Exploring the intricate assembly of a utility vehicle can significantly enhance your maintenance and repair skills. A comprehensive understanding of the various elements involved is crucial for anyone looking to ensure optimal performance and longevity. This section aims to provide valuable insights into the arrangement and function of key components, enabling users to navigate their machinery with confidence.

By familiarizing yourself with the layout of essential parts, you will be better equipped to identify issues and implement effective solutions. This knowledge not only empowers you as an owner but also promotes a deeper appreciation for the engineering behind these versatile vehicles. Embracing this understanding will facilitate smoother operations and enhance your overall experience.

Comprehensive Overview of Polaris Ranger 400 Components

This section provides an in-depth look at the various elements that make up a specific utility vehicle model. Understanding these components is crucial for maintenance, repair, and enhancing performance. Each part plays a vital role in the overall functionality and reliability of the vehicle, ensuring a smooth and efficient operation.

Key Components and Their Functions

Every vehicle consists of numerous essential components, each designed to serve a specific function. The engine, for example, is the heart of the machine, providing the necessary power to propel it forward. The transmission system is another critical element, facilitating the transfer of power from the engine to the wheels. Additionally, the suspension system enhances ride comfort by absorbing shocks and providing stability on uneven terrain.

Maintenance and Replacement Tips

Regular inspection and maintenance of these vital parts can significantly extend the lifespan of the vehicle. It is advisable to consult the manufacturer’s manual for guidelines on when to replace components, such as the air filter and brake pads. Utilizing high-quality replacement parts ensures optimal performance and safety.

Key Features of the Polaris Ranger 400

This section highlights the essential characteristics of a popular all-terrain vehicle designed for both utility and recreational use. With an emphasis on durability and performance, this model stands out for its impressive specifications and innovative design, making it a favorite among outdoor enthusiasts.

Performance and Reliability

The vehicle is equipped with a robust engine that ensures powerful performance in various terrains. Some of its key advantages include:

- Exceptional torque for heavy-duty tasks

- Reliable fuel efficiency for extended trips

- Advanced suspension system for a smoother ride

Versatile Design

The versatility of this all-terrain vehicle allows it to adapt to different needs and preferences. Its notable features are:

- Ample storage space for gear and equipment

- Customizable attachments for various applications

- Ergonomic seating for enhanced comfort during long journeys

Exploring the Engine Configuration

Understanding the layout and components of the power unit is essential for anyone interested in enhancing performance or troubleshooting issues. This section delves into the intricate arrangement of various engine elements, highlighting their roles and interconnections to optimize functionality.

Key Components of the Power Unit

The power unit consists of several critical components, including the combustion chamber, crankshaft, and fuel delivery system. Each part plays a vital role in ensuring efficient operation, with the combustion chamber facilitating the ignition process and the crankshaft converting linear motion into rotational energy.

Significance of Proper Arrangement

A well-organized engine configuration not only enhances power output but also contributes to overall reliability. Proper alignment of components minimizes wear and tear, leading to prolonged lifespan and reduced maintenance costs. Understanding this configuration aids in making informed decisions about upgrades and repairs.

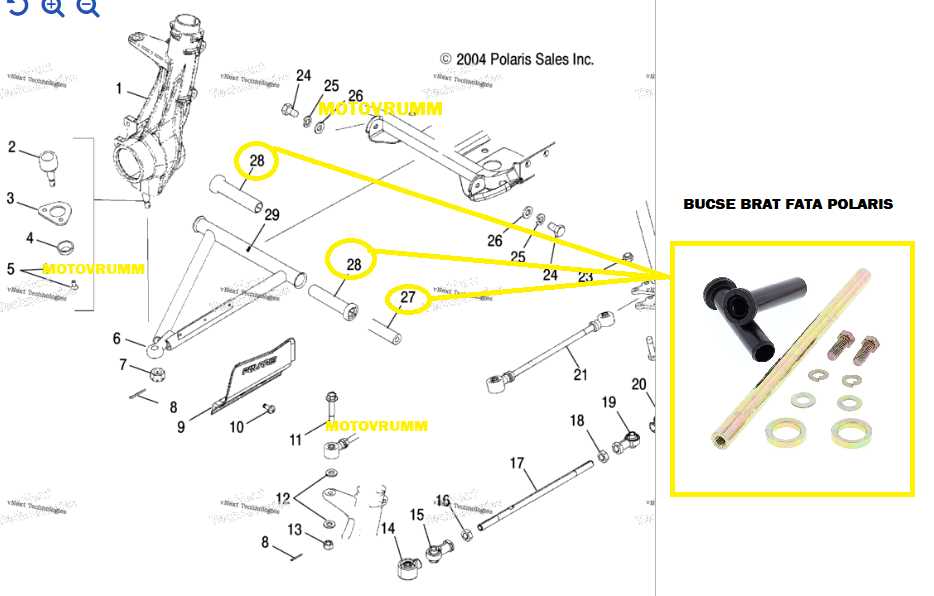

Suspension System Design and Function

The suspension system plays a crucial role in the overall performance and comfort of a vehicle. It is engineered to absorb shocks from uneven terrain, ensuring a smooth ride while maintaining stability and control. This intricate system consists of various components that work together to provide optimal handling and support for the vehicle’s weight, enhancing both safety and comfort for passengers.

Key Components of the Suspension System

The primary elements of the suspension system include springs, shock absorbers, and linkages. Springs are responsible for supporting the vehicle’s weight and absorbing impacts from bumps and potholes. Shock absorbers control the oscillations caused by the springs, preventing excessive bouncing and maintaining tire contact with the ground. Linkages connect these components, allowing for the appropriate movement and alignment necessary for effective suspension function.

Importance of Suspension System Maintenance

Regular maintenance of the suspension system is essential to ensure its longevity and performance. Worn or damaged components can lead to decreased handling, increased tire wear, and compromised safety. Routine inspections and timely replacements of springs, shock absorbers, and linkages can enhance vehicle performance, providing a safer and more enjoyable driving experience.

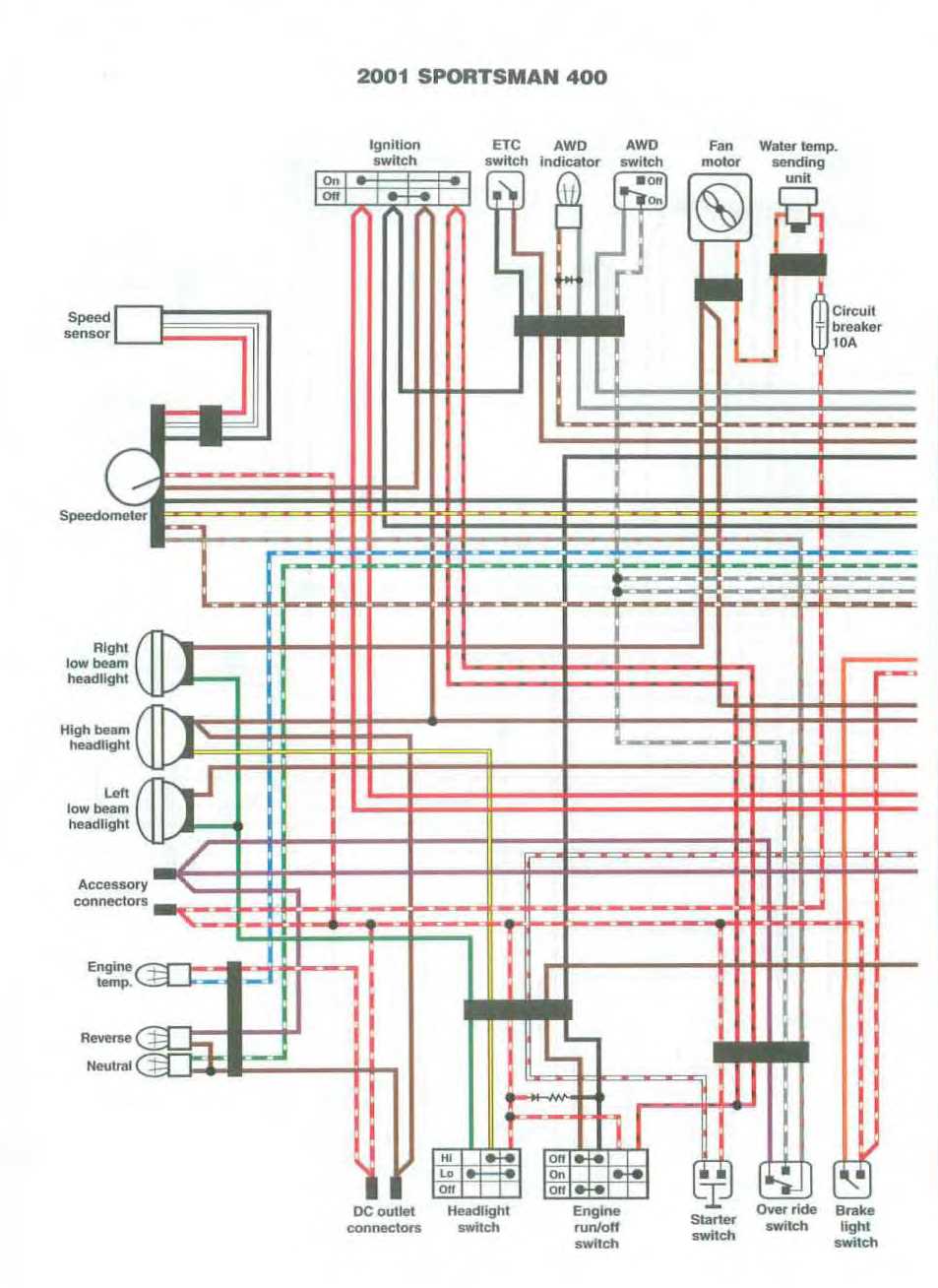

Understanding the Electrical System Layout

The electrical system in an all-terrain vehicle is crucial for its operation and functionality. A thorough understanding of this system helps in troubleshooting issues and ensuring the vehicle performs optimally. This section will provide an overview of the components and connections within the electrical framework.

Key elements of the electrical system include:

- Battery: The primary power source that supplies electricity to the entire system.

- Wiring Harness: A collection of wires that connects various components, facilitating communication and power transfer.

- Fuse Box: Protects the electrical system by preventing overloads, ensuring safe operation.

- Switches: Control various functions, allowing the operator to manage lights, ignition, and other features.

- Ground Connections: Essential for completing the electrical circuits and preventing electrical faults.

In addition to these components, understanding the layout and configuration of the electrical system is vital. Familiarity with how each part interacts can aid in effective maintenance and repair. Regular checks on wiring integrity, connection stability, and component functionality are recommended to ensure longevity and reliability.

By gaining insight into the electrical system’s design, users can make informed decisions regarding upgrades and repairs, enhancing the overall performance of their vehicle.

Steering Mechanism and Control Parts

The steering system in off-road vehicles plays a crucial role in ensuring precise navigation and handling. It consists of various components that work together to facilitate smooth maneuvering and control, allowing the driver to navigate different terrains effectively.

Key Components of the Steering System

Essential elements of the steering assembly include the steering wheel, column, and linkage. The steering wheel serves as the primary interface for the operator, while the steering column connects it to the rest of the system, transmitting the driver’s input. The linkage system is responsible for translating the rotational movement of the wheel into directional changes of the vehicle’s front wheels.

Importance of Regular Maintenance

Routine inspection and maintenance of the steering components are vital for optimal performance. Regular checks can prevent wear and tear, ensuring that all elements function smoothly and reducing the risk of mechanical failure during operation. Proper upkeep not only enhances safety but also improves overall driving experience.

Brake System Parts and Maintenance

The braking system is a crucial component of any vehicle, ensuring safety and control during operation. Proper understanding and upkeep of this system can greatly enhance performance and prolong the lifespan of the vehicle. This section delves into the various elements involved in the braking mechanism and offers maintenance tips to keep it functioning optimally.

Key Components of the Braking Mechanism

The braking mechanism comprises several essential elements, including calipers, rotors, and brake pads. Calipers house the brake pads and apply pressure to the rotors when the brake pedal is engaged. The rotors serve as the surface against which the pads grip, creating the friction necessary for deceleration. Regular inspection of these components is vital, as wear and tear can significantly impact braking efficiency.

Maintenance Recommendations

To ensure the braking system operates effectively, routine maintenance should be performed. This includes checking the brake fluid level, inspecting pads and rotors for wear, and ensuring calipers are functioning correctly. Replacing worn components promptly will prevent further damage and maintain safe operation. Additionally, periodic bleeding of the brake lines can help remove air bubbles, ensuring consistent brake performance.

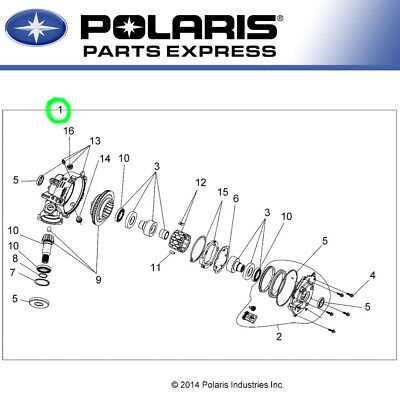

Transmission and Drivetrain Overview

The transmission and drivetrain systems are crucial components that facilitate the movement of the vehicle. They work in unison to convert engine power into motion, ensuring smooth acceleration and effective handling across various terrains. Understanding these systems can significantly enhance the maintenance and performance of the vehicle.

Key Components

Several essential parts make up the transmission and drivetrain assembly. These include gears, shafts, and differentials, which collectively contribute to the efficient transfer of power. Each component plays a specific role in ensuring that the vehicle operates effectively and reliably.

Functionality and Maintenance

Regular inspection and maintenance of the transmission and drivetrain systems are vital for optimal performance. Proper lubrication, timely adjustments, and the replacement of worn components can prevent potential issues and prolong the lifespan of these systems.

| Component | Function | Maintenance Tips |

|---|---|---|

| Transmission | Transfers power from the engine to the wheels | Check fluid levels regularly |

| Driveshaft | Connects the transmission to the wheels | Inspect for wear and damage |

| Differential | Allows wheels to rotate at different speeds | Change fluid as per manufacturer guidelines |

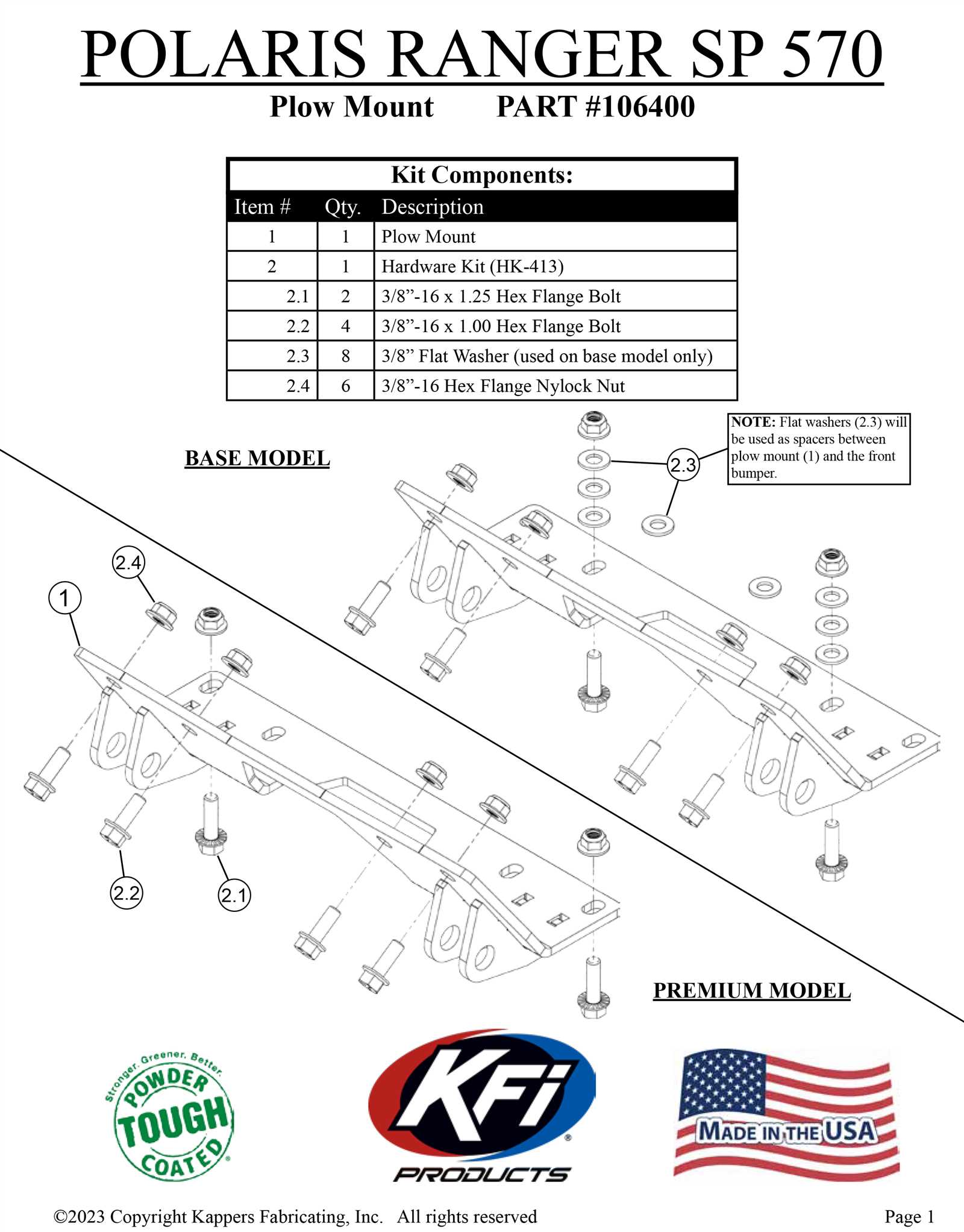

Body and Frame Structure Details

The body and frame of an all-terrain vehicle play a crucial role in its overall performance and durability. Understanding the layout and components that make up these structures is essential for maintenance and modifications. This section delves into the various elements that contribute to the strength and functionality of the vehicle’s exterior and supporting framework.

Chassis Design: The chassis serves as the foundation for the vehicle, providing stability and support for other components. It is typically constructed from high-strength materials that can withstand harsh conditions. The design may vary, incorporating elements such as reinforced crossmembers and brackets to enhance structural integrity.

Body Panels: The outer body panels are designed not only for aesthetic appeal but also for protection against environmental elements. They are often made from lightweight yet durable materials that contribute to the vehicle’s agility while safeguarding internal components from debris and damage.

Mounting Points: Properly placed mounting points are essential for securing various components, including the engine, suspension, and drivetrain. These points must be strategically engineered to distribute weight evenly and maintain balance during operation.

Weight Distribution: Effective weight distribution is vital for achieving optimal handling and stability. The design of the body and frame considers factors such as the placement of heavy components to ensure that the center of gravity remains low, enhancing the vehicle’s maneuverability.

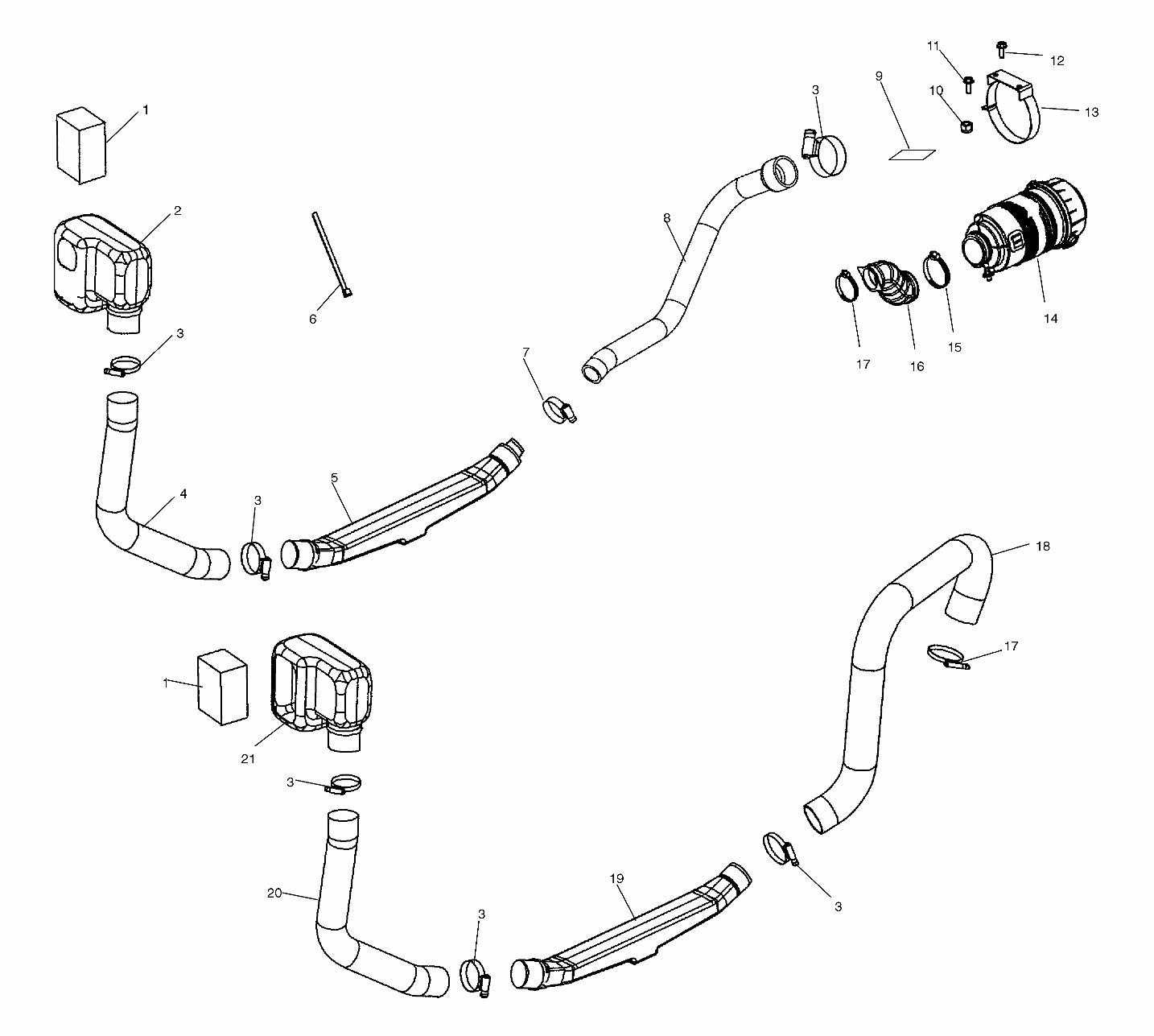

Cooling System Components and Their Roles

The cooling system in a utility vehicle is essential for maintaining optimal operating temperatures and ensuring the engine runs efficiently. Various components work together to dissipate heat generated during operation, preventing overheating and prolonging the lifespan of the engine. Understanding the individual roles of these components can enhance maintenance practices and improve overall performance.

Radiator

The radiator serves as a vital heat exchanger, transferring heat from the coolant to the surrounding air. As the engine heats up, coolant circulates through the engine block and absorbs heat. This heated fluid then flows into the radiator, where it is cooled by air drawn in through the grille. A properly functioning radiator is crucial for effective temperature regulation.

Water Pump

The water pump is responsible for circulating coolant throughout the cooling system. It ensures that coolant flows from the engine to the radiator and back, maintaining a constant flow and preventing hot spots. A reliable water pump is essential for the system’s efficiency, as any failure can lead to overheating and potential engine damage.

Fuel System Layout and

The configuration of the fuel system is crucial for ensuring optimal performance and efficiency of the vehicle. Understanding how the various components interact can help in maintaining and troubleshooting issues related to fuel delivery and consumption.

Key components of the fuel system include:

- Fuel tank

- Fuel pump

- Fuel filter

- Fuel injectors

- Fuel lines

Each element plays a specific role in the process of delivering fuel to the engine:

- Fuel tank: Stores the fuel until needed.

- Fuel pump: Moves the fuel from the tank to the engine.

- Fuel filter: Cleans the fuel to remove impurities before it reaches the engine.

- Fuel injectors: Atomizes the fuel for better combustion in the engine.

- Fuel lines: Transport the fuel between the various components.

Proper maintenance of these parts is essential for the longevity and efficiency of the overall system. Regular inspections and timely replacements can prevent fuel-related issues and ensure smooth operation.