In the realm of small agricultural machinery, knowing the various elements that make up your vehicle is crucial for efficient operation and maintenance. This knowledge not only enhances performance but also prolongs the lifespan of the equipment. Whether you are a hobbyist or a professional, grasping the intricacies of your machine can lead to more effective troubleshooting and repair strategies.

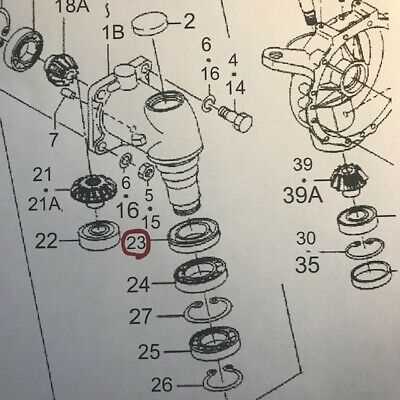

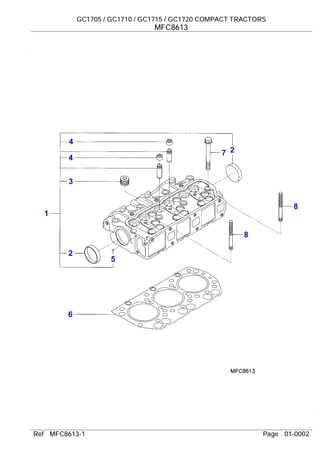

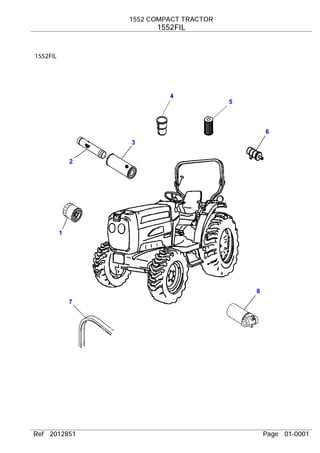

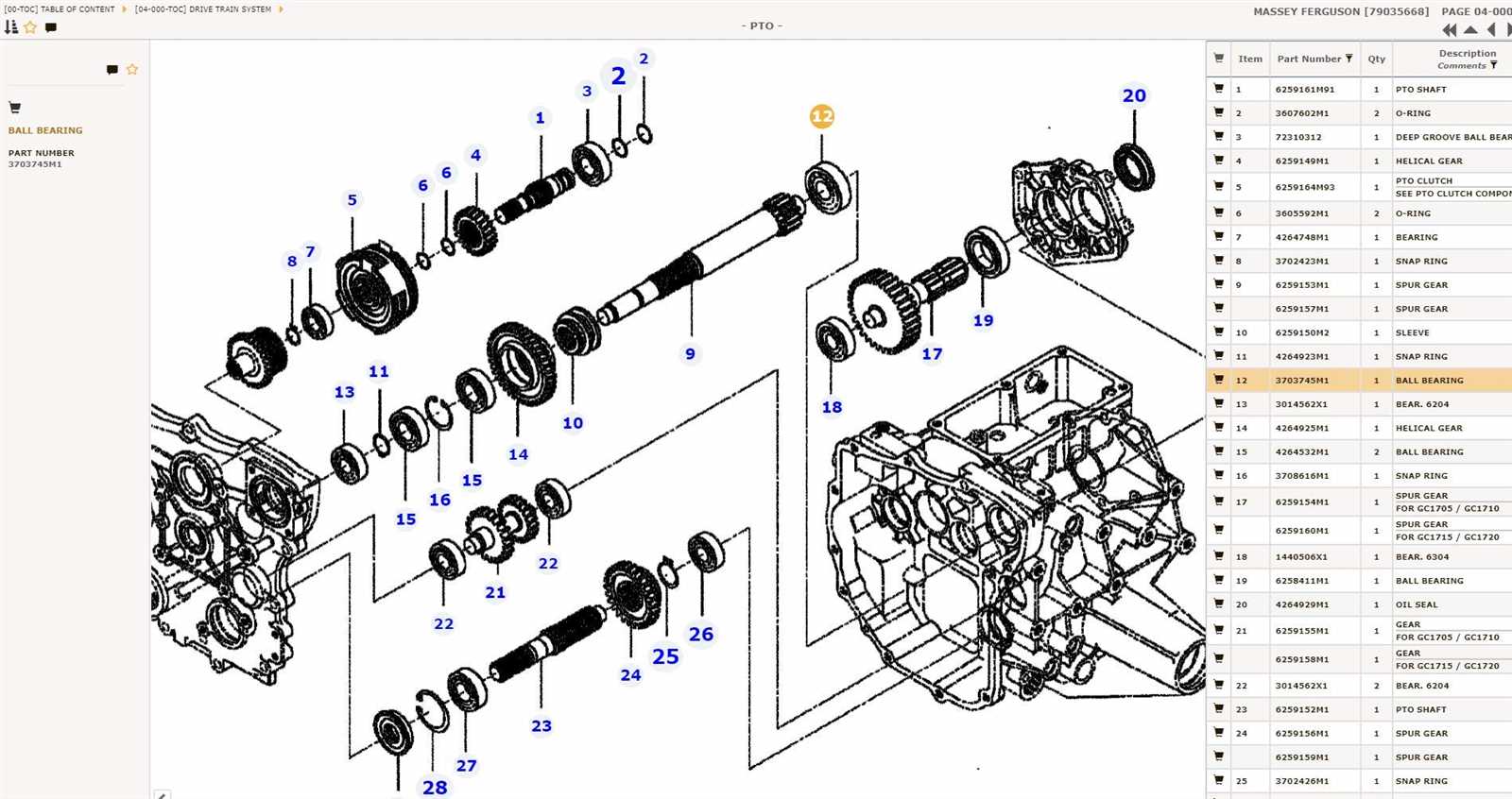

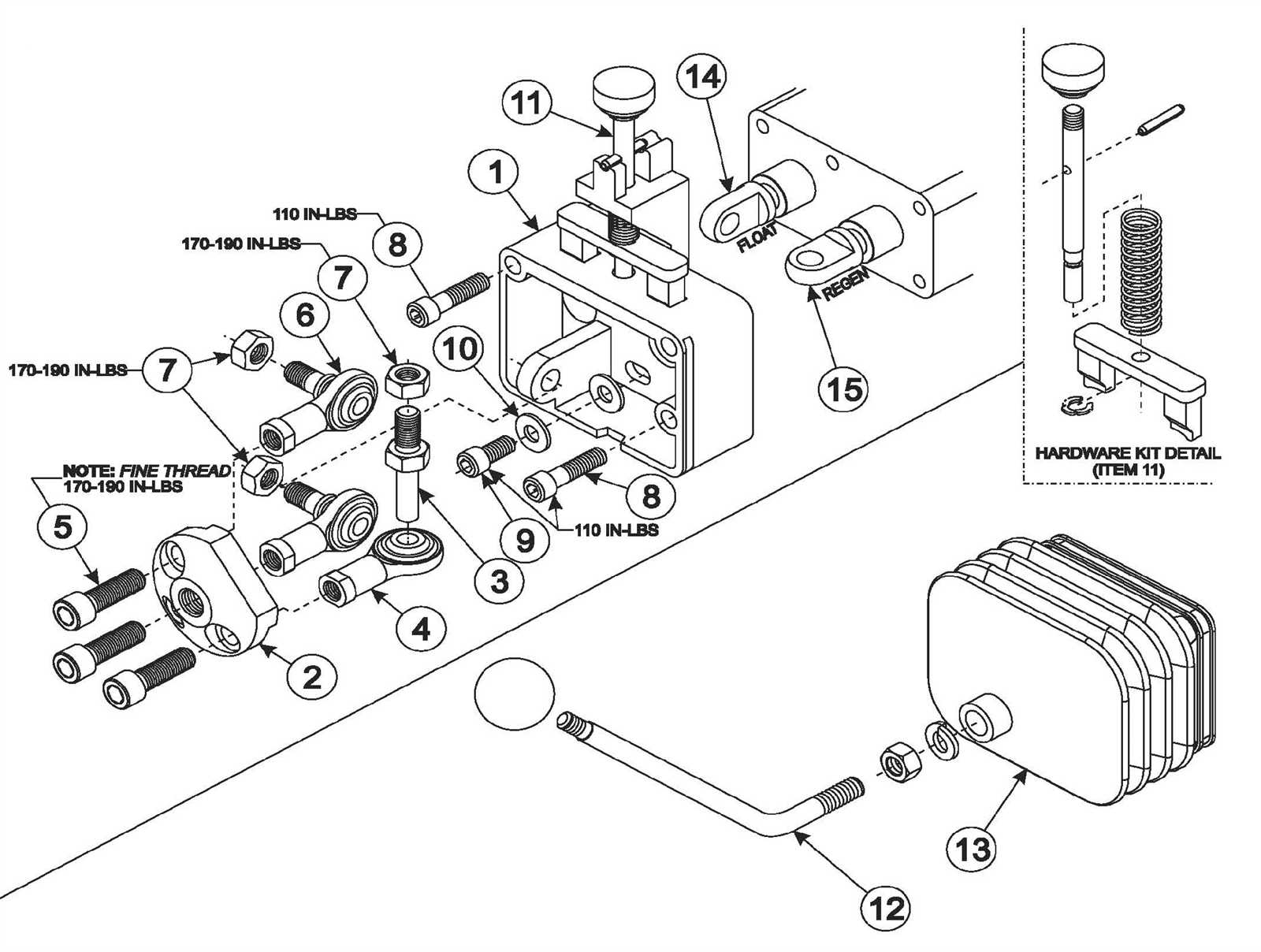

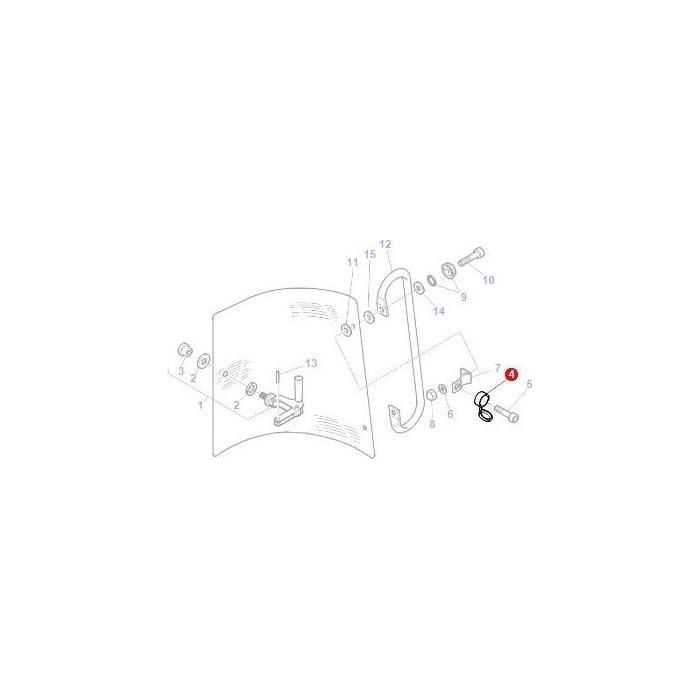

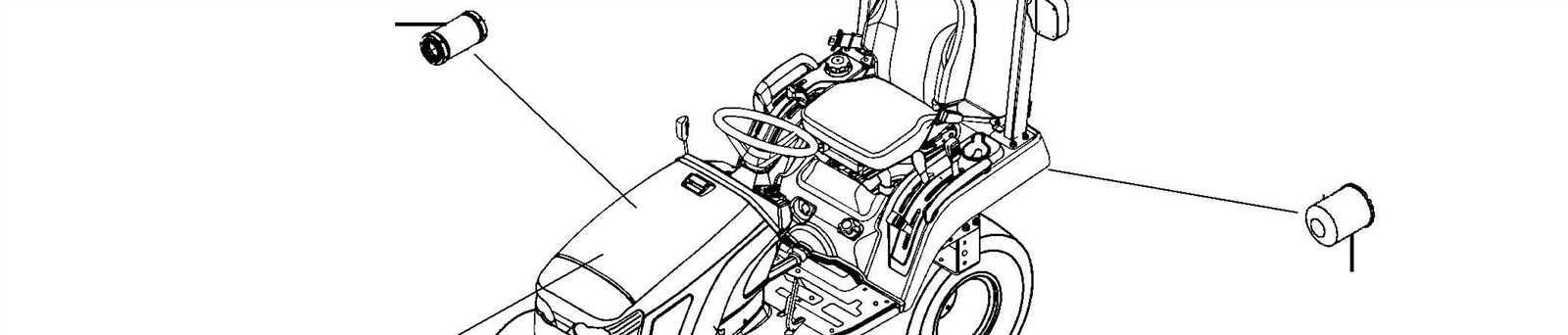

Utilizing a detailed visual representation of the individual components can serve as an ultimate guide for identifying and sourcing replacements when needed. Such illustrations provide clarity, ensuring that operators are familiar with each segment of the machinery, from the engine to the hydraulic systems. Understanding these parts empowers users to perform necessary upkeep with confidence and precision.

As we delve into this topic, we will explore the various sections and features of your compact tractor. This exploration will not only highlight essential functionalities but will also equip you with the information necessary for optimal performance and maintenance practices.

Massey Ferguson GC1710 Overview

This compact utility vehicle is designed for efficiency and versatility in various agricultural and landscaping tasks. Its robust construction and user-friendly features make it a popular choice among operators seeking reliability and performance in their daily work.

| Feature | Description |

|---|---|

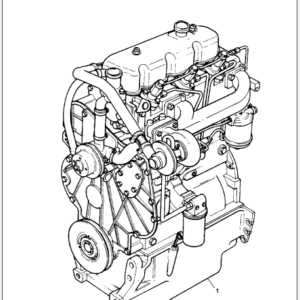

| Engine | Powerful and efficient engine, designed for optimal performance. |

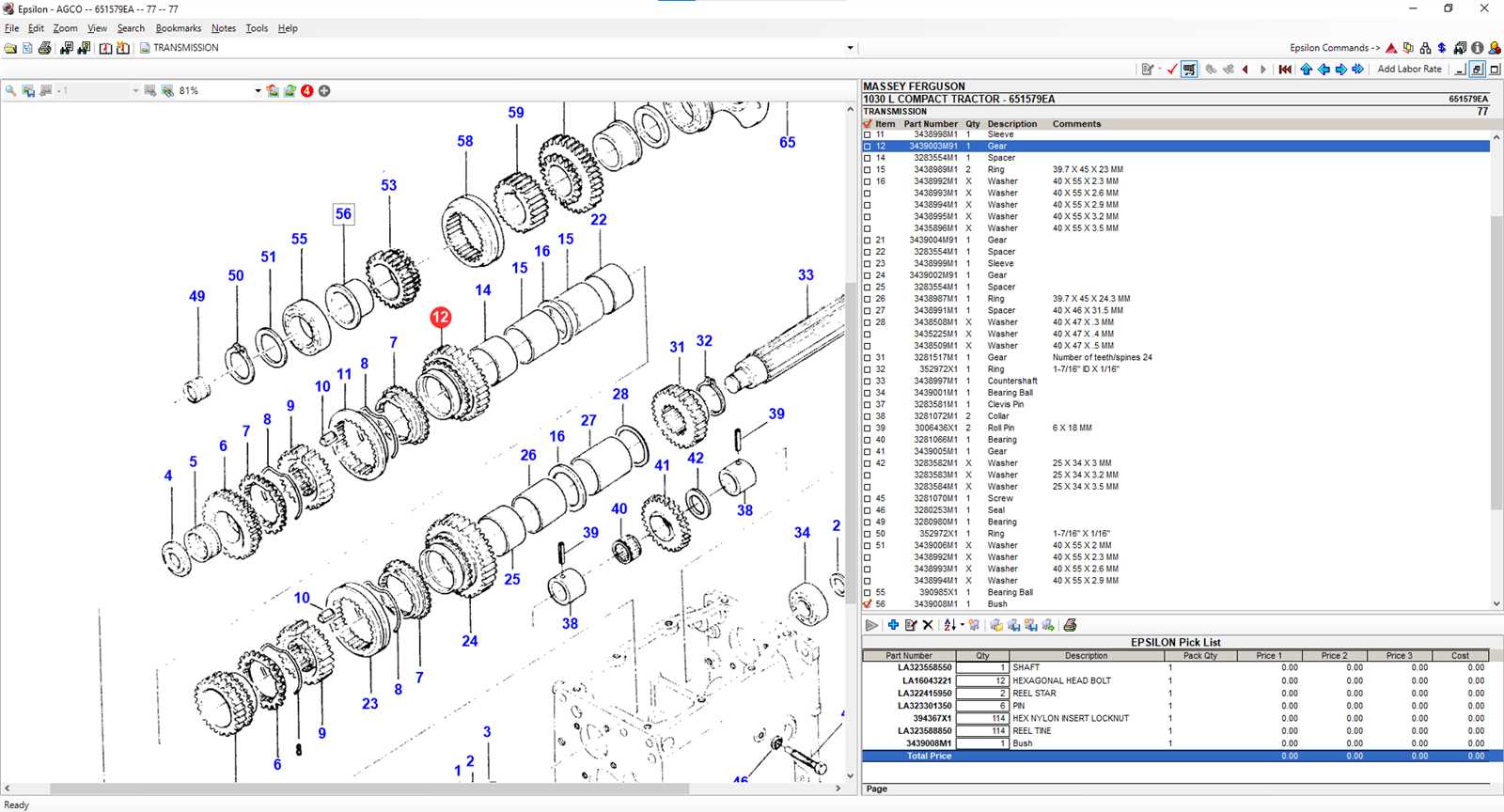

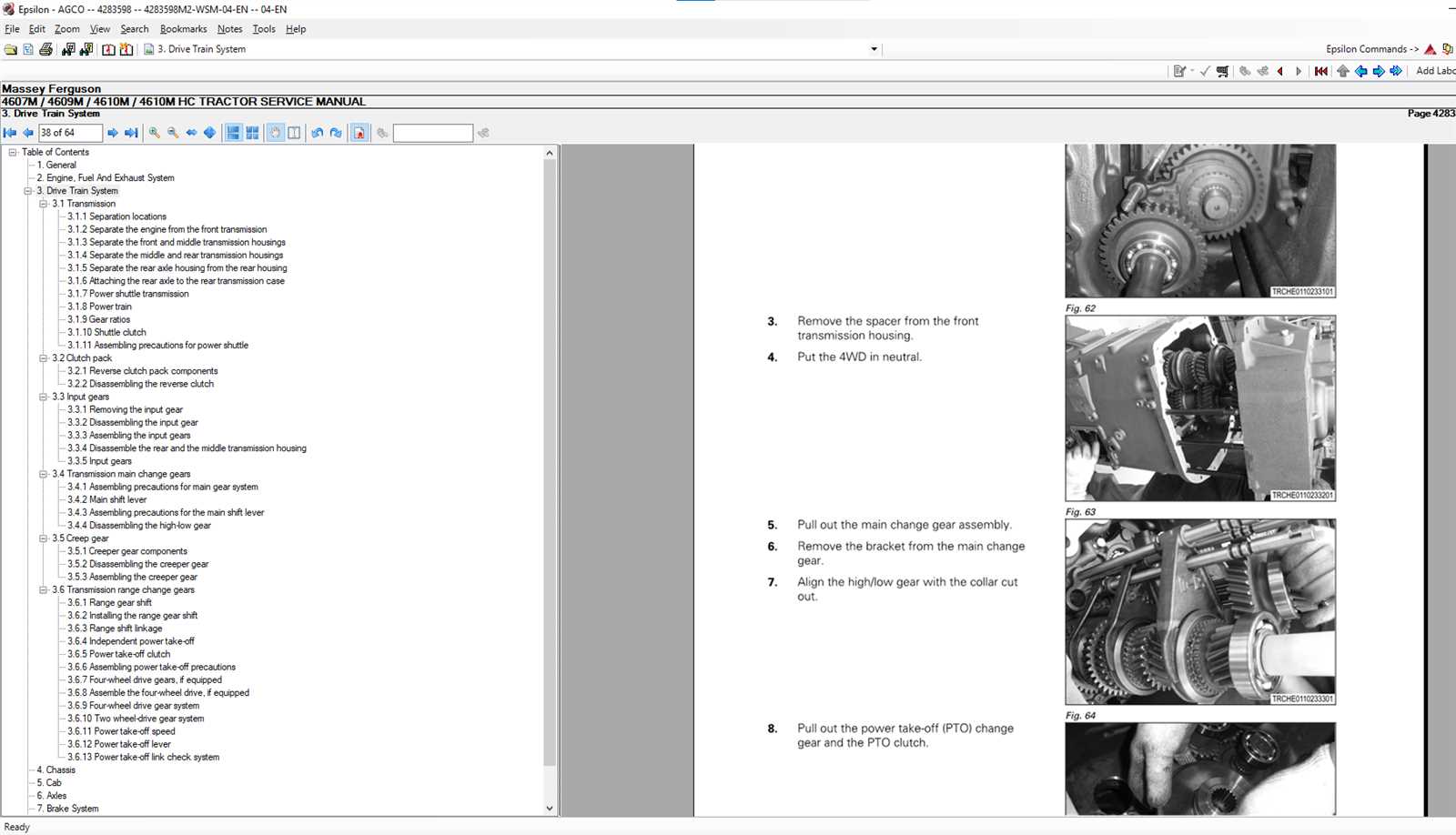

| Transmission | Smooth shifting capabilities that enhance control and maneuverability. |

| Dimensions | Compact size, allowing access to tight spaces while providing stability. |

| Attachments | Compatible with a variety of implements for diverse tasks. |

Key Features of the GC1710

This compact utility tractor is designed for versatility and efficiency, making it an excellent choice for a variety of tasks. Its robust build and thoughtful engineering provide users with reliability and ease of use, ideal for both residential and light commercial applications.

One of the standout characteristics of this machine is its powerful engine, delivering ample horsepower for demanding jobs while maintaining fuel efficiency. The user-friendly controls and ergonomic design enhance comfort during operation, allowing for extended use without fatigue.

Additionally, its compact size facilitates maneuverability in tight spaces, making it suitable for landscaping, gardening, and property maintenance. The availability of various attachments further enhances its functionality, enabling users to tackle a wide range of chores with ease.

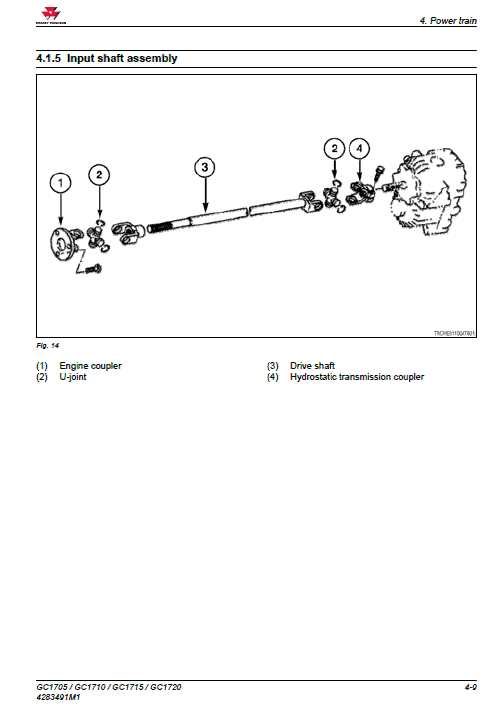

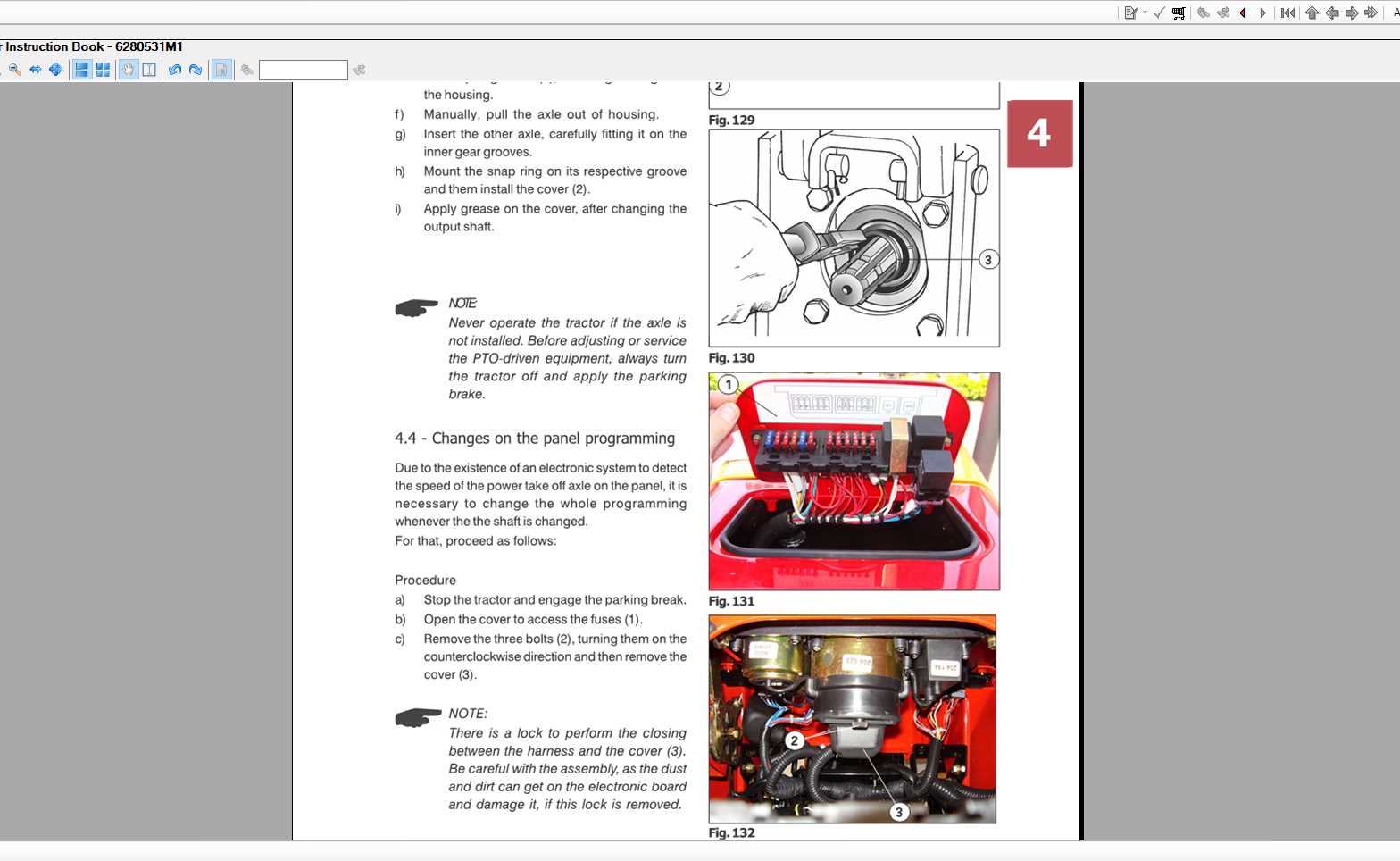

Moreover, the integrated hydraulic system ensures smooth operation of implements, providing precise control and responsiveness. This feature, combined with a solid transmission, allows for seamless transitions between tasks, boosting productivity.

Understanding Parts Diagrams

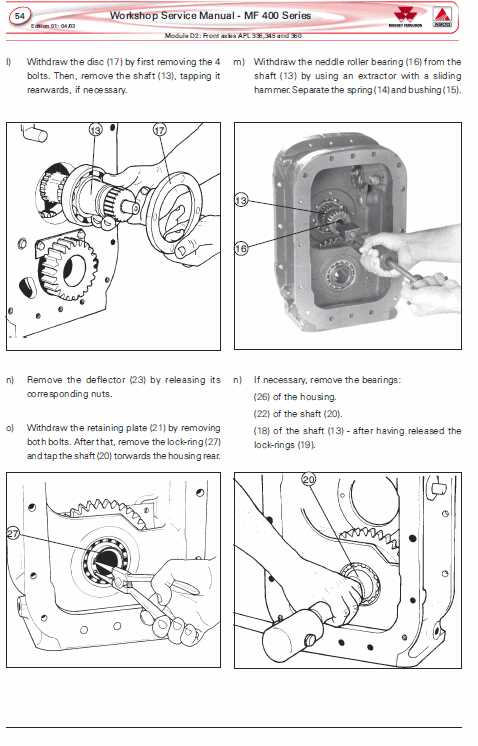

Visual representations of components play a crucial role in comprehending the intricate assembly of machinery. They provide a clear, organized view of each element’s placement and function, aiding in maintenance and repairs. By analyzing these illustrations, users can identify individual pieces and understand how they interconnect within the overall system.

Benefits of Component Illustrations

Utilizing these visual tools streamlines the process of identifying issues and sourcing replacements. They serve as essential references, ensuring that technicians can work efficiently and accurately. Here are some notable advantages:

| Advantage | Description |

|---|---|

| Clarity | Provides a clear view of the machinery layout. |

| Efficiency | Speeds up the process of locating specific elements. |

| Accuracy | Reduces the risk of errors during repairs or replacements. |

| Education | Enhances understanding of how parts interact within the system. |

Reading the Visuals

Interpreting these illustrations requires attention to detail. Each symbol and label conveys critical information about the corresponding components. Familiarity with these visuals allows users to efficiently navigate through complex machinery, facilitating a better understanding of maintenance requirements and assembly procedures.

Importance of Accurate Diagrams

Precise illustrations play a crucial role in the maintenance and repair of machinery. They serve as visual guides that enhance understanding and facilitate the identification of components, ensuring that tasks are completed efficiently. The clarity of these visuals can significantly impact the effectiveness of service efforts, minimizing errors and reducing downtime.

Enhanced Understanding

When dealing with complex equipment, accurate representations provide a clear overview of the various elements involved. This clarity allows technicians to familiarize themselves with the structure and function of each part, leading to more informed decision-making during repairs. Well-crafted visuals simplify intricate processes, making them accessible even to those with limited experience.

Reduction of Errors

Inaccurate or ambiguous illustrations can lead to misunderstandings, resulting in improper assembly or maintenance. By utilizing dependable graphics, users can avoid costly mistakes and ensure that each component is handled correctly. Attention to detail in these representations not only boosts confidence but also enhances overall productivity in repair tasks.

Common Issues with GC1710 Parts

When operating compact utility machines, users often encounter various challenges that can affect performance and reliability. Understanding these common problems is essential for effective maintenance and troubleshooting.

Frequent Concerns

- Worn components that lead to reduced efficiency.

- Hydraulic leaks causing performance drops.

- Electrical malfunctions resulting in starting issues.

Prevention and Solutions

- Regular inspections to identify wear early.

- Promptly addressing hydraulic issues to maintain fluid integrity.

- Routine checks of electrical systems to ensure reliable operation.

Where to Find Replacement Parts

Locating suitable components for your machinery can enhance its performance and longevity. Understanding where to seek these essentials is crucial for effective maintenance.

Online Resources

- Manufacturer’s Website: Check the official site for catalogs and ordering options.

- Specialized Retailers: Explore online stores focused on agricultural equipment.

- Marketplaces: Websites like eBay and Amazon may offer a variety of options.

Local Options

- Authorized Dealers: Visit nearby distributors who can provide genuine items.

- Repair Shops: Local mechanics often have access to necessary supplies.

- Flea Markets: Occasionally, vendors have hard-to-find items at reasonable prices.

Maintenance Tips for GC1710

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment. Proper maintenance not only enhances performance but also helps prevent costly repairs down the line. Adhering to a systematic routine can keep your machine running smoothly and effectively.

Routine Checks

Conducting routine inspections is crucial. Check fluid levels, including oil and coolant, and inspect belts and hoses for wear. Keeping these elements in good condition can prevent more significant issues.

Cleaning and Lubrication

Regular cleaning and lubrication of moving parts will reduce friction and wear. Ensure that dirt and debris are removed from filters and other critical areas to promote optimal function.

| Task | Frequency |

|---|---|

| Fluid Level Check | Weekly |

| Belt Inspection | Monthly |

| Cleaning Filters | Every 50 Hours |

| Lubrication | Every 100 Hours |

DIY Repairs and Upgrades

Engaging in self-service repairs and enhancements can significantly extend the lifespan and functionality of your machinery. By gaining a deeper understanding of components and their assembly, enthusiasts can tackle maintenance tasks effectively while also customizing their equipment to better meet specific needs.

When embarking on repair or upgrade projects, having a clear plan and understanding the essential elements involved is crucial. Below is a table outlining common tasks and the tools you might need for successful execution:

| Task | Required Tools | Estimated Time |

|---|---|---|

| Oil Change | Wrench, Oil Filter Wrench, Drain Pan | 1 hour |

| Blade Replacement | Socket Set, Screwdriver | 30 minutes |

| Battery Installation | Wrench, Safety Goggles | 45 minutes |

| Tire Maintenance | Jack, Tire Iron, Air Compressor | 1-2 hours |

By mastering these tasks, you not only save money but also gain valuable skills that can lead to more advanced projects in the future. Happy repairing!

Exploring Aftermarket Options

When it comes to enhancing the functionality and longevity of your equipment, considering alternative components can be a game changer. These options often provide a balance of cost-effectiveness and quality, allowing users to maintain their machinery without breaking the bank.

Benefits of Aftermarket Components

Opting for aftermarket solutions can lead to significant savings while still achieving satisfactory performance. Many aftermarket suppliers offer a wide range of products that are compatible with original equipment, ensuring seamless integration.

Considerations for Choosing Alternatives

It is essential to research the reliability and warranty policies of aftermarket providers. Ensuring that the components meet industry standards can save you from potential issues down the line.

| Feature | Aftermarket Option | Original Manufacturer |

|---|---|---|

| Cost | Lower | Higher |

| Availability | Widely available | Limited |

| Variety | Extensive | Specific |

| Quality | Variable | Consistent |

Cost Considerations for Parts

When maintaining or repairing machinery, understanding the financial implications of components is crucial. The expenses associated with replacements can vary significantly based on several factors, including quality, availability, and sourcing methods.

Quality vs. Price

Investing in high-quality components can often lead to enhanced performance and longevity. While these items may carry a higher initial cost, they can reduce the frequency of replacements, ultimately saving money in the long run.

Sourcing Options

Choosing where to purchase components can greatly impact overall expenses. Online retailers, local suppliers, and OEMs each present unique pricing structures. It’s essential to compare and delve into each option to find the ultimate balance between cost and reliability.

Comparing GC1710 with Similar Models

When evaluating compact tractors, it’s essential to consider how specific models stack up against their peers. This comparison helps potential buyers understand the features, performance, and versatility of different options available in the market. By examining similarities and differences, users can make informed decisions that best suit their agricultural or landscaping needs.

One noteworthy competitor features a robust engine that offers slightly higher horsepower, making it suitable for heavier tasks such as plowing and hauling. This model is also equipped with advanced transmission options, providing smoother gear transitions, which can enhance overall user experience during operation.

Another alternative stands out with its superior maneuverability and compact design, making it ideal for tight spaces and smaller properties. It often includes a more user-friendly control layout, allowing for easier handling and operation, particularly for those new to using tractors.

Additionally, there are options available that emphasize fuel efficiency, often allowing for longer operating times between refuels. These models may also incorporate innovative technology, such as GPS guidance systems, to streamline tasks and improve productivity.

Ultimately, understanding the nuances between these compact tractors can guide buyers in selecting the best fit for their specific requirements, whether for residential use, landscaping projects, or small-scale farming operations.