The efficient functioning of plumbing systems relies heavily on specific configurations designed to manage waste water flow. A crucial aspect of this design is the arrangement that prevents backflow and ensures proper drainage. Grasping the components involved is vital for both homeowners and professionals engaged in maintenance or installation tasks.

Within these setups, various elements work in harmony to facilitate smooth operation. Each segment plays a distinct role, contributing to the overall effectiveness of the system. Recognizing the significance of each individual piece is essential for troubleshooting and ensuring longevity in performance.

In this exploration, we will delve into the intricacies of these structures, highlighting how they interact and function together. By understanding these essential elements, you can enhance your knowledge and approach to managing household plumbing challenges with confidence.

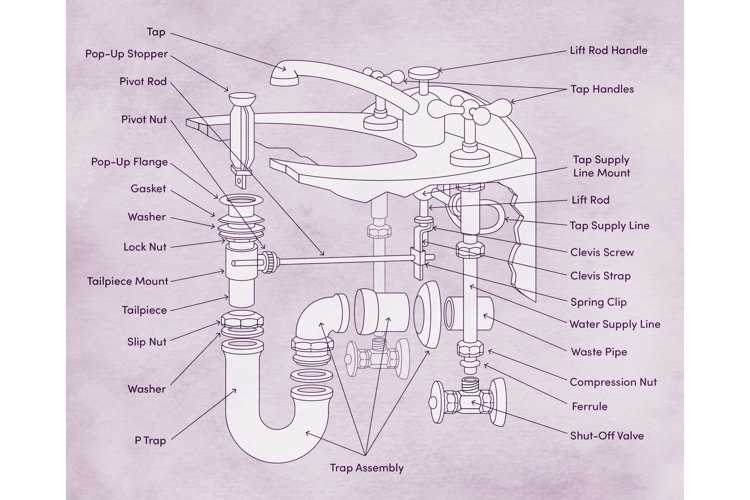

P-Trap Components Overview

This section provides a detailed look at the essential elements that work together to ensure efficient drainage in plumbing systems. Understanding these components is crucial for both installation and maintenance, as they play a vital role in preventing clogs and unpleasant odors.

Elbow: This curved section facilitates a change in direction for the flow of wastewater, allowing it to navigate around obstacles within the plumbing layout.

Vertical Pipe: This upright segment connects the curved section to the drainage system, helping transport waste away from fixtures effectively.

Seal: An important feature, this barrier maintains a water trap that prevents sewer gases from entering living spaces, ensuring a healthy environment.

Couplings: These connectors join different segments of piping, providing stability and ensuring a leak-free system. They come in various sizes to accommodate different pipe diameters.

Cleanout Plug: Positioned strategically, this access point allows for easy maintenance and removal of blockages, ensuring the system remains functional over time.

Each component serves a distinct purpose, and together they create a reliable system that is fundamental to effective waste management in homes and commercial buildings.

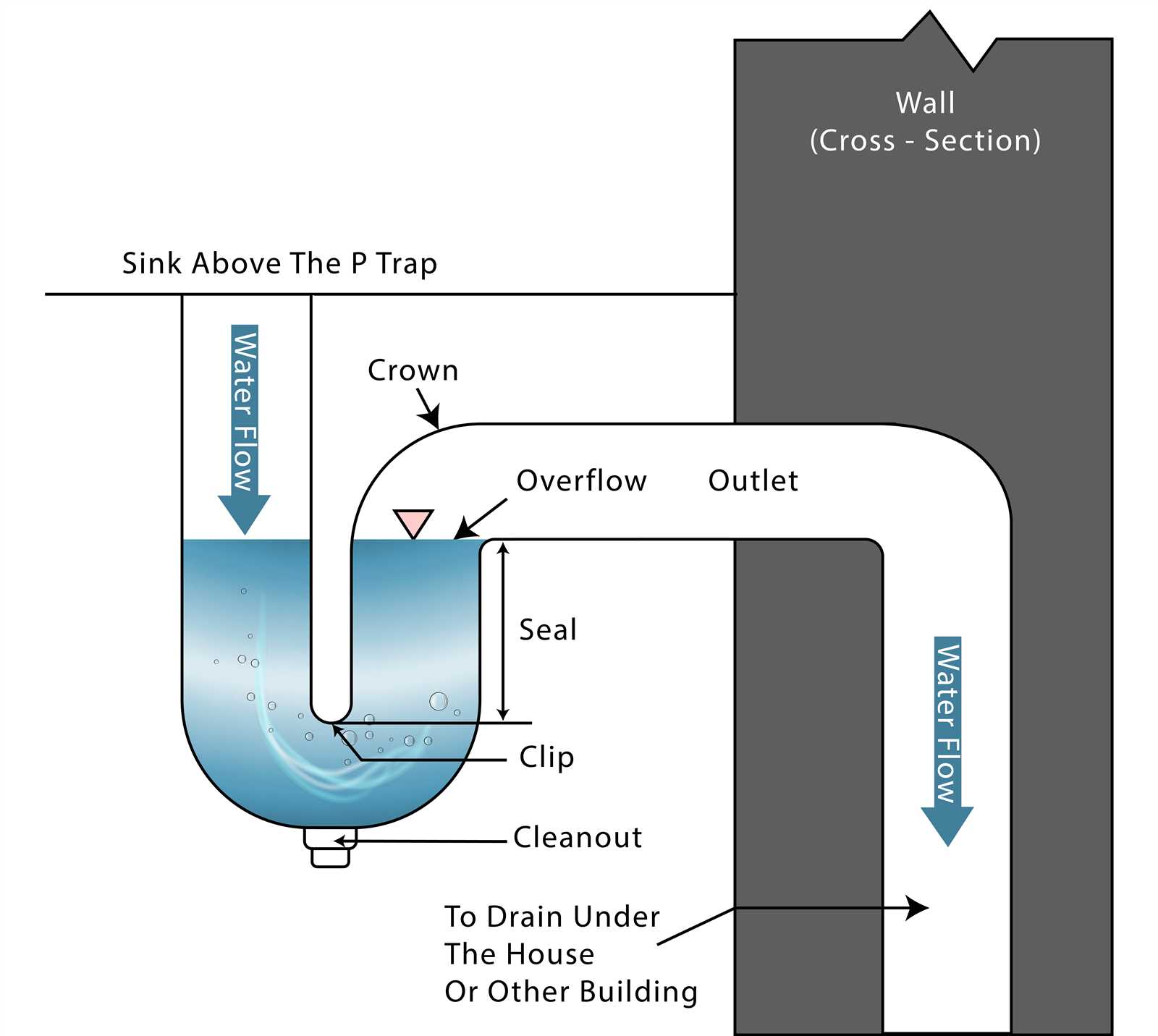

Understanding the Function of P-Traps

In plumbing systems, a crucial component serves to maintain a barrier between living spaces and the sewage system. This device plays a vital role in preventing unpleasant odors from entering homes while allowing wastewater to flow efficiently. Its design incorporates a unique curvature that holds a small amount of liquid, creating a seal that blocks gases from escaping.

The effectiveness of this mechanism relies on its ability to retain water, which forms a barrier against harmful fumes. When water flows through, it not only facilitates the removal of waste but also replenishes the liquid barrier, ensuring continuous protection. This function is essential for maintaining indoor air quality and the overall health of plumbing systems.

Furthermore, proper installation and maintenance of this device are important to avoid clogs and ensure longevity. Understanding how this component operates can help homeowners recognize potential issues early and address them effectively, thereby preserving the integrity of their plumbing infrastructure.

Identifying Main Parts of P-Trap

Understanding the components of a plumbing fixture is essential for maintaining an efficient drainage system. Each element plays a vital role in ensuring proper flow and preventing unpleasant odors from entering living spaces. Familiarity with these crucial sections can help in troubleshooting and performing necessary repairs.

| Component | Description |

|---|---|

| Inlet | The entry point where wastewater flows into the assembly. |

| Curve | A U-shaped section designed to trap water, creating a seal against gases. |

| Outlet | The exit where water is discharged into the drain system. |

| Cleanout Plug | A removable cap that allows access for clearing clogs and blockages. |

| Seal | A gasket or similar material that prevents leaks at connections. |

Materials Used in P-Trap Construction

The construction of drainage systems involves a variety of materials, each chosen for its specific properties and benefits. The selection of these substances is critical to ensure durability, resistance to corrosion, and efficient waste management. Understanding the materials used can provide insight into the longevity and functionality of these essential components.

Commonly Used Materials

The following materials are frequently utilized in the fabrication of these drainage solutions:

| Material | Properties | Applications |

|---|---|---|

| PVC | Lightweight, corrosion-resistant, affordable | Residential plumbing, waste systems |

| ABS | Strong, impact-resistant, easy to install | Drainage systems in colder climates |

| Metal (Brass or Copper) | Durable, heat-resistant, antimicrobial | Commercial applications, decorative plumbing |

| Stainless Steel | Corrosion-resistant, durable, aesthetic appeal | High-end installations, industrial uses |

Factors Influencing Material Choice

Several factors influence the selection of materials for drainage systems, including the environment in which they are installed, the type of waste handled, and budget constraints. Choosing the right material ensures optimal performance and longevity, reducing the need for repairs and replacements over time.

Common Issues with P-Trap Parts

Understanding the typical problems that can arise with drainage systems is crucial for effective maintenance. These issues often stem from wear, improper installation, or environmental factors, leading to functionality challenges. Below are some frequent complications encountered in these setups.

- Clogs:

Accumulation of debris, hair, and grease can lead to blockages. Regular cleaning is essential to prevent this issue.

- Leaks:

Seals may wear out over time, causing water to escape. Inspect connections regularly to identify and address leaks promptly.

- Odor:

Foul smells may emanate from stagnant water or trapped debris. Ensuring proper drainage can mitigate unpleasant odors.

- Improper Slope:

An incorrect angle can result in slow drainage or backups. It is important to check the installation angle to ensure optimal flow.

- Corrosion:

Metal components can corrode over time, especially in humid environments. Regular inspections can help identify early signs of deterioration.

By being aware of these common challenges, homeowners can take proactive measures to maintain their drainage systems and prevent costly repairs.

How to Clean P-Trap Effectively

Maintaining the plumbing system beneath your sink is crucial for preventing clogs and ensuring smooth water flow. Regular cleaning can help eliminate buildup and odors, making your kitchen or bathroom more pleasant. This guide will walk you through the essential steps to perform this task efficiently.

Step 1: Begin by gathering your tools, including a bucket, a wrench, and a brush. Make sure to have gloves handy to protect your hands from debris.

Step 2: Place the bucket beneath the plumbing fixture to catch any water or residue. Carefully loosen the connections with the wrench, allowing any trapped liquid to drain into the bucket.

Step 3: Remove the component and inspect it for any visible buildup. Use the brush to scrub away any grime or residue, ensuring that all surfaces are clean.

Step 4: Rinse the component thoroughly with warm water to wash away any remaining debris. Allow it to dry before reassembling.

Step 5: Reattach the cleaned component securely, ensuring that all connections are tight to prevent leaks. Test the system by running water to verify proper function.

Regular maintenance of this essential plumbing fixture will lead to long-term benefits, including improved hygiene and functionality.

Installing a New P-Trap

Replacing a drainage fixture beneath your sink is a straightforward task that can significantly improve the functionality of your plumbing system. This process involves removing the existing assembly and installing a new one to ensure proper drainage and prevent leaks.

Before starting the installation, gather all necessary tools and materials, including a wrench, new components, and plumber’s tape. It’s important to turn off the water supply and place a bucket under the area to catch any residual water.

Begin by disconnecting the old assembly. Use the wrench to loosen the nuts connecting the pipes. Carefully remove the unit, ensuring you clean the area of any debris or old sealant. This will provide a good foundation for the new installation.

Next, assemble the new components according to the manufacturer’s instructions. Ensure that all pieces fit snugly and are aligned correctly. Applying plumber’s tape to threaded connections can help create a watertight seal.

Finally, attach the new fixture to the existing drainage system. Tighten the connections without overdoing it to avoid damaging the fittings. Once everything is secured, turn the water supply back on and check for any leaks. If all is well, your new assembly should function effectively, ensuring efficient drainage for your sink.

Replacing Damaged P-Trap Components

When your plumbing system shows signs of wear, addressing compromised elements promptly is essential for maintaining functionality. Identifying and replacing the affected sections can prevent leaks and costly damage while ensuring efficient drainage.

Identifying the Problematic Parts

Start by inspecting the unit for any visible cracks, corrosion, or leaks. Common issues often arise from the seals or joints that may degrade over time. Pinpointing the exact location of the fault is crucial for a successful replacement.

Steps for Replacement

Once you’ve identified the damaged components, turn off the water supply and disassemble the affected areas carefully. Replace the faulty sections with new ones that match the original specifications. After reassembling, test for leaks before restoring full operation.

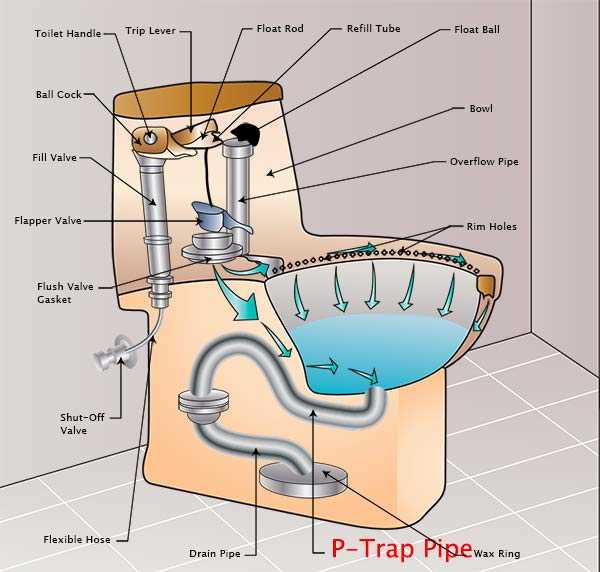

Differences Between P-Trap Designs

When it comes to plumbing fixtures, various configurations serve the essential purpose of preventing unwanted gases from entering living spaces. These designs can differ significantly in terms of materials, shapes, and installation methods, each offering unique advantages and potential drawbacks.

Material Composition: One of the primary distinctions lies in the materials used. Common options include plastic, metal, and cast iron. Plastic variants are lightweight and resistant to corrosion, while metal versions offer durability and a classic aesthetic. Cast iron, though less common today, provides excellent sound dampening and longevity.

Shape Variations: The shapes of these configurations also vary. Traditional curved forms are prevalent, but newer designs may feature straighter lines or more compact forms to accommodate tight spaces. Each shape influences how effectively the unit can trap water and prevent odors.

Installation Techniques: Installation can differ as well. Some configurations are designed for straightforward assembly, while others may require specialized tools or skills. Ease of installation can significantly affect maintenance and repairs in the long run.

Compatibility with Fixtures: Compatibility with various plumbing fixtures is another critical aspect. Some designs work better with specific sinks or bathtubs, while others are more versatile. Understanding these compatibility issues can help prevent future plumbing challenges.

In summary, recognizing the differences among these configurations is crucial for making informed choices during installation or renovation, ensuring optimal performance and longevity in plumbing systems.

How P-Traps Prevent Odors

One essential component in plumbing systems plays a crucial role in maintaining a pleasant indoor environment. By creating a barrier, it effectively prevents unpleasant smells from seeping back into living spaces. This function is vital for ensuring that homes remain comfortable and odor-free.

Mechanism of Odor Prevention

The system operates on a simple yet effective principle. It holds a small amount of water that acts as a seal, blocking gases from the sewer line. This water barrier is crucial for the following reasons:

- It maintains a consistent seal that prevents harmful fumes from escaping.

- The design allows for easy drainage while ensuring that the water remains in place.

- Regular usage helps keep the water fresh, enhancing its ability to block odors.

Importance of Maintenance

To ensure optimal performance, routine maintenance is necessary. Homeowners should consider the following tips:

- Check for any leaks that might compromise the water seal.

- Ensure that the fixture is used regularly to maintain water levels.

- Clean the area to prevent buildup that could obstruct flow.

By understanding the importance of this plumbing feature, individuals can ensure a healthier and more pleasant living environment, free from unwanted odors.

Signs You Need P-Trap Maintenance

Regular upkeep of your plumbing system is essential to prevent costly repairs. Certain indicators can signal that your drainage system requires attention. Recognizing these signs early can save you time and money while ensuring a smoothly functioning home.

Common Indicators

If you notice unpleasant odors emanating from your drains, it may indicate a blockage or accumulation of debris. Additionally, gurgling sounds when using sinks or tubs often suggest air trapped in the pipes, signaling a potential issue. Water pooling around fixtures is another warning sign that should not be ignored.

When to Seek Professional Help

If the aforementioned signs persist despite your efforts, it’s wise to consult a professional. They can delve into the specifics of the issue and provide the ultimate solutions needed to restore your system’s efficiency. Regular inspections can help prevent future complications and maintain optimal performance.

Choosing the Right P-Trap Size

Selecting the appropriate size for a plumbing fixture’s drainage system is crucial for ensuring proper function and efficiency. An incorrectly sized component can lead to drainage issues, unwanted odors, and potential damage to the plumbing system. This section will guide you through the factors to consider when determining the correct dimensions for your setup.

One of the primary considerations is the diameter of the drainage pipes connected to your fixture. It is essential to match the size of the connector to prevent clogs and ensure smooth water flow. Typically, the size ranges from 1.25 inches to 2 inches, depending on the type of sink, tub, or other appliances being used.

| Fixture Type | Recommended Diameter |

|---|---|

| Bathroom Sink | 1.25 inches |

| Kitchen Sink | 1.5 inches |

| Shower or Tub | 1.5 inches |

| Washing Machine | 2 inches |

Additionally, consider the overall length and configuration of the drainage route. Longer runs may require larger components to maintain adequate flow. When in doubt, consult a professional to assess your specific needs and ensure compliance with local plumbing codes.