Maintaining and servicing outdoor equipment can greatly extend its lifespan and ensure optimal performance. Understanding how different elements of your machinery interact and function together is crucial for seamless operation. A clear understanding of the layout and structure can simplify the process of identifying essential pieces and ensuring that everything runs smoothly.

Whether you are a professional or a hobbyist, knowing the arrangement and the function of various essential elements can be immensely helpful. This section will guide you through the fundamental elements of the equipment, offering insights into its design and ensuring you can easily access the components when necessary for upkeep or repairs.

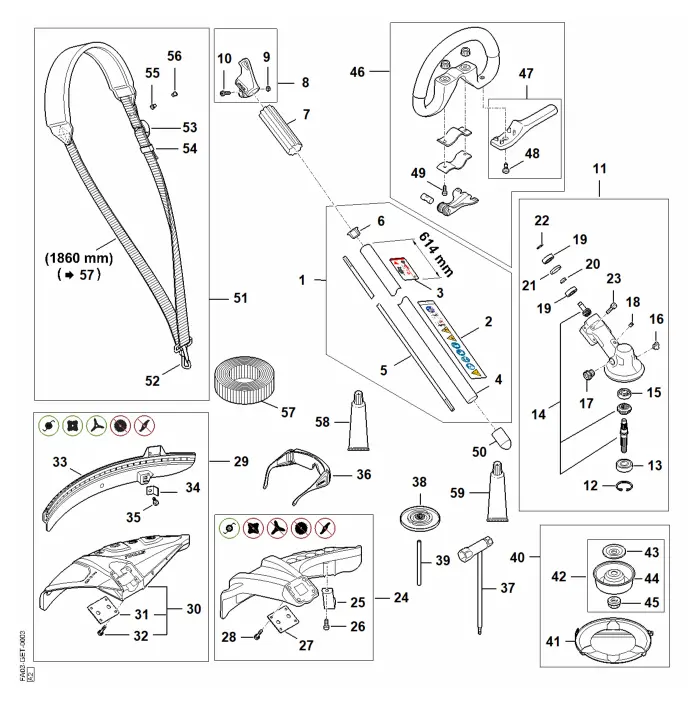

Key Components of the Stihl FSA 56

The device includes several important elements that work together to ensure smooth operation and efficiency. Each component is designed to provide a specific function, contributing to the overall performance. Understanding these elements helps in maintaining and optimizing the tool’s capabilities.

Power Source and Motor

The power source and motor form the core of the tool, delivering the necessary energy to drive its functions. The rechargeable energy unit ensures portability and ease of use, while the motor is responsible for converting this energy into mechanical action, driving the cutting mechanism efficiently.

Cutting Mechanism

The cutting element plays a vital role in performing the primary task of trimming. It is supported by a durable housing and connected to the motor through a rotating system. The sharp edges and high-speed rotation allow it to handle various types of vegetation with ease, providing a clean and precise cut.

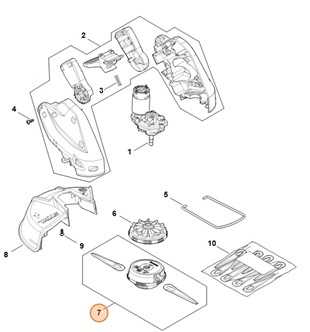

Understanding the Motor Assembly Layout

The internal structure of the motor system plays a crucial role in ensuring efficient performance. By examining the components that make up the assembly, one can gain a deeper understanding of how the unit operates as a whole. This section will explore the key elements involved in the motor’s function and their individual roles within the overall mechanism.

Main Components of the Motor

At the core of the assembly lies the motor unit itself, which is responsible for converting electrical energy into mechanical motion. Surrounding it are various essential parts such as the rotor, stator, and cooling system. Each of these elements contributes to maintaining proper airflow, ensuring that the motor does not overheat during operation.

Key Connections and Wiring

The motor assembly also includes important wiring and electrical connections. These links ensure that power is distributed evenly throughout the system. Proper alignment and secure connections are vital for preventing power loss and ensuring smooth functioning of the device.

Note: Regular inspection of these components helps to maintain the assembly’s efficiency and prolong the overall lifespan of the motor system.

Battery and Power Supply Overview

The efficient functioning of any cordless garden tool depends heavily on its energy system. A well-designed rechargeable unit ensures both long-lasting performance and environmental benefits. Understanding the energy source and its maintenance is key to optimizing the operation of your equipment.

Rechargeable Energy Units

Modern cordless tools use advanced rechargeable energy cells to provide the necessary power for extended usage. These cells are designed to balance power output with longevity, ensuring that users can complete tasks without frequent interruptions. Proper care and charging routines can significantly extend the life of these energy units.

Charging and Maintenance

To ensure the optimal performance of the power supply, it is essential to follow recommended charging practices. Consistent use of the correct charger and avoiding overcharging can prevent damage and prolong battery life. Additionally, storing the unit in moderate temperatures when not in use contributes to maintaining its efficiency over time.

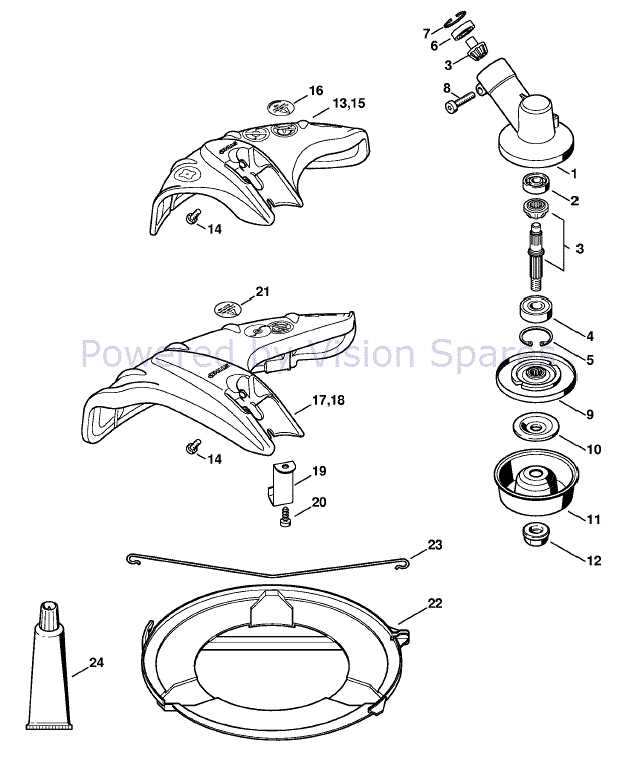

Exploring the Cutting Blade System

The cutting blade mechanism is an essential component in ensuring efficient trimming performance. It functions by providing precise and clean cuts, contributing to the overall effectiveness of the device in various vegetation control tasks. Understanding the structure and function of this system allows users to maintain and optimize their equipment for better results.

Key Components of the Blade Mechanism

The system includes several integral parts, each playing a critical role in its operation. From the blades themselves to the fasteners that hold them in place, every element is designed for durability and precision. Below is an overview of the primary components that make up the blade system:

| Component | Description | |||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Blades | Sharp cutting edges made of robust material, designed for efficient trimming of grass and light vegetation. | |||||||||||||||||||||||||

| Blade Guard | A protective cover that shields the

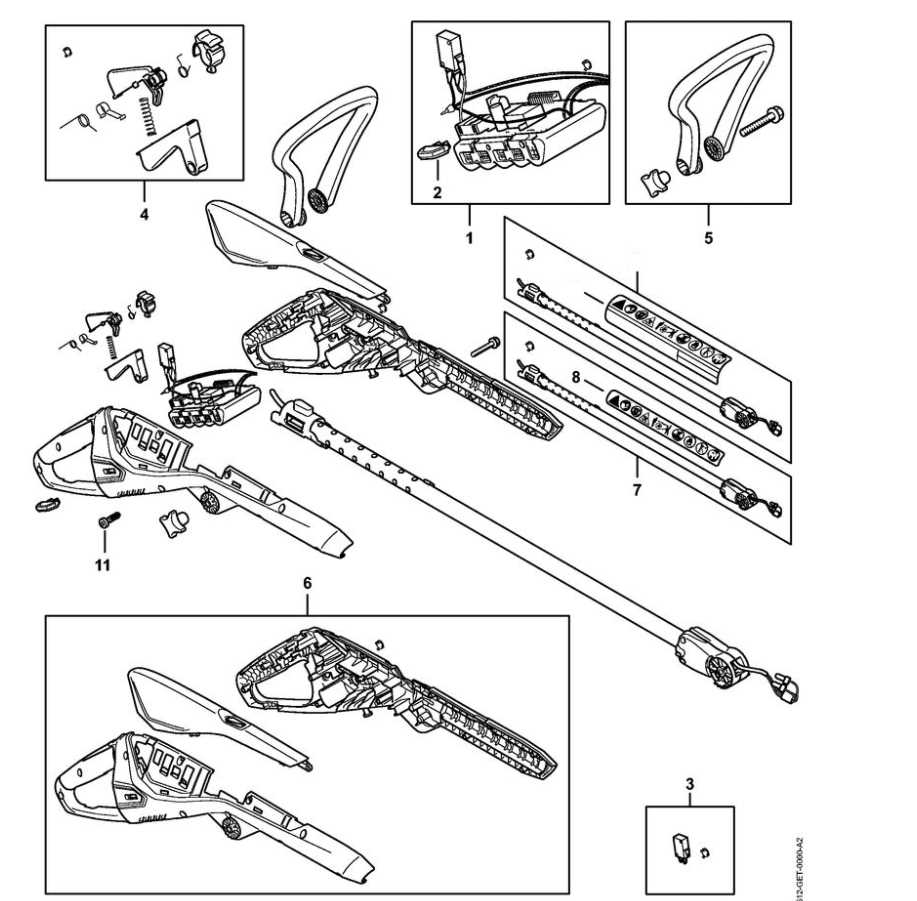

Handle and Control Mechanism BreakdownThe handle and control system is designed to provide seamless and intuitive operation. It plays a crucial role in ensuring the tool’s precision and ease of use. By examining the individual components, users can better understand how the system works and how it can be maintained for optimal performance. Handle Structure: The handle is ergonomically shaped to offer comfort and a secure grip during operation. It typically consists of molded materials that reduce vibration, helping users control the equipment with less strain over extended periods of use. Control Mechanism: The control system generally integrates triggers and switches, allowing the user to regulate speed and power with minimal effort. These components are strategically positioned to enhance accessibility while maintaining safety during operation. Understanding the breakdown of the handle and control system helps in identifying potential issues and carrying out routine maintenance to ensure long-lasting functionality. Safety Features and Their FunctionsEnsuring user protection while operating garden equipment is of utmost importance. Various safety mechanisms are incorporated into tools to minimize risks and enhance safety during use. Understanding these features and their purposes can significantly contribute to a safer working environment. Below are the key safety elements commonly found in gardening tools:

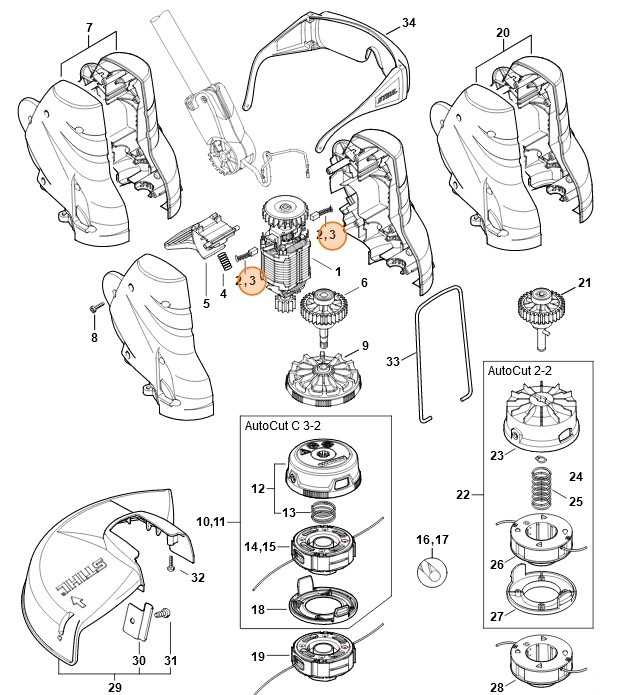

Each of these features plays a critical role in promoting safe practices and reducing the likelihood of accidents while using gardening equipment. Familiarity with these functions helps users operate tools more confidently and responsibly. Trimmer Head Parts Explained

The cutting mechanism of a lawn tool plays a crucial role in achieving a clean and efficient finish when tending to your garden. Understanding the components that make up this mechanism can help users maintain their equipment and ensure optimal performance. 1. Cutting Line: The most essential element of the cutting assembly, this flexible string is designed to slice through grass and weeds with precision. The thickness and material can vary, affecting durability and cutting ability. 2. Spool: This component holds the cutting line and feeds it as needed. Spools can be automatic or manual, with different designs that allow for easy line replacement. 3. Cap: The cap secures the spool in place and often features a mechanism for releasing the cutting line. It ensures that the line remains properly tensioned during operation. 4. Housing: The outer shell encases the internal components and protects them from debris and damage. A well-designed housing enhances durability and minimizes wear. 5. Drive Shaft: This part connects the motor to the cutting assembly, transmitting power to rotate the spool and line. Its design can impact the overall efficiency of the tool. 6. Adaptor: This piece enables the attachment of various cutting accessories, such as blades or different line types. Compatibility is key to maximizing functionality. By familiarizing yourself with these elements, you can better understand the mechanics behind your gardening tool and address any maintenance needs that may arise. Shaft and Support Elements Analysis

This section delves into the fundamental components responsible for stability and movement in cutting equipment. Understanding these elements is crucial for ensuring optimal performance and durability of the tool. Each part plays a vital role in the overall functionality, influencing both efficiency and user experience. Key Components

Importance of Quality Materials

In conclusion, a thorough analysis of the shaft and support elements reveals their critical role in the effective operation of cutting tools. Prioritizing quality and design in these components can lead to improved performance and user satisfaction. Charger and Charging Port Details

The efficiency of battery-operated devices heavily relies on their charging systems. Understanding the components and functionality of the charger and the charging port is essential for maintaining optimal performance and ensuring longevity. This section outlines the crucial aspects of these elements, providing insights into their roles and specifications. Charging System Overview

The charging system typically consists of a power adapter and a connection point on the device. The adapter converts electrical energy from an outlet to a suitable form for the device’s battery. The connection point facilitates the transfer of this energy, enabling the battery to recharge effectively. Connector Specifications

Protective Guard Design and PurposeThe protective shield is a vital component designed to enhance safety during operation. Its primary function is to minimize the risk of injury from debris and other hazards that may be propelled during use. By effectively containing these elements, the shield plays a crucial role in ensuring a secure working environment. Constructed from durable materials, the design of the guard balances strength and lightweight characteristics, allowing for both resilience and ease of handling. Moreover, its shape is meticulously crafted to provide optimal coverage without hindering visibility or maneuverability. This thoughtful engineering ensures that users can perform their tasks efficiently while remaining protected. In addition to safety, the guard serves an aesthetic purpose, contributing to the overall appearance of the equipment. Furthermore, regular maintenance of this component is essential for sustaining its effectiveness and prolonging the lifespan of the equipment. Users should inspect the shield periodically for any signs of wear or damage, ensuring it remains in top condition to fulfill its protective role. Maintaining the Gearbox AssemblyRegular upkeep of the gearbox assembly is essential for ensuring optimal performance and longevity of your equipment. This crucial component plays a significant role in the efficient transmission of power, and proper maintenance can prevent wear and tear, leading to costly repairs or replacements. Understanding the key aspects of maintaining this assembly will help you keep your device in top condition. To effectively care for the gearbox, follow these important steps:

By adhering to these guidelines, you will enhance the reliability of your equipment and extend its operational lifespan. Proper attention to the gearbox assembly ensures that it functions effectively, allowing you to achieve the best results in your tasks. Tips for Ordering Replacement Parts

When it comes to maintaining your equipment, ensuring that you have the right components is crucial for optimal performance. Knowing how to effectively procure necessary items can save you time and frustration. Here are some guidelines to help you navigate the ordering process with ease. First, it is essential to have the correct identification details of the components you need. This includes model numbers and specific descriptions, which can significantly reduce the risk of ordering incorrect items. If possible, refer to user manuals or official resources to gather this information. Next, consider sourcing components from authorized dealers or reputable suppliers. This ensures that you receive genuine items that meet quality standards. Avoiding third-party vendors with unclear reputations can help prevent potential issues with compatibility and durability. Before placing an order, check for availability and lead times. Some items may be out of stock or require longer shipping periods. Planning ahead can prevent unnecessary delays in your maintenance schedule. Finally, keep track of your orders and receipts. Having a record can assist in addressing any discrepancies or issues that may arise during the purchasing process. This organized approach can facilitate smoother transactions and enhance your overall experience. |