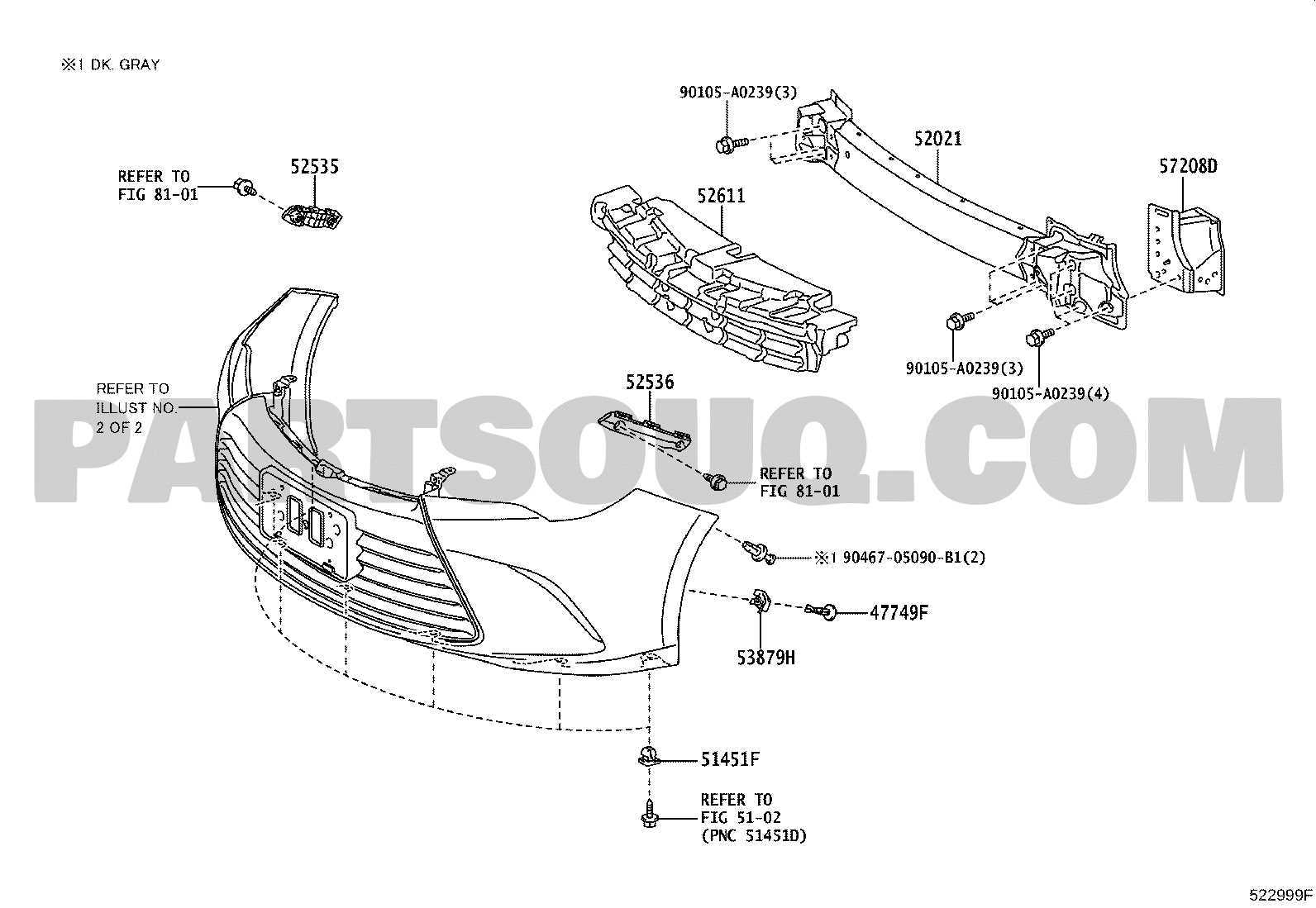

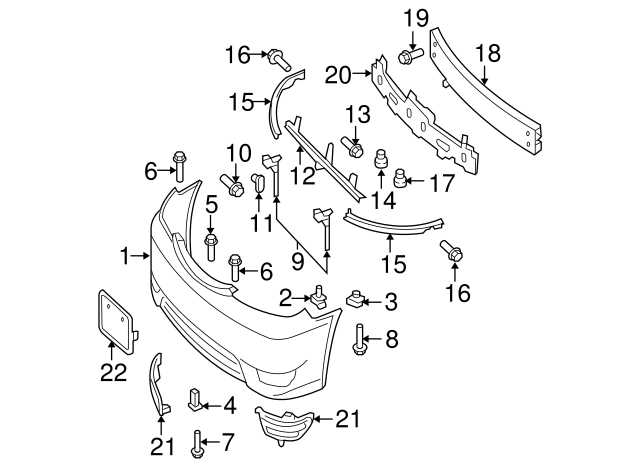

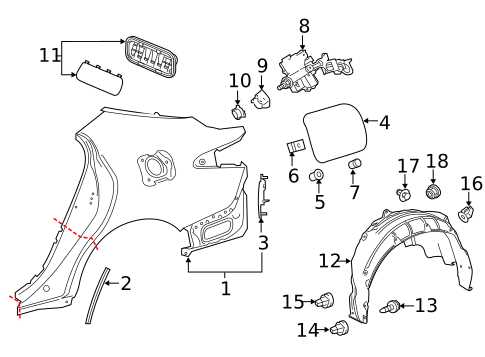

This section delves into the intricate arrangements of essential elements within a specific automotive model, offering insights into their functionality and connectivity. By exploring these layouts, enthusiasts and professionals alike can gain a comprehensive understanding of how each component interacts within the system.

Detailed visual representations serve as invaluable resources for those seeking to enhance their knowledge or undertake maintenance tasks. By analyzing these arrangements, users can efficiently identify, replace, or modify components to ensure optimal performance.

Additionally, familiarity with the layout not only aids in troubleshooting but also empowers individuals to make informed decisions regarding upgrades or repairs, ultimately contributing to a more seamless automotive experience.

The functionality of the vehicle’s movement relies heavily on the mechanisms that control power delivery. One of the essential systems responsible for efficient energy transfer is the transmission. This section outlines the primary components involved in the operation, ensuring the vehicle can shift gears and maintain speed smoothly.

Main Components

- Gearbox: A structure housing gears that work together to control speed and torque.

- Clutch: This mechanism engages or disengages power flow between the engine and the gearbox.

- Driveshaft: Transmits torque from the gearbox to the differential, ensuring rotational energy reaches the wheels.

- Differential: A gear assembly that allows the wheels to rotate at different speeds, critical for smooth cornering.

How It Operates

- When the engine generates power, the clutch allows selective engagement of the gearbox.

- The gearbox adjusts the torque and speed ratio by shifting through different gears.

- The driveshaft transfers rotational energy from the gearbox to the differential.

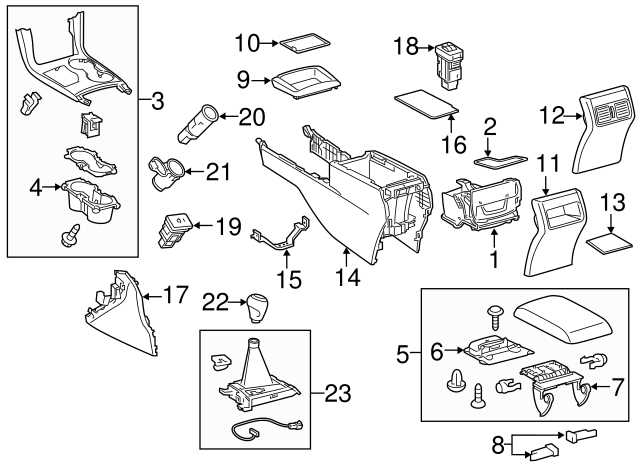

- Steering mechanism and instrument panel in direct view

- Center console for quick access to essential controls

- Air conditioning and ventilation outlets strategically placed for even airflow

- Front seats with adjustable features for personalized comfort

- Rear seating with folding mechanisms for additional cargo space

- Headrests positioned for maximum support and safety

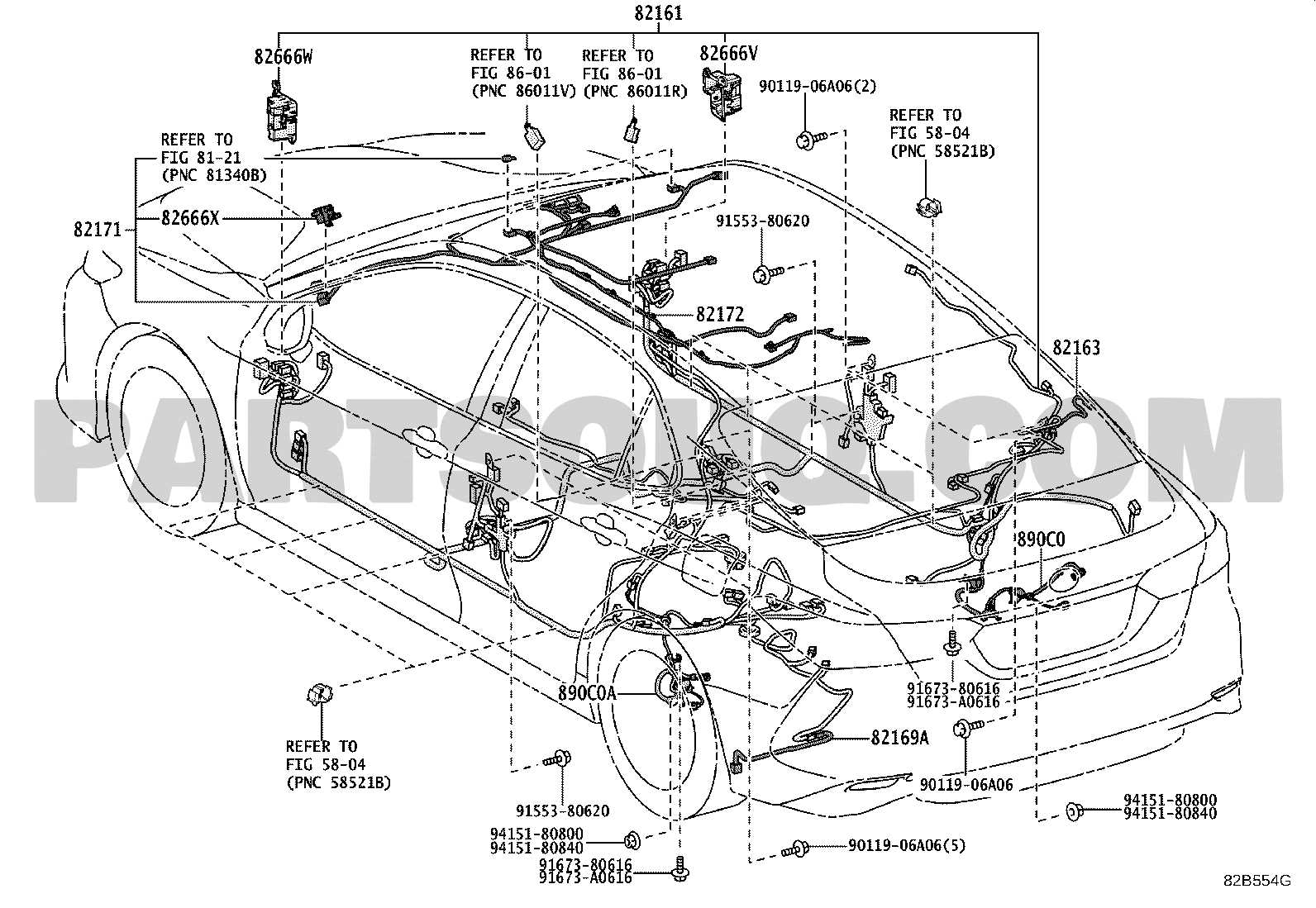

Electrical System Layout Explained

The electrical framework of a vehicle is a complex network designed to manage various essential functions. This system provides the necessary power for multiple components, ensuring that both basic and advanced features operate efficiently. Understanding the organization of this framework is crucial for maintaining overall functionality and detecting potential issues.

Main Power Distribution

The power distribution system plays a central role in delivering energy to different areas of the vehicle. It is connected to critical modules and wiring that ensure smooth operation of the engine, lighting, and safety features. The flow of current is managed through strategically placed circuits and fuses to prevent overloads and ensure protection.

Wiring and Component Connections

The wiring serves as the lifeline, connecting all major components, from control units to individual sensors. Each section of the system is designed to handle specific voltage and current levels, ensuring compatibility across various subsystems. Proper insulation and routing of the cables are essential for minimizing interference and maintaining reliability.

Suspension System Overview

The suspension setup plays a crucial role in ensuring a vehicle’s stability, handling, and overall comfort. It is designed to absorb shocks from uneven road surfaces while maintaining tire contact with the road for optimal control. This system impacts not only ride quality but also safety and maneuverability.

Main Components

The system is comprised of several key elements that work in harmony to manage movement. These include the springs, which bear the vehicle’s weight and absorb road impacts, and dampers, which control the motion of the springs to prevent excessive bouncing. Additionally, control arms help manage the alignment of the wheels and allow them to move up and down with minimal disruption to the chassis.

Stabilization and Balance

A crucial part of this setup is maintaining equilibrium during cornering and sudden maneuvers. Anti-roll bars are integrated to minimize body roll by distributing forces more evenly between wheels. This helps the vehicle stay level during sharp turns, enhancing both driver confidence and passenger comfort. Proper tuning of the entire structure is key to ensuring a balanced performance under different driving conditions.

Brake System Parts Identification

The braking mechanism of a vehicle is critical for ensuring safe operation on the road. This system is composed of several interconnected elements that work together to bring the vehicle to a smooth and controlled stop. Understanding how each component functions within this system is essential for proper maintenance and repair.

Key Components

The main components of the braking system include several elements designed to provide stopping power and maintain control. Each element has its unique role in converting kinetic energy into heat, effectively slowing down the vehicle.

| Component | Description | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Caliper | Houses the pads and applies pressure to the disc, causing friction to slow down the wheels. | ||||||||

| Rotors | Rotating discs that work in conjunction with the calipers to slow down the vehicle. | ||||||||

| Pads | Friction material that presses against the rotors to create the stopping force

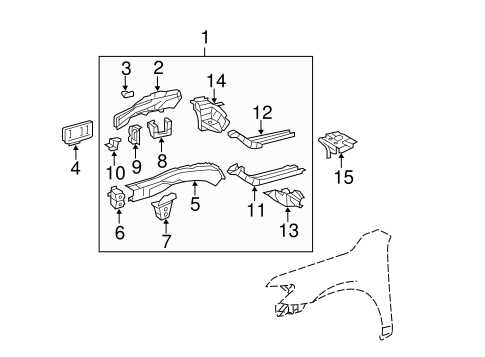

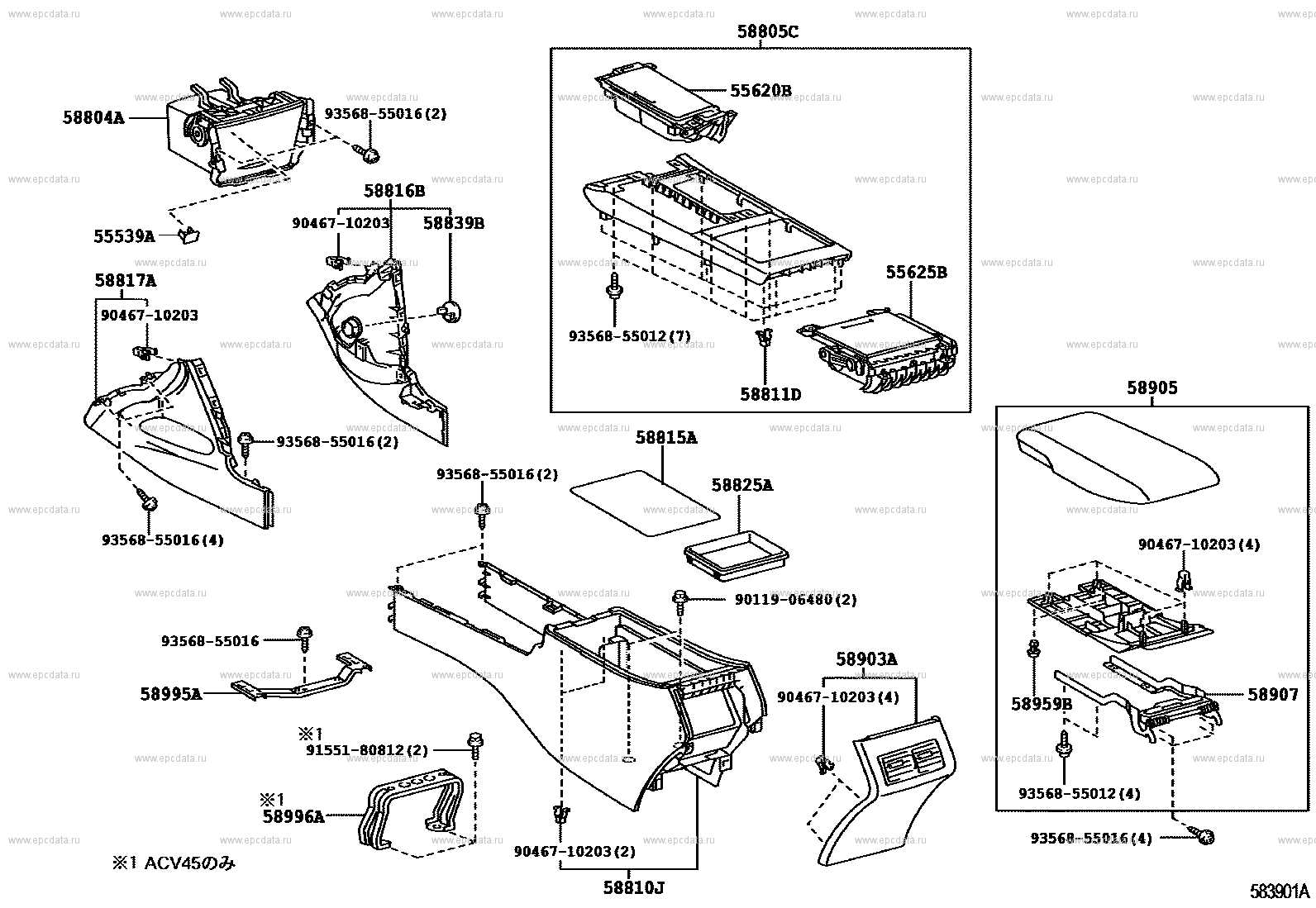

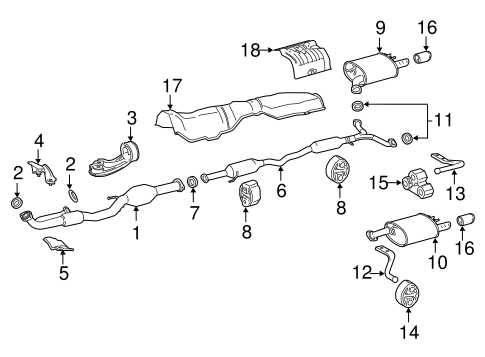

Fuel System Component Overview

The fuel system plays a critical role in ensuring the engine receives the proper amount of fuel for combustion. It is a carefully designed network that manages the storage, filtration, and delivery of fuel to the engine in a precise manner. Each element of this system works in unison to maintain efficiency, performance, and safety. Main ComponentsThis system consists of several interconnected elements that collaborate to transport fuel from the tank to the engine. Key components include the fuel pump, which provides the necessary pressure, and a filtration mechanism that removes impurities. The fuel injectors precisely control the amount of fuel that reaches the engine, ensuring optimal performance. Operational ProcessWhen the engine starts, fuel is drawn from the tank and pushed through a series of filters. The system’s pressurization ensures that the fuel reaches the injectors efficiently. These injectors spray the fuel into the combustion chamber in a fine mist, where it mixes with air, allowing for efficient combustion and power generation. Proper functioning of this entire process is essential for smooth engine operation. Cooling System Diagram InsightsThe cooling mechanism plays a crucial role in maintaining the temperature balance within an engine, preventing it from overheating during operation. By efficiently managing heat dissipation, the system ensures that all components remain within safe thermal limits. This process involves the circulation of a specific liquid that absorbs heat and disperses it through various channels. Key elements include a network of conduits, pumps, and heat exchangers, which work together to regulate temperature effectively. This network ensures a constant flow of the cooling medium, distributing it through critical areas of the engine. The continuous operation of these components allows for optimal thermal control, ensuring longevity and performance. To fully understand how this setup operates, it is essential to examine the layout and interactions of its primary units, which include the temperature regulator, distribution system, and cooling medium reservoir. Each of these elements contributes to maintaining engine efficiency and preventing potential malfunctions due to thermal stress. Interior Parts ArrangementThe layout of components within the vehicle’s cabin plays a crucial role in providing both comfort and functionality for the driver and passengers. Careful positioning of elements ensures ease of use, ergonomic design, and an overall sense of organization within the space. Understanding the arrangement can help in maintaining and optimizing the interior for a better driving experience. Key Components LayoutThe primary elements inside are arranged for optimal accessibility and efficiency. From the driver’s seat to the passenger zone, the configuration is designed to offer a seamless interaction with controls and features. Seating and Comfort ElementsSeating positions are crucial for both comfort and safety. Properly designed seats ensure that all occupants have the best possible experience. Exterior Components DescriptionThe outer structure of a vehicle plays a significant role in both aesthetics and functionality. These external elements are designed to enhance the appearance while providing practical benefits, such as protection and improved performance. Each component has a specific function that contributes to the overall efficiency and safety of the vehicle. Primary ElementsSeveral key elements form the framework of the vehicle’s exterior. These include the surfaces responsible for aerodynamic efficiency, as well as features that offer protection against environmental factors. Additionally, the design ensures improved visibility and accessibility. Detailed Overview

|