Understanding how various elements come together in an electric-powered outdoor tool can significantly enhance its maintenance and performance. By identifying the individual elements that make up the whole system, users can quickly address potential issues and extend the life of their equipment.

Each component plays a crucial role in ensuring the efficiency and functionality of the device. From energy sources to operational mechanisms, knowing how they interconnect is essential. Proper care and attention to these details can ensure smooth operation and prevent common malfunctions.

This guide offers a detailed look at the most essential elements of your equipment, providing valuable insights into their functions and how to maintain them effectively. Whether you’re troubleshooting or performing routine checks, understanding the key sections of the system will empower you to make informed decisions.

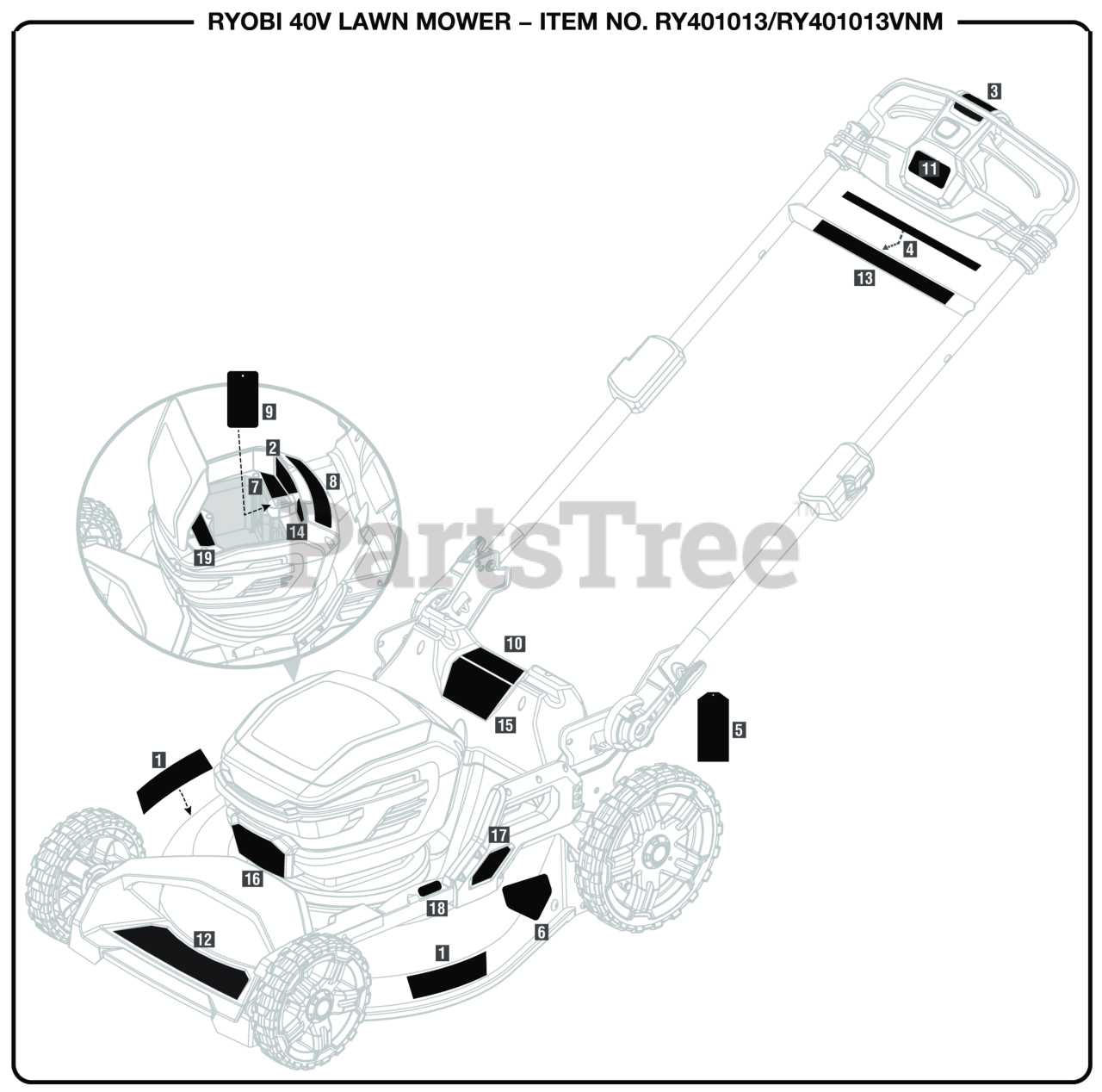

Key Components of Ryobi 40V Mower

The functionality of any electric garden tool depends on several interconnected elements that work together to ensure efficient operation. Understanding the essential parts of such equipment helps in proper maintenance and repair, extending its lifespan and ensuring optimal performance.

- Battery System: The power source provides energy to the tool, ensuring smooth and reliable operation over extended periods.

- Cutting Blades: These are responsible for trimming vegetation with precision and efficiency, playing a key role in the overall performance.

- Motor Assembly: This crucial element transforms the stored energy into mechanical movement, driving the cutting mechanism.

- Wheels and Frame: Support and mobility components, these ensure stability and ease of maneuvering during operation.

- Control Panel: The interface that allows the operator to manage settings and power, enhancing usability and safety.

Battery and Power Management Overview

The efficiency of outdoor power equipment heavily relies on effective energy storage and distribution systems. Understanding how batteries function and the management of their power output is essential for optimal performance and longevity.

Battery Technology

Modern devices often utilize lithium-ion technology, which offers advantages such as higher energy density and reduced weight. This allows for longer operating times while minimizing user fatigue.

Power Management Systems

Power management systems play a crucial role in optimizing energy use and extending battery life. These systems monitor charge levels, regulate power distribution, and ensure safe operation, enhancing overall reliability.

| Feature | Description |

|---|---|

| Charge Cycle | Number of times a battery can be charged and discharged. |

| Voltage Regulation | Maintains a steady output voltage to prevent damage. |

| Energy Density | Amount of energy stored per unit volume or weight. |

| Safety Features | Includes mechanisms to prevent overheating and overcharging. |

Understanding Blade Assembly and Function

The blade assembly is a critical component that directly influences the efficiency and effectiveness of grass trimming equipment. Its design and construction are tailored to optimize cutting performance, ensuring a clean and precise finish. Understanding how this assembly works and its various components can greatly enhance user experience and maintenance practices.

At the core of the blade assembly are the blades themselves, which are typically crafted from durable materials to withstand wear and tear. These blades are strategically positioned to create a rotating action that efficiently slices through vegetation. Proper alignment and sharpness are essential for achieving optimal results, as dull or misaligned blades can lead to uneven cuts and increased strain on the motor.

In addition to the blades, the assembly often includes various attachments such as washers, nuts, and spacers, which play vital roles in securing the blades in place and ensuring stability during operation. Understanding the interaction between these components helps in troubleshooting common issues and performing necessary repairs or replacements.

Regular inspection and maintenance of the blade assembly are crucial for prolonging the lifespan of the equipment. Keeping the blades sharp, checking for any signs of damage, and ensuring all components are securely fastened will contribute to a more efficient and effective cutting process. This proactive approach not only enhances performance but also ensures safety during operation.

Deck Construction and Durability

The construction of the cutting deck is crucial for optimal performance and longevity of any outdoor equipment. This component must withstand various environmental conditions while providing a sturdy platform for effective grass trimming. A well-engineered deck ensures not only reliability but also enhances the overall efficiency of the machine.

Material Quality

Using high-grade materials significantly impacts the durability of the deck. Stainless steel and heavy-duty plastic are popular choices that resist corrosion and wear. Additionally, incorporating reinforcement in critical areas can prevent structural failures over time.

Design Features

Innovative design elements, such as an aerodynamic shape, contribute to performance by promoting efficient airflow. Features like adjustable height settings and easy-clean options also enhance user experience and maintenance, ensuring the deck remains functional and resilient throughout its lifespan.

Handle Mechanism and Adjustment

The handle system in outdoor equipment plays a crucial role in user comfort and operational efficiency. Proper adjustment of this mechanism is essential for optimal control and maneuverability. Understanding the components and their functions will help users maintain their equipment effectively.

Key elements of the handle mechanism include the grip, adjustment levers, and pivot points. Each of these parts contributes to the overall functionality, ensuring a seamless user experience. Regular maintenance and adjustment can prevent wear and enhance performance over time.

| Component | Description | Adjustment Tips |

|---|---|---|

| Grip | Provides a comfortable hold for the user. | Ensure it is clean and free of debris; replace if worn. |

| Adjustment Lever | Allows for height modification of the handle. | Loosen the lever, adjust to the desired height, and tighten securely. |

| Pivots | Enable the handle to move smoothly during operation. | Lubricate regularly to prevent rust and ensure ease of movement. |

By paying attention to these components and making necessary adjustments, users can enhance their overall experience and extend the lifespan of their equipment.

Motor Housing and Cooling System

The motor enclosure plays a crucial role in protecting the internal components while ensuring efficient heat dissipation during operation. A well-designed housing not only safeguards against external elements but also contributes to the overall performance of the device.

Effective cooling systems are essential for maintaining optimal temperature levels, thereby enhancing the longevity of the motor. These systems can utilize various methods to prevent overheating, ensuring consistent performance even under demanding conditions.

| Component | Function |

|---|---|

| Motor Housing | Protects internal parts and aids in heat management |

| Cooling Vents | Facilitates airflow to reduce heat buildup |

| Fan System | Enhances air circulation around the motor |

Understanding the interaction between the housing and cooling mechanisms is vital for anyone looking to optimize performance and durability in their equipment. Regular maintenance and inspection of these components can prevent potential issues and ensure smooth operation.

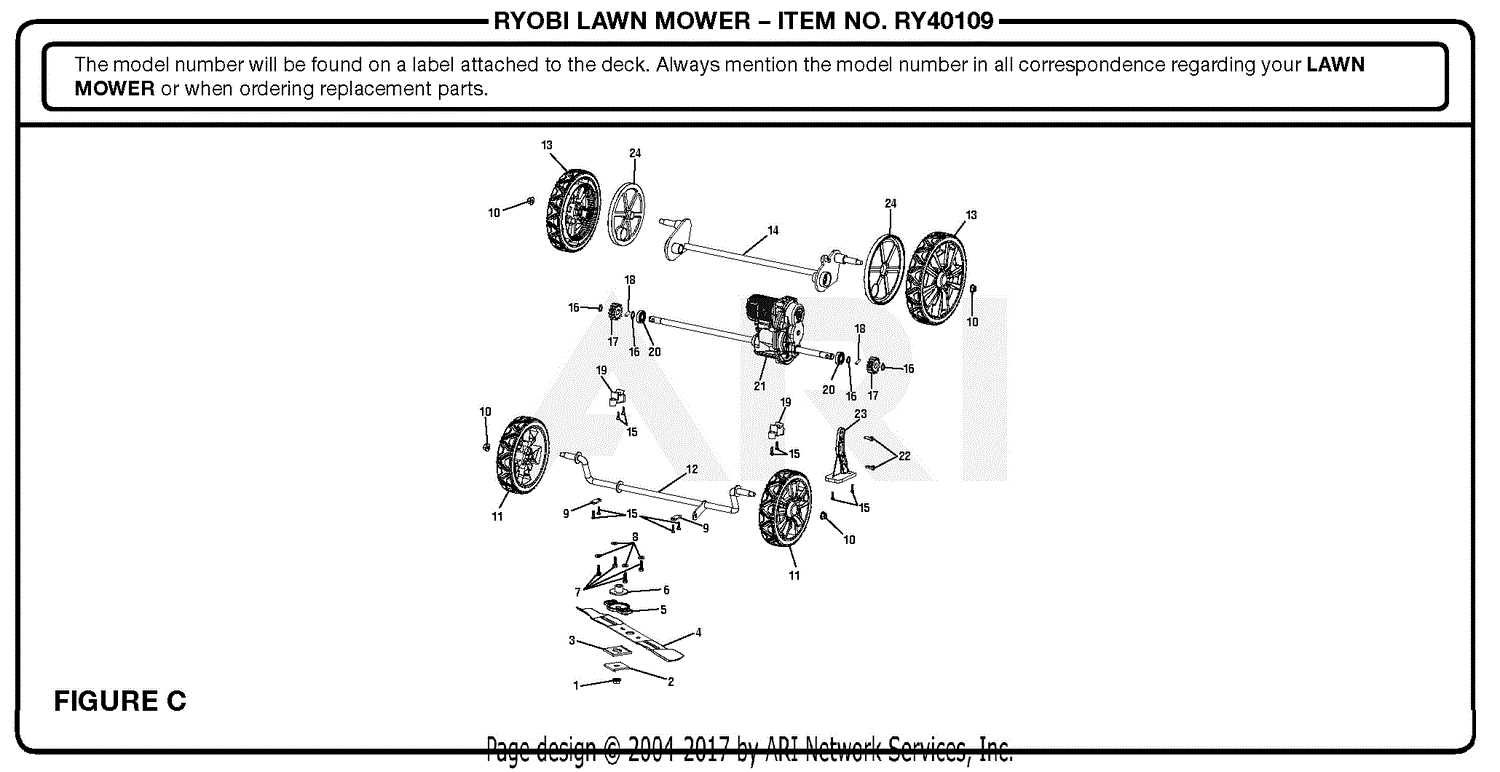

Inspecting Wheels and Axle Design

Evaluating the wheel and axle configuration is crucial for ensuring optimal performance and longevity of your equipment. Proper inspection can reveal issues that might affect mobility and stability, ultimately impacting efficiency during use.

Key Components to Examine

- Wheels: Check for wear, cracks, or deformities.

- Axles: Look for bends, rust, or damage.

- Bearings: Ensure smooth rotation and minimal friction.

Inspection Steps

- Lift the unit to access wheels and axles.

- Rotate each wheel to identify any irregular sounds.

- Inspect wheel alignment and adjust as necessary.

- Lubricate bearings to maintain performance.

Safety Switches and Electrical Controls

In modern outdoor equipment, the integration of safety mechanisms and electrical systems plays a crucial role in ensuring user protection and optimal functionality. These components are designed to prevent accidents and enhance the performance of the device, contributing to a safer and more efficient experience during operation.

Among the essential features are safety switches, which are strategically placed to ensure that the machine only operates under safe conditions. These switches can be activated or deactivated depending on user engagement, helping to prevent unintended starts and potential hazards.

| Component | Function |

|---|---|

| Safety Switch | Prevents accidental operation by requiring user input |

| Emergency Stop Button | Instantly halts operation in case of emergencies |

| Power Control Lever | Regulates the power output and speed settings |

| Battery Indicator | Monitors and displays battery charge level |

Understanding these elements is vital for safe operation and maintenance. Regular checks and timely replacements of malfunctioning components can greatly reduce risks and enhance the overall performance of the equipment.

Grass Catcher Attachment and Usage

The grass catcher attachment is an essential tool designed to enhance the efficiency of your gardening tasks. This accessory aids in collecting cuttings and debris, ensuring a clean and tidy outdoor space. Its usage simplifies the maintenance process, allowing for a more pleasant experience while working in your yard.

Benefits of Using a Grass Catcher

- Reduces the need for raking

- Promotes a healthier lawn by returning nutrients

- Minimizes cleanup time after mowing

- Helps manage debris during seasonal changes

How to Attach and Use

- Ensure your equipment is powered off and cool.

- Align the attachment with the designated slots.

- Secure the attachment firmly in place.

- Adjust the settings for optimal performance.

- Begin mowing, monitoring the catcher for fullness.

Maintenance of Charging Ports

Ensuring the proper functionality of charging interfaces is crucial for the longevity and efficiency of your equipment. Regular upkeep can prevent common issues and enhance performance. Here are key practices to follow.

- Regular Inspection: Check the ports for any visible signs of wear or damage. Look for dirt, debris, or corrosion that may hinder connections.

- Cleaning: Use a soft brush or a compressed air canister to remove dust and particles from the charging ports. Avoid using liquids that can seep into the device.

- Connection Checks: Ensure that the charging cables fit snugly into the ports. Loose connections can lead to ineffective charging and potential damage.

- Protective Covers: Consider using protective covers when the equipment is not in use. This helps keep the ports clean and prevents foreign objects from entering.

By adhering to these maintenance practices, you can ensure that the charging interfaces remain in optimal condition, ultimately extending the lifespan of your equipment and enhancing its reliability.

Troubleshooting Common Mechanical Issues

Addressing frequent mechanical problems can greatly enhance the efficiency and longevity of your equipment. Understanding how to identify and resolve these issues is essential for maintaining optimal performance. Below, we explore some common challenges and provide insights into effective troubleshooting methods.

Identifying Symptoms

Before diving into solutions, it is crucial to recognize the signs of malfunction. Unusual noises, inconsistent performance, or visible wear and tear often indicate underlying issues. Observing these symptoms can help pinpoint the exact problem.

Common Issues and Solutions

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| No Power | Dead battery, faulty connections | Check battery charge, inspect connections |

| Uneven Cutting | Dull blade, improper height adjustment | Sharpen or replace blade, adjust cutting height |

| Overheating | Clogged vents, continuous use | Clear vents, allow cool-down periods |

| Stalling | Fuel issues, clogged filters | Check fuel level, clean or replace filters |

By systematically assessing these common issues and implementing the suggested solutions, users can effectively maintain their equipment and ensure it operates smoothly for years to come.