth on two meshing gears. This ratio affects the output speed and torque of the system. For instance, a higher ratio means more torque is delivered to the wheels, which is beneficial for acceleration, while a lower ratio allows for higher speeds, making it suitable for cruising.

Understanding these ratios is essential for optimizing performance in vehicles. The right balance ensures that a vehicle can accelerate quickly when needed while maintaining efficiency during steady-state driving. Choosing the appropriate gear ratio can significantly impact fuel economy and overall driving experience.

Identifying Transmission Failure Symptoms

Recognizing the signs of a malfunctioning gear system is crucial for timely maintenance and repairs. Various symptoms can indicate underlying issues, affecting vehicle performance and safety. Understanding these warning signs can help prevent further damage and costly repairs.

Some common indicators of gear system failure include unusual noises, difficulty shifting gears, or unexpected slipping while driving. Additionally, a dashboard warning light may illuminate, signaling the need for immediate attention. Below is a summary of these symptoms:

| Symptom | Description |

|---|---|

| Unusual Noises | Grinding, whining, or clunking sounds when shifting. |

| Difficulty Shifting | Struggles to change gears or delays in response. |

| Slipping Gears | Unexpected loss of power or sudden changes in gear. |

| Warning Light | Illumination of a warning light on the dashboard. |

Being attentive to these signs and addressing them promptly can enhance the longevity of the vehicle’s system and ensure smoother operation.

Comparing 4L60E to Other Transmissions

This section explores the characteristics and performance of a widely used automatic gear system in relation to its counterparts. By analyzing various features, we can better understand the strengths and weaknesses of each design.

Key aspects to consider include:

- Durability: Some systems are built to withstand higher torque and demanding conditions.

- Weight: The overall weight can affect performance and efficiency.

- Gear Ratios: Different configurations can lead to varied acceleration and fuel economy.

When comparing systems, it is essential to evaluate:

- Performance in diverse environments.

- Maintenance requirements and ease of service.

- Cost-effectiveness over time.

Ultimately, selecting the right option depends on specific needs, whether for daily driving, towing, or performance enhancements.