In modern farming, efficiency and precision are essential. To achieve this, it is important to have a clear grasp of how various mechanical components work together in large machines designed for planting and crop management. By examining the internal organization of these machines, farmers can ensure optimal performance and timely maintenance.

Each section of such equipment plays a specific role, working in harmony with others to facilitate the entire process. Understanding how these elements interconnect can help prevent breakdowns and improve productivity in the field. In this article, we will break down the different sections and provide a detailed view of their function within the machine as a whole.

Proper maintenance and a good understanding of the core mechanisms are key to ensuring that such machinery operates at its full potential, reducing downtime and increasing the effectiveness of planting operations. Let’s explore the different components that make up this essential farming tool and how they contribute to its overall efficiency.

White 5100 Planter Overview

The agricultural equipment discussed here is widely recognized for its efficiency and durability in field operations. It has been engineered to provide reliable service across various soil types and planting conditions. This model has gained popularity due to its robust design and versatility, making it a preferred choice for many farming needs.

Key features of this machinery include:

- Optimized planting mechanisms for precision.

- Adaptability to different terrains and crops.

- Long-lasting components designed for reduced maintenance.

Farmers appreciate its user-friendly operation, which allows for smoother adjustments during planting seasons. Additionally, the machinery is built to handle the demands of modern agricultural practices, ensuring both high productivity and sustainability.

Components of the 5100 Planter

The equipment in question consists of numerous essential parts that work together to ensure efficient operation. Each piece plays a critical role in enhancing the planting process, from seed placement to soil management. Understanding how these elements function together is key to maintaining optimal performance and productivity.

Key Mechanical Elements

Among the mechanical elements, you will find components designed to ensure proper seed distribution and soil penetration. These are crucial for maintaining consistency during the planting process, allowing for uniform crop growth. Adjustments to these elements can significantly impact the results in varying soil conditions.

Additional Supporting Parts

The system also includes secondary elements that provide support for the core components. These parts contribute to durability and longevity, ensuring that the machinery can withstand extended use over different terrains. Proper maintenance of these elements is essential to avoid operational downtime.

| Component | Function | |||||||

|---|---|---|---|---|---|---|---|---|

| Seed Mechanism | Ensures accurate seed placement. | |||||||

| Row Units | Handles soil interaction and seed depth. | |||||||

| Component | Function |

|---|---|

| Seed Meter | Ensures accurate seed dispensing for uniform planting. |

| Depth Adjuster | Controls the planting depth for optimal seed coverage. |

| Press Wheels | Firmly pack the soil around the seed for better seed-to-soil contact. |

Seed Metering System Breakdown

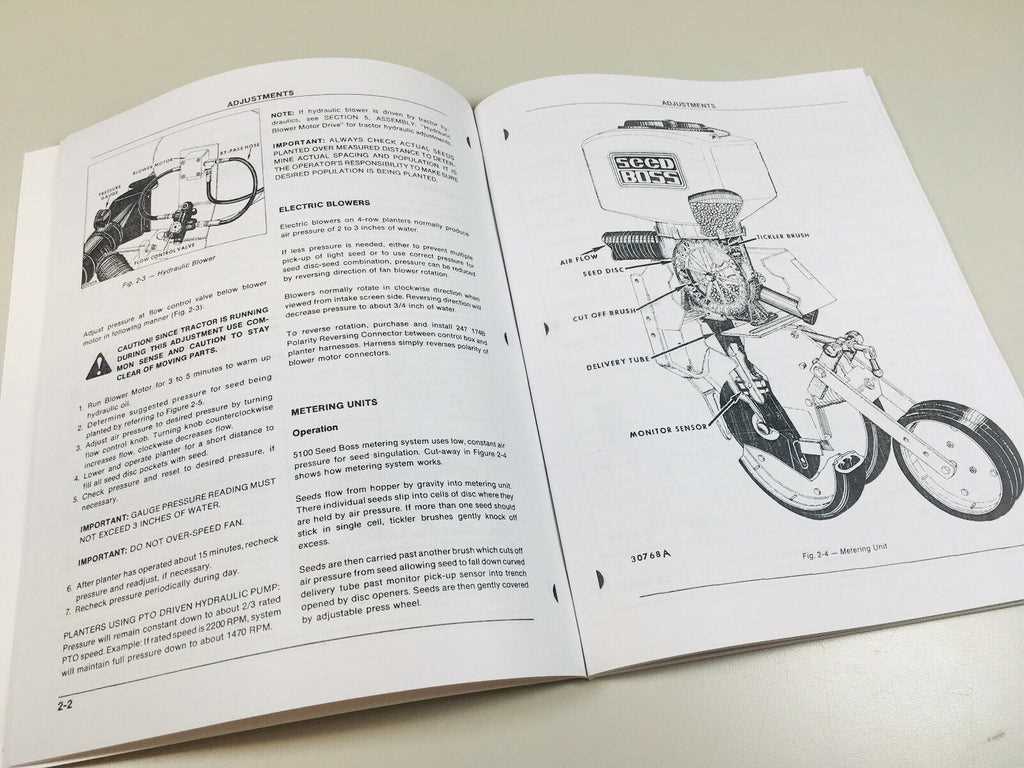

The seed distribution mechanism plays a crucial role in ensuring that each seed is placed at the correct depth and spacing. This system ensures the accurate delivery of seeds to the soil, facilitating even germination and optimal crop growth. Components of the system include various parts that work together to regulate seed flow and placement. These elements are responsible for metering seeds, controlling their release, and managing seed spacing. The system typically includes components such as seed discs, agitators, and motors that drive the flow of seeds. Proper maintenance and adjustments of these components are essential for achieving consistent planting performance. Any wear or malfunction in the system can lead to uneven seed placement, negatively affecting crop yields. Hydraulic System Parts ExplainedThe hydraulic system plays a crucial role in the efficient operation of modern agricultural equipment. By converting hydraulic fluid pressure into mechanical force, it allows for the smooth movement of various components, ensuring optimal performance during fieldwork. Understanding the key components involved in this system is essential for maintenance and troubleshooting, as well as for maximizing efficiency in the field. Main Hydraulic Components

The main components of the hydraulic system include the pump, valves, cylinders, and hoses. Each part works together to generate and control the flow of fluid, which powers the equipment’s various functions. The pump is responsible for generating fluid pressure, while the valves regulate the flow and direction of the fluid to different parts of the system. Cylinders convert hydraulic pressure into linear motion, performing tasks such as raising or lowering attachments. Hoses carry the fluid between components, ensuring proper flow throughout the system. Importance of Regular Maintenance

Regular maintenance of the hydraulic system is critical to avoid costly repairs and downtime. Checking fluid levels, inspecting hoses for wear, and ensuring that filters are clean are all important steps in keeping the system running smoothly. Additionally, paying attention to any unusual sounds or leaks can help identify potential issues before they escalate, allowing for timely interventions. Frame and Hitch StructureThe framework and hitch system of agricultural machinery play a critical role in ensuring stability, durability, and efficient operation. These components are designed to support the machine’s weight, maintain balance during use, and provide secure connections to the tractor or towing vehicle.

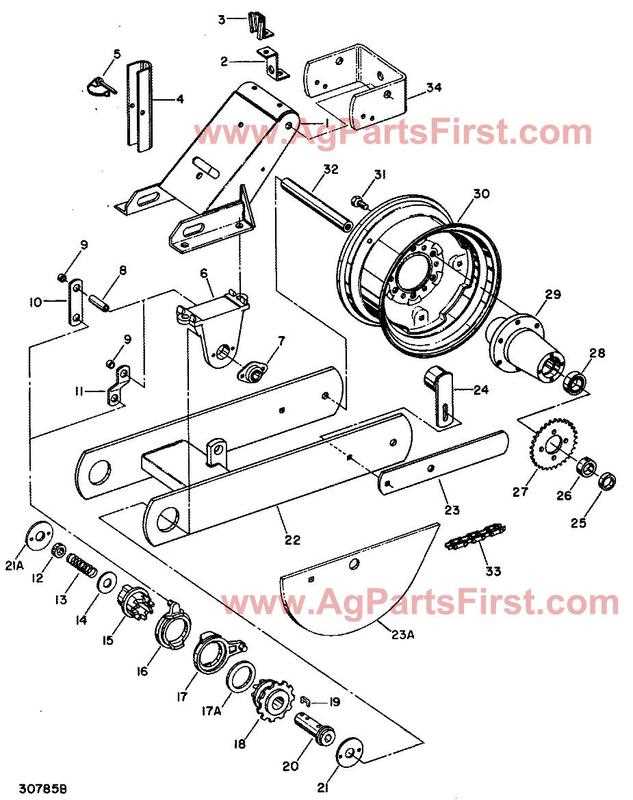

These elements work together to form the backbone of agricultural equipment, ensuring that the entire system operates effectively across different conditions and workloads. Planter Drive Mechanism OverviewThe drive system is essential for controlling the movement and function of planting equipment. It transfers power from the tractor or source to the components responsible for seed delivery, ensuring precise planting depth and spacing. The mechanism consists of gears, chains, and motors, all working in unison to maintain consistency and efficiency throughout the planting process. Each part of the drive system contributes to the synchronization of seed placement and row spacing. The proper functioning of this system is crucial for maximizing crop yields, as it ensures that seeds are deposited in optimal conditions for growth. Wear Components and Maintenance GuidelinesMaintaining the key wear components of your agricultural equipment is crucial for ensuring its optimal performance throughout the planting season. Regular upkeep and timely replacement of worn-out elements help reduce downtime, increase efficiency, and extend the lifespan of the machinery. Commonly Worn Components

Maintenance Tips

Replacement Options for Key ComponentsWhen it comes to maintaining agricultural machinery, selecting the right replacement options for essential components is crucial for ensuring smooth and efficient operations. Identifying compatible alternatives can improve performance and extend the life of the equipment. Below are some common alternatives for key elements in your machine:

By exploring a variety of replacement options, you can ensure that the critical components of your equipment are functioning at their best, helping you achieve optimal results in your agricultural tasks. |