When it comes to maintaining and enhancing the performance of your equipment, having a clear visual reference can make all the difference. A well-organized illustration of individual elements can provide valuable insights, helping users to identify and address issues efficiently.

Such a visual guide not only aids in understanding the functionality of each component but also simplifies the process of reassembly and replacement. By having an ultimate reference at hand, one can delve into the intricate workings of the device with confidence.

Whether you are a seasoned professional or a DIY enthusiast, familiarity with the various sections of your tool can enhance both safety and effectiveness. Armed with this knowledge, you can ensure your equipment operates at peak performance for years to come.

Bostitch MIII Overview

This section provides a comprehensive look at a widely used fastening tool known for its reliability and efficiency in various applications. This model is designed to enhance productivity while ensuring durability and ease of use. It is favored by professionals and DIY enthusiasts alike, making it an essential addition to any toolkit.

Key Features

The tool is equipped with several innovative characteristics that set it apart from others in its category. Its ergonomic design allows for comfortable handling during prolonged use, while its robust construction ensures longevity. Additionally, the quick-release mechanisms facilitate seamless loading and unloading, significantly reducing downtime.

Applications

This fastening device is versatile, suitable for both light and heavy-duty projects. It excels in tasks ranging from simple home repairs to complex construction jobs, making it a valuable asset for contractors and hobbyists. Its efficiency in fastening materials securely and swiftly enhances overall project workflow.

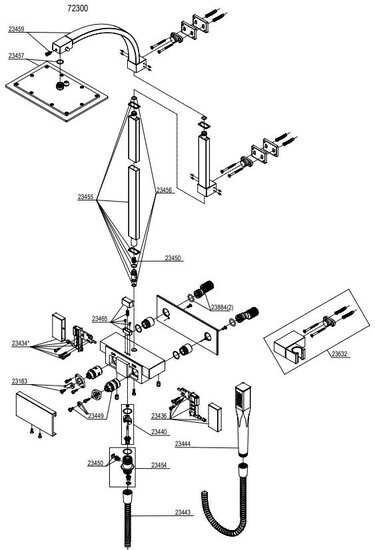

Understanding the Parts Diagram

Grasping the layout of components is essential for effective maintenance and troubleshooting. This visual representation allows users to identify each element’s role and position within a mechanism, facilitating a deeper comprehension of how everything functions together.

Significance of Component Identification

Recognizing individual elements is crucial for successful repairs and upgrades. When users can pinpoint specific items, they can make informed decisions about replacements or modifications, thereby enhancing the overall performance and longevity of the tool.

Navigating the Visual Representation

When examining the layout, pay attention to the labels and organization. Each segment is typically numbered or coded, guiding users through the various functions and interconnections. This structured approach not only simplifies the understanding of the assembly but also aids in locating potential issues more efficiently.

In conclusion, a clear grasp of the layout enhances both the user experience and the efficiency of maintenance tasks. Engaging with this representation empowers users to take control of their tools, ensuring they operate at their best.

Common Bostitch MIII Issues

When working with fastening tools, users often encounter specific challenges that can hinder performance and efficiency. Understanding these common complications is essential for maintaining optimal functionality and ensuring longevity of the equipment. Below are some prevalent issues that may arise, along with suggestions for resolution.

Jamming Problems

One of the most frequent complaints involves fasteners becoming lodged in the mechanism. This issue can stem from using the incorrect size of fasteners or insufficient lubrication. To resolve this, always ensure compatibility with the specified fastener sizes and periodically apply appropriate lubricant to moving parts.

Inconsistent Fastening

Another common concern is the inconsistency in the depth of fasteners. Factors contributing to this can include worn components or improper adjustment settings. To rectify this, inspect the drive mechanism for wear and recalibrate the settings according to the manufacturer’s guidelines. Regular maintenance checks can significantly reduce these inconsistencies.

Tools Needed for Maintenance

Proper upkeep of equipment requires a selection of essential implements. These tools not only facilitate routine checks but also ensure that your device operates efficiently over time. Having the right gear on hand is crucial for performing maintenance tasks effectively.

- Screwdrivers: Both flathead and Phillips screwdrivers are necessary for loosening or tightening screws.

- Wrenches: Adjustable and socket wrenches are important for securing nuts and bolts.

- Pliers: Useful for gripping and bending components, pliers assist in various repairs.

- Lubricants: A good quality lubricant helps maintain moving parts and prevents rust.

- Cleaning supplies: Brushes and cloths are essential for removing debris and dust from the machine.

Utilizing these implements not only streamlines the maintenance process but also extends the lifespan of your equipment. Regular inspections and timely repairs will contribute to optimal performance.

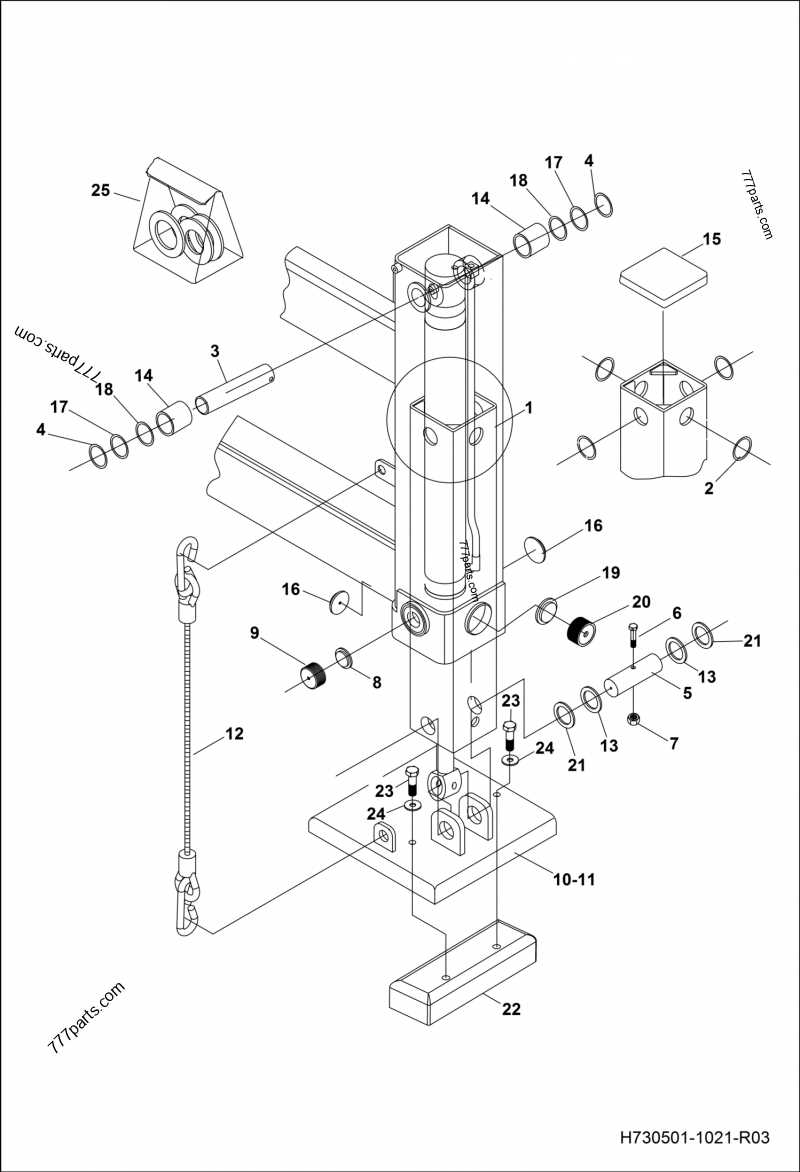

Identifying Each Component

Understanding the various elements of a tool is essential for effective maintenance and operation. Each piece plays a crucial role in ensuring optimal performance, and recognizing their functions can aid in troubleshooting and repairs. This section will guide you through the main components commonly found in these devices.

Key Elements and Their Functions

Every unit consists of several integral parts that work together harmoniously. For instance, the motor is responsible for driving the mechanism, while the housing protects internal components from damage. Additionally, the feed system ensures that materials are supplied efficiently for smooth operation. Familiarizing yourself with these elements can enhance your ability to manage any issues that may arise.

Maintenance and Replacement

Knowing how to identify and access each component is vital for proper upkeep. Regular inspections can help pinpoint wear and tear, allowing for timely replacements. Components like blades and springs often require attention, and understanding their location and function simplifies the process of maintenance. By keeping each element in check, you can ensure longevity and reliability in your equipment.

Replacement Parts Availability

Access to essential components is crucial for maintaining and restoring tools to their optimal performance. Ensuring that users can easily obtain the necessary replacements contributes significantly to the longevity and efficiency of equipment. This section explores the availability and sourcing options for these vital elements.

Where to Find Components

Various platforms offer the opportunity to purchase required components. Online retailers, specialized shops, and authorized distributors serve as reliable sources. Additionally, local hardware stores may carry commonly needed items, enhancing convenience for users seeking immediate solutions.

Typical Component Options

| Component Type | Availability | Estimated Price |

|---|---|---|

| Replacement Blades | Widely available | $15 – $30 |

| Drive Belts | Specialty retailers | $10 – $25 |

| Battery Packs | Online platforms | $20 – $50 |

| Motor Units | Authorized dealers | $50 – $150 |

Being aware of where and how to procure these components can significantly enhance the user experience, leading to more efficient repairs and maintenance. By utilizing available resources, users can ensure their equipment remains in peak condition.

Assembly Instructions for Beginners

For those new to the assembly process, understanding how to effectively put together various components can be both exciting and daunting. This guide aims to simplify the steps involved, ensuring that even novices can confidently tackle the task at hand.

Before starting, gather all necessary elements and tools to avoid interruptions. Familiarize yourself with each piece, noting how they connect and function together. Organizing your workspace can significantly enhance your efficiency and focus during the assembly.

Begin by following the step-by-step instructions provided, paying close attention to the order of assembly. Each component has a specific role, and correctly sequencing their installation is crucial for a successful outcome. If any parts seem difficult to fit, re-evaluate their orientation or alignment.

Once you have assembled the main structure, check all connections to ensure stability and integrity. It’s beneficial to refer back to your initial overview to confirm that everything is in place. Finally, take a moment to review your work, making any necessary adjustments to enhance functionality.

Safety Tips for Using the Tool

When operating any machinery, prioritizing safety is crucial to prevent accidents and injuries. Understanding the essential precautions can enhance your experience and ensure a secure working environment. This section provides vital guidelines to help you use your equipment responsibly.

1. Wear Personal Protective Equipment: Always use appropriate gear such as safety goggles, gloves, and ear protection. This equipment shields you from potential hazards while you work.

2. Read the Manual: Familiarize yourself with the user guide before handling the tool. Understanding its features and functionalities can prevent misuse and help you operate it effectively.

3. Inspect Before Use: Regularly check the equipment for any damage or wear. Ensuring that all components are in good condition can significantly reduce the risk of malfunction during operation.

4. Maintain a Clean Workspace: Keep your area free from clutter and debris. A tidy environment minimizes distractions and reduces the chance of accidents occurring.

5. Follow Proper Operating Procedures: Always adhere to the recommended practices for using the tool. This includes following the correct sequence of operations and not bypassing any safety features.

6. Avoid Distractions: Stay focused while operating the machinery. Refrain from engaging in conversations or multitasking, as distractions can lead to errors.

7. Keep Hands and Body Clear: Maintain a safe distance from moving parts and ensure that your hands and clothing are clear of the working area to prevent entanglement.

8. Store Properly: After use, store the equipment in a designated area. Ensure that it is out of reach of children and pets, and secure it to prevent accidental activation.

By adhering to these safety tips, you can create a safer work environment and enhance your overall experience with the tool.

Upgrading Your Bostitch MIII

Enhancing your tool’s performance can significantly improve your efficiency and precision in various tasks. This section will explore key modifications that can elevate the functionality of your device, ensuring you achieve optimal results in your projects.

Essential Upgrades for Improved Performance

One of the first areas to consider is the replacement of older components with more advanced alternatives. Upgrading the internal mechanisms can lead to smoother operation and increased durability. Look for components designed for high performance and longevity, which can handle more demanding jobs without compromising quality.

Maintaining and Customizing for Specific Needs

In addition to upgrading internal parts, you can also customize the exterior for better usability. Adding ergonomic handles or improved safety features can make a significant difference in comfort and control. Regular maintenance, such as lubrication and cleaning, ensures that your device continues to operate at peak efficiency, prolonging its lifespan and enhancing your overall experience.

Comparative Analysis with Other Models

This section aims to explore the differences and similarities between a specific tool and its competitors within the same category. By examining various features, performance metrics, and user feedback, we can gain insights into how this particular model stands out or falls short when compared to others on the market.

One notable aspect to consider is the design efficiency. Some alternatives may prioritize lightweight materials for easier handling, while others might focus on robust construction for enhanced durability. This trade-off can significantly impact user experience and overall satisfaction.

Additionally, operational capabilities such as speed, precision, and ease of maintenance are critical factors. While some units excel in rapid functionality, others may offer superior accuracy, making them preferable for specific tasks. Understanding these distinctions can help potential users make informed decisions based on their unique requirements.

Lastly, it’s essential to evaluate customer support and warranty offerings among various brands. A model backed by strong service and comprehensive coverage can provide peace of mind, potentially influencing a buyer’s choice beyond just the tool’s specifications.