For those engaged in outdoor maintenance or professional logging, having a reliable tool is essential. An in-depth exploration of the various elements that constitute a robust cutting instrument can significantly enhance its efficiency and lifespan. Knowing each segment’s role and functionality is crucial for effective operation and maintenance.

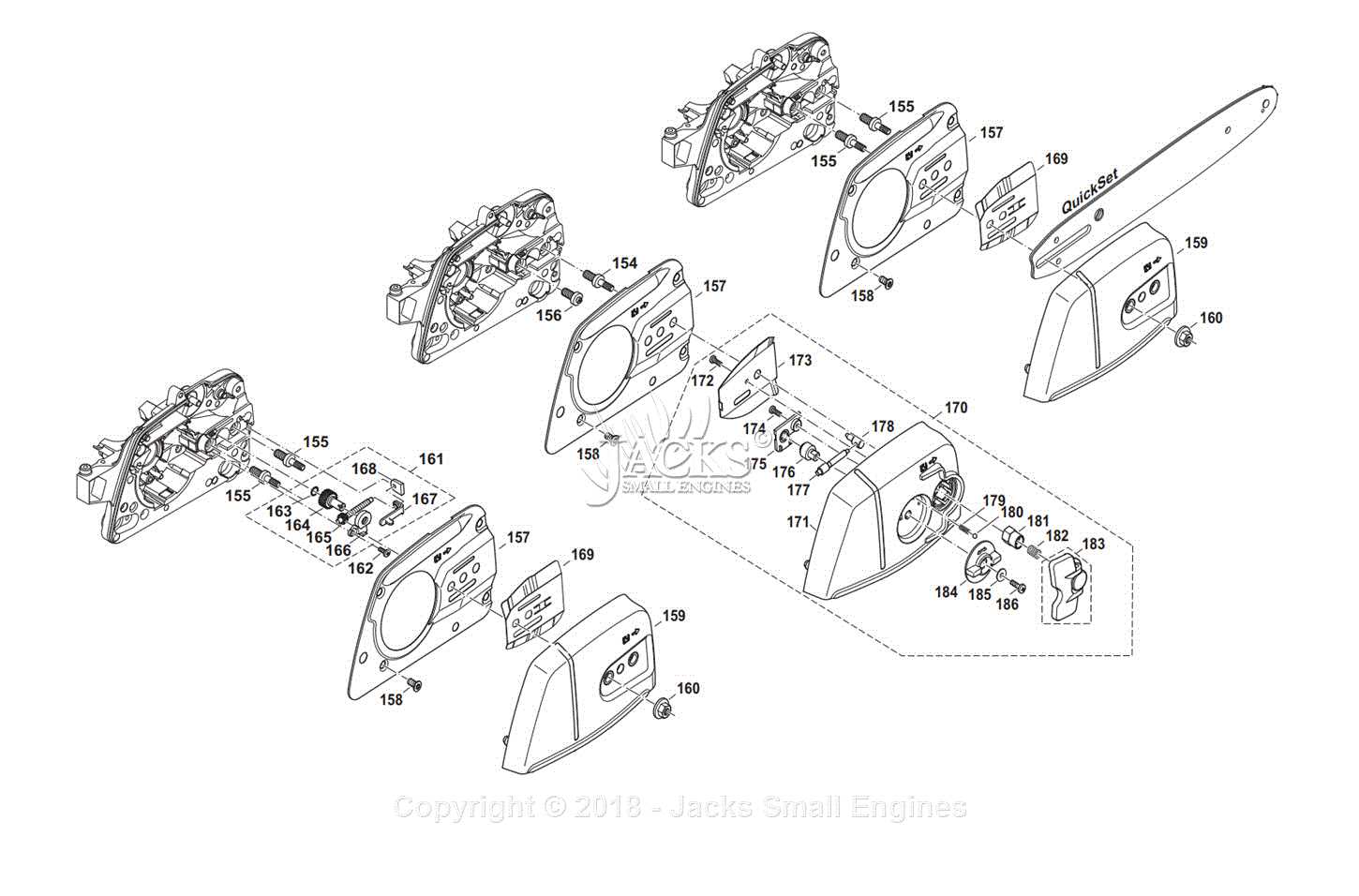

In this section, we will delve into the intricate network of components that make up this essential equipment. Each piece, from the motor to the guide, contributes to the overall performance. Familiarity with these individual sections empowers users to troubleshoot issues, perform necessary repairs, and optimize usage.

Whether you are a seasoned user or a novice, understanding the intricacies of this powerful device will facilitate more informed decisions during repairs or upgrades. This knowledge not only ensures better care of your tool but also maximizes its operational effectiveness, enabling you to tackle any task with confidence.

Understanding the role of each component in a mechanical tool is essential for effective operation and maintenance. By recognizing the core elements and their functions, users can better troubleshoot issues and ensure optimal performance.

- Engine Unit: The powerhouse of the tool, converting fuel into mechanical energy to drive the cutting mechanism.

- Ignition System: Responsible for starting the motor, it ensures a reliable spark to ignite the fuel mixture.

- Drive Mechanism:

Maintenance Tips for Stihl 250

Regular care and upkeep are essential for ensuring the longevity and efficiency of any power tool. By following key maintenance practices, you can avoid common issues and keep your equipment running smoothly over time.

Cleaning and Lubrication

Frequent cleaning is vital to prevent debris buildup, which can hinder performance. It’s crucial to clean the air filters and cooling system regularly. Additionally, applying proper lubrication to the moving parts will reduce friction and minimize wear, extending the lifespan of the tool.

Common Issues with Chainsaw Components

Mechanical tools used for cutting can face various operational problems over time. These issues can arise due to wear, improper maintenance, or external factors affecting performance. It is essential to identify these problems early to ensure safe and efficient operation.

Component Potential Problem Suggested Solution Cutting Mechanism Blunt or damaged teeth How to Replace Chainsaw Components

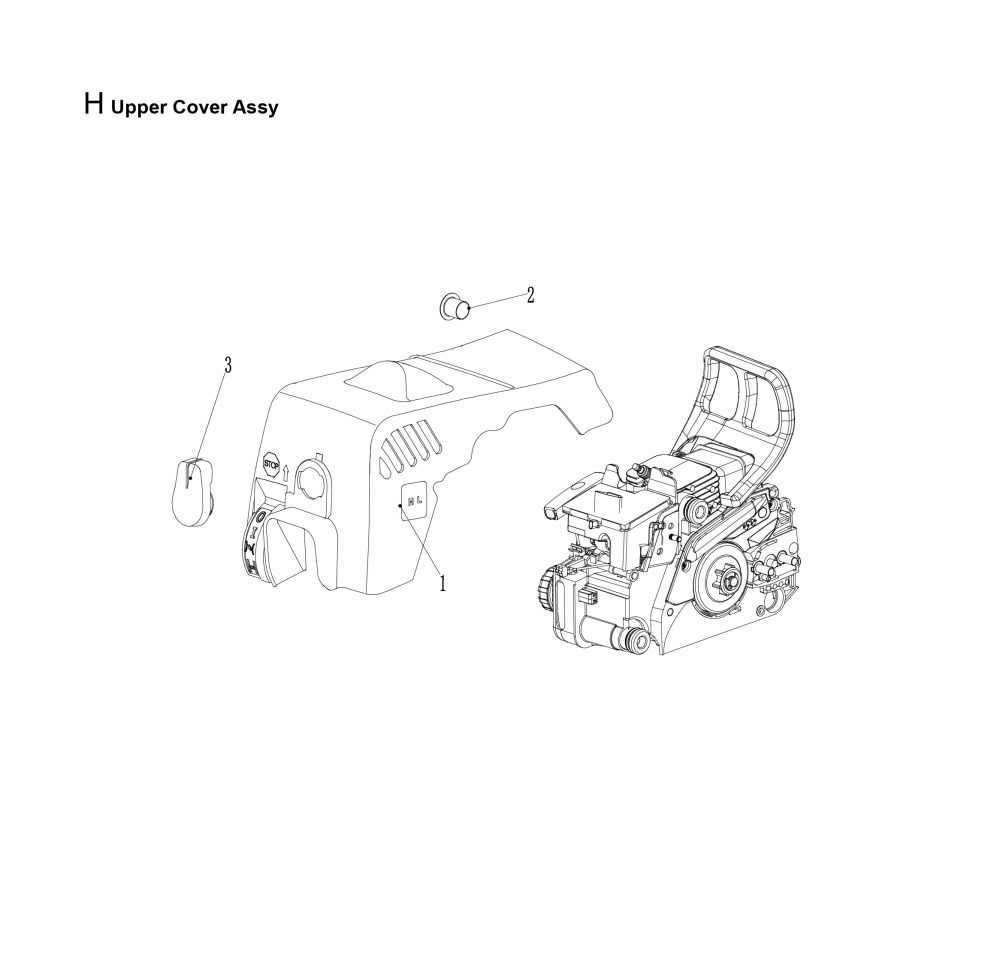

Regular maintenance of cutting equipment ensures its optimal performance and longevity. Over time, various elements may wear out or become damaged, requiring timely replacement. This guide outlines the key steps for safely and efficiently replacing essential components to keep your tool in top shape.

Step 1: Preparing the Tool

Before beginning any work, make sure the equipment is turned off and fully disconnected from any power sources. Allow the machine to

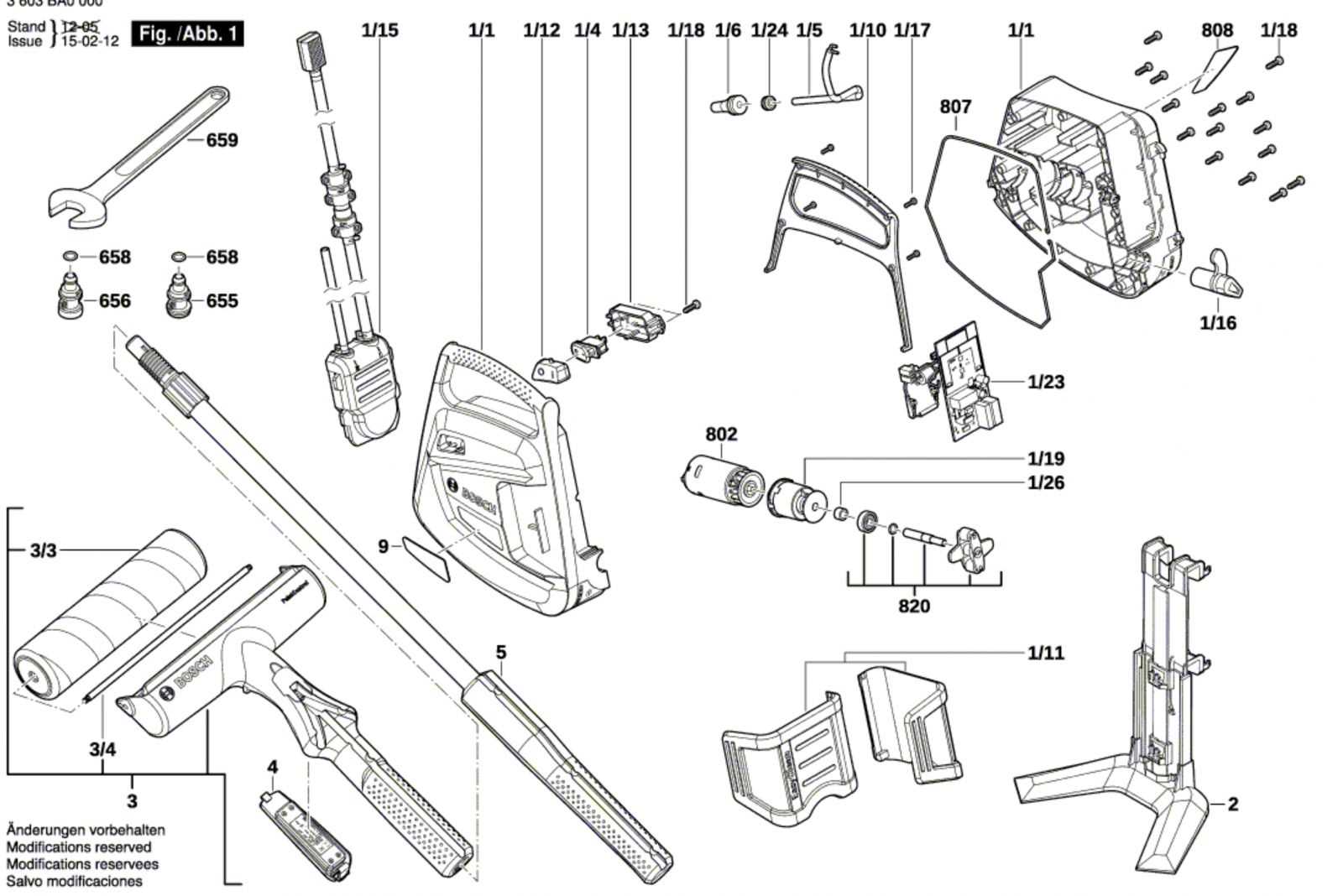

Tools Needed for Repairs

When working on mechanical maintenance, it’s essential to have the proper set of tools to ensure effective and safe repair work. Whether addressing simple issues or performing more complex adjustments, having the right equipment can make a significant difference in both time and effort.

Basic Tools

- Screwdrivers with varying sizes and types of heads

- Wrenches for different bolt sizes

- A set of pliers for gripping and turning components

- A socket set for tightening and loosening fasteners

- A multi-purpose tool for

Finding Genuine Components

When it comes to replacing specific elements in your equipment, it’s important to ensure you’re using original products to maintain performance and longevity. Authentic replacements are specifically designed for your model, offering reliable functionality and compatibility. Using substitutes or imitations can often lead to malfunctions or reduced efficiency, which is why sourcing legitimate elements is critical.

Where to Source Authentic Replacements

There are several reliable options when searching for genuine replacements. Authorized dealerships are one of the best places to start, as they guarantee authenticity and often provide expert advice.

User Manual Resources

For those who operate mechanical tools, having access to detailed instructions is essential. These guides offer comprehensive information, from basic setup to advanced maintenance tips, ensuring your equipment runs smoothly and efficiently over time.

- Official manufacturer websites often provide downloadable guides in PDF format. These are reliable sources, ensuring that you are following the most up-to-date instructions.

- Online forums and user communities can also be invaluable. Experienced users frequently share tips, troubleshooting advice, and even direct links to specific sections of digital manuals.

Safety Precautions While Operating

Ensuring personal safety and the safety of those around you is paramount when handling powerful equipment. Proper precautions must be taken to minimize risks associated with operating such tools. Adhering to established safety guidelines not only protects the operator but also enhances the overall efficiency of the task at hand.

Before starting the equipment, it’s essential to inspect all components for any signs of damage or wear. A thorough check helps to prevent malfunctions during use. Additionally, wearing appropriate safety gear can significantly reduce the likelihood of injuries.

Safety Gear Purpose Protective goggles To shield eyes from debris Ear protection To minimize noise exposure Gloves To enhance grip and protect hands Steel-toed boots To protect feet from heavy objects Hard hat To safeguard against falling objects While operating the equipment, maintain a firm grip and a stable stance. Keep the working area clear of obstacles and bystanders to avoid accidents. Regular breaks should also be taken to maintain focus and prevent fatigue.

Lastly, familiarizing yourself with the operational manual and adhering to all safety recommendations will enhance your competence and confidence while using the equipment. Being well-informed is the first step toward safe operation.

Upgrades and Accessories for Performance

Enhancing the efficiency and functionality of your power tool can significantly improve your overall experience. By incorporating various modifications and supplementary components, you can tailor your equipment to meet specific tasks, ensuring optimal operation and longevity. This section explores several recommended enhancements and add-ons that can elevate your tool’s performance.

Performance Enhancements

One of the most effective ways to boost your tool’s capabilities is through engine tuning. Upgrading the air filter and exhaust system can increase airflow, leading to improved combustion and enhanced power output. Additionally, consider installing a high-performance spark plug, which can provide better ignition and increased efficiency, resulting in a smoother operation.

Useful Accessories

Integrating useful accessories can also enhance functionality. A quality guide bar and chain combination can improve cutting precision and speed, making your work more efficient. Furthermore, protective gear such as chainsaw chaps and gloves should not be overlooked, as they provide essential safety while operating machinery. Investing in a reliable carrying case or maintenance kit will ensure that your tools remain in excellent condition and ready for any task.