In the realm of restroom technology, an intricate system of elements ensures efficient functionality and water conservation. These components work together harmoniously to facilitate optimal performance, making them indispensable for any bathroom setup.

By exploring the various segments within this framework, one can gain insights into their roles and interactions. A comprehensive grasp of these pieces is vital for troubleshooting, maintenance, and upgrades, allowing for a seamless experience.

Whether you’re a homeowner seeking to enhance your facilities or a professional in the industry, delving into the specifics of these mechanisms reveals the ultimate path to achieving reliability and efficiency in water management systems.

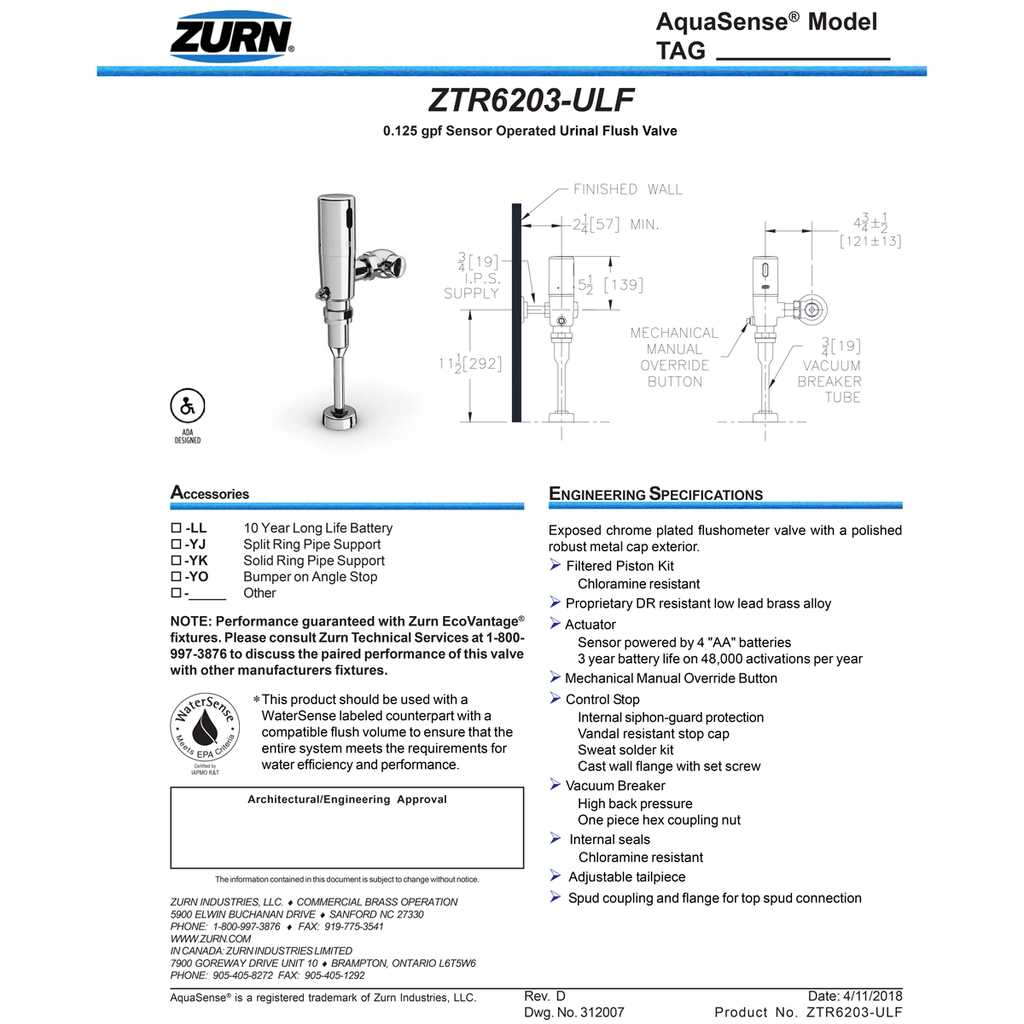

Zurn Flush Valve Overview

This section provides an essential understanding of a critical component in plumbing systems, focusing on its function and significance. The mechanism plays a vital role in water management within restroom facilities, ensuring efficiency and reliability in operation.

Key features include its durable construction and easy maintenance, making it a preferred choice for many installations. Additionally, the design promotes optimal water flow, minimizing wastage while maximizing performance.

Understanding the mechanism is crucial for both users and professionals in the field. Familiarity with its functions can lead to better maintenance practices and enhanced longevity of the system.

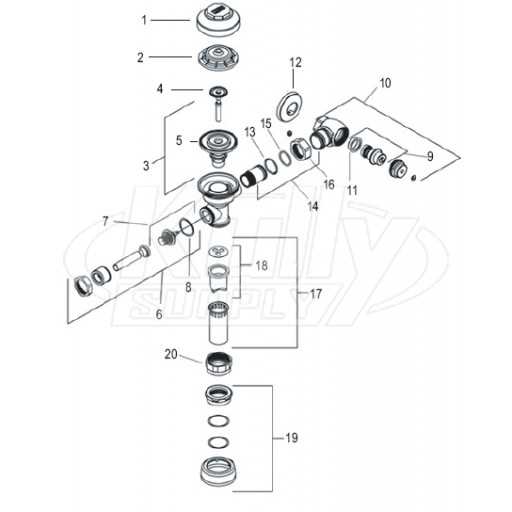

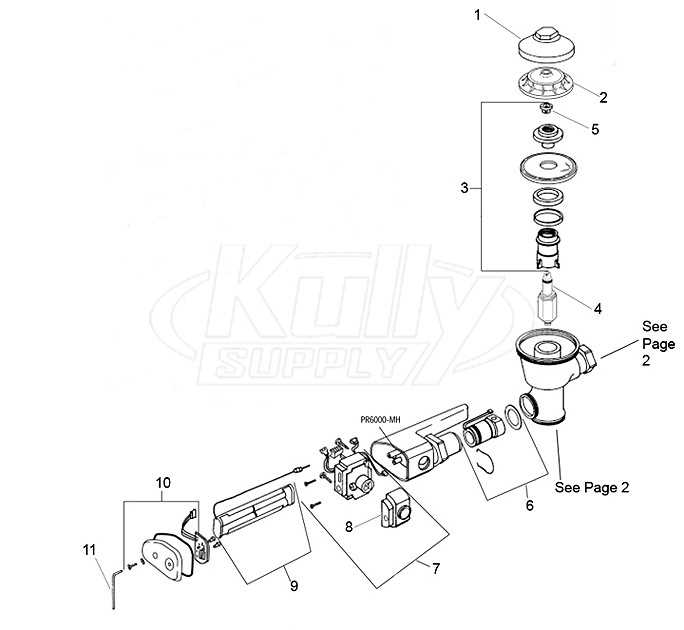

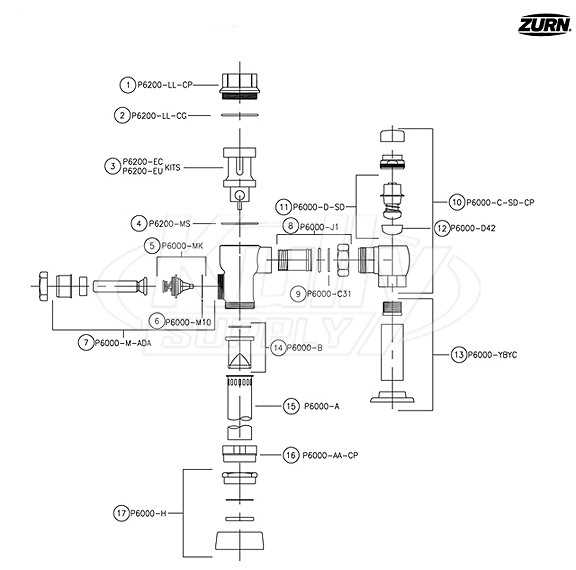

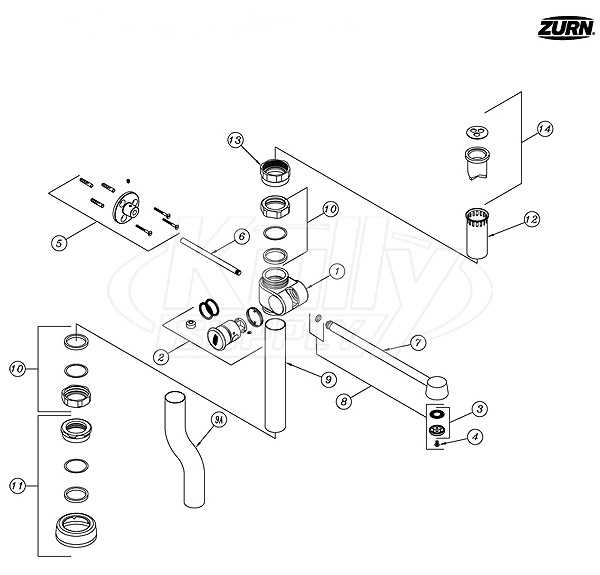

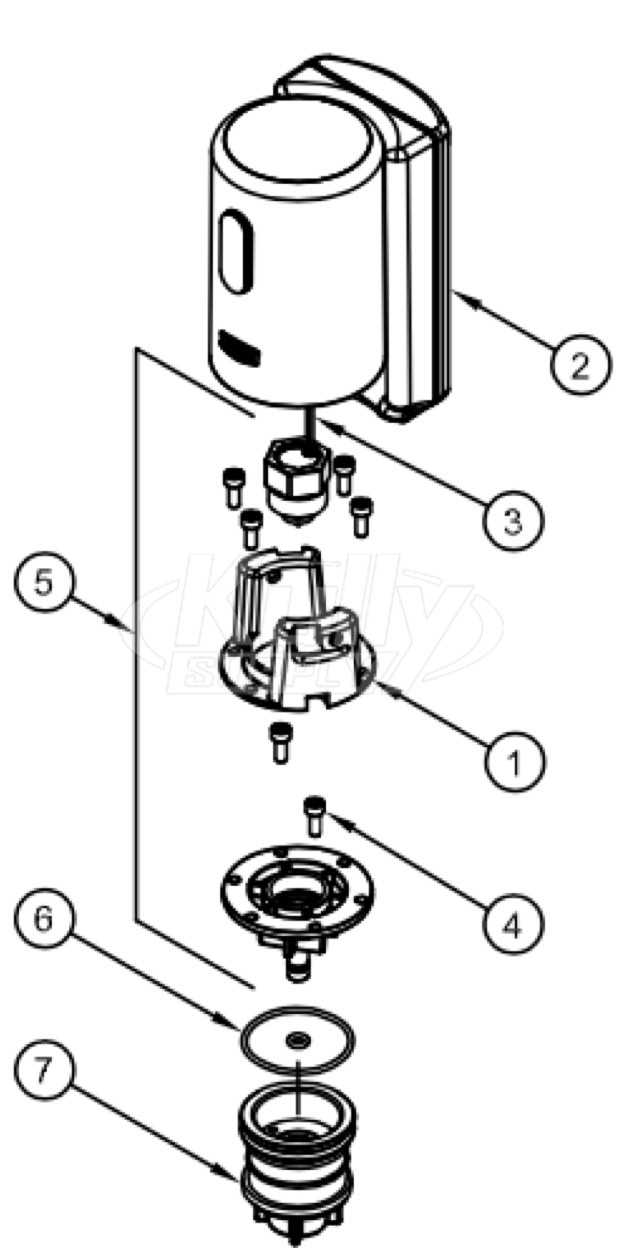

Components of a Flush Valve

The operation of a restroom fixture relies on a variety of essential elements that work in harmony to ensure efficient performance. Understanding these components can enhance maintenance and troubleshooting, leading to improved functionality and longevity of the system.

Main Elements

At the core of the mechanism is the actuator, which initiates the release of water. This component is crucial as it responds to user interaction, allowing for precise control. Accompanying the actuator is the seal, designed to prevent leaks and maintain pressure within the system. Its integrity is vital for optimal operation.

Another key element is the diaphragm, which regulates water flow during operation. It adapts to changes in pressure, ensuring consistent performance. Additionally, the inlet and outlet mechanisms facilitate the movement of water, playing a crucial role in the overall efficiency. Regular inspection and maintenance of these components can significantly enhance the lifespan and reliability of the entire system.

How to Read a Diagram

Understanding a visual representation of components can significantly enhance your ability to assemble or troubleshoot various systems. This skill allows you to interpret symbols, connections, and functions, leading to more efficient repairs or installations. Familiarity with the layout will enable you to grasp the relationship between individual elements and their collective purpose.

Identifying Key Symbols

Every illustration includes a set of symbols that represent different elements. It is crucial to familiarize yourself with these icons, as they provide essential information about functionality. Look for a legend or key that explains the meaning of each symbol, making it easier to navigate the visual guide.

Understanding Connections

Pay attention to the lines and arrows that indicate how parts are interconnected. These pathways reveal the flow of operations and can highlight critical junctions. By analyzing these connections, you can better understand how each component interacts within the system, allowing for more effective troubleshooting or installation.

In summary, becoming proficient at interpreting visual guides enhances your overall understanding of mechanical systems, paving the way for successful projects and efficient maintenance.

Common Issues with Flush Valves

Various challenges can arise with the mechanisms that control water flow in restroom facilities. Understanding these common problems is essential for effective maintenance and optimal performance. Timely identification and resolution of issues can prevent further complications and ensure efficient operation.

Leaking Mechanisms

One of the most frequent concerns is leakage. This can occur due to wear and tear on seals or gaskets, which often leads to water waste and increased utility bills. Regular inspections and timely replacements of these components can mitigate such issues.

Inconsistent Water Flow

Another common problem is inconsistent water release. This can be attributed to blockages, improper installation, or component malfunctions. It is crucial to address these factors promptly to maintain proper functionality and avoid interruptions during use.

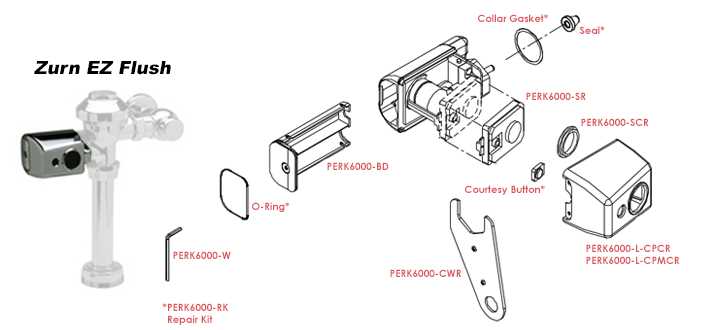

Replacing Zurn Valve Parts

When it comes to maintaining restroom fixtures, ensuring all components are functioning properly is crucial. Over time, various elements may wear out, requiring replacement to maintain efficiency and functionality. This section will guide you through the essential steps and considerations for effectively swapping out these components.

| Component | Common Signs of Wear | Replacement Tips |

|---|---|---|

| Seal | Leaking or inconsistent flow | Ensure a tight fit; lubricate before installation |

| Actuator | Unresponsive or slow action | Check for debris; align properly during replacement |

| Diaphragm | Uneven pressure or noise | Use a compatible model; follow manufacturer guidelines |

Maintenance Tips for Longevity

To ensure the enduring performance of your plumbing components, regular upkeep is essential. Implementing a consistent maintenance routine can prevent common issues and extend the lifespan of the system.

1. Regular Inspections: Frequently check for any signs of wear or leaks. Addressing minor problems promptly can save time and resources.

2. Clean Components: Keep all elements free from debris and mineral buildup. A gentle cleaning solution can help maintain optimal functionality.

3. Check for Proper Alignment: Ensure all mechanisms are correctly positioned. Misalignment can lead to inefficiency and premature failure.

4. Replace Worn Parts: Identify and replace any damaged or degraded elements. Investing in quality replacements can make a significant difference.

5. Consult Professionals: When in doubt, seek advice from experts. Their insights can provide clarity and guide you in maintaining the system effectively.

By following these tips, you can delve into a proactive approach, ensuring that your plumbing system operates at its ultimate efficiency for years to come.

Understanding Flush Mechanisms

Effective water disposal systems rely on various components that ensure optimal operation and efficiency. Grasping how these systems function can enhance maintenance and improve overall performance.

Key Components

- Control Mechanism: Initiates the cycle.

- Water Supply: Provides the necessary fluid.

- Seal: Prevents leakage and ensures pressure retention.

- Release Mechanism: Facilitates the removal of waste.

Operational Process

- Activation: The control mechanism is engaged.

- Water Flow: The supply channel opens, allowing fluid to enter.

- Seal Engagement: The seal maintains pressure until needed.

- Waste Removal: The release mechanism activates, clearing the contents.

Comparing Different Zurn Models

This section explores the various designs and configurations available, highlighting their unique features and functionalities. Understanding these differences can guide users in selecting the most suitable option for their specific requirements.

Model Features

Each model comes equipped with distinct functionalities. For instance, one variant may emphasize water efficiency, while another focuses on durability and ease of maintenance. Analyzing these attributes can help identify the ultimate choice for any setting.

Performance Evaluation

Performance metrics vary across the board, affecting user experience and satisfaction. Comparative assessments can reveal which models excel in high-traffic environments versus those designed for quieter spaces, ensuring optimal decision-making.

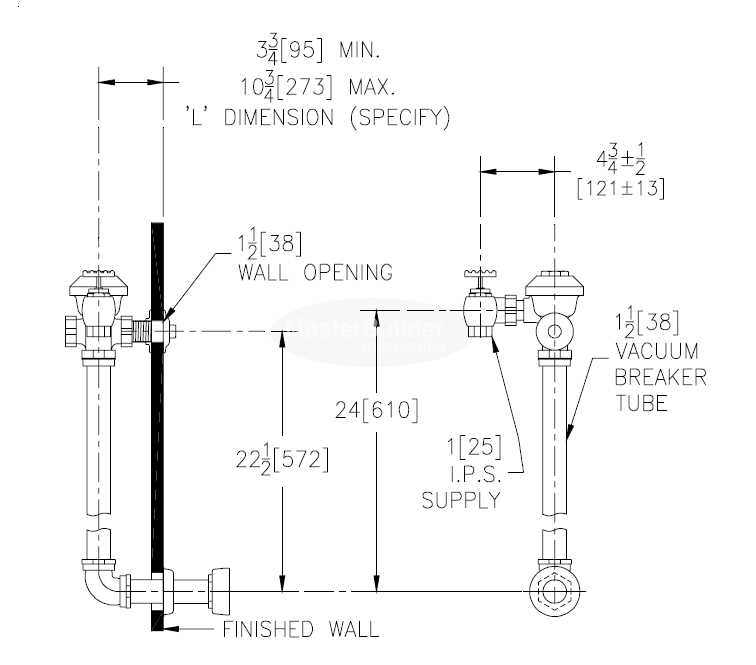

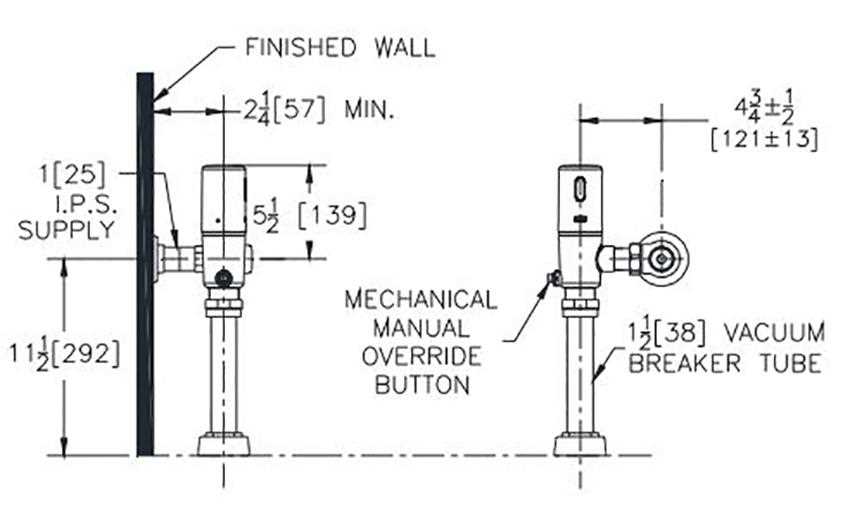

Tools Required for Installation

To ensure a smooth and efficient installation process, it’s essential to gather the appropriate tools beforehand. Having the right equipment not only facilitates the task but also enhances the overall experience, reducing potential frustrations.

Essential Tools

- Adjustable Wrench

- Phillips Screwdriver

- Flathead Screwdriver

- Pliers

- Tape Measure

- Level

Additional Supplies

- Sealant

- Safety Glasses

- Bucket

- Rags

- Gloves

Gathering these items will prepare you for a successful installation, ensuring that each step is completed efficiently and safely.

Finding Replacement Parts Online

Locating components for plumbing fixtures can be a straightforward process with the right resources. The internet offers numerous platforms to simplify this search, making it easy to find what you need efficiently.

- Check Manufacturer Websites: Official sites often provide comprehensive catalogs.

- Utilize Online Retailers: Many e-commerce sites specialize in home improvement supplies.

- Explore Specialty Stores: Some retailers focus exclusively on plumbing items, ensuring a wide selection.

- Visit Forums and Community Groups: Engaging with others can yield valuable recommendations and insights.

- Use Part Numbers: Searching by specific identifiers can narrow down results quickly.

Ultimately, having a strategy for your search will save time and ensure you find the right replacements.

Benefits of Using Zurn Products

Choosing high-quality fixtures can greatly enhance the efficiency and durability of plumbing systems. These products are designed with innovative technology and superior materials, ensuring optimal performance and longevity.

Key Advantages

- Reliable Performance: Engineered for consistent functionality, minimizing the need for repairs.

- Water Efficiency: Many models feature water-saving designs that help reduce consumption.

- Durability: Built to withstand harsh conditions, these fixtures offer long-lasting service.

Environmental Impact

- Reduced Waste: Efficient designs contribute to lower water usage.

- Recyclable Materials: Many products are made from sustainable resources.

- Compliance: Meets various environmental standards, promoting eco-friendly practices.