When working with heavy machinery, having a clear understanding of the arrangement and functionality of various components is crucial. This section delves into the intricate designs that make up the machinery, highlighting how each element interacts within the larger system. Recognizing these configurations not only aids in maintenance but also enhances overall efficiency.

Visual aids play a vital role in grasping the complexity of mechanical systems. By examining these representations, operators and technicians can pinpoint specific elements and their respective functions, facilitating a more streamlined approach to repairs and upgrades. It empowers users to make informed decisions regarding replacements and enhancements, ensuring optimal performance.

Moreover, an in-depth exploration of these layouts fosters a greater appreciation for the engineering behind the machinery. Understanding how each part contributes to the overall operation can inspire confidence in handling equipment and performing necessary adjustments. This knowledge is essential for anyone involved in the maintenance and operation of complex machinery.

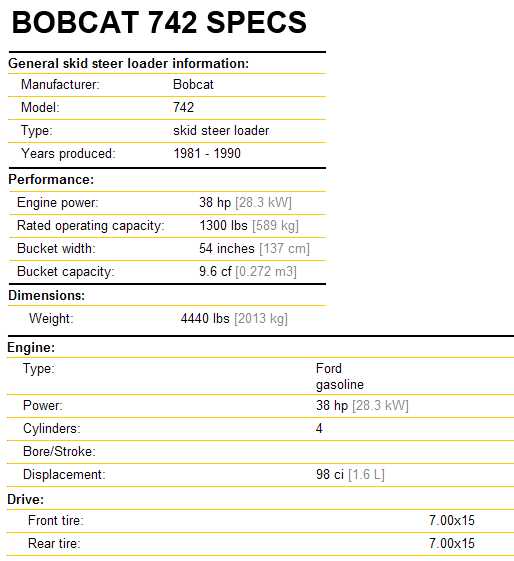

Overview of Bobcat 742 Parts

This section provides a comprehensive look at the essential components of a specific machine model. Understanding the various elements that make up this equipment is crucial for effective maintenance and operation. Each part plays a vital role in ensuring optimal performance and longevity.

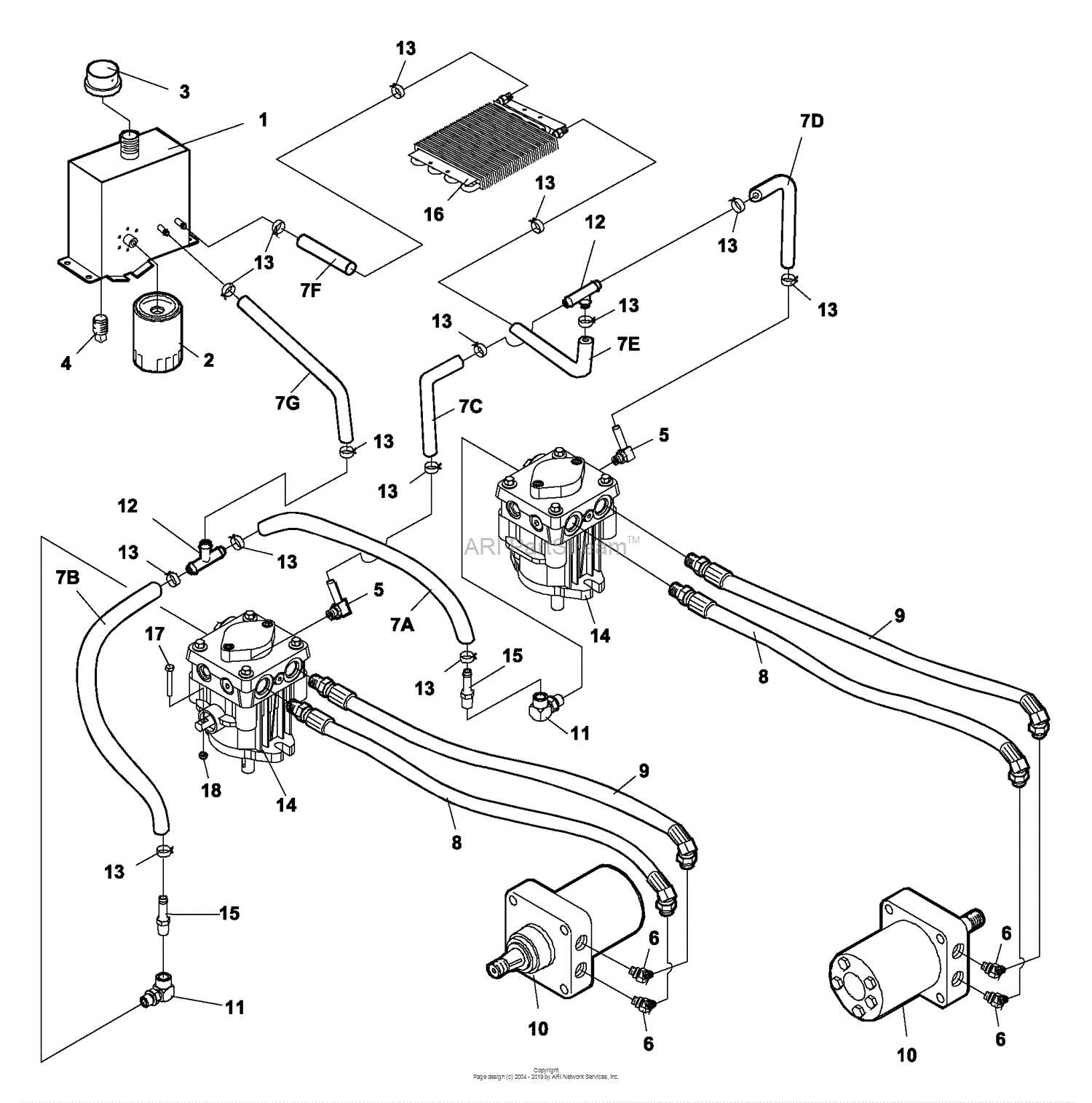

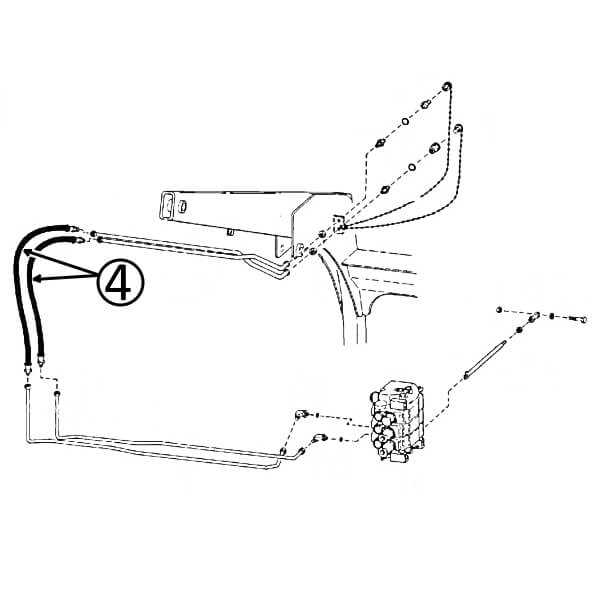

Key Components: The machinery consists of several integral sections, including the hydraulic system, engine assembly, and structural framework. Each section serves a unique function, contributing to the overall efficiency and capability of the unit.

Maintenance Considerations: Regular inspections and replacements of these elements are necessary to prevent unexpected failures. Familiarity with the individual components allows operators to identify issues early and ensure smooth functionality.

Importance of Parts Diagrams

Visual representations of components play a crucial role in the maintenance and repair processes of machinery. They provide a clear overview of each element within the system, enabling users to identify, locate, and understand the function of various parts effectively. This understanding is essential for both experienced technicians and those less familiar with the machinery.

Utilizing these visual guides can lead to several benefits:

- Enhanced Clarity: Clear visuals help in comprehending the assembly and interaction of different components.

- Efficient Repairs: Identifying specific elements allows for quicker troubleshooting and replacement.

- Improved Communication: These visuals facilitate better communication between technicians and clients, ensuring everyone understands the necessary work.

- Comprehensive Understanding: Users can gain insight into how components interact, leading to a deeper appreciation of the machine’s functionality.

Overall, having access to well-structured visual aids is invaluable for ensuring efficient operation and maintenance, ultimately contributing to the longevity and reliability of the equipment.

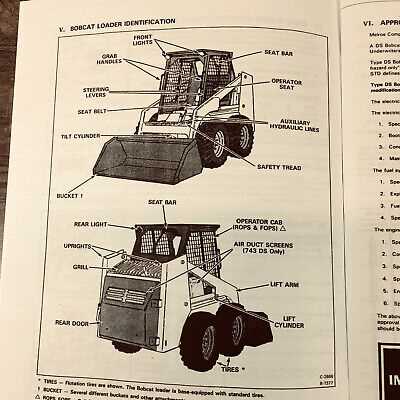

Common Components of Bobcat 742

This section highlights the essential elements found in a specific model of compact machinery. Understanding these components is crucial for maintenance and effective operation. Each part plays a vital role in ensuring the overall functionality and reliability of the equipment.

Key elements include the engine, which provides the necessary power for operation, and the hydraulic system, responsible for lifting and maneuvering various attachments. The undercarriage, consisting of tracks or wheels, facilitates movement across different terrains. Additionally, the control system allows operators to manage the machine’s functions with precision, enhancing efficiency during use.

Moreover, attachments such as buckets and forks contribute to the versatility of the equipment, enabling it to perform a wide range of tasks, from digging to lifting. Regular inspection and maintenance of these components ensure the longevity and performance of the machinery, making it an indispensable tool in various industries.

Finding Replacement Parts Easily

Locating suitable components for machinery can often be a daunting task. However, by employing the right strategies, you can streamline the process and ensure that you obtain the necessary items without unnecessary delays. Understanding where to look and what to consider can save you both time and resources.

Utilizing Online Resources

The internet is a treasure trove of information when it comes to sourcing essential components. Numerous websites offer comprehensive catalogs, providing detailed specifications and compatibility information. Make sure to take advantage of forums and community groups where fellow users share their experiences and recommendations regarding specific suppliers. This can lead you to reputable sources that you may not have found otherwise.

Consulting Local Dealers

Another effective approach is to reach out to local suppliers or authorized dealers. They often have access to the latest inventory and can provide valuable insights into which components are best suited for your requirements. Establishing a relationship with these professionals can also lead to personalized support and advice tailored to your needs.

Understanding Part Numbers and Codes

In the realm of machinery and equipment, the significance of numerical identifiers cannot be overstated. These alphanumeric sequences serve as a universal language, enabling users to communicate effectively about components and their specifications. By grasping the system behind these identifiers, one can streamline the process of sourcing and identifying essential elements for maintenance and repair tasks.

The Structure of Identifiers

Typically, these codes consist of a combination of letters and numbers that convey crucial information about a component’s specifications and compatibility. The initial characters may denote the category or type of the item, while subsequent digits often provide details about dimensions, material composition, or design variations. Understanding this structure can greatly enhance one’s ability to navigate catalogs and databases effectively.

Importance of Accurate Identification

Utilizing correct identifiers is vital to ensuring that the right components are acquired for specific machinery. Misidentification can lead to incompatible parts, resulting in operational inefficiencies or even damage to the equipment. Thus, investing time in learning the nuances of these codes can pay significant dividends in maintaining performance and extending the lifespan of machinery.

Tips for Maintaining Your Equipment

Proper care of machinery is essential for ensuring longevity and optimal performance. Regular maintenance can prevent unexpected breakdowns and costly repairs. Implementing a consistent routine for inspecting and servicing your equipment will enhance its efficiency and reliability.

Regular Inspections

- Schedule periodic checks for wear and tear on all moving parts.

- Inspect fluid levels, including hydraulic and engine oil, to ensure they are within recommended ranges.

- Look for signs of leaks, rust, or damage to components.

Cleaning and Lubrication

- Clean the exterior and interior surfaces to remove dirt and debris that could affect performance.

- Apply appropriate lubricants to joints and bearings to minimize friction and wear.

- Replace filters regularly to maintain air and fluid quality.

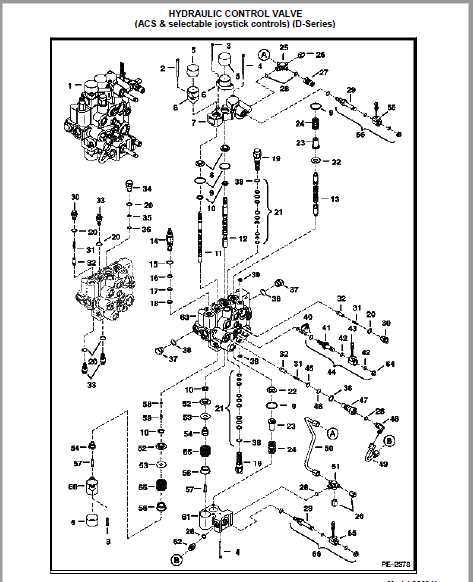

How to Read Parts Diagrams

Understanding technical illustrations is essential when identifying and replacing components in any mechanical system. These visuals often provide a clear representation of various elements, offering a systematic way to locate specific items and their relationships within the assembly.

To effectively interpret these images, it’s important to familiarize yourself with the layout. Typically, each image is divided into sections, showing the complete structure and how each piece connects with the others. The numbers or codes alongside the items help you identify them in the accompanying list, making it easier to find what you need.

Key Symbols and Numbering

Pay attention to the numbering system. Numbers or symbols are used to reference the specific items in the chart. These correspond to the descriptions and part numbers in a table, ensuring quick identification. Each section might include fasteners, larger components, or even optional accessories, all indicated with unique identifiers.

| Number | Description | Reference Code |

|---|---|---|

| 1 | Main Assembly | A1234 |

| 2 | Fastener Kit | B5678 |

| 3 | Optional Bracket | C9012 |

By cross-referencing the codes in the table with the visual guide, you can pinpoint the exact elements you need for maintenance or replacement.

Where to Buy Genuine Parts

When it comes to maintaining machinery, finding reliable sources for original components is essential for ensuring long-term performance and reliability. Selecting trusted retailers or distributors that offer certified equipment guarantees a better fit and extended lifespan for your machine.

Below is a table highlighting various options where you can source these essential components:

| Supplier | Location | Website |

|---|---|---|

| Heavy Equipment Retailers | Various locations nationwide | www.heavyequip.com |

| Authorized Dealers | Local and regional outlets | www.authdealequip.com |

| Online Marketplaces | Worldwide shipping | www.equipmentmarketplace.com |

By purchasing from these reliable sources, you ensure that your equipment continues to function smoothly with components that meet the required standards.

Comparing OEM and Aftermarket Options

When it comes to replacing components for your machine, there are two primary options to consider: original equipment manufacturer (OEM) parts and aftermarket alternatives. Both choices have their own benefits and challenges, making the decision dependent on your specific needs and priorities. Understanding the differences can help you choose the most suitable option for your equipment.

Quality and Compatibility

OEM components are designed specifically for your machine model, ensuring precise compatibility and reliability. These parts are typically backed by the original manufacturer, which can provide peace of mind regarding their quality and durability. On the other hand, aftermarket options often offer a broader selection at competitive prices. However, their quality and fit may vary depending on the supplier, so careful research is essential to ensure a good match for your equipment.

Cost and Availability

One of the biggest advantages of aftermarket products is their affordability. These parts are usually available at a lower cost compared to their OEM counterparts, making them a popular choice for those looking to save money. However, OEM components might be more readily available through official channels, especially for newer models, providing an advantage in terms of quick replacements and maintaining manufacturer warranties.

Frequently Asked Questions about Parts

This section addresses common questions regarding components and their maintenance. Whether you’re dealing with replacements, upgrades, or general care, the following information should help clarify the most common concerns users face.

What should I consider when choosing replacement components?

- Ensure compatibility with your machine model to avoid malfunctions.

- Always check the material quality and durability before purchasing.

- Review the manufacturer’s recommendations for optimal performance.

How do I know when it’s time to replace a component?

- Look for signs of wear such as rust, cracks, or abnormal noises.

- If the machine’s performance has noticeably decreased, this could indicate a need for replacement.

- Regular maintenance checks can help detect issues early before they lead to bigger problems.

If you have any other questions, consult a trusted expert or refer to the product’s technical manual for detailed instructions.

Resources for Bobcat Owners

Finding the right tools and guidance for maintaining and repairing your equipment is essential for long-term performance. Accessing reliable materials, whether in the form of manuals or technical support, ensures smooth operation and helps prevent potential issues.

Online Support Platforms

Many manufacturers offer extensive online resources, including detailed guides, troubleshooting advice, and expert recommendations. These platforms provide users with the most up-to-date information and direct access to customer service.

Local Service Centers

For those who prefer hands-on assistance, service centers are a great option. Certified technicians are available to provide in-depth repairs and maintenance, ensuring your machine stays in top condition. Additionally, local centers often have access to genuine components to ensure compatibility and longevity.