The complexity of machinery often lies in the intricate arrangement of its components. Gaining a clear understanding of these assemblies is crucial for effective maintenance and repair. A comprehensive exploration of the layout helps users to identify each element and its function, fostering better handling and troubleshooting.

Accurate knowledge of how these elements interconnect can significantly enhance operational efficiency. By familiarizing oneself with the configuration and relationships among various units, operators can optimize performance and minimize downtime. This section aims to provide valuable insights into the structure and functionality of the assembly in question.

Familiarity with these configurations is essential for anyone involved in the upkeep of such equipment. Whether you are a technician, operator, or enthusiast, understanding the specifics can lead to improved outcomes and extended longevity of the machinery. Embracing this knowledge equips individuals with the tools needed for successful engagement with their equipment.

This section aims to provide an overview of a specific agricultural machine, emphasizing its design and functionality. Understanding the structure and components of this vehicle is essential for effective maintenance and operation, as each part plays a crucial role in its overall performance.

Key Features of the Machinery

This machine is known for its robust construction and reliable performance in various farming tasks. Key features include its powerful engine, efficient transmission system, and user-friendly controls, all contributing to its versatility on the field.

Maintenance Considerations

Key Components of the B414 Tractor

This section explores the essential elements that contribute to the functionality and efficiency of this agricultural machine. Understanding these components is crucial for effective maintenance and operation.

Engine and Transmission

The power unit and gear system are vital for performance. Key aspects include:

- Engine Type: A reliable engine ensures optimal power output.

- Transmission System: Smooth gear transitions facilitate ease of use.

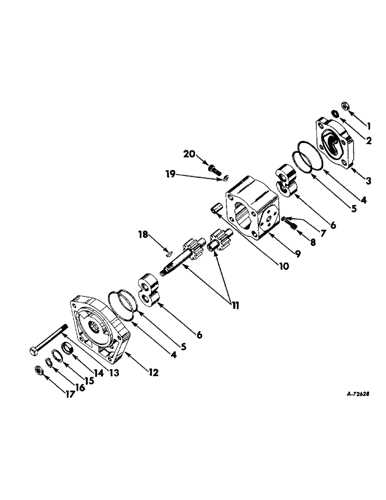

Hydraulic System

The hydraulic mechanism plays a critical role in various operations, enabling the attachment of implements and enhancing maneuverability:

- Pumps: Provide necessary pressure for hydraulic functions.

- Hoses and Valves: Ensure effective fluid movement and control.

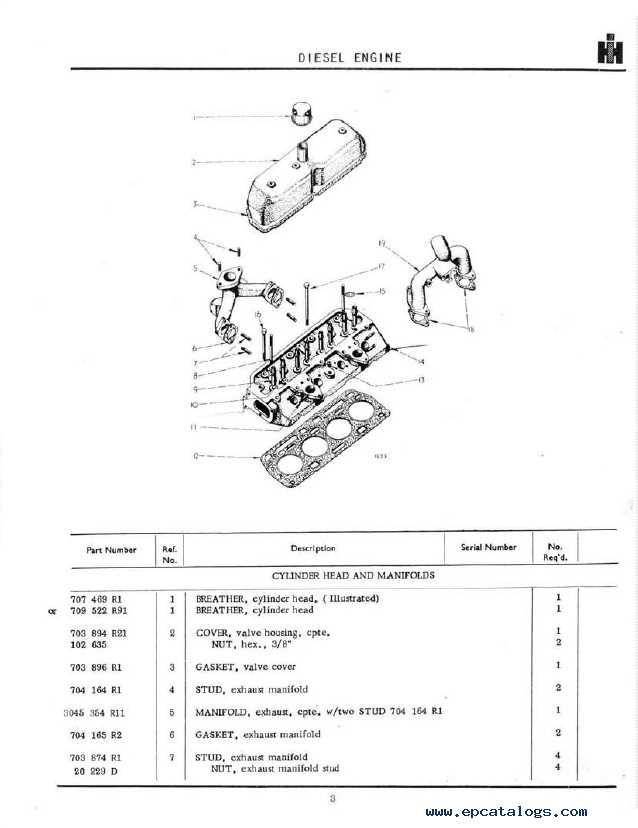

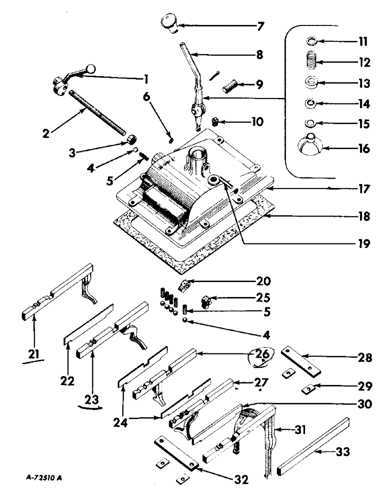

Visual Guide to Part Locations

This section provides an informative overview of the various components found in a specific agricultural machine. By understanding the arrangement of these elements, users can navigate the equipment more efficiently, facilitating maintenance and repair tasks.

Component Layout Overview

Familiarity with the layout of the machine’s components is essential for effective troubleshooting and servicing. Each element is strategically placed to optimize functionality and accessibility.

Detailed Component Reference

The following table outlines the key components, their respective locations, and brief descriptions of their functions:

| Component | Location | Description |

|---|---|---|

| Engine | Front section | Power unit that drives the machinery. |

| Transmission | Below the engine | Controls the power transfer to the wheels. |

| Fuel Tank | Rear section | Stores fuel for the engine. |

| Hydraulic System | Side panel | Manages fluid power for various operations. |

| Electrical System | Underneath dashboard | Controls electrical components and functions. |

Importance of Maintenance and Repairs

Regular upkeep and timely repairs are crucial for the longevity and efficiency of machinery. Ensuring that all components function optimally not only enhances performance but also reduces the likelihood of unexpected breakdowns. This proactive approach saves time and resources, ultimately contributing to the smooth operation of equipment.

Enhancing Operational Efficiency

Well-maintained machinery operates at peak efficiency, which leads to improved productivity. Routine checks and servicing help identify potential issues before they escalate, ensuring that all systems work harmoniously.

Cost-Effectiveness

Investing in maintenance prevents costly repairs and replacements in the long run. By addressing minor problems early, operators can avoid significant financial burdens associated with major failures.

Common Issues and Solutions

In the realm of machinery maintenance, encountering difficulties is a common occurrence. Understanding typical problems and their respective solutions can greatly enhance performance and prolong the lifespan of equipment. This section will delve into prevalent challenges faced by users and provide practical remedies.

Electrical Malfunctions

One frequent issue arises from electrical faults. Symptoms may include flickering lights or unresponsive components. To resolve this, inspect wiring connections and replace any damaged fuses. Additionally, ensuring proper grounding can help mitigate similar issues.

Hydraulic System Leaks

Another common concern involves hydraulic fluid leaks, which can lead to diminished efficiency. Identifying the source of the leak is crucial. Regularly check hoses and seals for wear and replace them as necessary. Maintaining optimal fluid levels can also prevent further complications.

Finding Replacement Parts Easily

Locating suitable components for machinery can often be a challenging task. However, understanding the right strategies and resources can streamline the process significantly. By utilizing various tools and platforms, users can enhance their ability to find the necessary items with ease and efficiency.

Utilizing Online Resources

The internet offers a wealth of information and resources for sourcing equipment components. Websites dedicated to machinery parts often provide detailed catalogs and search functions that can help users pinpoint exactly what they need. Additionally, forums and user groups can be invaluable for sharing insights and recommendations on where to find specific items.

Consulting with Experts

Engaging with professionals in the field can also prove beneficial. Local dealers and service providers often possess extensive knowledge about compatible components and may have direct access to inventory. Establishing relationships with these experts can facilitate quicker resolutions when seeking replacements.

Comparative Analysis with Similar Models

This section explores the similarities and differences between the examined model and other comparable machines in the market. Understanding these distinctions can help potential users make informed decisions based on their specific needs.

Key aspects to consider in this comparative analysis include:

- Performance: Evaluating horsepower, torque, and operational efficiency.

- Design Features: Assessing ergonomics, build quality, and user interface.

- Maintenance Requirements: Analyzing ease of service and availability of replacement components.

Here are notable competitors in the same category:

- Model A: Known for its superior fuel efficiency and compact design.

- Model B: Offers enhanced lifting capabilities and advanced technology.

- Model C: Praised for its durability and lower maintenance costs.

In conclusion, this analysis highlights essential factors that differentiate these machines, providing valuable insights for prospective buyers.

Assembly and Disassembly Instructions

This section provides essential guidelines for assembling and disassembling the machine effectively. Understanding the proper sequence of steps ensures safety and efficiency during the process.

Before starting, ensure you have the necessary tools and a clean workspace. Follow these steps for assembly:

- Gather all components and verify their condition.

- Align parts according to the provided layout.

- Secure each piece with appropriate fasteners.

- Double-check connections for stability.

For disassembly, adhere to the following procedure:

- Disconnect power supply and any attachments.

- Loosen fasteners carefully to prevent damage.

- Remove components in the reverse order of assembly.

- Organize removed parts for easy identification during reassembly.

Following these instructions will help maintain the integrity of the machine and facilitate future maintenance.

Upgrades and Modifications for Performance

Enhancing the functionality of agricultural machinery can significantly improve its efficiency and effectiveness. By implementing strategic upgrades and modifications, operators can optimize performance, extend the lifespan of components, and adapt equipment to meet specific operational demands.

Engine Enhancements

One of the most impactful areas for improvement lies within the engine. Upgrading to a high-performance air intake system can increase airflow, resulting in better combustion and more power. Additionally, tuning the engine control unit (ECU) can unlock potential performance gains by adjusting fuel maps and ignition timing.

Transmission and Drive Modifications

Modifying the transmission system can enhance torque delivery and improve acceleration. Installing a more efficient gearbox or upgrading the clutch can lead to smoother operation and increased responsiveness. Furthermore, implementing better traction aids, such as differential locks, can enhance grip in challenging terrains, allowing for more reliable operation under various conditions.

Resources for Technical Support

Accessing reliable resources for assistance is essential when dealing with machinery and equipment. Understanding where to find help can streamline troubleshooting and maintenance processes, ensuring optimal performance.

Online Documentation

Many manufacturers provide comprehensive online resources that can aid in resolving issues. These documents often include:

- User manuals with detailed instructions

- Maintenance guides outlining routine checks

- FAQs addressing common concerns

Customer Support Services

Engaging with customer support can provide personalized assistance. Consider the following options:

- Direct contact via phone or email for immediate help

- Chat services on official websites for quick queries

- Local service centers for in-person support

History and Evolution of the B414

This section explores the development and transformation of a specific agricultural machine over the years. The journey reflects advancements in technology, design, and functionality that have significantly impacted farming practices.

Initial Design and Features

The early models introduced a robust framework and practical features tailored for various farming tasks. These innovations set the foundation for subsequent enhancements, catering to the evolving needs of farmers.

Technological Advancements

Over time, significant improvements were made in engine performance and operational efficiency. These changes not only increased productivity but also ensured better fuel economy, reflecting the industry’s shift towards sustainability.

Owner Testimonials and Experiences

This section shares insights and feedback from individuals who have utilized specific machinery. Their stories reflect the diverse experiences encountered during operation, maintenance, and overall satisfaction with their equipment. Hearing from actual users provides valuable perspectives that can guide potential buyers and enthusiasts alike.

Real-Life Experiences

Many operators appreciate the reliability of their machinery in various tasks. One owner noted, “This equipment has never let me down during critical projects.” Such testimonies highlight the confidence users have in their tools, reinforcing the importance of quality and performance in everyday applications.

Challenges and Solutions

While satisfaction is prevalent, some users have faced challenges. For example, a user mentioned, “I encountered issues initially, but support helped me resolve them quickly.” This showcases not only the hurdles but also the effective customer service that can make a significant difference in user experience.

Future of B414 Parts Availability

The ongoing evolution in the agricultural machinery sector indicates a shift in the accessibility of components essential for specific models. As technology advances, manufacturers are exploring innovative solutions to ensure that these crucial elements remain available to users.

Several factors will influence the future accessibility of these components:

- Increased demand for sustainable practices may encourage manufacturers to invest in more durable materials.

- Advancements in 3D printing technology could lead to the on-demand production of rare components.

- Global supply chain optimization will enhance the distribution of parts, reducing lead times.

Furthermore, collaboration between manufacturers and aftermarket suppliers will play a vital role in maintaining a steady supply of essential components. By focusing on partnerships, stakeholders can ensure that users have access to reliable resources for maintenance and repairs.