In the realm of machinery, grasping the intricate workings of components is crucial for maintenance and performance enhancement. This section aims to provide an insightful overview of how various elements interact and contribute to the overall functionality of your equipment.

By exploring detailed illustrations and schematics, one can gain a clearer perspective on assembly and disassembly processes. These resources serve as valuable tools for both seasoned technicians and novice users, allowing for informed decisions during repairs and upgrades.

Ultimately, having access to precise visual aids empowers users to delve into the complexities of their machinery, ensuring optimal performance and longevity. A thorough understanding not only simplifies maintenance but also fosters a deeper appreciation for the engineering behind each unit.

Understanding the Honda HS828 Design

The design of this snow-clearing machine reflects a blend of functionality and user-centric innovation. Its structure is crafted to ensure efficient performance, making it an essential tool for managing winter conditions. Each element plays a pivotal role in delivering the ultimate user experience, enhancing both power and ease of use.

Key Features

One of the standout characteristics of this model is its robust engine, which guarantees optimal output. Additionally, the arrangement of components allows for seamless operation, contributing to superior handling on various terrains. The thoughtful placement of controls enhances accessibility, ensuring users can maneuver with confidence.

Durability and Maintenance

Constructed with high-quality materials, this equipment is designed for longevity. Regular upkeep is straightforward, allowing for prolonged service life. Understanding the layout aids users in identifying critical areas for maintenance, ultimately prolonging the machine’s effectiveness.

Components of the Honda HS828

This section explores the essential elements that make up the equipment, focusing on their roles and interconnections. Understanding these components is crucial for efficient operation and maintenance.

- Engine: Powers the machine and determines its performance.

- Auger: Responsible for gathering and displacing snow effectively.

- Chassis: Provides the framework that supports all other elements.

- Drive System: Facilitates movement and maneuverability.

- Controls: Enables the user to operate the machinery intuitively.

Each of these components plays a vital role, contributing to the overall functionality and efficiency of the unit.

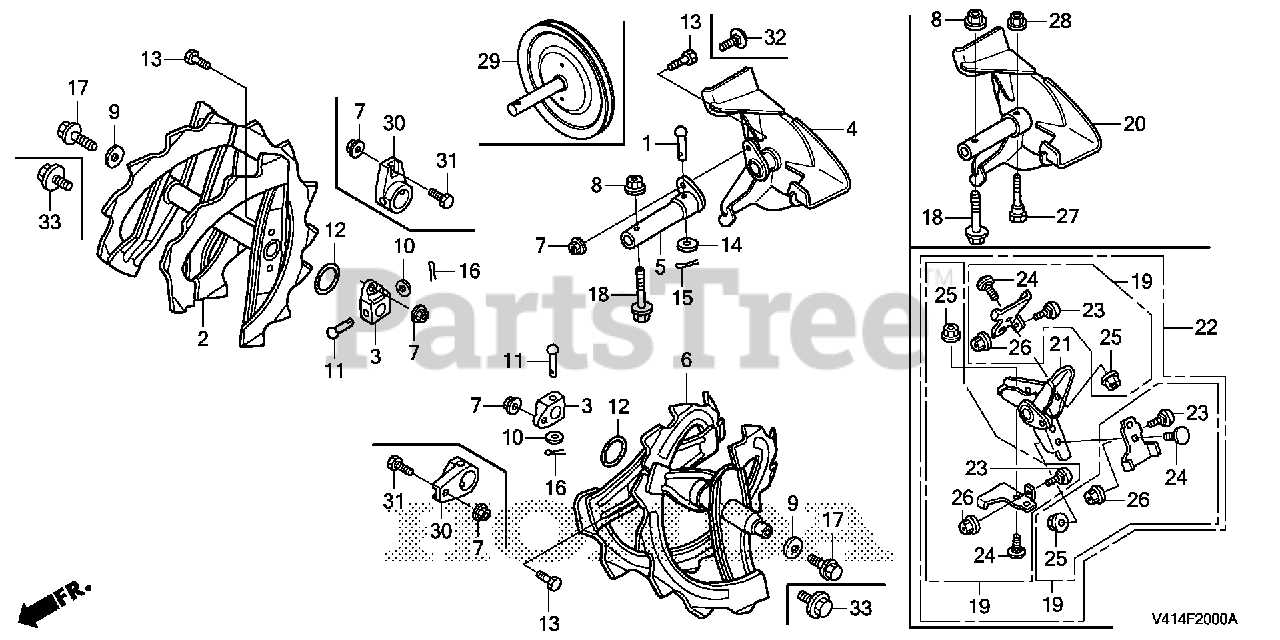

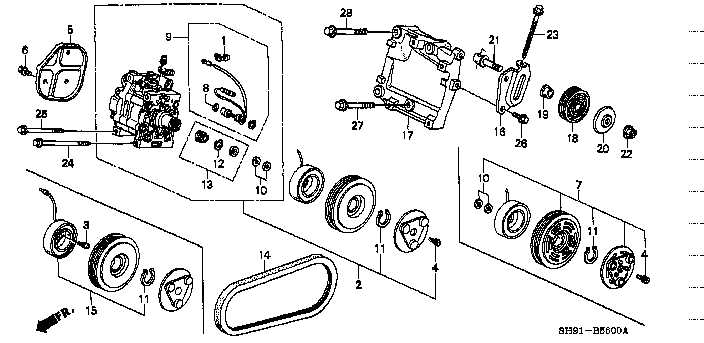

Importance of Parts Diagrams

Understanding the intricacies of mechanical assemblies is crucial for effective maintenance and repair. Visual representations of components facilitate clarity, enabling users to identify and source necessary elements with ease. This enhances not only the efficiency of repairs but also prolongs the lifespan of the machinery.

These visual aids serve as invaluable resources, allowing technicians and enthusiasts alike to pinpoint specific items quickly. They also reduce the likelihood of errors during assembly or disassembly, fostering a smoother workflow. Ultimately, utilizing such resources can lead to significant time and cost savings in the long run.

Furthermore, having access to detailed schematics encourages proper handling and installation practices. It empowers users to engage more confidently with their equipment, transforming potentially daunting tasks into manageable projects. This knowledge ultimately promotes a deeper understanding of the mechanics at play.

How to Read a Parts Diagram

Understanding an assembly illustration is essential for effective maintenance and repair tasks. These visual aids provide a comprehensive view of components, making it easier to identify and locate specific elements within a machine.

| Element | Description |

|---|---|

| Labels | Indicate the name or number of each component, providing clarity on the parts being referenced. |

| Lines | Show connections and relationships between various components, illustrating how they fit together. |

| Legends | Offer explanations for symbols and codes used within the illustration, aiding in accurate interpretation. |

| Sections | Highlight different views or cross-sections, giving a deeper understanding of the assembly’s structure. |

Common Replacement Parts for HS828

Maintaining optimal performance of your equipment often requires the timely replacement of certain components. Identifying which elements may need attention is crucial for ensuring longevity and efficiency. Below are some frequently needed components that users typically consider for replacement.

Blades are essential for effective operation, and regular wear can necessitate their replacement. Keeping them sharp is vital for achieving the best results.

Belt replacements are common due to wear and tear. A well-functioning belt ensures that power is transmitted smoothly, impacting overall functionality.

Filters play a critical role in maintaining air quality and performance. Periodically replacing these can prevent issues related to clogging and inefficiency.

Wheels are often subject to damage or wear. Ensuring they are in good condition is important for mobility and stability.

Battery replacements may also be necessary, especially if the equipment relies on electrical components. A fresh battery can greatly enhance reliability and performance.

Maintenance Tips for Honda HS828

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. Implementing simple maintenance routines can prevent costly repairs and enhance efficiency. Below are key practices to keep in mind.

Routine Checks

Conduct periodic inspections to identify wear and tear. Focus on critical components to ensure they are functioning properly and replace any parts that show signs of damage.

Cleaning Procedures

Maintaining cleanliness is crucial for performance. Remove debris and dirt regularly to prevent build-up that can hinder operation.

| Task | Frequency |

|---|---|

| Inspect belts and cables | Monthly |

| Clean air filters | Every 10 hours of use |

| Check fluid levels | Before each use |

Where to Find Genuine Parts

Locating authentic components for your equipment is crucial for maintaining optimal performance and longevity. Reliable sources ensure that you receive high-quality items that match the specifications of your model.

Authorized Dealers

- Visit local authorized dealers for a comprehensive selection.

- Consult their staff for expert guidance and assistance.

- Check for warranties and guarantees on products.

Online Retailers

- Explore reputable online platforms specializing in equipment components.

- Read customer reviews to assess reliability and quality.

- Look for options that provide detailed product descriptions and images.

Aftermarket vs. Original Components

When it comes to choosing replacement elements for machinery, a key consideration lies between utilizing components from the original manufacturer and opting for alternatives produced by third parties. Each option presents unique advantages and potential drawbacks that can significantly influence performance, longevity, and overall satisfaction.

Quality and Reliability

Original components are often praised for their superior quality and reliability, as they are designed specifically for compatibility with the machinery in question. Conversely, aftermarket alternatives can vary widely in quality; while some brands produce exceptional products, others may compromise on materials and craftsmanship.

Cost Considerations

Aftermarket parts generally offer a more economical solution, appealing to budget-conscious users. However, the initial savings may be offset by the potential need for more frequent replacements or repairs, making the long-term value a crucial factor to consider. Weighing cost against quality can help in making an informed decision that aligns with individual needs and usage scenarios.

Step-by-Step Repair Guide

This section offers a comprehensive approach to addressing common issues that may arise with your equipment. By following these organized steps, you can effectively troubleshoot and resolve problems, ensuring optimal performance and longevity.

Preparation

Before diving into repairs, gather the necessary tools and materials. This will streamline the process and minimize interruptions.

- Check for any safety gear required.

- Ensure you have the right tools, such as wrenches and screwdrivers.

- Gather replacement components if needed.

Repair Steps

- Begin by disconnecting the power source to prevent any accidents.

- Inspect the equipment thoroughly for visible damage or wear.

- Remove any damaged parts carefully using the appropriate tools.

- Install the new components, ensuring they fit securely and correctly.

- Reconnect the power source and perform a test run to check for functionality.

- Document any changes made for future reference.

By adhering to these steps, you can maintain the efficiency and reliability of your machine, addressing issues promptly and effectively.

Identifying Faulty Parts

Recognizing defective components is crucial for maintaining optimal performance and safety. Various indicators may signal underlying issues, and understanding these signs can help in timely interventions.

Visual Inspection: Begin by examining the exterior of the equipment. Look for any noticeable damage, such as cracks, rust, or excessive wear. Discoloration can also indicate overheating or material degradation.

Unusual Noises: Listen for any abnormal sounds during operation. Grinding, squeaking, or rattling noises often suggest that parts are not functioning correctly and may require immediate attention.

Performance Issues: If the machine is operating below its usual standards, it could be a sign of faulty components. Decreased efficiency, increased vibration, or failure to start are all potential warnings.

Fluid Leaks: Check for any fluid leakage, as this can be a clear indicator of failing seals or gaskets. Addressing leaks promptly can prevent further damage and ensure longevity.

By being vigilant and proactive, one can effectively identify and address issues, thereby prolonging the lifespan of the machinery.

Tools Needed for Repairs

When undertaking maintenance or repairs, having the right equipment is crucial for efficiency and effectiveness. Utilizing appropriate tools not only simplifies the process but also enhances safety and ensures precision.

Essential tools typically include wrenches, screwdrivers, and pliers, which are fundamental for disassembly and reassembly. Additionally, specialized instruments, such as torque wrenches and diagnostic tools, may be required to address specific issues.

Investing in quality equipment can significantly impact the ease of repairs and longevity of components. Properly organizing your tools can also streamline the workflow, minimizing downtime and maximizing productivity.

Frequently Asked Questions

This section addresses common inquiries related to the components and maintenance of outdoor equipment, providing clarity and assistance to users seeking information.

- What should I do if a part is damaged?

Inspect the component and consult the manufacturer’s guide for replacement options. Ensure you use compatible alternatives.

- How can I identify the correct replacement component?

Refer to the equipment’s documentation for part numbers and specifications, or seek assistance from a knowledgeable retailer.

- Where can I find replacement components?

Authorized dealers, online marketplaces, and local repair shops are good sources for acquiring the necessary items.

- What maintenance steps should I follow regularly?

Routine inspections, cleaning, and lubrication are essential to prolong the life of your equipment.

- Is it necessary to use original components?

While original components ensure compatibility and performance, high-quality alternatives may also be suitable.

Resources for Honda HS828 Owners

For those who own this powerful machine, having access to reliable information and support is crucial. This section provides valuable resources to enhance the experience of using and maintaining your equipment.

Online Communities

Engaging with online forums and social media groups can connect you with fellow enthusiasts. These platforms often share tips, troubleshooting advice, and personal experiences that can be incredibly helpful.

Manufacturer’s Support

Consulting the official website or customer service can yield essential guidance and detailed documentation. Warranties and recall information are also important aspects that can ensure your machine remains in optimal condition.