For effective operation and long-term reliability of any outdoor equipment, it’s essential to have a clear understanding of its structure and how each part functions. Every component plays a vital role in ensuring the machine operates smoothly, whether it’s for routine upkeep or handling more intensive tasks. A clear insight into the arrangement and interaction of these elements can help avoid potential issues and extend the equipment’s lifespan.

In this section, we’ll delve into the key elements that are critical to ensuring the machinery operates at its full potential. By familiarizing yourself with these components, you’ll be better equipped to perform maintenance, troubleshoot issues, and carry out repairs when necessary. From moving parts to smaller, often overlooked sections, each piece is important in achieving optimal performance.

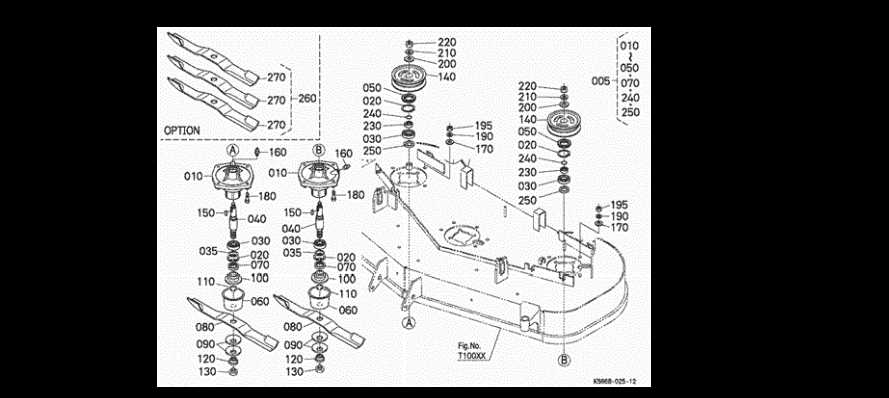

Kubota ZD21: Key Deck Components

The cutting system of this machine is designed with efficiency and durability in mind. Several essential components work together to ensure optimal performance, allowing for even and precise mowing results. Understanding these parts is crucial for maintaining the functionality and longevity of the system.

- Blades: The sharp, rotating elements responsible for cutting grass evenly. Regular maintenance is necessary to prevent dullness and ensure smooth operation.

- Spindles: These are the supports for the blades, keeping them secure and in proper alignment during operation. Any damage or wear to these can affect cutting precision.

- Belts: These transfer power from the engine to the cutting system. Over time, belts can stretch or crack, requiring inspection and replacement.

- Pulleys: These work

Understanding the Deck Assembly Layout

The assembly of the cutting platform consists of several interconnected components that ensure smooth operation and effective grass management. These components are carefully arranged to provide optimal functionality, ensuring even cutting and durability under various working conditions. By examining the arrangement of these elements, one can better understand how they work together to achieve precise cutting results.

Main Structural Components

The main structure includes the blade system, pulleys, and tensioners, all of which play crucial roles in the overall performance. The blade system is responsible for cutting, while the pulleys help in transmitting power. Tensioners ensure proper alignment and stability during operation. Proper maintenance of these components guarantees longevity and consistent performance.

Interaction of Mechanical Elements

Various mechanical elements such as belts, spindles, and idlers interact to maintain the proper motion and power distribution throughout the system. These elements are essential in balancing the operational load

Essential Blades and Their Function

Blades are critical components in mowing machinery, directly influencing the quality of the cut and the efficiency of the equipment. Choosing the right type of blade for specific tasks ensures optimal performance and longevity of the machine. Each blade design serves a distinct purpose, from basic trimming to handling tougher vegetation, making it essential to understand their functions and roles.

Types of Blades

There are several blade types available, each designed to cater to different mowing conditions. Common variants include standard blades, mulching blades, and high-lift blades. Each type has unique characteristics that make it suited for specific tasks, such as discharging grass or finely chopping clippings for better decomposition.

Blade Characteristics

Blade Type Main Function Standard Spindle Mechanism Overview and Maintenance

The spindle mechanism plays a crucial role in ensuring efficient cutting performance. By transferring power from the engine to the cutting blades, this system allows for smooth and consistent operation. Understanding its components and how they interact is essential for maintaining optimal functionality and preventing downtime.

Key Components of the Spindle System

The spindle assembly consists of several parts that work together to rotate the cutting blades. These include the shaft, bearings, and housing. The bearings are particularly important as they reduce friction and support the rotational motion of the spindle. Regular inspection of these components helps in identifying early signs of wear and tear.

Routine Maintenance for Spindle Longevity

To extend the life of the spindle system, it is recommended to regularly lubricate the bearings and check for any looseness or damage in the assembly. Tightening bolts and replacing worn-out bearings can prevent costly repairs and ensure smooth operation. Additionally, cleaning the spindle area from debris can minimize the risk of damage from foreign

Key Pulley Systems and Their Role

Pulley mechanisms play a crucial role in machinery, facilitating the efficient transmission of motion and force across various components. These systems are designed to handle the dynamic loads and rotational movements necessary for the proper functioning of mechanical assemblies. By reducing the effort needed to move different parts, pulleys ensure smoother and more controlled operations.

Main Pulley Functions

Pulleys serve multiple purposes, primarily focusing on redirecting and distributing force. Their primary function is to convert rotational energy into linear motion, providing a more efficient means of transferring power. Pulleys also help reduce wear on connected parts by easing the strain on belts and other transmission elements, extending the lifespan of the system.

Pulley Types and Configurations

There are various pulley designs tailored to specific applications. The main types include fixed, movable, and compound pulleys

Belt Placement and Tensioning Techniques

Proper positioning and adjustment of belts are essential for ensuring optimal performance and longevity of the equipment. Understanding the right methods for placing and tensioning belts can prevent slippage and wear, thereby enhancing efficiency.

Placement involves aligning the belts correctly along their designated paths. It is crucial to follow the recommended routing to avoid misalignment, which can lead to premature failure. Always consult the manufacturer’s guidelines for the correct setup.

Tensioning is equally important as it ensures that the belts maintain the necessary grip on pulleys. Insufficient tension can result in slippage, while excessive tension may cause undue strain on components. Regular checks should be performed to adjust the tension to the specified range, using appropriate tools to achieve accurate results.

In summary, maintaining correct belt placement and tensioning not only maximizes performance but also prolongs the lifespan of the machinery. Regular inspection and adjustment should be integral parts of the maintenance routine.

Deck Frame Structure and Durability

The frame of a mowing system plays a crucial role in its overall performance and longevity. A well-designed framework not only supports the weight of the machinery but also contributes to its stability during operation. This section explores the essential elements that enhance the structure’s resilience and reliability, ensuring optimal functionality over time.

Key Components of Frame Design

- Material Selection: Using high-quality materials, such as reinforced steel or durable composites, significantly increases strength and resistance to wear.

- Construction Techniques: Advanced welding and fastening methods ensure that joints remain secure under various loads and conditions.

- Weight Distribution: An efficient design distributes weight evenly, reducing stress on any single point and preventing structural failures.

Maintaining Structural Integrity

- Regularly inspect for signs of wear or damage.

- Clean and maintain the frame to prevent rust and corrosion.

- Address any issues promptly to avoid larger repairs in the future.

Proper Alignment of Cutting Height Adjusters

Ensuring the correct positioning of height adjustment mechanisms is essential for achieving optimal cutting performance. This process involves precise calibration to guarantee that the blades operate at the desired elevation, promoting uniform grass length and enhancing the overall health of the lawn.

To achieve proper alignment, consider the following steps:

- Begin by checking the existing height settings on the adjustment levers.

- Inspect the adjusters for any signs of wear or damage that may affect their functionality.

- Make sure the mechanism is clean and free from debris that could hinder movement.

- Utilize a level to verify that all adjustment points are even and consistent.

- Adjust the height settings according to the manufacturer’s recommendations.

Regular maintenance and checks will ensure that the cutting height adjusters remain aligned, resulting in a well-maintained lawn.

Discharge Chute Configuration and Usage

The discharge chute is a vital component in optimizing the performance of a mowing system. Its primary function is to direct clippings away from the cutting area, ensuring a clean and efficient mowing experience. Understanding its configuration and proper usage can significantly enhance lawn care results.

Configuration Considerations

When setting up the discharge chute, several factors should be taken into account:

- Positioning: Ensure the chute is correctly aligned to facilitate effective clipping discharge.

- Height Adjustment: Modify the chute height according to the type of grass and desired cutting height.

- Material: Choose a durable material for the chute to withstand the rigors of operation.

Usage Tips

To maximize the efficiency of the discharge chute, consider the following tips:

- Regularly inspect the chute for blockages to maintain optimal airflow.

- Adjust the angle of the chute based on mowing conditions to achieve the best results.

- Keep the chute clean and free from debris to prevent clogs.

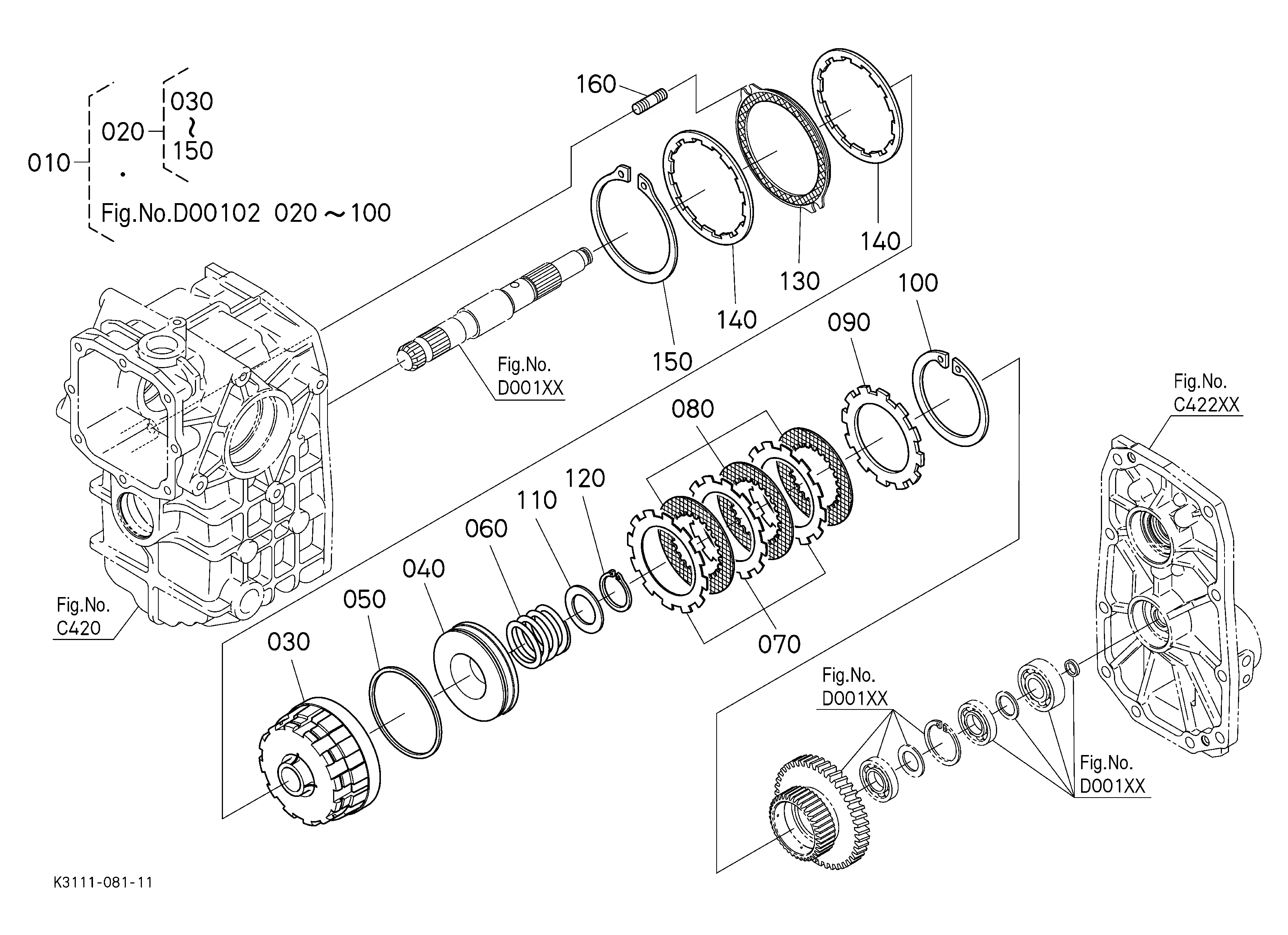

Gearbox Setup for Optimal Performance

Achieving the best functionality from a machinery system heavily relies on the correct configuration of the transmission unit. This component plays a crucial role in ensuring efficient power transfer and smooth operation, ultimately enhancing overall productivity.

To optimize performance, consider the following key aspects during the setup:

- Alignment: Ensure that the gearbox is properly aligned with the engine and other components. Misalignment can lead to excessive wear and potential failure.

- Lubrication: Use the recommended lubricant for the gearbox. Proper lubrication reduces friction and heat buildup, prolonging the life of the unit.

- Adjustments: Regularly check and adjust the tension of the belts or chains connected to the gearbox. This helps maintain optimal torque transmission.

- Inspection: Periodically inspect the gearbox for signs of wear, leaks, or damage. Early detection of issues can prevent costly repairs.

- Load Management: Be aware of the load specifications. Operating beyond the designed capacity can lead to premature failure.

By focusing on these aspects, users can significantly enhance the performance and reliability of their machinery, ensuring efficient operation in various applications.

Best Practices for Deck Cleaning and Care

Maintaining outdoor equipment surfaces is essential for longevity and optimal performance. Regular cleaning and care can prevent rust, damage, and the buildup of debris, ensuring that everything functions smoothly. Implementing proper techniques can enhance the aesthetic appeal and extend the life of your machinery.

Start by removing any loose dirt and grass clippings using a broom or blower. For stubborn stains and grime, utilize a mild detergent mixed with water and a soft-bristle brush. This approach will help dislodge built-up residues without causing harm to the surfaces. Rinse thoroughly with clean water to eliminate any soap residue.

After cleaning, inspect for any signs of wear or damage, addressing minor issues promptly to prevent escalation. Additionally, applying a protective coating can shield surfaces from moisture and harmful elements. Finally, store your equipment in a dry, covered area when not in use to keep it safe from the elements and prolong its lifespan.

Troubleshooting Common Deck Issues

When it comes to maintaining outdoor equipment, addressing frequent challenges is essential for optimal performance. Identifying and resolving these problems can ensure a smooth operation and extend the lifespan of your machinery.

Here are some common issues you might encounter:

- Uneven Cutting: This can result from dull blades or improper height settings. Regularly inspect and sharpen blades, and adjust the cutting height to achieve uniform results.

- Clumping Grass: If you notice clumps of grass after mowing, it may indicate a blockage or wet conditions. Clean the underside regularly and mow when the grass is dry.

- Strange Noises: Unusual sounds can signal loose components or damaged parts. Conduct a thorough inspection and tighten any loose screws or bolts.

- Vibration Issues: Excessive vibration often stems from unbalanced blades or worn-out bearings. Check for damage and ensure blades are balanced before operation.

Addressing these common challenges proactively can help maintain equipment efficiency and prevent more significant issues in the future.