Every power tool consists of various elements that work together to deliver optimal performance. Grasping the layout and functionality of these components is essential for effective maintenance and repair. This section will explore a specific model’s intricate design, shedding light on how each piece contributes to the overall efficiency.

By examining the arrangement of these essential components, users can gain insight into the tool’s operation and troubleshoot issues more effectively. Understanding the function of each element not only enhances the user experience but also prolongs the lifespan of the equipment.

In this guide, we will delve into a detailed representation of the model’s structure, providing clarity on where each element fits and how it interacts with others. This knowledge empowers users to engage in informed decision-making when it comes to maintenance and upgrades.

Understanding Husqvarna 40 Chainsaw Components

When exploring the intricacies of power tools designed for cutting, it’s essential to grasp the various elements that contribute to their functionality. Each component plays a vital role in ensuring efficient operation, durability, and safety during use. By delving into these essential features, one can appreciate how they work in harmony to achieve the ultimate performance.

The engine serves as the heart of the machine, providing the necessary power for cutting tasks. Its design and capacity significantly influence the overall effectiveness and ease of handling.

The guide bar and chain are critical for directing the tool’s movement, with the former offering stability and the latter enabling precise cuts. Understanding their specifications can help in selecting the right equipment for specific projects.

The fuel system, including the tank and lines, ensures that the engine receives the right mixture for optimal operation. Regular maintenance of this system is crucial for prolonging the life of the tool.

Finally, the safety features integrated into the design provide essential protection for users. Familiarity with these components enhances safety and improves the overall experience while working with cutting machinery.

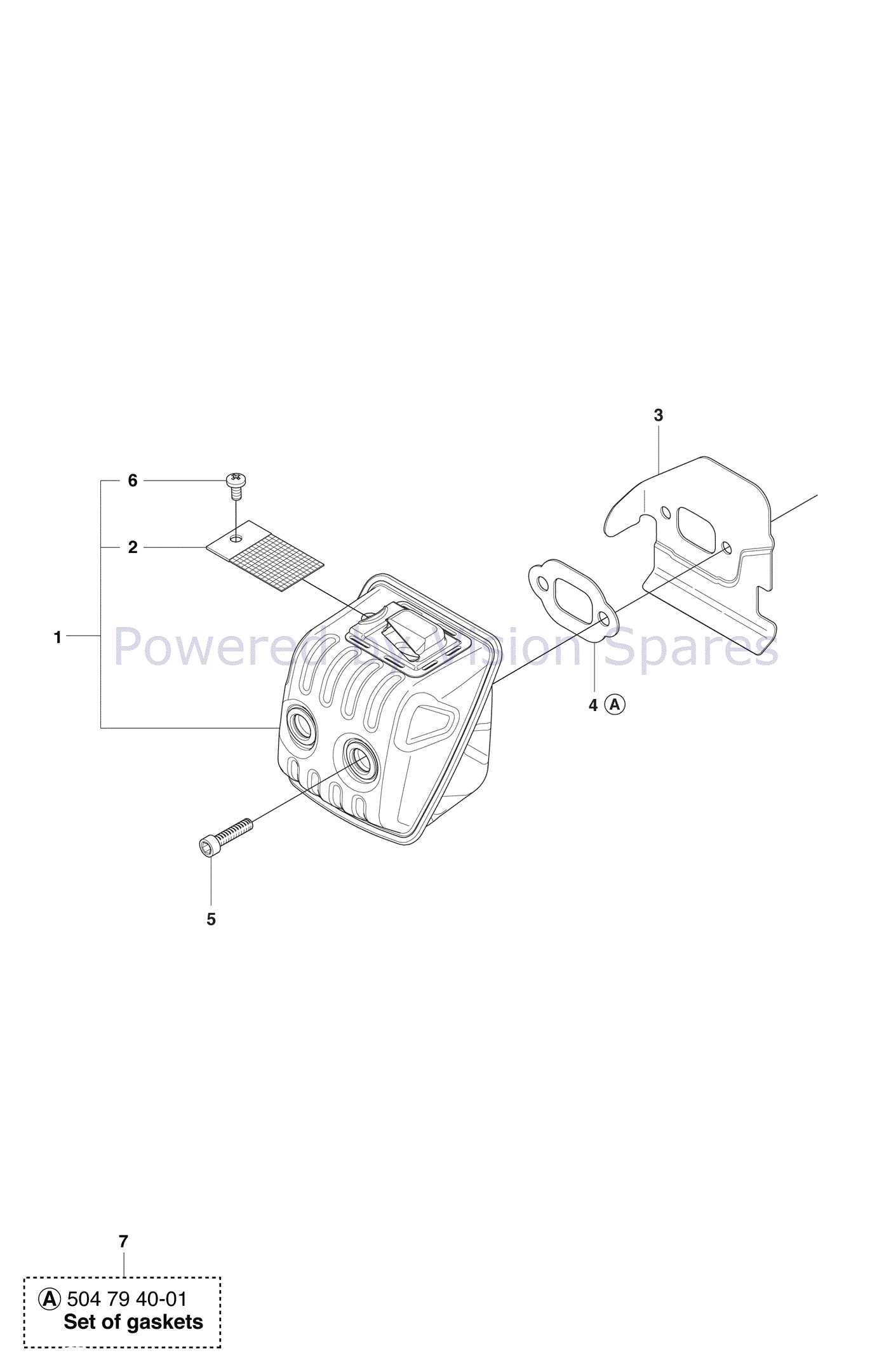

Exploring the Parts Diagram Features

Understanding the intricacies of mechanical components is essential for efficient maintenance and repair. A comprehensive illustration not only enhances visibility but also facilitates a deeper appreciation of how each element interacts within the system. By analyzing such visual guides, users can navigate their equipment with greater confidence and expertise.

Detailed Component Representation

Each segment is meticulously labeled, allowing for quick identification. This clarity ensures that individuals can pinpoint specific pieces swiftly, reducing the time spent on repairs. Accessibility of this information is crucial for anyone aiming to perform effective troubleshooting.

Enhanced Understanding of Functionality

Beyond mere identification, these visuals delve into the functional roles of various elements. By grasping the ultimate purpose of each component, users can make informed decisions regarding maintenance schedules and replacement needs. Insight into functionality fosters a proactive approach to equipment care.

Common Issues with Chainsaw Parts

Maintenance and performance challenges can arise from various components in power tools. Understanding these common problems helps users troubleshoot effectively and maintain optimal functionality.

Frequent Problems

- Worn-out components leading to decreased efficiency.

- Fuel leaks that affect operation.

- Clogged filters causing poor airflow.

- Misaligned mechanisms resulting in erratic performance.

Prevention Tips

- Regularly inspect and replace worn components.

- Keep filters clean to ensure proper airflow.

- Check for leaks and tighten connections as needed.

- Store the tool in a dry, clean environment.

Step-by-Step Assembly Instructions

Assembling your equipment can seem daunting, but with clear guidance and careful attention, the process becomes manageable. This section outlines the sequential steps to effectively piece together your tool, ensuring optimal performance and safety. Follow these instructions to achieve a seamless assembly experience.

Gather Your Components

Before diving into assembly, collect all necessary components and tools. Ensure you have everything laid out in a well-lit workspace. This will help you avoid missing any crucial parts and streamline the assembly process.

Assembly Procedure

Start by securing the base unit, then attach the necessary elements according to the manual. It’s essential to align each component accurately and tighten fasteners as you go to prevent any instability. Once the main parts are connected, check that all connections are firm and that moving elements operate smoothly. Finally, conduct a thorough inspection to confirm everything is assembled correctly.

Maintenance Tips for Longevity

Proper upkeep is essential for maximizing the lifespan of your outdoor power equipment. Regular maintenance not only ensures optimal performance but also reduces the likelihood of costly repairs. Here are some key practices to keep your machinery in peak condition.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Oil Level Check | Before Each Use | Ensure the lubricant is at the recommended level to reduce friction and wear. |

| Air Filter Cleaning | Every 5 Uses | Remove and clean the air filter to maintain proper airflow and efficiency. |

| Spark Plug Inspection | Every 10 Uses | Check for wear and replace if necessary to ensure smooth ignition. |

| Chain Tension Adjustment | Before Each Use | Ensure the cutting mechanism is properly tensioned for effective operation. |

| Blade Sharpening | As Needed | Keep the cutting edge sharp for clean cuts and reduced strain on the motor. |

| Fuel Quality Check | Before Each Use | Use fresh, high-quality fuel to prevent engine issues and enhance performance. |

By following these maintenance guidelines, you can ensure your equipment remains reliable and efficient, providing you with the best results for years to come.

How to Identify Replacement Parts

Finding the right components for your equipment can seem daunting, but understanding the process simplifies it significantly. Knowing where to look and how to interpret information is crucial for making informed decisions. This guide will help you navigate through the identification of necessary elements for optimal performance.

Consulting Manufacturer Resources

Start by checking the official documentation provided by the manufacturer. User manuals often include detailed information about various components, including their specifications and part numbers. Additionally, online resources such as the manufacturer’s website can offer interactive tools to locate specific items and their corresponding identifiers.

Using Visual References

Visual aids can be invaluable. Many manufacturers provide illustrated guides showcasing each element’s location and function. Pay close attention to these references; they help in recognizing and distinguishing between similar-looking components. If available, take advantage of exploded views, which can clarify how different pieces fit together.

In summary, identifying the correct components involves thorough research and careful observation. Taking the time to utilize available resources will enhance your understanding and ensure you acquire the right items for maintenance and repairs.

Tools Required for Repair Work

Proper maintenance and repair of mechanical equipment require a specific set of instruments to ensure efficiency and safety. Having the right tools at hand not only simplifies the process but also enhances the quality of the work done. Below is a list of essential instruments commonly needed for repair tasks.

Essential Tools

| Tool | Purpose |

|---|---|

| Wrench Set | Used for loosening or tightening bolts and nuts. |

| Screwdriver Set | Essential for driving screws in various sizes and types. |

| Plier | Helpful for gripping, twisting, or cutting wires. |

| File | Used for smoothing rough edges and surfaces. |

| Safety Goggles | Protective eyewear to prevent injury during repairs. |

Additional Tools

| Tool | Purpose |

|---|---|

| Torque Wrench | Ensures bolts are tightened to the correct specifications. |

| Multimeter | Used for measuring voltage, current, and resistance. |

| Oil Can | For lubrication of moving parts. |

| Cleaning Brush | Helps in maintaining cleanliness of components. |

| Toolbox | Organizes and stores all instruments securely. |

Safety Precautions While Handling Parts

Ensuring safety while dealing with various components is crucial to prevent accidents and injuries. Proper handling techniques and awareness of potential hazards can significantly reduce risks in any maintenance or repair activity.

Always wear protective gear such as gloves, goggles, and a hard hat to shield yourself from flying debris or sharp edges. Being adequately equipped is the first line of defense against unforeseen incidents.

Keep your workspace organized to minimize the chances of slipping or tripping over tools and materials. An orderly environment promotes focus and enhances overall safety.

Disconnect power sources before starting any disassembly or inspection to prevent accidental activation. Ensuring that everything is powered down helps maintain a safe working condition.

Be mindful of weight distribution when lifting or moving components to avoid strains or falls. Utilizing proper lifting techniques can prevent physical injuries.

Regularly inspect tools for wear and tear to ensure they function correctly. Faulty equipment can lead to accidents, so addressing issues promptly is essential.

Finally, educate yourself about the specific risks associated with the components you are handling. Knowledge is a vital tool in maintaining a safe working environment.

Where to Buy Genuine Parts

Finding authentic components for your outdoor equipment is essential for maintaining optimal performance and ensuring safety. Utilizing original items not only prolongs the life of your machinery but also guarantees compatibility and reliability. Here are some recommended sources where you can purchase these essential elements.

Authorized Dealers

One of the most reliable places to acquire genuine components is through authorized dealers. These retailers have a direct connection to manufacturers and ensure that the items they sell are original. By purchasing from them, you can be confident in the quality and authenticity of what you receive.

Online Retailers

In today’s digital age, numerous online platforms offer a wide selection of authentic components. Be sure to choose reputable sites that specialize in outdoor equipment to avoid counterfeit products. Look for customer reviews and ratings to ensure that the seller is trustworthy.

| Source | Advantages |

|---|---|

| Authorized Dealers | Guaranteed authenticity, expert advice, and warranty support. |

| Online Retailers | Convenience, broader selection, and often competitive pricing. |

Comparing Models: Husqvarna 40 vs. Others

When evaluating various models within the realm of outdoor power equipment, it’s essential to understand the nuances that set each one apart. This section delves into a comparative analysis, highlighting the strengths and weaknesses of a popular model alongside its competitors in the same category. By examining performance, usability, and design, users can make informed decisions based on their specific needs.

Performance Metrics

One of the primary factors to consider is performance. The model in question offers a robust engine capacity, providing sufficient power for most tasks. In contrast, some competitors may feature larger engines, but this often comes with increased weight and reduced maneuverability. Evaluating torque and cutting speed can further clarify which option suits your requirements best.

Usability and Design Features

Ergonomics play a critical role in user satisfaction. The design of the model is aimed at reducing fatigue during extended use, thanks to its lightweight construction and well-placed handles. While some alternatives may boast additional features, such as vibration dampening systems or tool-free assembly, these enhancements must be weighed against their impact on overall ease of use. Ultimately, the choice will depend on individual preferences and intended applications.

In conclusion, by comparing the performance and usability of different models, potential users can identify the equipment that best meets their operational needs, ensuring efficiency and satisfaction with their investment.

FAQs about Chainsaw Parts and Diagrams

This section aims to address common inquiries regarding the components and illustrations associated with cutting tools. Understanding these elements can enhance maintenance and improve overall functionality.

- What are the key components of a cutting tool?

Typically, the main elements include the motor, guide bar, chain, and safety features.

- How can I identify a specific component?

Most manuals contain detailed illustrations to help locate each item easily.

- Why is it important to refer to an illustration?

Visual aids simplify the assembly, disassembly, and maintenance processes, ensuring accuracy.

- Where can I find replacement items?

Many online retailers and local hardware stores offer a variety of replacements for different models.

- What should I do if I can’t find a specific component?

Contacting customer service or visiting specialized forums can provide valuable guidance.