In the realm of fluid transfer systems, comprehending the configuration and interaction of various components is essential for efficient operation and maintenance. A detailed layout of these elements aids users in identifying and resolving issues, ensuring optimal functionality.

Each segment within the assembly plays a vital role in the overall performance of the system. Familiarity with how these elements are arranged and function together can significantly enhance the user experience, leading to better decision-making during repairs and replacements.

By examining the visual representation of the component assembly, operators can easily locate specific sections, enhancing their ability to troubleshoot and maintain their equipment effectively. This knowledge not only improves the longevity of the system but also contributes to safety during operation.

Fill Rite Pump Parts Overview

This section provides an overview of the essential components that make up a typical fuel transfer system. Understanding the various elements is crucial for efficient operation and maintenance. Each component plays a significant role in ensuring the system functions smoothly and reliably.

Key Components

Among the most important elements are the motor, which powers the entire mechanism, and the meter that accurately measures the amount of liquid being transferred. Additionally, hoses and nozzles are vital for the safe dispensing of fuel. Proper knowledge of these parts contributes to effective troubleshooting and enhances performance.

Maintenance Considerations

Regular inspection of these components is necessary to prevent malfunctions. Ensuring that all parts are in good working order not only improves efficiency but also prolongs the lifespan of the entire system. Always consult the manufacturer’s guidelines for best practices regarding upkeep and replacement.

Common Components of Fill Rite Pumps

Understanding the essential elements that make up fuel transfer systems is crucial for efficient operation and maintenance. Each component plays a vital role in ensuring smooth functionality and reliability.

- Motor: Provides the necessary power to drive the mechanism.

- Meter: Measures the volume of liquid transferred, ensuring accuracy.

- Hose: Facilitates the movement of liquid from the source to the desired location.

- Nozzle: Controls the flow and prevents spills during dispensing.

- Filter: Removes contaminants from the liquid to protect the system.

- Control Valves: Regulate the flow of liquid, enhancing safety and efficiency.

Each of these elements contributes to the overall effectiveness and safety of the system, making regular inspections and maintenance essential for optimal performance.

Understanding Fill Rite Pump Functionality

This section delves into the operation and principles behind a specific fluid transfer device. The focus is on how this mechanism efficiently moves liquids from one location to another, ensuring precision and reliability in various applications.

Key Components and Their Roles

At the heart of this mechanism lies several essential components that work in unison. Each element, from the motor to the flow measurement device, plays a crucial role in facilitating the transfer process. The motor powers the system, while the flow meter accurately gauges the amount of liquid dispensed. Together, these parts ensure optimal performance and minimize wastage.

Operational Mechanism

The operation of this device is based on a straightforward yet effective principle. When activated, the motor generates the necessary force to draw liquid into the system. This liquid is then propelled through the designated outlet, where it can be directed as needed. The seamless integration of components allows for consistent delivery, making it an indispensable tool in various industries.

Importance of Quality Pump Parts

Ensuring the effectiveness and longevity of any fluid transfer mechanism relies heavily on the quality of its components. High-grade materials and precise manufacturing processes play a pivotal role in the performance and reliability of these systems. Investing in superior elements not only enhances functionality but also reduces the risk of malfunctions.

Benefits of Using High-Quality Components

- Enhanced Durability: Premium materials withstand wear and tear, extending the lifespan of the system.

- Improved Efficiency: High-quality components promote optimal performance, leading to better fluid flow and reduced energy consumption.

- Lower Maintenance Costs: Reliable parts minimize breakdowns, resulting in fewer repairs and less downtime.

Consequences of Inferior Components

- Increased Failure Rate: Substandard elements are prone to breakage, causing unexpected interruptions.

- Reduced Performance: Low-quality components can hinder the overall effectiveness of the system.

- Safety Hazards: Compromised parts may lead to leaks or spills, posing risks to personnel and the environment.

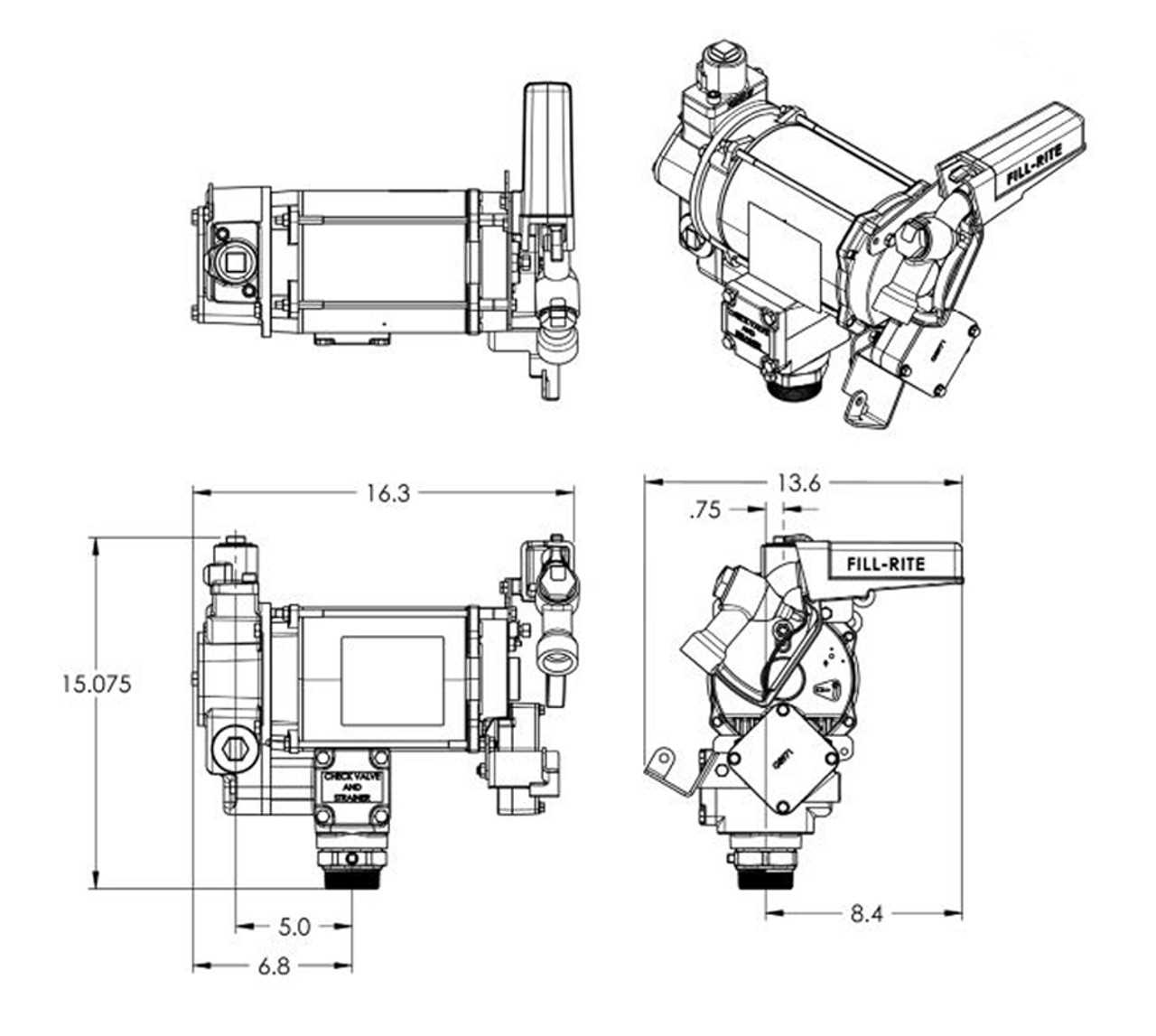

Identifying Fill Rite Model Variations

Understanding the different variations of a specific brand can significantly enhance your experience and efficiency when working with various fuel dispensing systems. Each model may come with unique features and specifications tailored to meet diverse operational requirements. By familiarizing yourself with these variations, you can make informed decisions regarding maintenance, upgrades, or replacements.

Common Features Across Models

Many models share fundamental characteristics, such as flow rates, power sources, and control mechanisms. However, subtle differences in design, materials, and capabilities may exist, affecting performance and durability. Recognizing these features can help users select the most appropriate unit for their specific needs.

Decoding Model Numbers

Model numbers often contain essential information that reveals the specifications and features of the equipment. Each segment of the number may signify a particular attribute, such as size, capacity, or intended use. By decoding these numbers, users can quickly identify the appropriate variant and understand its unique functionalities.

Maintenance Tips for Fill Rite Pumps

Proper upkeep of your fuel transfer equipment is essential for optimal performance and longevity. Regular maintenance not only ensures efficiency but also minimizes the risk of costly repairs and downtime. Adhering to a structured maintenance routine can significantly enhance the reliability of your device.

Inspect Regularly: Conduct frequent checks to identify wear and tear, leaks, or loose connections. Early detection of issues can prevent more serious problems later on.

Keep It Clean: Ensure the exterior and interior components are free from dirt and debris. A clean unit functions better and reduces the risk of contamination in the fluid being transferred.

Lubrication: Apply appropriate lubricants to moving parts according to the manufacturer’s specifications. Regular lubrication minimizes friction and extends the lifespan of mechanical components.

Monitor Performance: Keep an eye on the flow rate and pressure during operation. Any significant changes may indicate underlying issues that need addressing.

Follow Manufacturer Guidelines: Always refer to the maintenance manual provided by the manufacturer. It contains specific recommendations tailored to your model, ensuring you follow best practices.

Tools Required for Pump Repairs

Repairing a liquid transfer device requires specific instruments to ensure efficiency and safety. Having the right tools on hand can significantly streamline the process, reduce the risk of damage, and enhance overall functionality.

Essential Instruments

Among the vital instruments are wrenches, screwdrivers, and pliers. Each tool serves a specific purpose, facilitating the disassembly and reassembly of components effectively. Additionally, a torque wrench is crucial for maintaining proper fastening standards, while a multimeter can help diagnose electrical issues.

Recommended Tool Kit

| Tool | Purpose |

|---|---|

| Wrench Set | Loosening and tightening fasteners |

| Screwdriver Set | Adjusting screws in various components |

| Pliers | Gripping and twisting wires |

| Torque Wrench | Ensuring proper tension on bolts |

| Multimeter | Measuring electrical parameters |

Investing in quality tools will not only improve repair outcomes but also prolong the lifespan of the equipment.

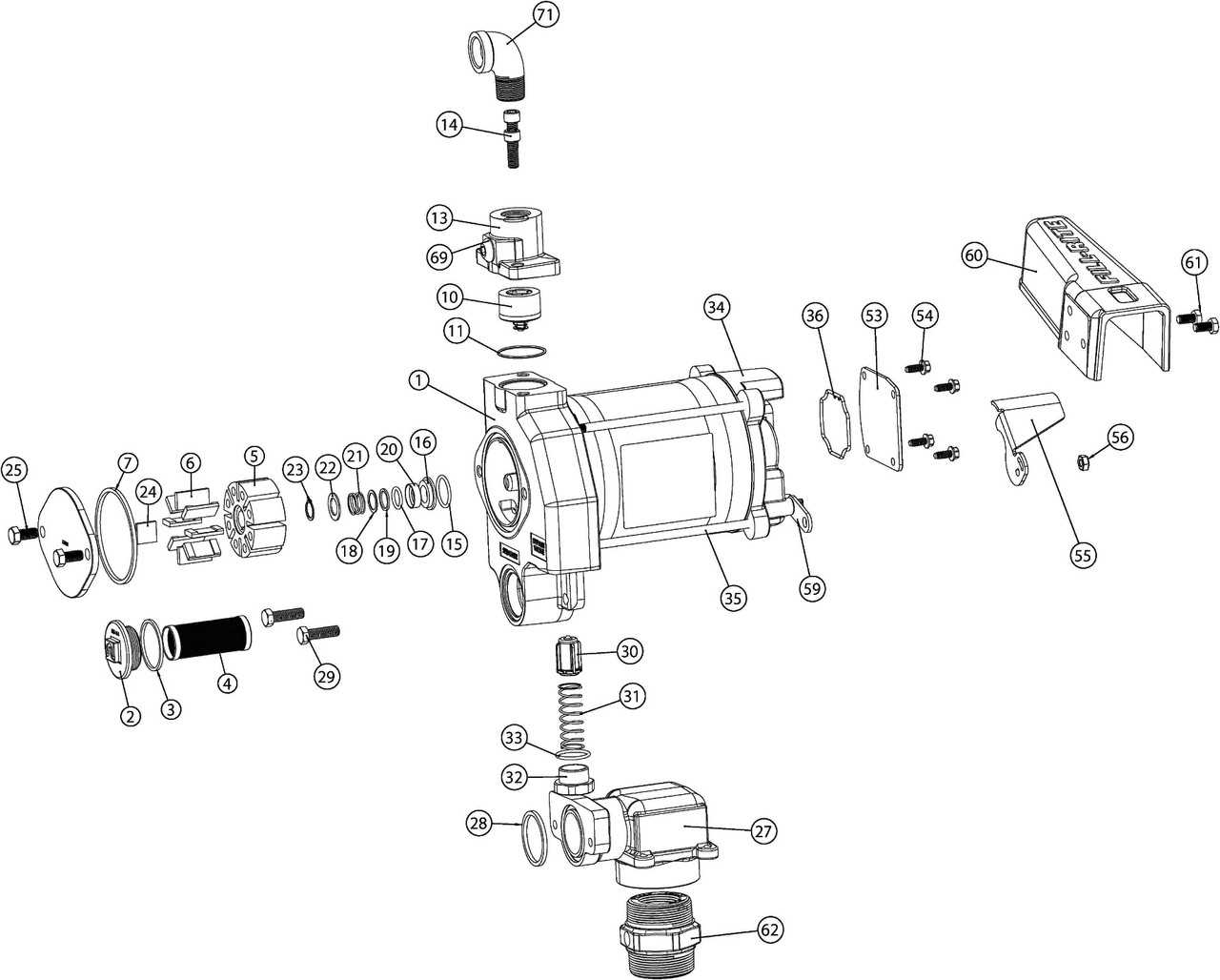

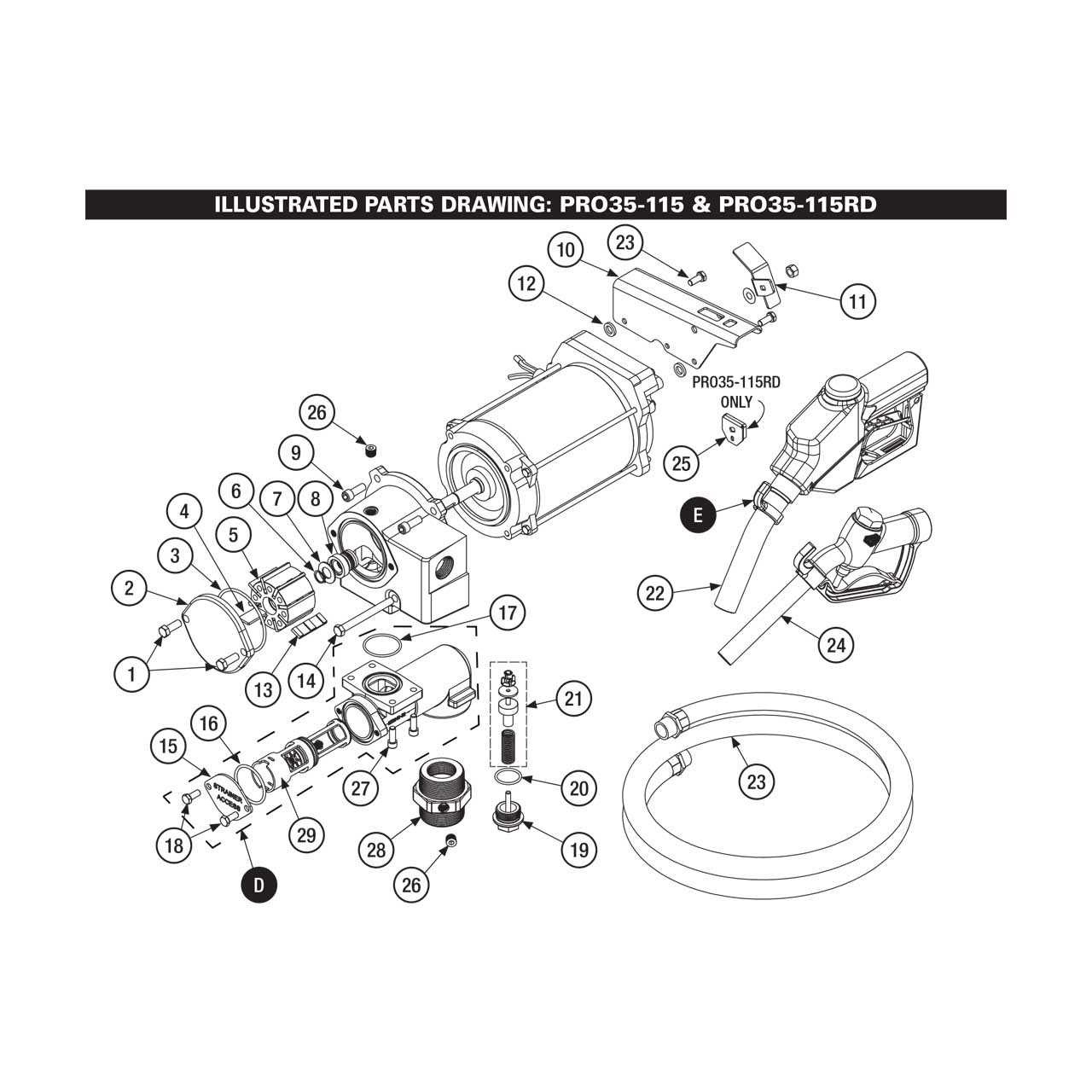

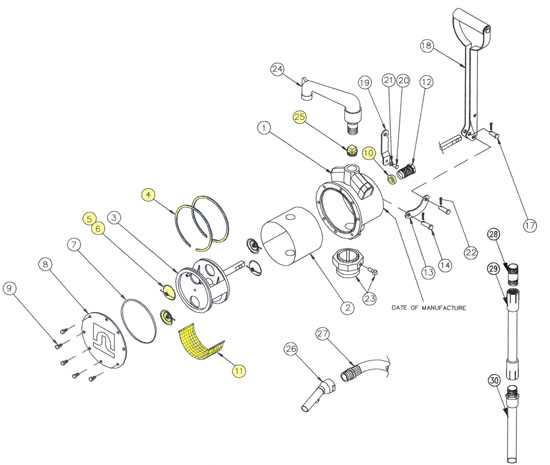

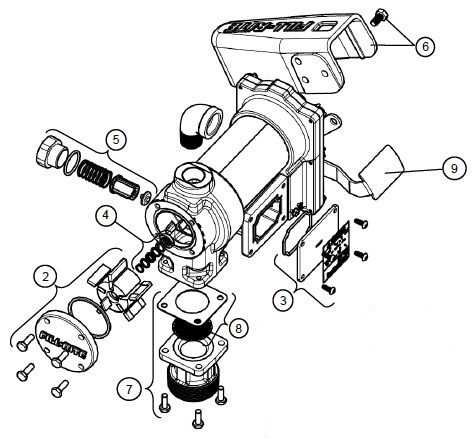

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide crucial information about the various elements within a system, allowing users to identify, analyze, and replace specific components as needed.

Interpreting Symbols and Labels

Each illustration typically features a range of symbols and labels that denote different elements. Familiarizing yourself with these icons is vital. Look for key notations that indicate the function or specifications of each part. Additionally, pay attention to any reference numbers, which often correlate with a list of available components.

Following the Assembly Flow

Another important aspect is the sequence in which components are organized. Most visuals arrange elements in a way that reflects their assembly or connection order. By following this flow, you can better understand how parts interact and identify the appropriate steps for disassembly or replacement.

In summary, mastering the interpretation of visual representations enhances your ability to perform repairs effectively and ensures a thorough understanding of the system’s structure.

Ordering Replacement Fill Rite Parts

When it comes to maintaining your equipment, ensuring that all components are functioning properly is crucial. Obtaining the right replacements can greatly enhance performance and extend the lifespan of your machinery. Whether you’re looking to replace a damaged component or upgrade to a more efficient alternative, knowing how to effectively source these items is essential.

To begin the process, identify the specific components you need. Make use of the original manufacturer’s reference numbers or descriptions, as this will help streamline your search. It’s advisable to consult your equipment’s manual or the manufacturer’s website for detailed specifications and recommendations.

Once you have the necessary information, you can explore various purchasing options. Authorized dealers, online retailers, and specialized suppliers are excellent resources. Ensure that you verify the reputation of the seller to guarantee the quality and authenticity of the items you are ordering.

In addition, consider reaching out to customer support for assistance. They can provide valuable insights into the availability of items and may help you locate hard-to-find replacements. Properly addressing your needs ensures that your equipment continues to operate smoothly and efficiently.

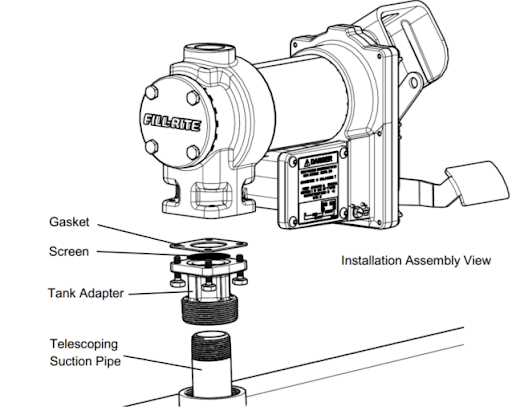

Installation Process for Pump Components

The installation of essential components in fluid transfer systems requires careful planning and execution. Proper integration of these elements ensures optimal performance and longevity. Understanding the sequence and methods involved is crucial for achieving seamless operation.

Begin by reviewing the manufacturer’s guidelines, which provide specific instructions tailored to the equipment being used. Ensure all necessary tools are on hand, including wrenches, screwdrivers, and sealants. Preparing the workspace by cleaning the area will facilitate a smoother installation process.

Next, assemble the individual components according to the provided schematics. It is important to tighten connections firmly but avoid over-torquing, which can lead to damage. Utilize appropriate gaskets and seals to prevent leaks, ensuring a tight fit between surfaces.

After assembly, conduct a thorough inspection to verify that all elements are securely in place and aligned correctly. Once satisfied with the setup, proceed to test the system under controlled conditions. Monitor for any irregularities or leaks during the initial operation phase, making adjustments as needed to ensure optimal functionality.

Common Issues with Pump Parts

When dealing with fluid transfer equipment, several common challenges can arise that may hinder efficiency and performance. Understanding these issues can help users identify and rectify problems quickly, ensuring smooth operation.

- Leaking Seals: One of the most frequent issues involves worn or damaged seals, which can lead to significant fluid loss and environmental concerns.

- Clogged Filters: Accumulation of debris can obstruct filters, reducing flow and causing the system to work harder than necessary.

- Motor Malfunctions: Electrical or mechanical failures in the motor can disrupt the entire operation, leading to downtime and repair costs.

- Poor Connections: Loose or corroded connections can create pressure drops and leaks, compromising the system’s integrity.

- Wear and Tear: Components such as impellers and shafts can degrade over time, affecting the overall performance and requiring timely replacement.

Regular maintenance and timely inspections can prevent these common issues, prolonging the lifespan of the equipment and ensuring reliable operation.

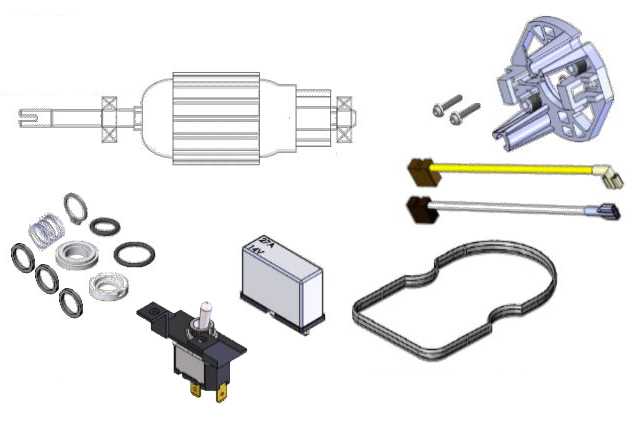

Enhancing Performance with Upgraded Parts

Upgrading components can significantly improve the overall efficiency and functionality of equipment. By selecting high-quality alternatives, users can experience enhanced performance, reduced downtime, and prolonged service life. The right modifications not only optimize operations but also contribute to cost savings in the long run.

Consider the following benefits of utilizing upgraded components:

- Improved Efficiency: Enhanced materials and designs often lead to better energy consumption and operational output.

- Increased Durability: Higher quality components are designed to withstand harsher conditions, reducing wear and tear.

- Optimized Performance: Tailored upgrades can enhance specific functions, leading to smoother and faster operations.

- Cost-Effectiveness: While initial investment may be higher, the reduction in maintenance and replacement costs makes upgrades financially beneficial.

When considering enhancements, it is essential to evaluate compatibility with existing systems. Conducting thorough research and consulting with experts can guide users in selecting the most appropriate alternatives. With the right upgrades, users can unlock the full potential of their equipment and achieve superior performance levels.