The exploration of mechanical systems reveals intricate structures that convert energy into motion. This section delves into the fundamental elements that work in harmony to create efficient propulsion. By examining these crucial components, one gains insight into the functionality and engineering principles that underpin this remarkable technology.

Each section of the assembly plays a vital role, contributing to the overall effectiveness of the machinery. From the sources of energy to the mechanisms that facilitate movement, understanding how these elements interact is essential for grasping the complete picture. This knowledge not only enhances appreciation for engineering marvels but also highlights the innovation involved in their design.

Visual representations of these mechanical structures aid in comprehending the relationships between various components. Such illustrations provide clarity and facilitate a deeper understanding of how each piece contributes to the system’s operation. By dissecting these visuals, one can better appreciate the complexity and ingenuity inherent in such technological advancements.

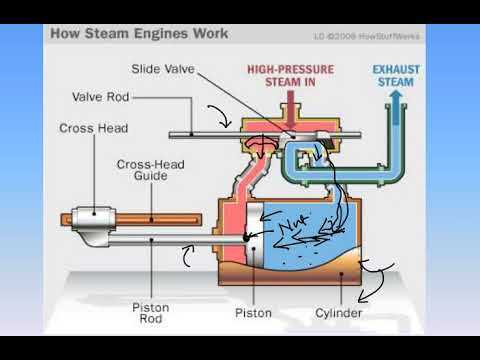

Understanding the Steam Engine Basics

This section aims to explore the fundamental concepts underlying a remarkable invention that revolutionized transportation and industry. By examining its core components and their interactions, we gain insight into the mechanisms that enabled the transformation of thermal energy into mechanical motion.

Key Concepts

- Conversion of heat into motion

- Principles of pressure and expansion

- Role of various components in the process

Core Components

- Boiler: The vessel where water is heated to produce vapor.

- Piston: A moving element that converts vapor pressure into mechanical movement.

- Cylinder: The chamber where the piston operates, allowing for efficient energy transfer.

- Valves: Mechanisms that control the flow of vapor and regulate pressure within the system.

Understanding these fundamentals provides a foundation for appreciating the complexities and advancements in this transformative technology.

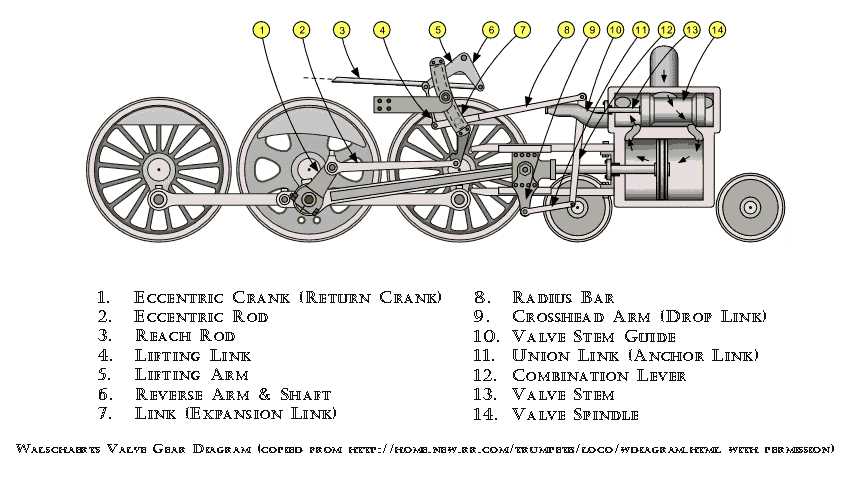

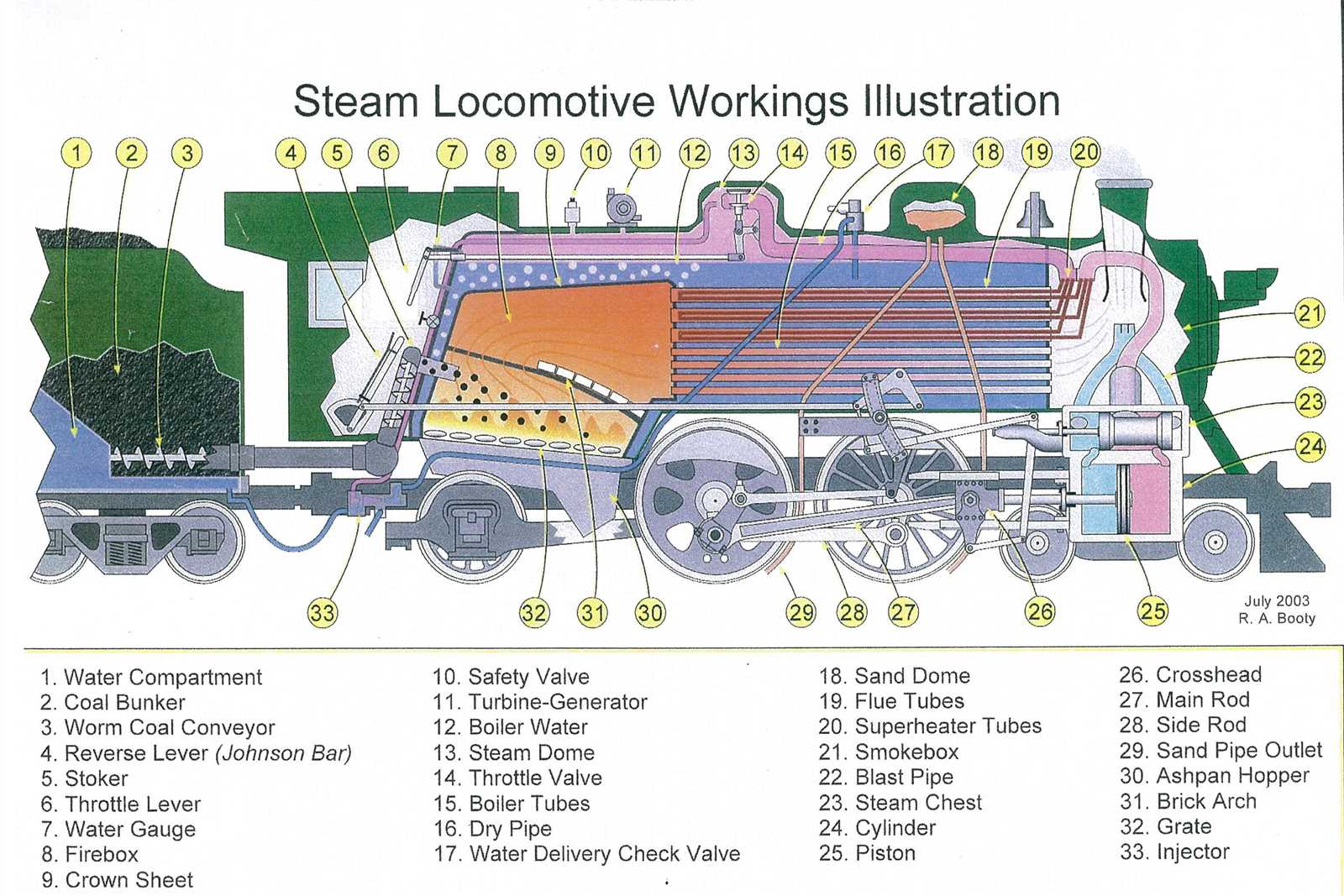

Key Components of a Steam Engine

Understanding the fundamental elements that make up this innovative machine is essential for grasping its functionality and historical significance. Each component plays a critical role in the overall operation, contributing to the transformation of thermal energy into mechanical work.

Cylinder: This vital section houses the movement mechanism, allowing for the conversion of heat into motion. Its design influences the efficiency and power output of the system.

Piston: Positioned within the cylinder, the piston is responsible for translating pressure into linear movement. This movement is crucial for generating the force needed to perform various tasks.

Crankshaft: Acting as a connecting element, the crankshaft transforms the linear motion of the piston into rotational motion, enabling the drive of additional machinery or vehicles.

Boiler: This component is tasked with producing steam from water, serving as the heart of the system. Its construction and materials significantly affect the pressure and temperature of the generated vapor.

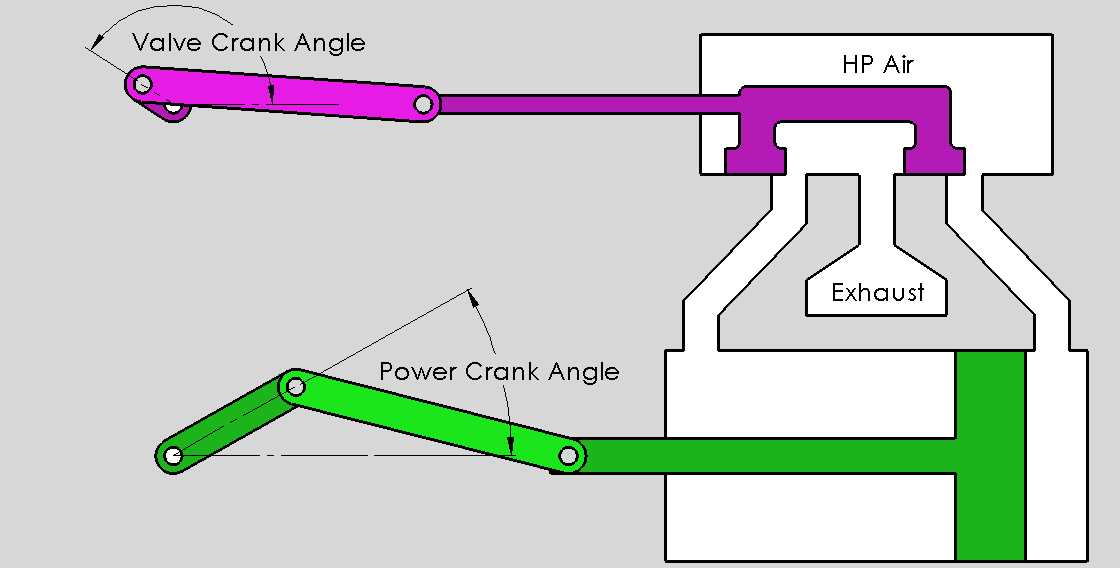

Valves: Essential for regulating the flow of steam, valves control the timing and direction, ensuring that the movement is smooth and efficient throughout the cycle.

Flywheel: This rotating mass stabilizes the operation, helping to maintain a consistent output by storing energy and smoothing out the delivery of power.

Each of these elements works in concert, creating a complex and effective mechanism that revolutionized transportation and industry in its time.

How Steam Engines Work Together

The operation of this classic mechanism involves a harmonious interplay of various components that work in unison to convert thermal energy into kinetic energy. Understanding how these elements interact reveals the elegance of their design and function, showcasing the ingenuity of early industrial advancements.

The Role of Pressure and Motion

At the core of this system lies the generation of pressure, which propels movement through a series of meticulously designed chambers. When heated, the fluid expands, creating a force that drives pistons. This conversion of thermal energy into mechanical motion is crucial, as it translates into work that can be harnessed for various applications.

Synchronization of Components

Effective synchronization between the various elements ensures smooth operation. As one component moves, it triggers the next, establishing a continuous cycle. This seamless coordination is vital for maintaining efficiency and maximizing output, demonstrating the remarkable engineering behind these historical machines.

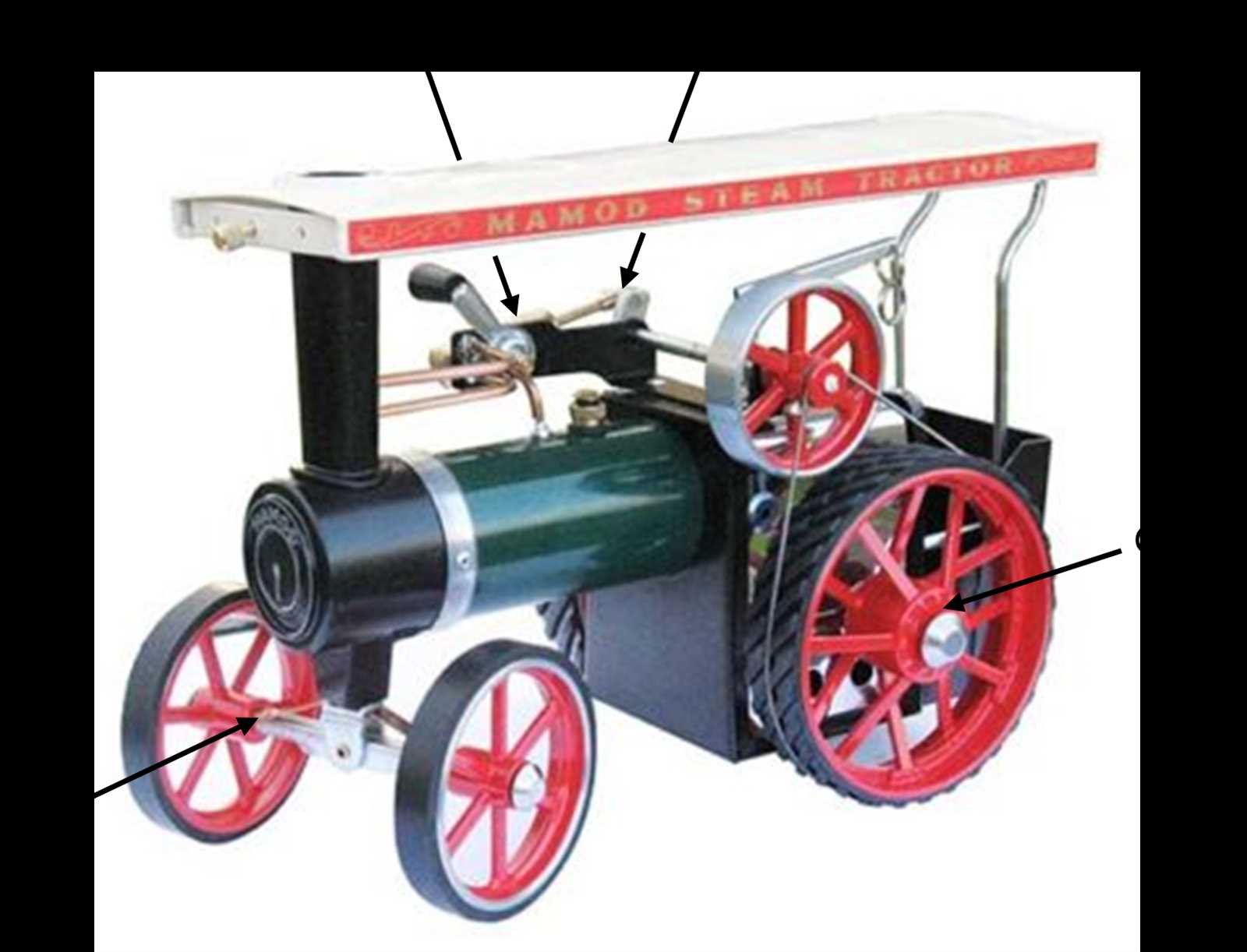

Common Types of Steam Engines

Various types of machines harness the power of vapor to generate motion, each with unique characteristics and applications. Understanding these classifications can provide insights into their design and functionality.

Types of Vapor-Powered Machines

There are several prominent classifications based on their operational principles and structural design. Each type has played a significant role in the development of transportation and industry.

| Type | Description | Application |

|---|---|---|

| Locomotive | Designed for rail transport, these machines are powerful and capable of pulling heavy loads. | Railways |

| Stationary | Fixed machines used primarily in factories for various mechanical processes. | Industrial settings |

| Marine | Built for naval vessels, these machines operate efficiently in water environments. | Shipping |

| Portable | These are compact and can be moved, often used for agricultural tasks. | Agriculture |

Conclusion

The diversity in designs reflects the adaptability of these machines to various tasks. Each type continues to influence modern technology, showcasing the enduring legacy of vapor propulsion.

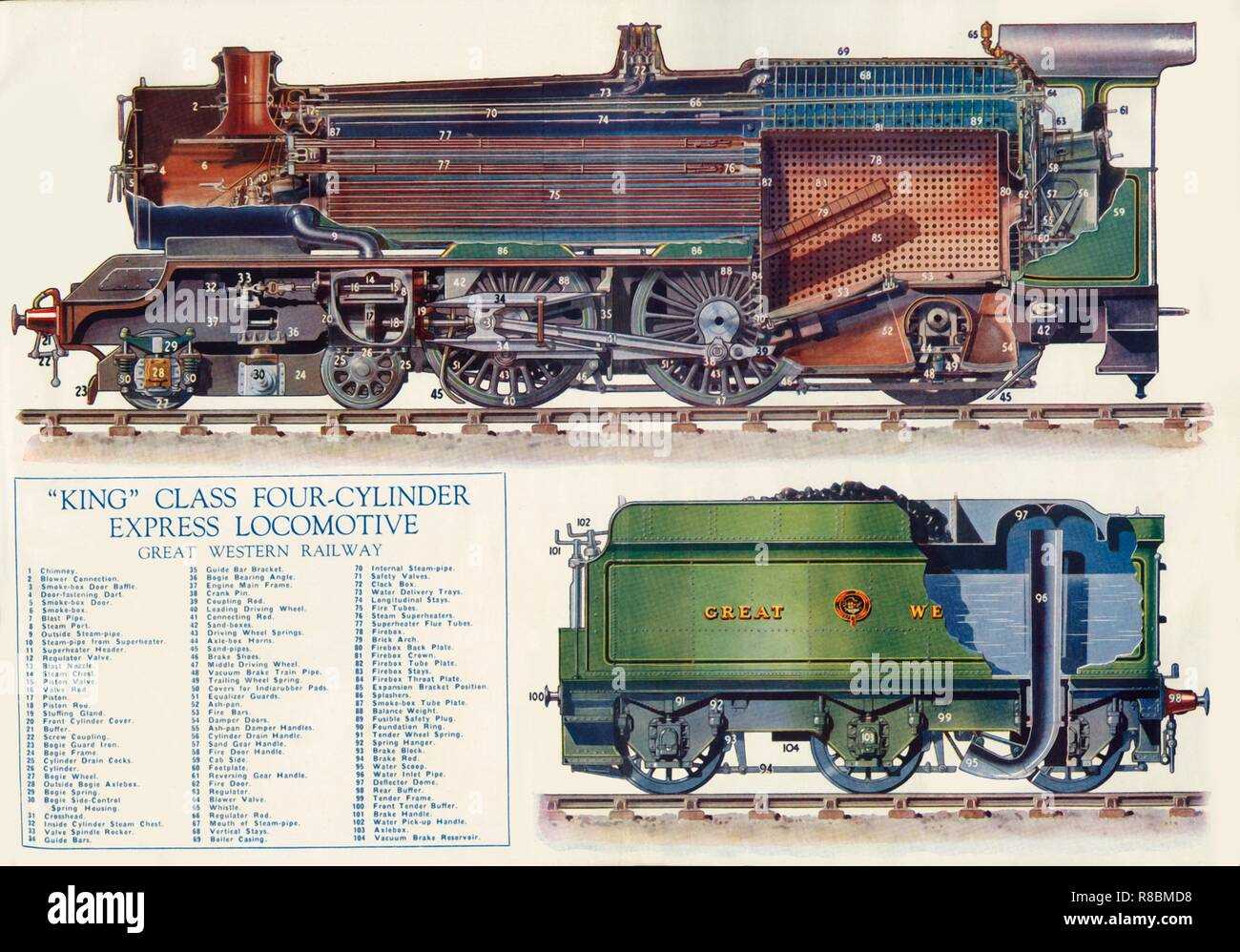

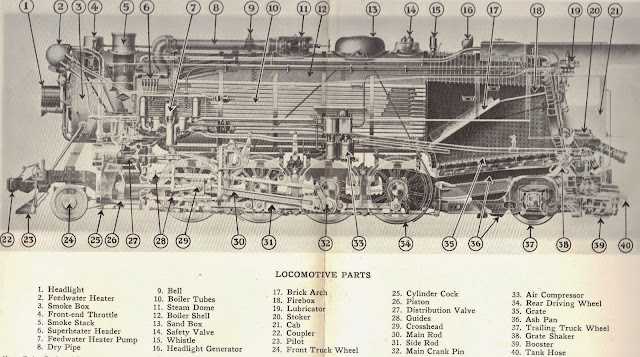

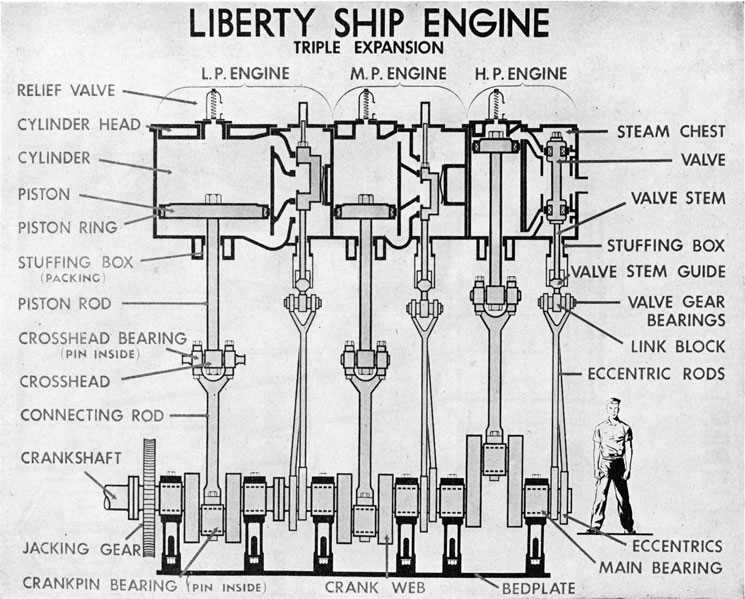

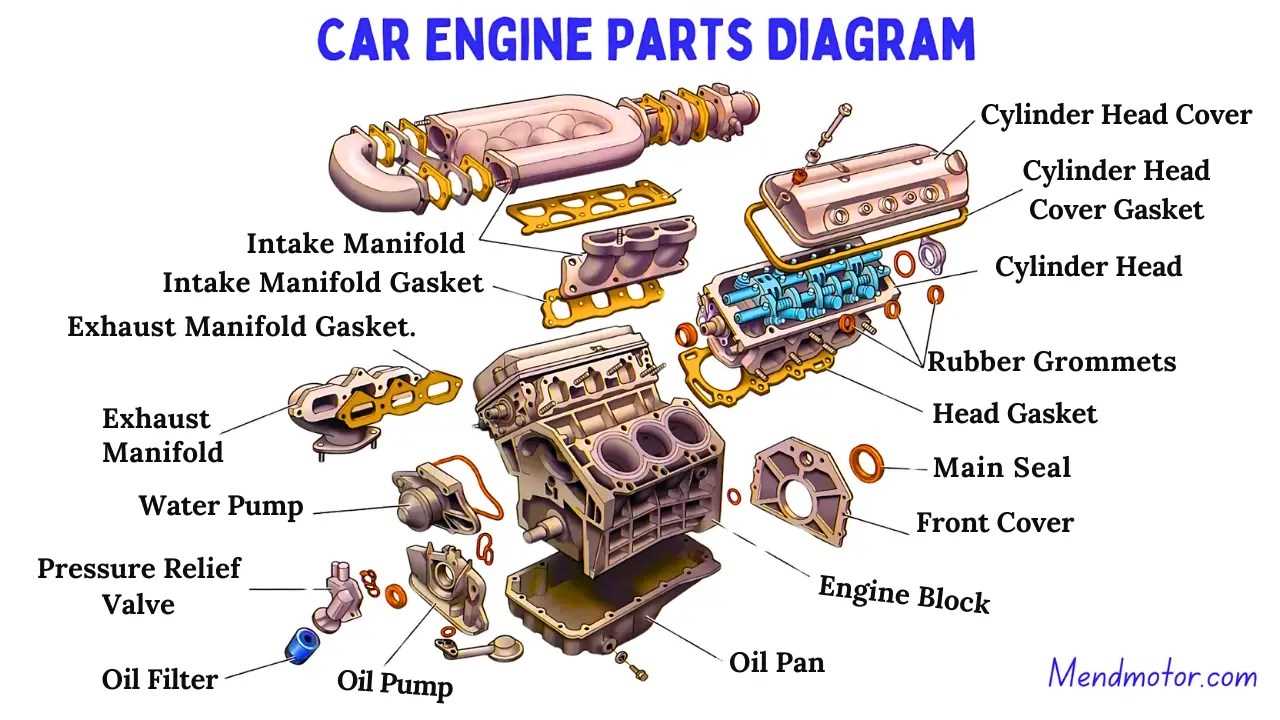

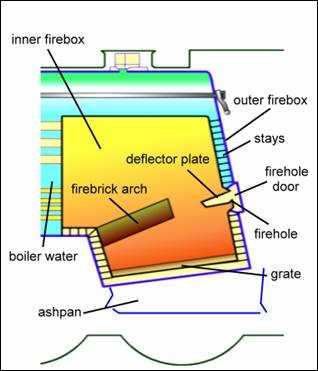

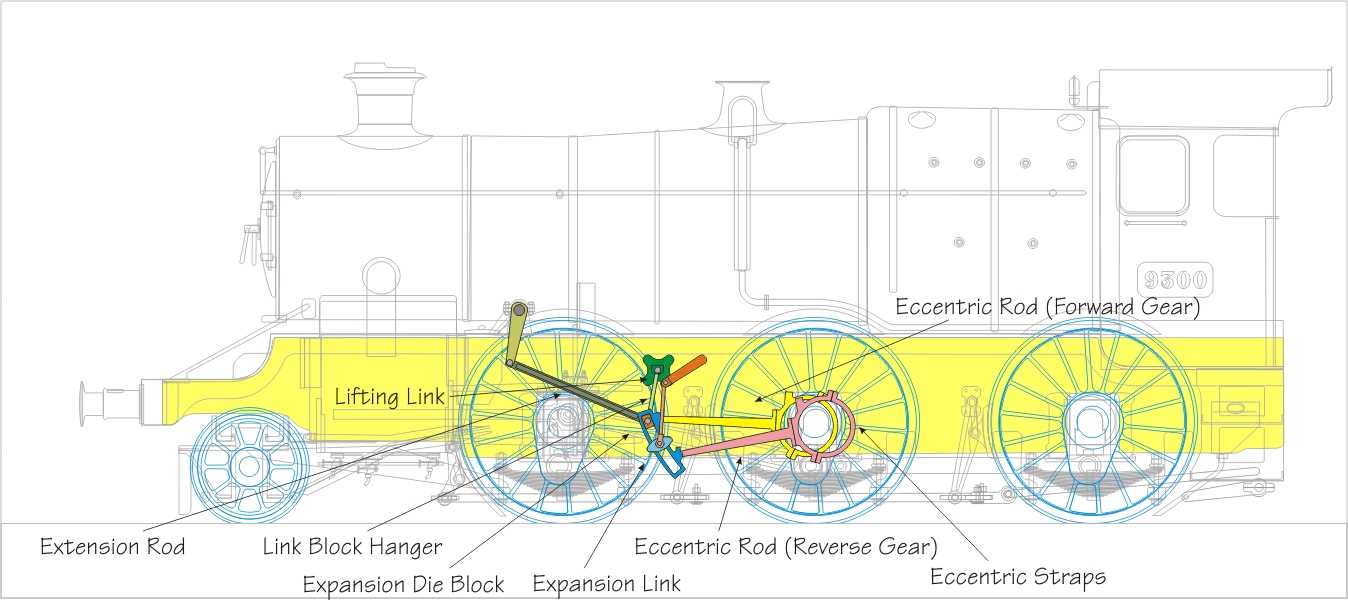

Detailed Diagram of Engine Parts

This section provides an in-depth visual representation of the various components that make up the machinery. Understanding each element and its role is crucial for grasping how the entire system functions efficiently.

Key Components Overview

Each segment plays a specific role, contributing to the overall operation. From the primary mechanisms that generate power to the auxiliary structures that ensure smooth functioning, every piece is integral.

Functionality and Interaction

Exploring how these components interact reveals the intricacies of the system. Their interdependence showcases the engineering marvel behind such machinery, emphasizing the importance of each individual unit in achieving optimal performance.

Functions of Each Engine Component

This section explores the vital roles played by various components in a thermodynamic system. Understanding how each element contributes to the overall operation enhances comprehension of the entire mechanism.

Key Elements and Their Roles

- Boiler: Generates the high-pressure vapor needed for propulsion.

- Piston: Converts the pressure from vapor into mechanical movement.

- Crankshaft: Transforms linear motion of the piston into rotational force.

- Flywheel: Stabilizes the motion and stores energy for continuous operation.

- Exhaust Valve: Releases spent vapor, allowing fresh intake for efficiency.

Supporting Components

- Connecting Rod: Links the piston to the crankshaft for smooth transfer of motion.

- Governor: Regulates speed by adjusting the intake of vapor.

- Lubrication System: Minimizes friction between moving parts, ensuring longevity.

History of Steam Engine Development

The evolution of machinery powered by vapor has been a pivotal aspect of technological advancement, influencing various industries and transforming societies. This progression spans centuries, marked by significant innovations and contributions from numerous inventors. Each development brought humanity closer to harnessing this powerful force, leading to remarkable achievements in transportation, manufacturing, and beyond.

Early Innovations

The journey began in ancient times, with early experiments in utilizing heat to create motion. The most notable early invention was the aeolipile, crafted by Hero of Alexandria in the first century AD. This rudimentary device showcased the principles of vapor propulsion, laying the groundwork for future inventions. However, it wasn’t until the 17th century that serious exploration into vapor-driven machinery gained momentum, spurred by scientific discoveries and the burgeoning demand for efficient power sources.

Industrial Revolution and Advancements

The late 18th century marked a turning point with the advent of the Industrial Revolution. Innovators like James Watt refined earlier models, enhancing their efficiency and practicality. This period saw a rapid proliferation of applications, from railroads to factories, revolutionizing transportation and production. As technology advanced, so did the complexity and capabilities of these machines, leading to a profound impact on economic structures and daily life.

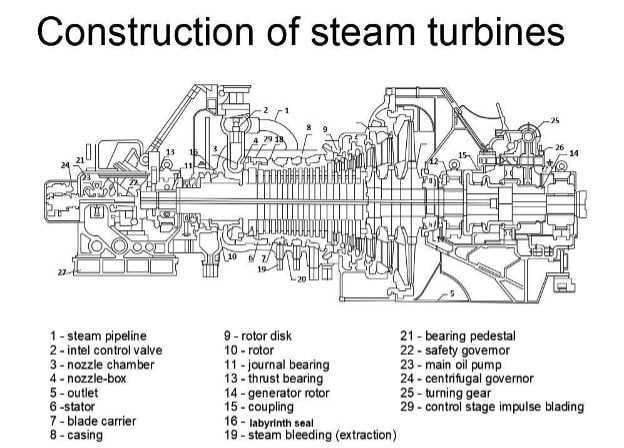

Modern Applications of Steam Technology

The use of thermal energy in contemporary industries has evolved significantly, showcasing a variety of innovative implementations that enhance efficiency and sustainability. This approach continues to play a vital role in powering numerous systems, offering solutions across different sectors.

Industrial Uses

In manufacturing, thermal systems are employed to facilitate processes such as refining, drying, and sterilization. These methods enable precise control over temperature and pressure, leading to improved product quality and operational reliability.

Energy Generation

Thermal power plants utilize this technology for electricity production, converting thermal energy into mechanical work. This conversion not only supports grid demands but also contributes to cleaner energy solutions through advancements in design and operation.

| Application | Description |

|---|---|

| Manufacturing | Utilizes heat for refining and drying processes. |

| Energy Production | Converts thermal energy into mechanical power for electricity. |

| Food Processing | Employs thermal methods for cooking and preservation. |

Maintenance Tips for Steam Engines

Ensuring the longevity and efficiency of your mechanical systems requires diligent care and attention. Regular upkeep not only enhances performance but also prevents potential breakdowns. Here are some essential recommendations to keep your machinery in optimal condition.

Regular Inspection

Conduct frequent assessments to identify any signs of wear or damage. Pay special attention to components that are subject to high stress. Look for cracks, corrosion, or loose fittings, as these can lead to significant issues if not addressed promptly.

Lubrication and Cleaning

Proper lubrication is vital for reducing friction and wear. Use the recommended lubricants for different components, ensuring that they are applied in appropriate quantities. Additionally, maintain cleanliness by removing dirt and debris regularly, as accumulated grime can affect performance and lead to overheating.

Remember: A proactive approach to maintenance will enhance reliability and extend the lifespan of your equipment. Implementing these practices will lead to smoother operation and greater efficiency.

Challenges in Steam Engine Design

The development of early mechanical systems brought numerous hurdles that inventors had to overcome. The intricate balance between efficiency and reliability often led to innovative yet complex solutions. Each component needed to function harmoniously, creating a unique set of difficulties for designers.

| Challenge | Description |

|---|---|

| Material Limitations | Finding suitable materials that could withstand high pressures and temperatures was crucial. |

| Thermal Efficiency | Maximizing energy conversion while minimizing heat loss posed a significant challenge. |

| Mechanical Wear | Components often experienced rapid deterioration, necessitating frequent maintenance. |

| Safety Concerns | High-pressure systems posed risks of catastrophic failures, prompting the need for improved safety measures. |

| Regulatory Standards | As technology progressed, compliance with evolving regulations became increasingly important. |

Innovations in Steam Engine Parts

Throughout history, advancements in mechanical systems have led to significant improvements in functionality and efficiency. These enhancements have transformed how energy is harnessed and utilized, allowing for more reliable and powerful operations.

Innovative materials have played a crucial role in these developments, with stronger and lighter composites replacing traditional substances. This shift not only boosts durability but also optimizes overall performance.

Moreover, design enhancements have introduced new configurations that minimize friction and improve energy transfer. By refining shapes and integrating modern technology, designers have achieved greater efficiency and reduced wear over time.

Finally, the incorporation of automation and smart technologies has revolutionized control mechanisms, enabling precise adjustments and real-time monitoring, which ensures optimal operation in various conditions.

Future of Steam Engine Technology

The evolution of thermal machines holds great promise for innovation and efficiency in various sectors. As we explore advancements in this domain, we find potential applications that can enhance sustainability and performance, contributing to a cleaner future.

Innovative Applications

New designs and materials are being explored to increase efficiency and reduce emissions. These innovations could lead to a resurgence in utilizing this technology for power generation, transportation, and industrial processes, aligning with modern environmental goals.

Integration with Modern Systems

Combining traditional methodologies with contemporary technologies, such as automation and renewable energy sources, may pave the way for smarter solutions. This integration could ultimately reshape how we harness energy, making it more accessible and sustainable.