In the world of construction and heavy machinery, the intricate design of equipment plays a vital role in ensuring efficiency and reliability. Each element within these complex machines contributes to their overall functionality, making it essential to grasp how they interact and support one another.

As we delve into the intricacies of these components, it becomes evident that a comprehensive understanding of their arrangement and purpose is crucial. By exploring the specific roles and connections among various sections, we can enhance our operational knowledge and troubleshoot issues more effectively.

Ultimately, a detailed examination of these elements will provide insights into the maintenance and optimization of machinery, empowering operators and engineers alike. This exploration not only facilitates smoother operations but also contributes to the longevity and performance of the equipment.

Understanding Paver Parts

This section aims to explore the various components that contribute to the functionality and efficiency of outdoor surface installation. By examining each element, we can appreciate how they work together to create a durable and aesthetically pleasing environment.

Key Components

Each element plays a crucial role in ensuring stability and performance. Familiarity with these components can enhance both maintenance and overall effectiveness.

| Component | Function |

|---|---|

| Base Layer | Provides stability and drainage. |

| Surface Material | Offers durability and aesthetic appeal. |

| Edging | Prevents shifting and maintains alignment. |

| Joint Fillers | Helps to prevent weed growth and stabilize joints. |

Importance of Each Element

Understanding the significance of each element allows for better decision-making during installation and maintenance. It ensures that the outdoor area remains functional and visually appealing over time.

Components of a Paver Machine

This section explores the essential elements that contribute to the functionality and efficiency of a paving machine. Understanding these components is crucial for optimizing performance and maintenance.

- Chassis: The foundational framework that supports all other elements.

- Engine: Provides the necessary power for operation, often a diesel unit.

- Conveyor System: Facilitates the movement of material to the application area.

- Auger: Ensures even distribution of the material across the surface.

- Screening Unit: Prepares and refines the material before application.

- Compaction Mechanism: Compresses the material to achieve desired density and stability.

Each component plays a vital role in ensuring that the machine operates smoothly and delivers high-quality results in construction projects.

Functions of Each Paver Part

Understanding the roles of various components in a paving machine is essential for optimal operation and maintenance. Each element plays a distinct role that contributes to the overall functionality and efficiency of the equipment. By grasping these functions, operators can ensure better performance and longevity of the machinery.

The screed is responsible for leveling and compacting the material, creating a smooth surface for the final product. Its ability to adjust thickness and width directly influences the quality of the pavement laid down. The hopper, on the other hand, serves as the receptacle for the raw material, feeding it into the machine at a controlled rate to maintain a steady workflow.

Another critical component is the conveyor system, which transports the mixture from the hopper to the screed. It ensures an even distribution and minimizes the risk of material segregation. Additionally, the auger plays a vital role in moving the material laterally, allowing for precise control of the flow into the screed area.

Finally, the engine provides the necessary power for all operations, influencing the speed and efficiency of the entire process. Each element must work in harmony to achieve the desired outcome, highlighting the importance of understanding their individual functions.

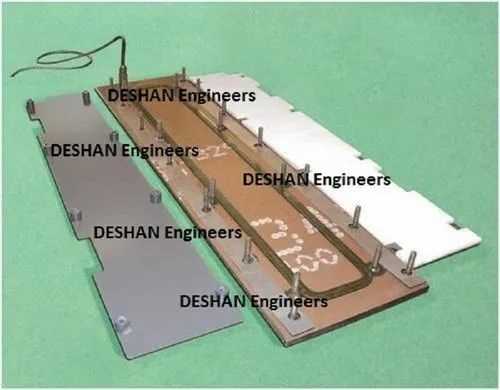

Diagram Overview and Significance

This section explores the importance of visual representations in understanding complex machinery components. Such illustrations serve as vital tools for both education and maintenance, allowing users to grasp relationships between various elements effectively.

Clear depictions enhance communication among technicians, enabling precise troubleshooting and efficient repairs. By breaking down intricate systems into comprehensible visuals, one can identify key functions and interconnections.

| Aspect | Importance |

|---|---|

| Clarity | Facilitates better understanding of component functions |

| Efficiency | Speeds up diagnostic and repair processes |

| Training | Serves as an educational tool for new technicians |

Common Issues with Paver Parts

In the realm of outdoor surfaces, various components can encounter problems that affect their functionality and longevity. Recognizing these challenges is essential for maintenance and repair, ensuring that the overall structure remains safe and aesthetically pleasing.

Several typical complications can arise:

- Cracking: Weather changes and heavy loads can lead to fractures, compromising integrity.

- Discoloration: Exposure to sunlight and chemicals can result in fading and uneven coloration.

- Joint Erosion: Over time, the material between segments may wear away, leading to instability.

- Settling: Improper installation or shifting ground can cause sections to become uneven.

- Weed Growth: Gaps can allow for vegetation to sprout, detracting from visual appeal.

Addressing these issues promptly can prevent further damage and enhance the overall performance of the outdoor surface.

To mitigate these concerns, consider the following strategies:

- Regular inspections to identify signs of wear.

- Using sealants to protect against moisture and stains.

- Implementing proper drainage solutions to reduce settling.

- Maintaining vegetation around the installation to minimize weed growth.

- Reinforcing joints with appropriate materials for added stability.

By proactively managing these common complications, one can ensure a durable and visually appealing outdoor surface for years to come.

Maintenance Tips for Paver Equipment

Proper upkeep of construction machinery is essential for ensuring longevity and optimal performance. Regular maintenance not only minimizes downtime but also enhances safety and efficiency during operations. Here are some key recommendations to keep your equipment running smoothly.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Inspect Hydraulic System | Weekly | Check for leaks and ensure fluid levels are adequate. |

| Clean the Engine | Monthly | Remove debris and dirt from the engine area to prevent overheating. |

| Check Tires | Weekly | Inspect for proper inflation and signs of wear or damage. |

| Lubricate Moving Parts | Biweekly | Apply grease to joints and pivot points to reduce friction. |

| Inspect Electrical Components | Monthly | Examine wiring and connections for signs of corrosion or wear. |

Implementing these maintenance practices can significantly extend the lifespan of your machinery and improve overall productivity. Regular attention to these tasks helps avoid costly repairs and ensures safe operation on the job site.

Identifying Parts in the Diagram

Understanding the components of machinery is essential for effective operation and maintenance. Each element serves a specific function, and recognizing them can greatly enhance troubleshooting and repair efforts. This section focuses on the various segments illustrated in the schematic, providing clarity and insight into their roles.

Key Components Overview

The schematic typically highlights several crucial elements, including the engine assembly, drive mechanisms, and control systems. Familiarizing oneself with these sections allows for better comprehension of the overall functionality. Each component interacts with others, contributing to the seamless operation of the equipment.

Visual Cues and Labels

Diagrams often incorporate visual markers and annotations to simplify identification. Look for distinctive shapes and labels that provide immediate recognition of each section. This visual language aids operators and technicians in quickly locating and addressing specific areas during inspections and repairs.

Replacement Parts: What to Know

Understanding the essentials of components that require replacement is crucial for maintaining the efficiency and longevity of your machinery. Over time, wear and tear can lead to diminished performance, making it necessary to know when and how to replace specific elements to ensure optimal functionality.

Identifying the Need for Replacement

It’s important to recognize the signs indicating that a component may need to be swapped out. Common indicators include unusual noises, decreased performance, or visible wear. Regular inspections can help in spotting these issues early, preventing more extensive damage and costly repairs.

Choosing Quality Alternatives

When it comes to sourcing new elements, prioritizing quality over price is vital. Look for reputable suppliers that offer reliable options. Genuine replacements are often more dependable, while aftermarket choices can provide a cost-effective solution if thoroughly researched. Always consider warranty and support options before making a purchase.

Best Practices for Paver Operation

Efficient and effective functioning of construction machinery is crucial for achieving optimal results in road and surface laying. Adopting best practices ensures not only the longevity of the equipment but also enhances the quality of the finished work. This section explores essential guidelines that operators should follow to maximize performance and maintain safety standards.

Regular Maintenance

Consistent upkeep is vital for any machinery. Operators should implement a routine inspection schedule to check for wear and tear, fluid levels, and potential mechanical issues. Timely repairs prevent unexpected breakdowns and maintain operational efficiency. Always refer to the manufacturer’s manual for specific maintenance requirements and adhere to recommended service intervals.

Operator Training

Investing in proper training for operators significantly improves performance and safety. Skilled individuals are more likely to understand the intricacies of the equipment and how to respond to varying site conditions. Hands-on experience, coupled with theoretical knowledge, enhances decision-making capabilities, ultimately leading to better outcomes in projects.

Impact of Quality Parts on Performance

The significance of utilizing high-quality components in machinery cannot be overstated. Superior materials not only enhance the overall efficiency but also contribute to longevity and reliability. Understanding this relationship is crucial for anyone looking to optimize their equipment’s functionality.

Key Benefits of Using Quality Components

- Enhanced Efficiency: Quality elements work seamlessly together, reducing friction and energy loss.

- Increased Durability: High-grade materials resist wear and tear, extending the lifespan of machinery.

- Improved Safety: Reliable components minimize the risk of failures that can lead to accidents.

Long-Term Cost Savings

Investing in superior components may appear costlier initially, but the long-term advantages include:

- Fewer replacements and repairs.

- Lower operational costs due to increased efficiency.

- Reduced downtime, allowing for consistent productivity.

Comparing Different Paver Models

When selecting machinery for road construction, understanding the nuances between various models is essential. Each design offers unique features tailored to specific tasks and conditions, influencing efficiency and performance.

Key factors to consider when comparing models include:

- Engine Performance: Assess the power output and fuel efficiency.

- Weight Distribution: Consider how the weight impacts stability and maneuverability.

- Heating Systems: Evaluate the effectiveness of the heating mechanism for materials.

- Control Mechanisms: Look at user-friendliness and precision of the controls.

- Maintenance Requirements: Analyze how easy it is to service and maintain each unit.

In addition to these factors, evaluating user feedback and expert reviews can provide insights into real-world performance. It’s advisable to create a comparison chart that highlights the strengths and weaknesses of each model, aiding in informed decision-making.

- Gather specifications for each model.

- Identify the primary use case for your needs.

- Rank each option based on the factors outlined above.

- Consult with industry professionals for additional perspectives.

Ultimately, a thorough comparison ensures that the chosen machinery meets project demands effectively, balancing both performance and cost considerations.

Technological Advances in Paver Design

Recent innovations in construction technology have transformed the landscape of design and functionality in surface laying equipment. These advancements focus on enhancing efficiency, durability, and user experience while maintaining environmental sustainability.

Enhanced Automation: The integration of automated systems has revolutionized how these machines operate, allowing for precise control and reduced labor costs. Automated functions streamline the laying process, ensuring consistency and high-quality results.

Advanced Materials: The use of innovative materials has improved the longevity and resilience of surfaces. High-performance composites and recycled materials not only provide superior strength but also contribute to eco-friendly practices in the industry.

Smart Technology: The incorporation of IoT and smart sensors has enabled real-time monitoring and data analysis, leading to informed decision-making and maintenance. This technology helps in optimizing performance and reducing downtime.

Ultimately, these technological strides not only enhance productivity but also pave the way for future developments, ensuring that construction methods evolve in alignment with modern demands and environmental considerations.

Safety Considerations When Using Pavers

When working with paving materials, it is essential to prioritize safety to prevent accidents and injuries. Proper planning, awareness, and the use of appropriate protective equipment can significantly reduce risks associated with installation and maintenance activities.

Personal Protective Equipment (PPE)

- Always wear safety goggles to protect your eyes from dust and debris.

- Use gloves to prevent cuts and abrasions from sharp edges.

- Wear sturdy footwear with good grip to avoid slips and falls.

- Consider a hard hat when working in areas with overhead hazards.

Site Preparation and Maintenance

- Ensure the work area is clear of obstacles to allow for safe movement.

- Check for underground utilities before digging to avoid accidents.

- Keep tools and materials organized to minimize trip hazards.

- Regularly inspect equipment to ensure it is in good working condition.

By adhering to these safety guidelines, individuals can create a secure environment while working with various types of flooring materials, ensuring a smooth and efficient process.