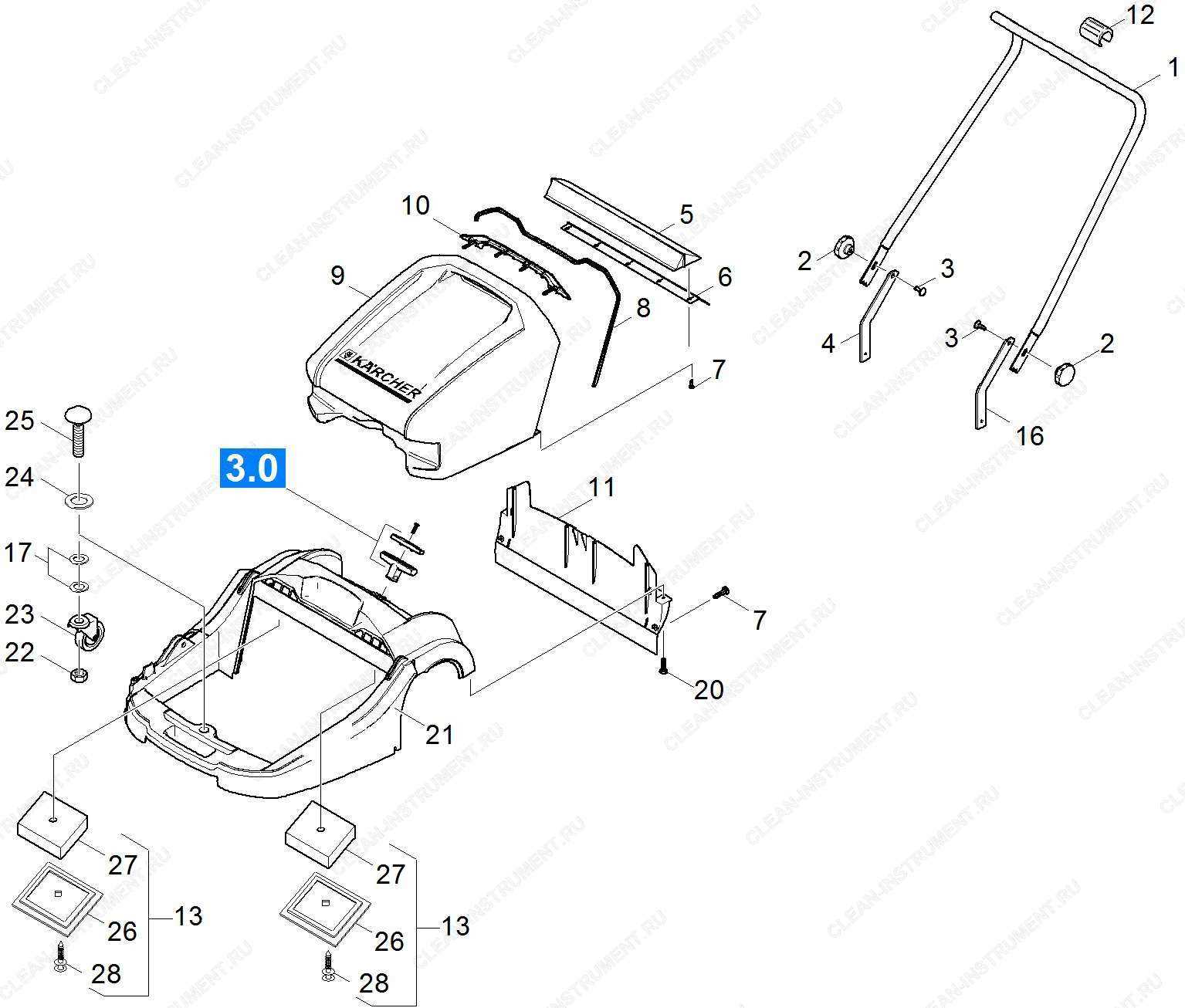

Every lawn maintenance device is a culmination of various elements that work in harmony to ensure optimal performance. Understanding these components is essential for effective maintenance and repair, allowing users to keep their equipment in top condition.

In this section, we will explore the intricate assembly of the machine, providing a clear view of each part’s function. Familiarity with these elements not only aids in troubleshooting but also enhances overall user experience by empowering owners with the knowledge to address potential issues.

By delving into the specifics, you will gain insights into how each component interacts within the system. This understanding will enable you to make informed decisions regarding repairs and upgrades, ultimately extending the lifespan of your equipment.

This model is designed with several noteworthy characteristics that enhance its performance and usability. Its robust construction ensures durability, while the innovative features provide convenience for users, making it suitable for a variety of tasks.

Performance and Efficiency

The engine delivers reliable power, enabling effective operation across different terrains. Additionally, the cutting system is engineered for precision, ensuring a clean and even finish every time.

User-Friendly Design

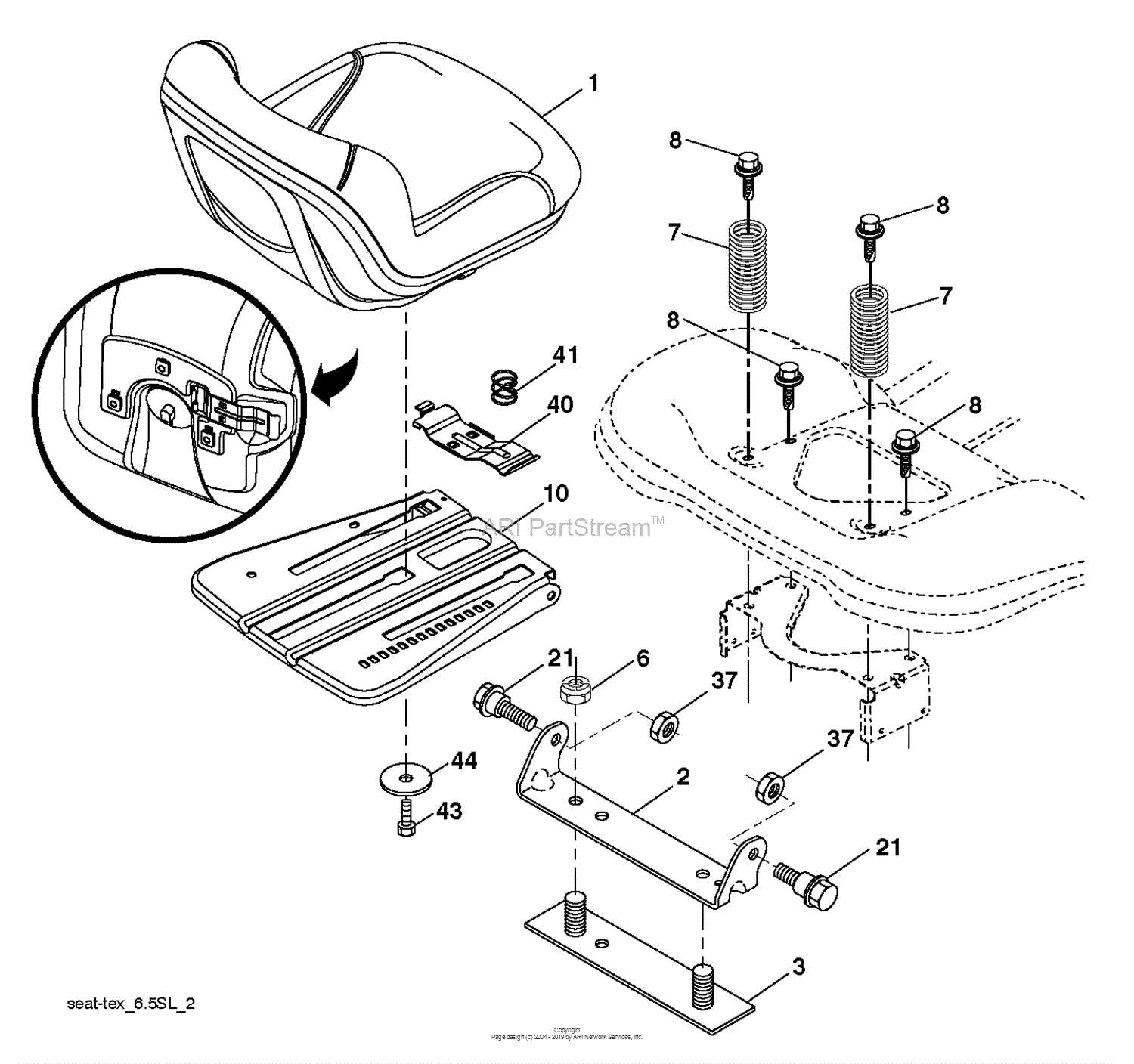

With an intuitive control panel, navigating the functions becomes effortless. The adjustable seating enhances comfort during extended use, catering to the needs of various operators.

| Feature | Description |

|---|---|

| Engine Power | Reliable performance suitable for various tasks |

| Cutting System | Precision cutting for a clean finish |

| Control Panel | Intuitive layout for easy operation |

| Seating | Adjustable for enhanced comfort |

Common Issues with Lawn Tractors

Lawn tractors are essential tools for maintaining large grassy areas, but they can encounter various challenges that hinder their performance. Understanding these common problems can help users troubleshoot effectively and maintain their equipment in optimal condition.

Mechanical Failures

One frequent issue is mechanical failure, which can stem from wear and tear over time. This can manifest in various forms, such as engine problems, transmission failures, or issues with the cutting deck. Regular maintenance is crucial to avoid these complications.

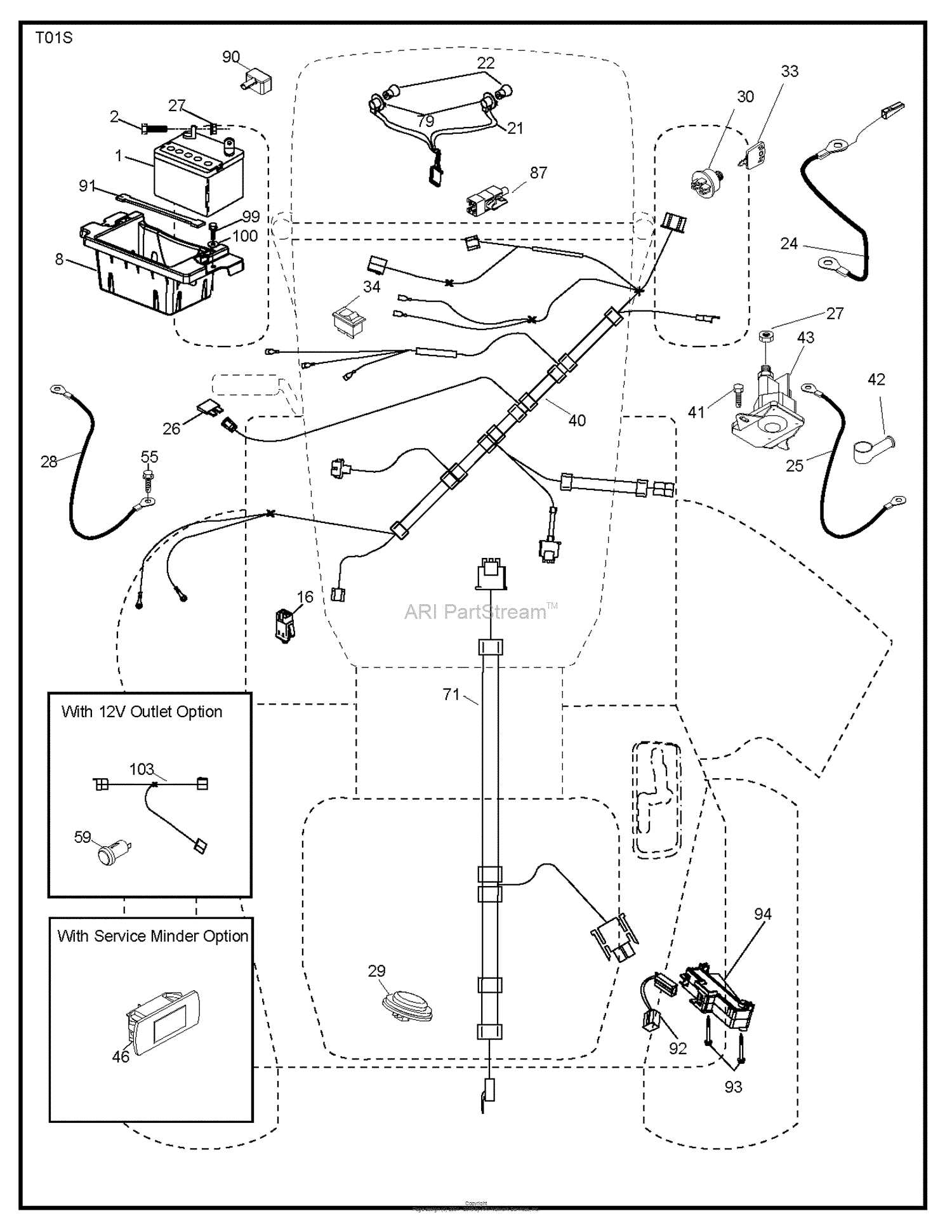

Electrical Issues

Electrical problems are also common in lawn tractors. Battery failures, faulty wiring, or malfunctioning switches can lead to starting issues or operational failures. Ensuring that all electrical components are in good condition can prevent these headaches.

| Issue | Description | Solution |

|---|---|---|

| Engine Trouble | Loss of power or stalling | Check fuel supply and spark plugs |

| Transmission Problems | Difficulty shifting gears | Inspect fluid levels and linkage |

| Cutting Deck Malfunction | Uneven cutting or failure to engage | Examine belts and blades |

| Battery Issues | Tractor won’t start | Test battery voltage and connections |

Benefits of Regular Maintenance

Consistent upkeep of machinery plays a vital role in ensuring optimal performance and longevity. By adhering to a routine maintenance schedule, users can enhance efficiency and minimize unexpected issues.

Some key advantages include:

- Improved Efficiency: Regular checks help maintain peak operational performance, leading to better output.

- Extended Lifespan: Proactive care reduces wear and tear, significantly prolonging the equipment’s lifespan.

- Cost Savings: Preventive maintenance can help avoid costly repairs and downtime, resulting in financial savings.

- Safety Assurance: Routine inspections can identify potential hazards, ensuring a safer working environment.

- Increased Resale Value: Well-maintained machinery retains higher market value, making it more appealing to potential buyers.

By prioritizing regular maintenance, users can secure these benefits and ensure reliable operation for years to come.

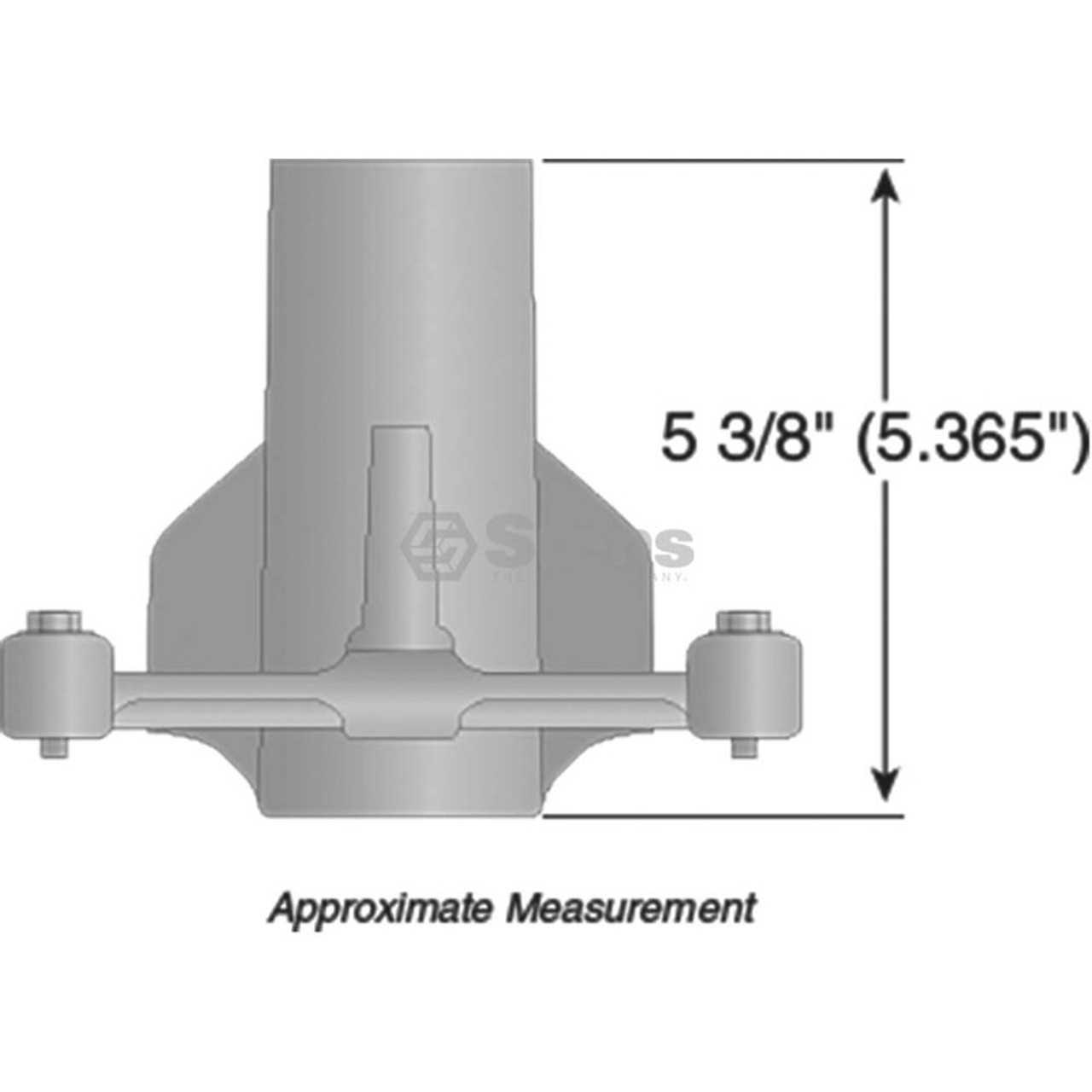

Essential Replacement Parts Overview

This section provides an overview of crucial components necessary for maintaining optimal functionality in your lawn care equipment. Understanding these elements ensures your machine operates efficiently and prolongs its lifespan.

Belts: These are vital for transferring power from the engine to the blades, facilitating effective cutting. Regular inspection and replacement can prevent malfunctions.

Filters: Air and fuel filters are essential for keeping contaminants at bay, promoting cleaner operation and better engine performance. Replacing these filters at recommended intervals is key.

Blades: Sharp and well-maintained blades are critical for achieving a clean cut. Dull blades can damage grass and lead to uneven growth.

Batteries: A reliable power source is crucial for starting and operating your equipment. Regular checks and timely replacements ensure uninterrupted performance.

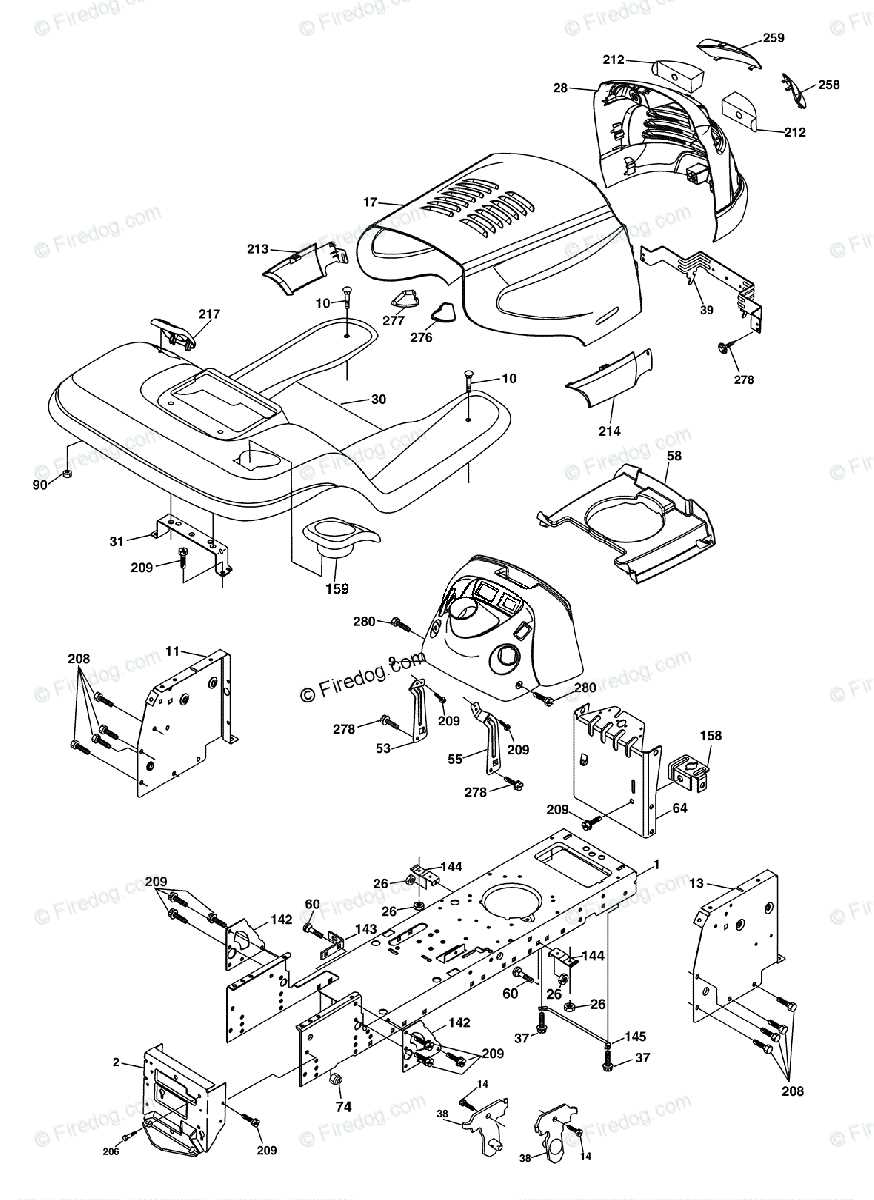

Locating Your Parts Diagram

Finding the schematic for your equipment can greatly enhance your maintenance experience. Understanding the layout and components will help you identify the necessary pieces for repairs or upgrades. This guide provides an overview of how to efficiently locate these valuable resources.

Start by visiting the manufacturer’s official website, where comprehensive resources are typically available. Look for a section dedicated to support or resources, which often houses a variety of manuals and visual guides. Alternatively, authorized dealers may offer printed versions or digital access to these materials.

If you’re unable to find what you need online, consider reaching out to customer service for assistance. They can provide guidance on where to locate the correct documentation. Additionally, online forums and user communities can be excellent sources of information, as fellow enthusiasts often share their insights and resources.

Identifying Engine Components

Understanding the various elements within a power unit is crucial for maintenance and repair. Each part plays a specific role, contributing to the overall functionality of the machinery. By familiarizing oneself with these components, operators can diagnose issues more effectively and ensure optimal performance.

The engine typically comprises several key sections, including the cylinder block, where combustion occurs, and the crankshaft, which converts linear motion into rotational force. Additionally, the valve train regulates airflow into and out of the combustion chamber, while the fuel system delivers the necessary fuel for operation.

Recognizing these components and their interactions not only enhances troubleshooting skills but also aids in conducting routine maintenance. Keeping these parts in good condition is essential for the longevity and efficiency of the equipment.

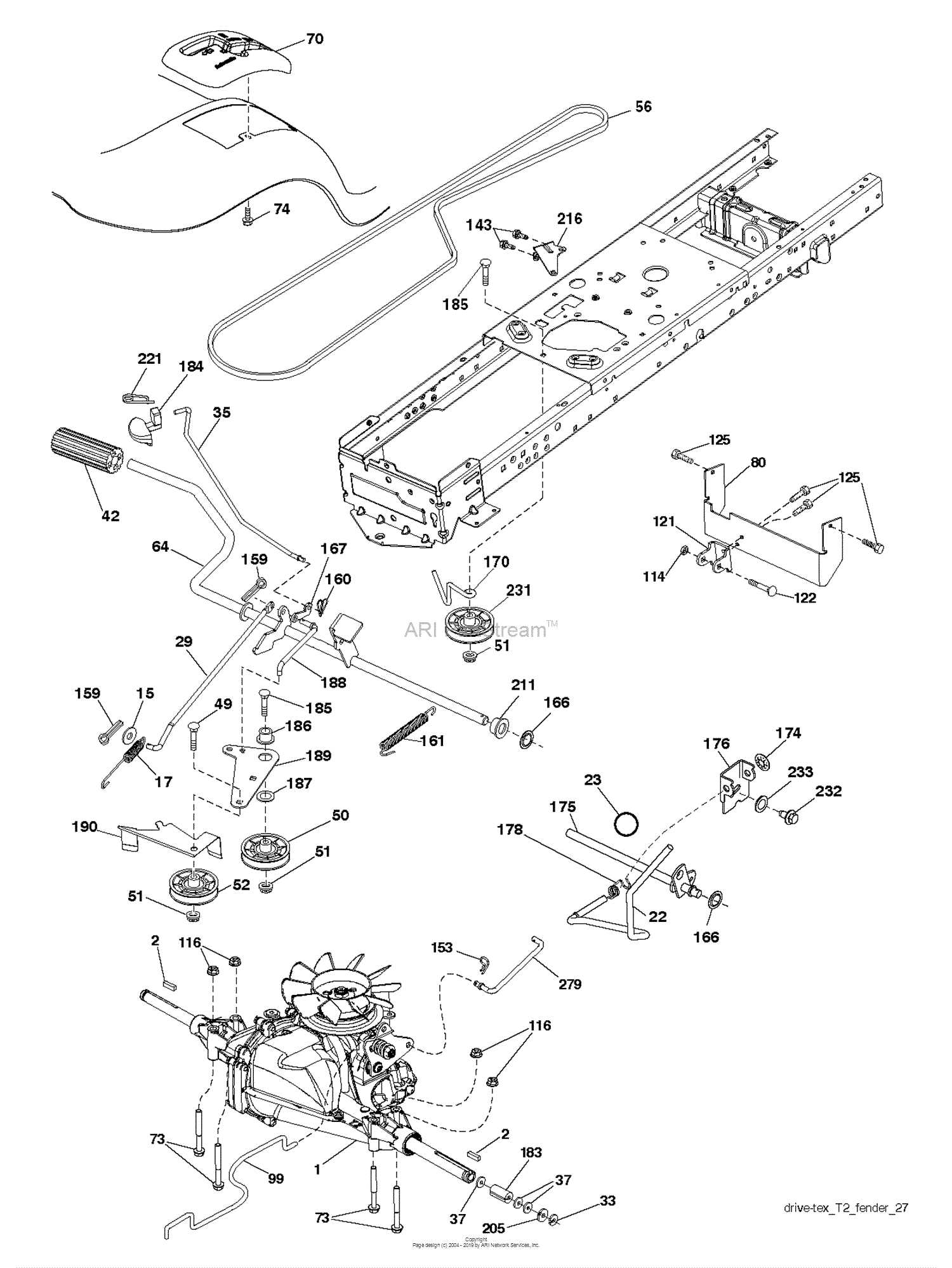

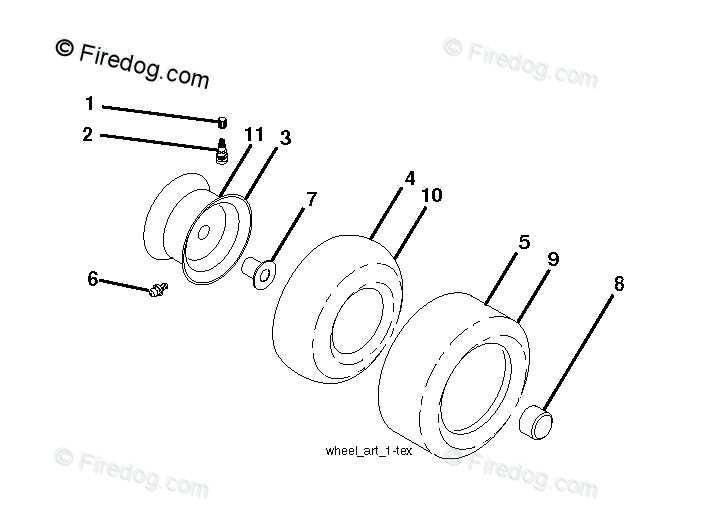

Transmission System Explained

The transmission system is a critical component in various machines, enabling efficient power transfer from the engine to the wheels. Its primary function is to adjust the torque and speed delivered, ensuring optimal performance under different conditions.

Types of Transmission

There are several types of transmission systems, each designed for specific applications. The most common include manual and automatic transmissions. Manual systems require the operator to shift gears, offering greater control over performance. In contrast, automatic systems manage gear changes automatically, providing ease of use.

Key Components

The essential elements of a transmission system include gears, shafts, and the clutch mechanism. Gears play a vital role in changing the speed and torque, while shafts connect the engine to the wheels. The clutch allows for smooth engagement and disengagement of power, enhancing overall driving experience.

Maintenance Tools You Need

Keeping your outdoor equipment in optimal condition requires the right set of tools. Having the appropriate instruments not only simplifies maintenance tasks but also ensures that your machinery operates efficiently and lasts longer.

Here is a list of essential tools that every owner should consider having:

- Wrenches: Adjustable wrenches and socket sets are crucial for tightening and loosening bolts and nuts.

- Screwdrivers: A variety of flathead and Phillips screwdrivers will help in assembling and disassembling parts.

- Oil and Lubricants: Regular lubrication of moving parts prevents wear and tear, enhancing performance.

- Spark Plug Wrench: This tool is necessary for replacing spark plugs to maintain engine efficiency.

- Cleaning Brushes: Use these for cleaning air filters and other components to ensure proper airflow.

- Safety Gear: Gloves and goggles protect you while performing maintenance tasks.

Investing in these tools will facilitate easier upkeep of your equipment, ensuring that it remains functional and reliable for years to come.

Ordering Genuine Replacement Parts

Ensuring the longevity and performance of your equipment requires using authentic components. Acquiring original replacements guarantees compatibility and quality, which are vital for optimal functionality.

When looking to obtain replacement items, consider the following steps:

- Identify the Model: Make sure you know the exact model of your machinery to find suitable replacements.

- Consult the Manual: Reference the product documentation for specific part numbers and descriptions.

- Visit Authorized Dealers: Purchase components from certified retailers to ensure you receive genuine products.

- Online Resources: Explore official websites for ordering options, as many provide a convenient online shopping experience.

- Check for Warranty: Verify if the item is under warranty to potentially reduce costs on replacements.

Following these guidelines will help maintain the integrity and efficiency of your machinery, ensuring it operates at its best.

DIY Repair Tips for Owners

For those who enjoy taking matters into their own hands, tackling repairs can be a rewarding experience. Understanding your equipment can help you perform maintenance and fix common issues effectively. With a bit of knowledge and the right approach, you can save time and money while keeping your machine in top shape.

1. Familiarize Yourself with the Components

Before diving into repairs, it’s essential to understand the various components and their functions. A thorough understanding allows you to diagnose problems more efficiently and select the right tools for the job.

2. Gather Necessary Tools

Having the right tools at your disposal is crucial for any repair task. Basic tools such as wrenches, screwdrivers, and pliers should be part of your toolkit. Depending on the nature of the repairs, consider adding specialized tools that can make your tasks easier.

3. Follow Safety Precautions

Always prioritize safety while working on machinery. Wear appropriate protective gear, such as gloves and safety glasses, to safeguard yourself from potential injuries. Disconnect the power source before starting any repair to prevent accidents.

4. Consult Reliable Resources

Utilize manuals, online forums, and instructional videos for guidance. These resources can provide valuable insights and step-by-step instructions to assist you in your repair endeavors.

5. Take Your Time

Rushing through repairs can lead to mistakes. Take your time to ensure that each step is performed correctly. Patience can lead to better results and a deeper understanding of your equipment.

By implementing these tips, owners can effectively address common issues and maintain their machinery, ensuring it runs smoothly for years to come.

Consulting Professional Technicians

When facing challenges with machinery, seeking the expertise of trained professionals can significantly enhance the troubleshooting process. These specialists possess the knowledge and skills to diagnose issues accurately and recommend appropriate solutions, ensuring optimal performance and longevity of the equipment.

Benefits of Professional Consultation

Engaging with experienced technicians offers numerous advantages. They can provide detailed assessments, access to specialized tools, and insights gained from extensive experience. This not only saves time but also minimizes the risk of costly errors during repairs or maintenance.

Finding the Right Expert

It’s essential to select a qualified technician who understands the specific needs of your equipment. Look for certifications, customer reviews, and recommendations from trusted sources. A reliable professional will guide you through maintenance plans and can offer ongoing support for any future needs.

Upgrades for Enhanced Performance

Improving the efficiency and functionality of your lawn care equipment can significantly enhance its overall performance. By incorporating specific modifications and high-quality components, you can achieve better results and extend the lifespan of your machine.

- Engine Enhancements: Upgrading the engine with high-performance filters and tuning kits can improve power output and fuel efficiency.

- Cutting Deck Improvements: Installing a reinforced cutting deck can provide a more precise cut while increasing durability against wear and tear.

- Tires and Traction: Opting for superior traction tires can enhance grip and stability on various terrains, ensuring better maneuverability.

- Transmission Upgrades: Modifying the transmission system can lead to smoother operation and improved speed control.

Implementing these upgrades not only boosts performance but also contributes to a more enjoyable and effective mowing experience.