In the world of heavy machinery, a comprehensive grasp of individual elements is crucial for optimal performance and maintenance. These components work together to ensure efficiency and longevity, making it imperative for operators and enthusiasts alike to familiarize themselves with their arrangement and functionality.

Visual aids play a significant role in this learning process, providing clarity on how each segment interconnects. An insightful representation can enhance one’s understanding, revealing not only the structure but also the dynamics involved in operation.

By delving into the intricacies of these mechanisms, users can effectively troubleshoot issues, plan for replacements, and enhance overall productivity. Ultimately, having access to a detailed visual reference empowers users to make informed decisions regarding their machinery.

Understanding the Ford 1500 Tractor

This section aims to explore the essential components and functionalities of a renowned agricultural machine. By examining its structure, users can gain insights into its operation and maintenance, ensuring optimal performance in various tasks.

| Component | Description |

|---|---|

| Engine | Provides the necessary power for various agricultural activities. |

| Transmission | Facilitates the transfer of power from the engine to the wheels. |

| Hydraulics | Enables lifting and operating attachments with ease. |

| Chassis | Forms the main structure, supporting all components and providing stability. |

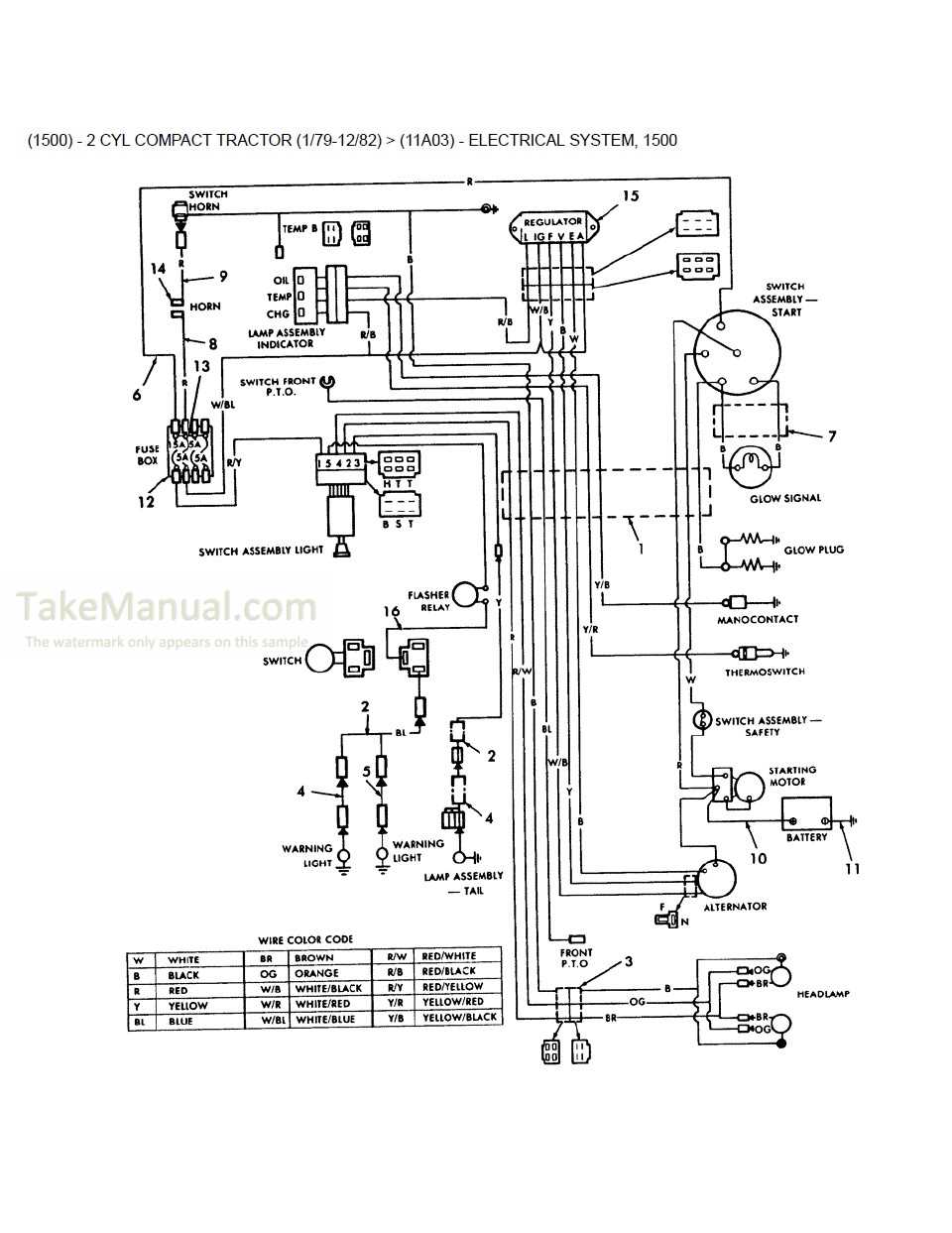

| Electrical System | Powers lighting, starting, and other electronic features. |

Key Components of the Ford 1500

Understanding the essential elements of this machinery is crucial for optimal performance and maintenance. Each component plays a significant role in ensuring smooth operation and longevity.

Engine: The heart of the machine, providing the necessary power to perform various tasks. Its efficiency directly impacts overall functionality.

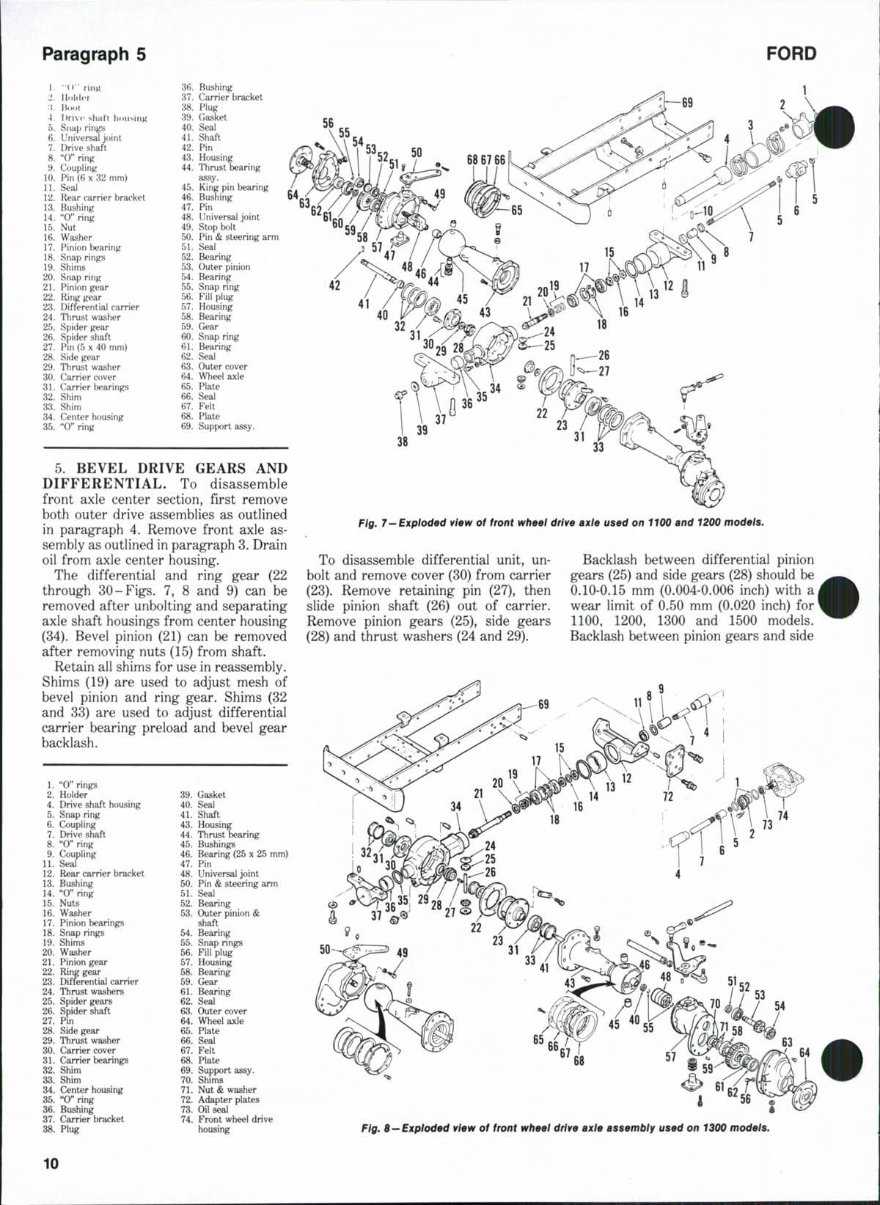

Transmission: This system facilitates the transfer of power from the engine to the wheels, allowing for effective movement across diverse terrains.

Hydraulic System: Vital for controlling attachments and implements, this system enhances versatility, enabling a range of applications from lifting to digging.

Chassis: The framework that supports all other components, ensuring stability and structural integrity during operation.

Electrical System: Responsible for powering lights, ignition, and other essential functions, this system is crucial for the seamless operation of the machinery.

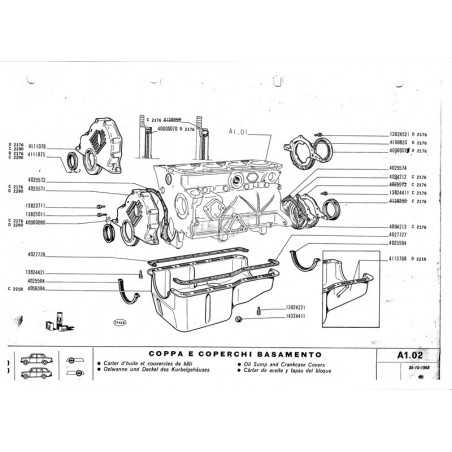

Importance of a Parts Diagram

Understanding the intricate components of machinery is crucial for effective maintenance and repairs. A visual representation serves as a valuable resource, enabling users to identify and locate essential elements efficiently. This aids not only in troubleshooting but also in ensuring that every piece functions harmoniously within the larger system.

Enhanced Efficiency

Utilizing a visual guide can significantly streamline the repair process. By providing clear illustrations, it minimizes the chances of errors and reduces the time spent searching for specific items, ultimately leading to faster and more accurate work.

Facilitating Learning

For those new to machinery, a visual reference enhances comprehension. It allows individuals to delve deeper into understanding how various components interact, fostering a greater appreciation for mechanical systems and improving overall skill levels.

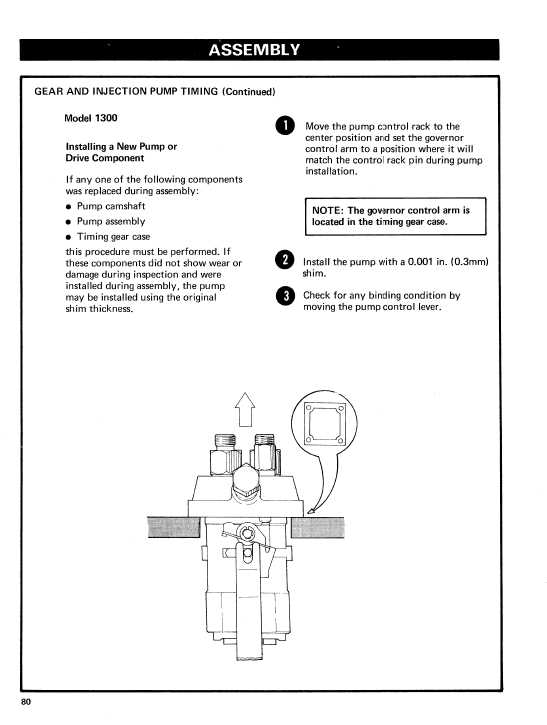

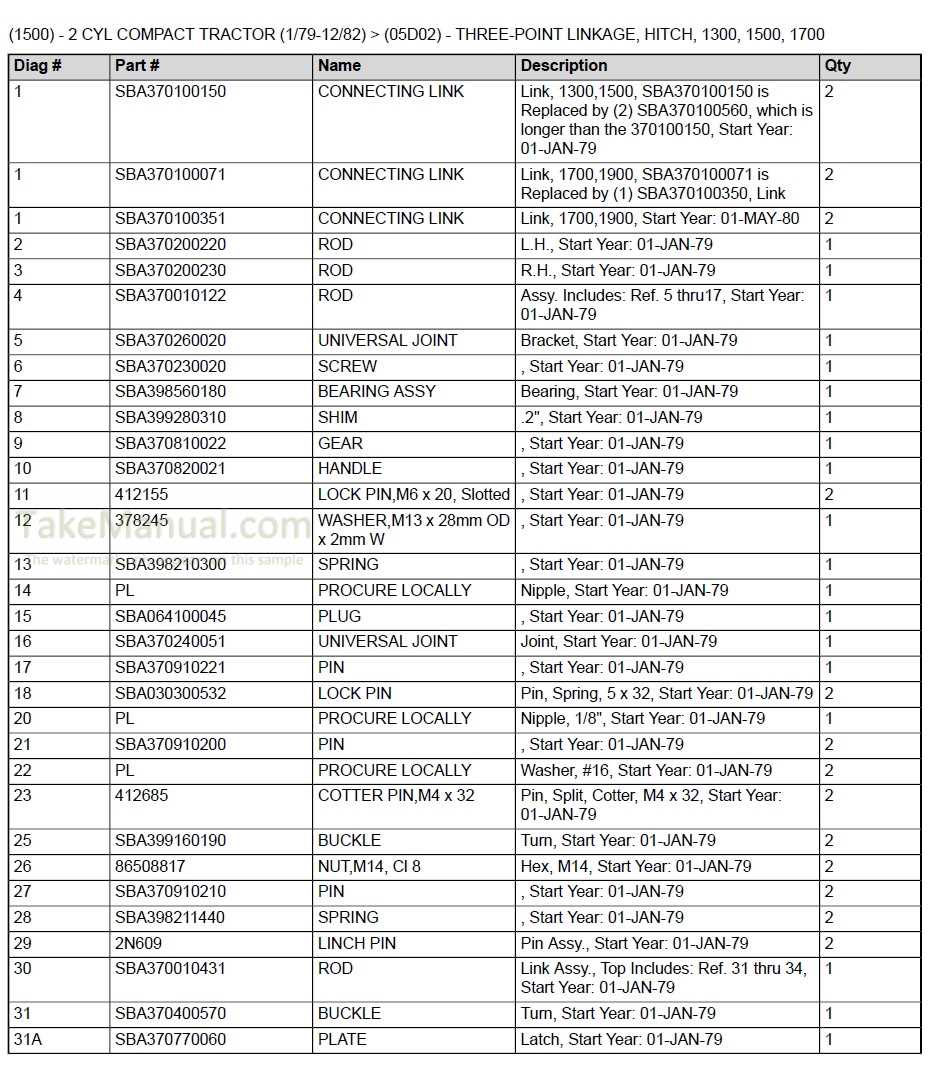

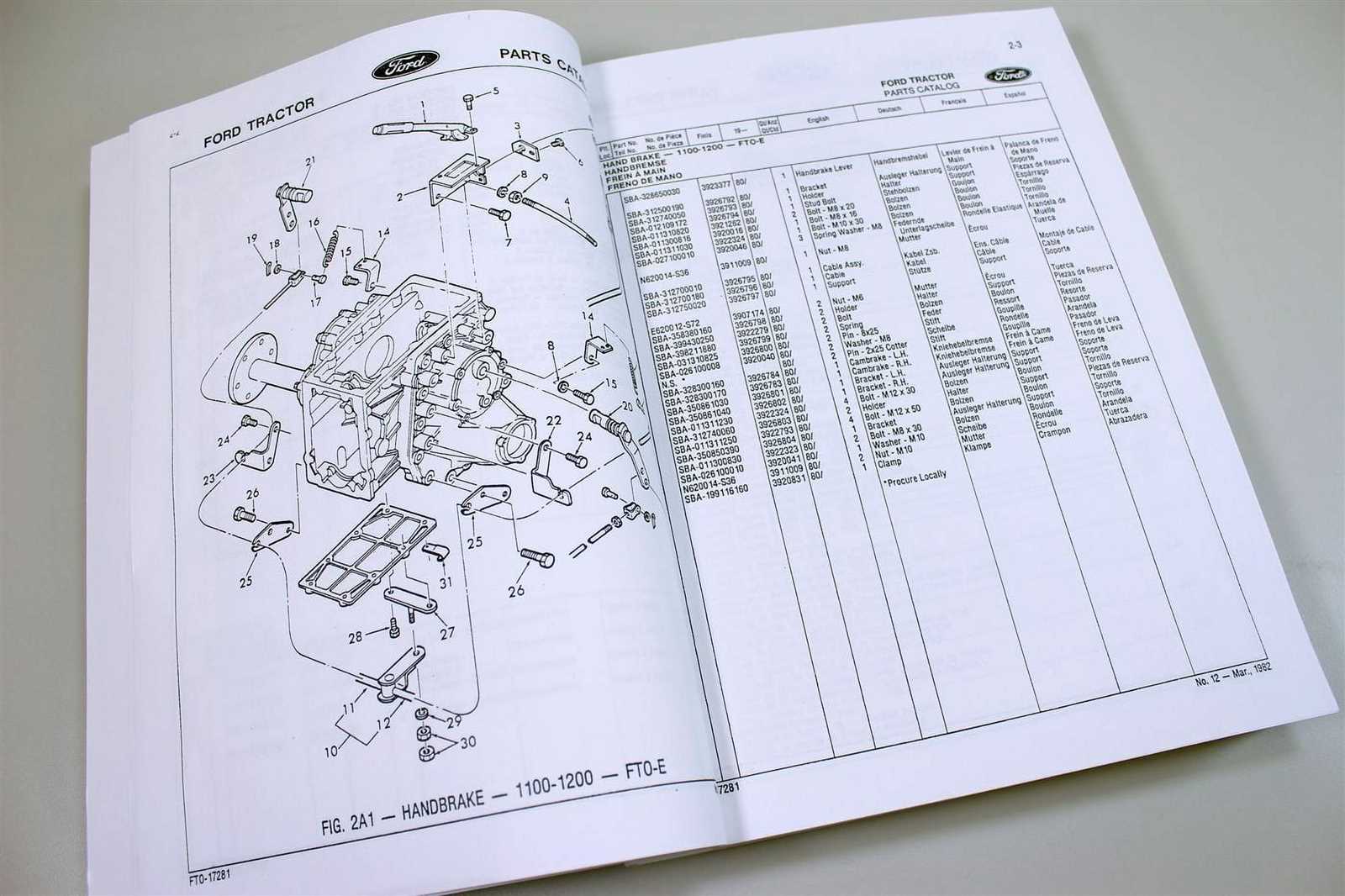

How to Read Parts Diagrams

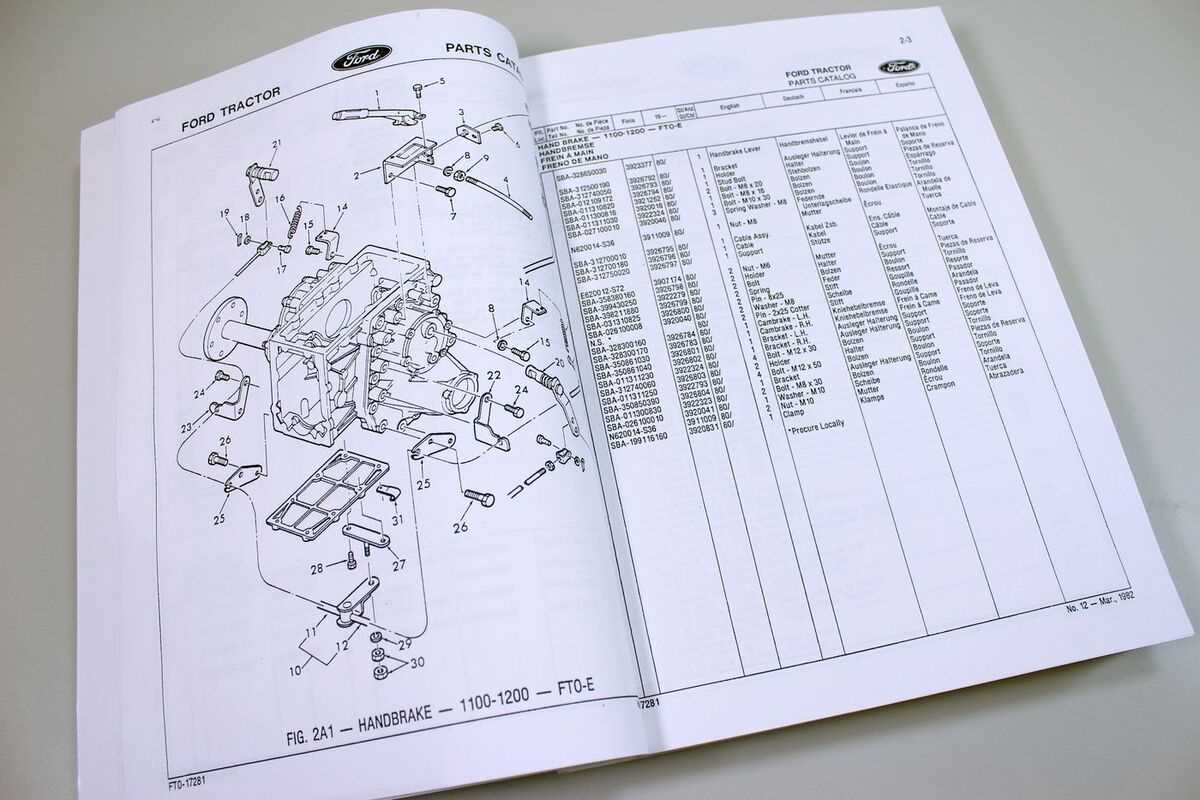

Understanding visual representations of components can greatly enhance your ability to identify and source the necessary elements for machinery maintenance. These illustrations serve as guides, detailing various sections and their interconnections, allowing you to navigate complex assemblies with ease.

Here are some essential tips for interpreting these illustrations effectively:

- Familiarize Yourself with Symbols: Each illustration utilizes specific symbols and notations. Take the time to understand what each symbol represents.

- Identify Key Sections: Break down the illustration into manageable parts. Focus on one section at a time to avoid feeling overwhelmed.

- Use Reference Numbers: Most illustrations include reference numbers next to components. These numbers correspond to a list, providing detailed information about each item.

- Look for Exploded Views: Exploded views can help you see how components fit together. This perspective clarifies assembly and disassembly processes.

By mastering these techniques, you’ll be better equipped to interpret these valuable resources, ensuring efficient repairs and maintenance. Understanding the layout and meaning behind these visuals can save time and prevent errors during your work.

Commonly Replaced Parts Overview

When it comes to maintaining heavy machinery, certain components tend to require replacement more frequently than others. Understanding these essential elements is crucial for ensuring optimal performance and longevity of the equipment. This section delves into the most commonly substituted components, highlighting their importance and the reasons behind their wear and tear.

Filters are among the most frequently changed items. Oil, air, and fuel filters accumulate debris and contaminants over time, leading to reduced efficiency. Regular replacement helps maintain smooth operation and protects internal mechanisms from damage.

Batteries also see significant turnover. Given the demanding nature of machinery, batteries can deplete quickly, especially in harsh conditions. Ensuring a reliable power source is vital for consistent functionality and starting capability.

Belts and hoses are susceptible to wear due to constant movement and exposure to varying temperatures. Cracks or frays can lead to failures, making it essential to inspect and replace these components periodically to avoid unexpected breakdowns.

Tires are another critical aspect of equipment maintenance. They endure substantial wear from rough terrains, affecting stability and safety. Regular checks and timely replacements ensure optimal traction and performance during operation.

By focusing on these key components, operators can enhance the reliability and efficiency of their machinery, minimizing downtime and costly repairs. Understanding the common wear items helps in planning maintenance schedules effectively.

Where to Find Genuine Parts

When it comes to maintaining your equipment, sourcing authentic components is crucial for ensuring optimal performance and longevity. Utilizing original items not only enhances functionality but also provides peace of mind, knowing that you are investing in quality. Here are some reliable options to explore when searching for these essential elements.

Authorized Dealers

One of the most dependable sources for authentic components is through authorized dealers. These vendors are officially recognized and carry a wide range of original merchandise. They often have knowledgeable staff who can assist you in finding the right item for your specific model, ensuring compatibility and reliability.

Online Retailers

In today’s digital age, online marketplaces have become a popular option for sourcing quality items. Websites specializing in machinery and equipment often feature a comprehensive selection of genuine components. Always check the seller’s ratings and reviews to ensure you are purchasing from a reputable source. Additionally, many manufacturers have their own online stores, providing a direct avenue for acquiring authentic merchandise.

Aftermarket vs. OEM Components

When it comes to replacing mechanical elements in heavy machinery, users often face a crucial decision between original and alternative offerings. Understanding the differences in quality, cost, and performance can significantly impact both the functionality and longevity of the equipment.

Original Equipment Manufacturer (OEM) components are produced by the same company that made the original machinery. These items are designed to match the specifications and standards set by the manufacturer, ensuring a perfect fit and reliable performance. Many operators prefer these for their assurance of quality and compatibility.

On the other hand, aftermarket options are created by third-party manufacturers. While they often come at a lower price point, the quality can vary widely. Some aftermarket products may even exceed OEM standards, providing enhanced features or durability. However, users must exercise caution and conduct thorough research to ensure that they select trustworthy alternatives.

Ultimately, the choice between these two types of components depends on individual preferences, budget constraints, and the specific requirements of the machinery involved. Evaluating both options can lead to informed decisions that maximize efficiency and reduce downtime.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and optimal performance of your machinery. By adhering to a systematic maintenance schedule, you can significantly extend the lifespan of your equipment and enhance its efficiency, ultimately saving time and resources.

Routine Checks

Conducting frequent inspections helps identify potential issues before they escalate. Look for signs of wear and tear, and ensure all components are functioning properly. Common areas to monitor include:

| Component | Inspection Frequency | Notes |

|---|---|---|

| Fluid Levels | Weekly | Check oil, coolant, and fuel levels. |

| Belts and Hoses | Monthly | Inspect for cracks or fraying. |

| Filters | Every 50 hours | Replace air and fuel filters as needed. |

Cleaning and Lubrication

Keeping your machinery clean is crucial. Remove dirt and debris regularly to prevent buildup. Additionally, ensure all moving parts are properly lubricated to minimize friction and wear.

Identifying Parts by Model Year

Understanding the components of machinery is crucial for efficient maintenance and repair. Each model year often brings changes in design, materials, and specifications, making it essential for users to accurately identify the relevant elements for their specific version. This ensures compatibility and optimal performance, reducing the risk of malfunction.

Variations Across Years

Models from different production years may exhibit noticeable differences. Engine specifications, for example, can vary significantly, impacting power output and fuel efficiency. Additionally, features such as transmission types and hydraulic systems may also change, leading to a need for precise identification of the right components.

Resources for Identification

Utilizing manuals and online databases can aid in pinpointing the specific characteristics of each year. Many manufacturers provide detailed documentation that includes schematics and part numbers, which can be invaluable in ensuring that the right components are sourced for repairs or upgrades. Engaging with community forums and expert advice can also enhance understanding and facilitate more informed decisions.

Common Repairs for Ford 1500

Regular maintenance and timely repairs are essential for ensuring optimal performance and longevity of agricultural machinery. Understanding common issues can help operators address problems before they escalate, reducing downtime and repair costs.

Here are some frequent repairs encountered with this type of equipment:

- Engine Overhaul: Rebuilding or replacing components to address performance issues.

- Hydraulic System Repairs: Fixing leaks and maintaining optimal pressure to ensure smooth operation.

- Transmission Issues: Addressing shifting problems or replacing worn gears.

- Electrical System Diagnostics: Troubleshooting wiring problems or faulty connections.

- Cooling System Maintenance: Cleaning or replacing radiators to prevent overheating.

- Tire Replacement: Ensuring proper traction and stability by replacing worn tires.

By staying proactive with these repairs, operators can maintain efficient functionality and extend the life of their machinery.

Resources for Parts and Service

For anyone seeking reliable components and maintenance assistance, having access to quality resources is essential. This section provides an overview of where to find essential supplies and professional support, ensuring optimal performance and longevity of your machinery.

Authorized Dealers: Partnering with certified distributors guarantees that you receive genuine components that meet industry standards. These establishments often provide expert advice and can assist in identifying the correct items needed for your equipment.

Online Retailers: Numerous e-commerce platforms specialize in equipment supplies. These sites offer a wide range of options, often at competitive prices. Always check for customer reviews to ensure the credibility of the seller.

Local Repair Shops: Many communities host specialized service centers equipped to handle various machinery. Establishing a relationship with local technicians can provide quick access to repairs and maintenance without the long wait times often associated with larger operations.

Manufacturer Resources: Directly consulting the manufacturer’s website can yield valuable information. Many brands offer downloadable guides, manuals, and lists of recommended suppliers, simplifying the search for required items.

Online Forums and Communities: Engaging with fellow enthusiasts and professionals in dedicated forums can provide insights and recommendations. Sharing experiences and tips can lead to discovering hidden gems for sourcing and servicing your equipment.

By utilizing these resources, you can ensure that your machinery remains in top working condition, ready to tackle any task.

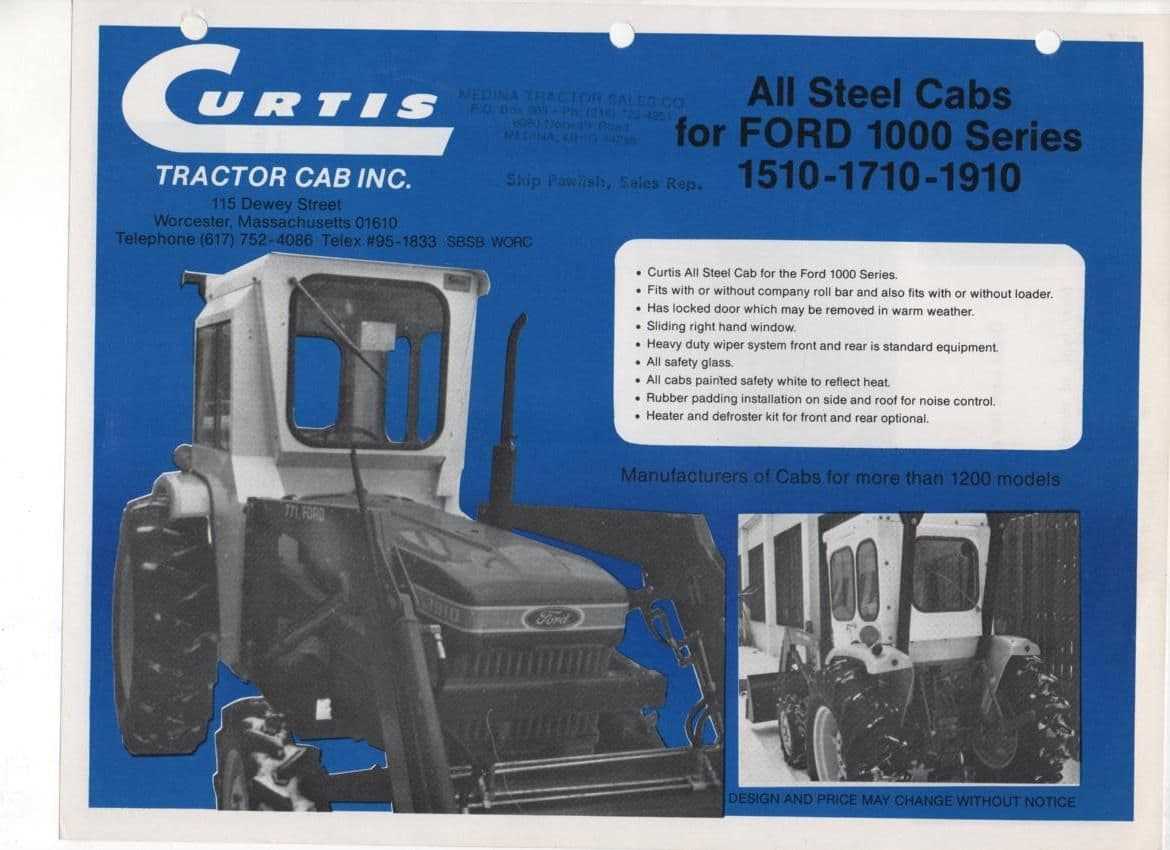

Upgrading Your Ford 1500 Tractor

Enhancing the performance and efficiency of your agricultural machine can significantly improve your productivity. By focusing on key areas, you can elevate the functionality and longevity of your equipment.

Engine Modifications: Upgrading the engine components can lead to improved power output and fuel efficiency. Consider investing in high-performance air filters and exhaust systems to optimize airflow.

Hydraulic System Improvements: Enhancing the hydraulic system is essential for better lifting and towing capabilities. Upgrading hoses and valves can provide increased responsiveness and strength.

Transmission Enhancements: Adjusting the transmission can improve gear shifting and overall handling. Look into aftermarket options that provide smoother operation and durability.

Cab Comfort: Don’t overlook the operator’s experience. Upgrading seats, adding soundproofing, and installing climate control features can make a significant difference during long hours of use.

By thoughtfully considering these upgrades, you can ultimately transform your equipment into a more powerful and reliable ally in your agricultural endeavors.

Frequently Asked Questions About Parts

This section addresses common inquiries regarding components and their maintenance. Understanding these essentials can enhance performance and longevity.

General Inquiries

- What are the most critical components to check regularly?

- How can I identify wear and tear on my equipment?

- Where can I find quality replacements for worn items?

Installation and Maintenance

- What tools do I need for installation?

- Are there any specific instructions for maintenance?

- How often should I conduct routine checks?