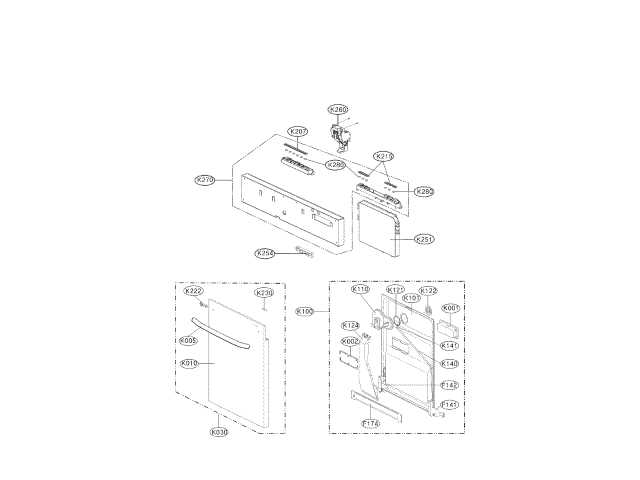

When it comes to maintaining the functionality of any home device, knowing its internal structure is essential. Every household machine, especially those with intricate mechanisms, requires periodic checks and potential replacements of various elements to ensure long-lasting performance. Being familiar with the layout of these essential elements can help in identifying and resolving common issues.

For a more detailed view, examining the specific sections and understanding how each element interacts can be incredibly helpful. This breakdown allows for a deeper understanding of the overall structure, making troubleshooting more efficient. Regular maintenance can also prevent small problems from escalating into larger, more costly repairs.

In this guide, we will explore the critical internal elements of an LG appliance, highlighting their significance and functionality. Whether you’re dealing with an unexpected malfunction or simply want to be more prepared for future maintenance, understanding these key components is an invaluable skill.

Overview of Lg Dishwasher Model LDF7561ST

The kitchen appliance in question combines modern design with high efficiency, offering advanced features tailored for optimal performance. It stands out due to its user-friendly controls, energy-saving capabilities, and smart functionality, making it a reliable addition to any home.

Key Features and Functionality

This unit incorporates a variety of settings designed to handle different cleaning needs, from delicate glassware to heavily soiled cookware. The inclusion of innovative technology ensures thorough washing while reducing water and energy consumption, contributing to both convenience and sustainability.

Design and Usability

Its sleek exterior seamlessly integrates with various kitchen aesthetics, while the interior layout is engineered to maximize space and accommodate a wide range of items. The intuitive interface simplifies the operation, allowing users to select specific cycles and settings with ease.

Key Components and Their Functions

Understanding the primary elements of a kitchen appliance is essential for effective maintenance and troubleshooting. Each part plays a distinct role, ensuring the overall system operates smoothly. Below is an outline of the critical components and their specific purposes.

- Control Panel: This interface allows users to select settings and monitor the operation status. It provides direct access to various programs and cycle options.

- Water Inlet Valve: Regulates the flow of water into the system, ensuring the right amount of water enters during each phase.

- Spray Arms: These rotating elements distribute water throughout the interior, ensuring all items are thoroughly cleaned.

- Heating Element: Responsible for heating the water to optimal temperatures, aiding in both cleaning and drying processes.

- Filter: Captures food particles and debris, preventing them from clogging other sections and ensuring efficient performance.

Each of these components is vital to the smooth and effective operation of the system, working in harmony to deliver optimal performance.

How to Identify the Main Motor

When working with an appliance, pinpointing the core element responsible for the operation of the internal mechanisms is crucial. Among various components, there is one essential piece that drives the overall functionality. Recognizing this central element requires careful observation of its structure and placement.

First, locate the larger cylindrical unit connected to several wires and positioned near the base. This is typically the primary driving force behind the internal movement. Its size and multiple connections make it stand out from other parts.

Next, focus on the arrangement of connectors. The main power source is often linked to this unit, and it will have a noticeable configuration that distinguishes it from other smaller components. Identifying these traits will help in recognizing the correct element.

Understanding the Water Inlet Valve

The water inlet valve is a critical component in controlling the flow of liquid into the system. Its primary function is to regulate the amount of water entering the unit during various cycles, ensuring the correct volume is supplied for optimal performance. This valve is electrically operated and opens or closes based on signals from the control panel, maintaining a delicate balance between water pressure and system needs.

How it Works: When activated, the valve allows the incoming water supply to enter, ensuring the right quantity is delivered. If the valve malfunctions, it may lead to issues such as insufficient or excessive water intake, which can hinder the operation of the unit.

Common Issues: Over time, the valve may become clogged with mineral deposits or debris, causing blockages or slow water flow. In some cases, the valve’s electrical components may fail, preventing it from opening or closing properly. Regular maintenance and timely replacement can prevent such malfunctions and ensure efficient operation.

Exploring the Role of the Drain Pump

The drain pump plays a critical role in maintaining the efficiency of fluid removal from various appliances. It ensures that water is properly expelled during specific cycles, allowing the system to function smoothly without interruptions. Understanding the function of this component is essential for troubleshooting and maintaining the overall performance of the equipment.

Key Features of the Drain Pump

One of the main attributes of this component is its ability to handle significant amounts of water, ensuring rapid and efficient disposal. Additionally, it often includes mechanisms to prevent blockages, making it a reliable part of the fluid management system.

Common Issues and Maintenance

Over time, wear and tear can affect the pump’s performance, leading to reduced efficiency or complete failure. Regular maintenance, such as inspecting and cleaning the pump, can extend its lifespan and help prevent issues that may arise from clogging or motor damage.

Control Board and Its Importance

The control board is a crucial component that orchestrates the various functions of the appliance. It acts as the central hub, ensuring that all processes run smoothly and efficiently. Without it, the appliance would be unable to perform its designated tasks, leading to potential malfunctions or complete failure.

Functionality relies heavily on this essential part, as it processes inputs from various sensors and user commands. It regulates operations such as water intake, heating cycles, and draining, thus ensuring optimal performance. The control board also plays a vital role in diagnostics, allowing users and technicians to troubleshoot issues effectively.

Maintaining the integrity of the control board is vital for the longevity of the appliance. Regular checks can prevent unexpected breakdowns and enhance overall reliability. In cases where replacement is necessary, sourcing high-quality components is imperative to ensure compatibility and performance.

Inspecting the Door Latch Mechanism

The door latch mechanism plays a critical role in ensuring the secure closure of appliances. This component not only facilitates proper sealing but also guarantees safe operation during cycles. Understanding how to inspect and maintain this mechanism can prevent potential issues and prolong the lifespan of the device.

When examining the latch system, consider the following key points:

- Visual Inspection: Check for any visible signs of wear, damage, or misalignment. Look for cracks or broken parts that may hinder functionality.

- Functionality Test: Open and close the door several times to ensure the latch engages and releases smoothly. Listen for any unusual sounds that may indicate a problem.

- Cleaning: Remove any debris or residue that may interfere with the latch operation. Use a damp cloth to clean the latch area thoroughly.

- Adjustment: If the door does not close properly, adjust the latch alignment as necessary. Ensure that it aligns with the strike plate to create a secure seal.

Regularly inspecting this mechanism can enhance safety and efficiency. If issues persist after these checks, professional assistance may be required to resolve complex problems.

Maintenance Tips for Spray Arms

Ensuring optimal performance of the cleaning mechanisms is essential for efficient operation. Regular attention to these components can prevent issues and enhance longevity. Proper care not only improves effectiveness but also minimizes the risk of malfunctions.

Inspect for Clogs: Periodically examine the nozzles and openings for any debris or mineral buildup. Using a soft brush or a toothpick can help clear any blockages, allowing for unobstructed water flow.

Regular Cleaning: Remove the spray arms and clean them thoroughly with warm, soapy water. This practice will help eliminate grease and grime that may accumulate over time, ensuring consistent performance.

Check for Damage: Look for any signs of wear or cracks in the arms. If you notice any damage, consider replacing the component to maintain the efficiency of the cleaning system.

Ensure Proper Alignment: After cleaning, make sure the spray arms are correctly positioned. Misalignment can hinder their ability to distribute water evenly, affecting the cleaning process.

Use the Right Cleaning Agents: When using cleaning solutions, opt for those that are safe for your appliance. Harsh chemicals can deteriorate the materials of the spray arms, leading to premature failure.

Locating the Heating Element

Identifying the component responsible for heating is crucial for ensuring optimal performance in any appliance that relies on hot water for cleaning. This element plays a vital role in raising the temperature of the water, allowing for effective removal of stains and ensuring proper sanitation of items being cleaned.

Accessing the Interior

To begin your search for the heating component, it is essential to access the interior of the unit. This typically involves removing the lower spray arm and any associated covers. Make sure to disconnect the appliance from the power source before proceeding to avoid any electrical hazards.

Identifying the Element

Once the interior is accessible, look for the heating element, which is usually located at the bottom of the appliance. It often resembles a long, tubular metal structure. Take care to inspect it for any signs of damage or corrosion, as these issues can impede its functionality. If necessary, consult the manufacturer’s manual for specific details regarding the component’s placement and maintenance.

Proper Care of the Detergent Dispenser

Ensuring the longevity and effectiveness of the cleaning agent container is crucial for optimal performance. Regular maintenance not only enhances the efficiency of the washing cycle but also prevents residue buildup and blockages that can hinder operation.

Regular Cleaning Practices

To maintain functionality, it is essential to clean the compartment frequently. Use a damp cloth or sponge to wipe away any spills or residues. Avoid abrasive cleaners, as they can damage the surface. Make it a habit to inspect the area during routine cleaning sessions.

Checking for Blockages

Occasionally, check for any obstructions within the container. Ensure that the dispensing mechanism is clear and that the outlet is not clogged. This step is vital for ensuring that the cleaning solution flows freely, allowing for thorough washing results.

Common Issues with Float Assembly

The float assembly plays a crucial role in maintaining the proper water levels within appliances designed for cleaning. When problems arise with this component, they can lead to significant operational inefficiencies, ultimately affecting performance. Understanding these common issues can aid in troubleshooting and maintenance, ensuring smooth functionality.

Water Level Control Problems

One prevalent issue is inaccurate water level regulation. This can occur due to debris accumulation or wear and tear over time, causing the float to stick or malfunction. As a result, the system may either overfill or underfill, leading to inadequate cleaning or potential leaks. Regular inspection and cleaning of the float assembly can help mitigate these issues.

Float Malfunction Symptoms

Symptoms of float assembly malfunctions may include unusual sounds during operation or error messages on control panels. Additionally, users might notice inefficient cleaning results or persistent odors. Addressing these symptoms promptly by examining the float mechanism can prevent further complications and ensure the appliance operates effectively.