The intricate world of watercraft propulsion systems is vital for enhancing performance and efficiency. These systems consist of various elements that work together to ensure optimal movement across the water. A comprehensive grasp of these components is essential for enthusiasts and operators alike.

Among the most crucial aspects of these systems is the configuration of the propulsion mechanism. Understanding how each element interacts not only aids in maintenance but also improves overall functionality. This knowledge enables users to address issues effectively and maximize their vessel’s capabilities.

In this exploration, we will delve into the essential components involved in the propulsion system, providing a clear overview of their roles and relationships. This foundational insight will serve as a guide for anyone looking to enhance their experience on the water.

Understanding Seadoo Jet Pump Components

In the realm of watercraft propulsion systems, several key elements work in harmony to ensure efficient performance and maneuverability. Each component plays a vital role in transforming the energy generated by the engine into thrust, allowing for smooth navigation across the water’s surface.

Central to this assembly is the housing, which encases and protects various mechanisms. It serves as the foundation for stability and durability, ensuring that the internal parts function optimally even under challenging conditions. Within this structure lies the impeller, a critical component responsible for drawing in water and forcing it out at high speed, creating the necessary propulsion.

Another essential element is the wear ring, designed to minimize gaps and enhance efficiency by maintaining close tolerances between the rotating impeller and the stationary components. This precision reduces turbulence and increases the effectiveness of the thrust generated. Additionally, the nozzle directs the flow of water, allowing for better steering and control, which is crucial for navigating tight spaces and performing maneuvers.

Moreover, the driveline connects the engine to the impeller, transmitting power seamlessly. This connection ensures that the system operates cohesively, translating the engine’s rotational force into the movement of water. Regular maintenance of these components is essential to ensure longevity and optimal performance, as wear and tear can significantly impact efficiency and handling.

Essential Parts of Jet Pumps

Understanding the key components of water propulsion systems is crucial for maintenance and performance enhancement. Each element plays a vital role in ensuring efficiency and reliability, contributing to the overall functionality of the mechanism.

Intake is the entry point for water, designed to optimize flow and minimize turbulence. A well-crafted inlet enhances the efficiency of the entire system.

Impeller serves as the heart of the propulsion system, converting rotational energy into kinetic energy. The design and material of this component are critical for achieving high thrust and durability.

Housing protects internal mechanisms while also directing water flow. Its shape and size can significantly impact performance and should be maintained to prevent any obstructions.

Wear Ring is essential for maintaining the gap between the impeller and housing, ensuring optimal performance. Regular inspection of this component is necessary to avoid excessive wear that can lead to decreased efficiency.

Nozzle controls the direction and speed of the water exiting the system. Adjustments to this element can fine-tune maneuverability and power output, allowing for a more responsive experience.

Each of these components is integral to the success of the overall system. Regular maintenance and understanding of their functions can lead to improved performance and longevity.

How Jet Pump Functions Explained

The operation of a propulsion system in watercraft involves a series of components working together to create thrust. This mechanism is vital for efficient movement across water surfaces, combining fluid dynamics with mechanical design.

Key Components

- Intake: Captures water from the surroundings.

- Impeller: Rotates to accelerate the water.

- Nozzle: Directs the flow, generating thrust.

Operational Process

- Water enters through the intake, creating a flow.

- The impeller spins rapidly, increasing water velocity.

- The nozzle focuses the high-speed flow, propelling the vessel forward.

Common Issues with Jet Pumps

Many watercraft enthusiasts encounter a range of problems with their propulsion systems. Understanding these challenges is crucial for maintaining optimal performance and ensuring safety on the water. Issues can stem from various components, leading to reduced efficiency and potential damage if not addressed promptly.

One frequent complication involves blockages that hinder the flow of water, affecting speed and maneuverability. Debris, seaweed, or sand can accumulate, necessitating regular inspection and cleaning. Another common concern is wear and tear on internal components, which can lead to leaks or decreased thrust. Over time, seals and bearings may degrade, requiring timely replacement to prevent further complications.

In addition, vibrations during operation often signal misalignment or imbalance within the system. These vibrations can cause additional stress on parts, leading to accelerated wear. It’s essential to regularly check for proper alignment and to secure all fittings to minimize these effects.

Lastly, improper maintenance practices can exacerbate existing issues. Regular servicing, including fluid checks and part replacements, is vital to ensure longevity and reliability. By addressing these common problems, operators can enjoy a smoother and safer experience on the water.

Maintenance Tips for Jet Pumps

Regular upkeep of your watercraft’s propulsion system is crucial for optimal performance and longevity. Following a few essential guidelines can help prevent issues and ensure a smooth ride on the water.

- Routine Inspections: Frequently check the assembly for signs of wear or damage. Look for cracks, corrosion, or loose components.

- Cleaning: Remove debris and sediment from the intake area. This helps maintain efficiency and prevents clogging.

- Fluid Changes: Regularly replace the lubricants as recommended by the manufacturer. Fresh fluids contribute to better operation and prevent overheating.

- Seal Maintenance: Inspect and replace seals as needed to avoid leaks and ensure a watertight system.

- Component Alignment: Ensure that all parts are properly aligned and securely fastened to prevent vibrations that can lead to damage.

By adhering to these maintenance tips, you can enhance the performance and durability of your watercraft’s propulsion mechanism, allowing for enjoyable and safe experiences on the water.

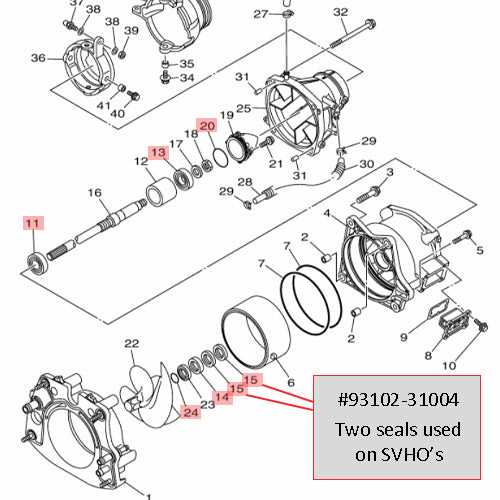

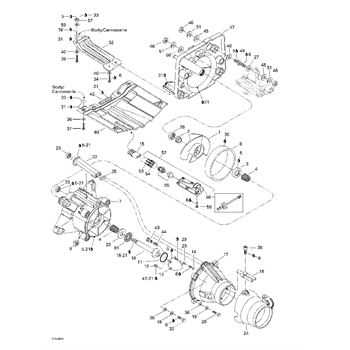

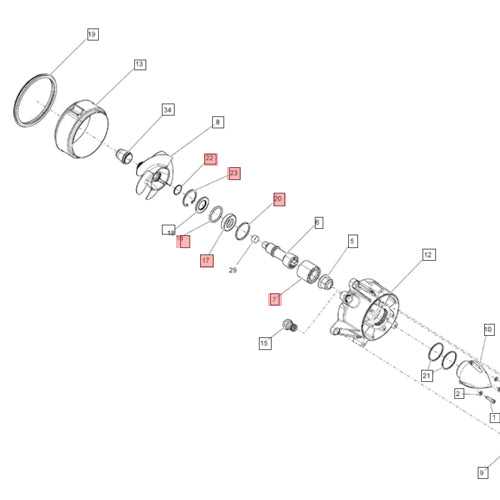

Identifying Jet Pump Components on Diagrams

Understanding the various elements of a propulsion system is crucial for effective maintenance and repair. Recognizing the individual components illustrated in schematics allows users to pinpoint issues and streamline their troubleshooting processes. This section focuses on how to decipher these visual representations, highlighting essential parts and their functions.

Key Components Overview

Each element in the system plays a vital role in ensuring optimal performance. Familiarity with these parts not only aids in repairs but also enhances overall efficiency. Below is a brief overview of common components you may encounter:

| Component | Description |

|---|---|

| Impeller | A rotating element that generates thrust by moving water. |

| Wear Ring | A protective ring that reduces clearance between the impeller and housing. |

| Housing | The outer structure that encases the propulsion mechanism. |

| Diffuser | A component that helps convert kinetic energy into pressure. |

Interpreting Visual Guides

When analyzing visuals, it’s important to pay attention to labels and annotations. Each part is typically marked, providing clarity on its function and placement within the assembly. Familiarizing yourself with the layout will significantly enhance your ability to diagnose and address any concerns effectively.

Replacement Parts for Seadoo Jet Pumps

Maintaining the optimal performance of your watercraft often requires replacing specific components that experience wear over time. Understanding which elements need attention is crucial for ensuring longevity and efficiency. This section explores the essential replacements that can enhance your vessel’s performance and reliability.

Key components include seals, bearings, and housing assemblies, each playing a vital role in the overall functionality. Regular inspection of these elements helps identify potential issues before they escalate, ensuring a smoother and safer ride. Selecting high-quality alternatives can significantly improve performance and durability.

When seeking replacements, it’s important to consider compatibility and material quality. Utilizing original equipment or reliable aftermarket options can lead to better results. Keeping a well-stocked inventory of these critical items will enable quick repairs and reduce downtime on the water.

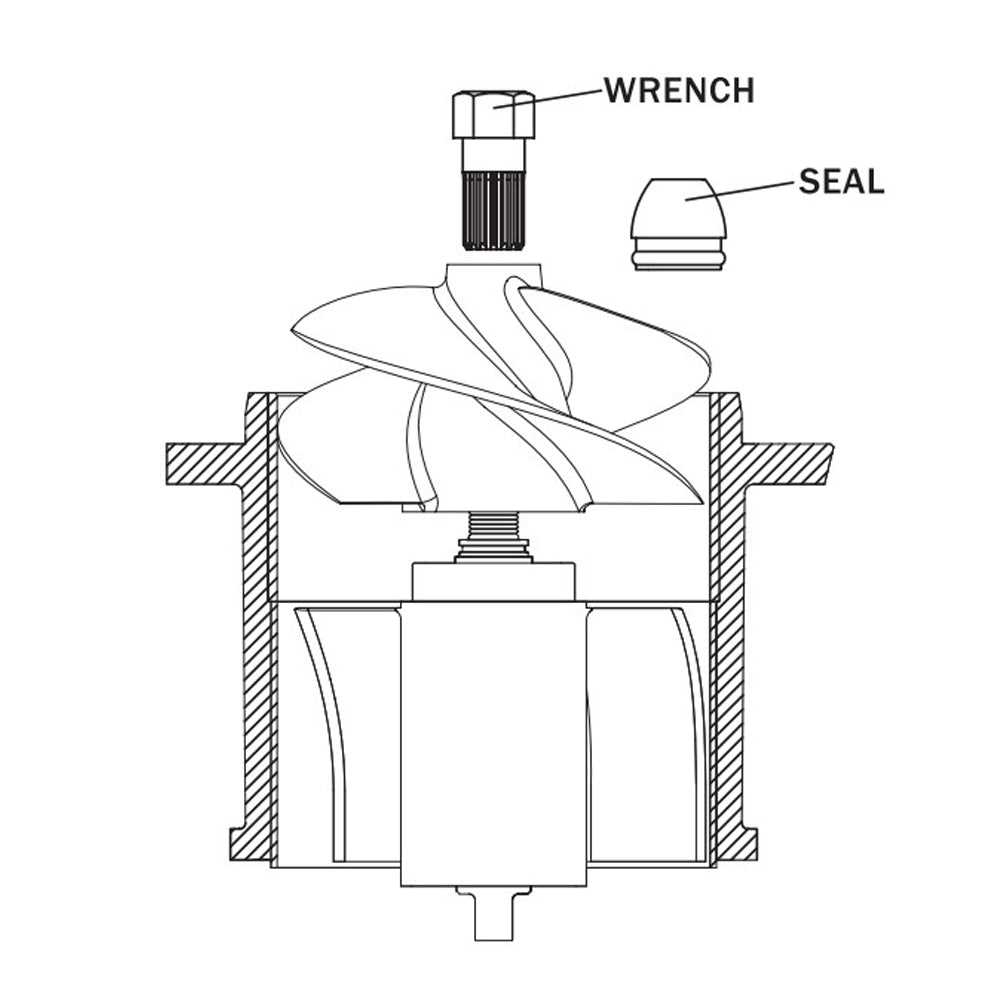

Tools Needed for Jet Pump Repairs

When tackling maintenance and restoration tasks on watercraft propulsion systems, having the right tools is essential for efficiency and effectiveness. A well-equipped toolkit can simplify the repair process, ensuring that you can address any issues that arise without unnecessary delays.

Essential Tools

- Socket set

- Wrenches (metric and standard)

- Screwdrivers (flathead and Phillips)

- Pliers (needle-nose and standard)

- Torque wrench

- Utility knife

- Rubber mallet

Specialized Equipment

- Seal puller

- Compression gauge

- Multimeter

- Grease gun

- Cleaning brush

- Protective gloves and goggles

Having these tools on hand not only streamlines the repair process but also helps ensure a thorough and safe job, ultimately leading to better performance and longevity of your watercraft system.

Safety Precautions for Jet Pump Work

When engaging in maintenance or repairs involving propulsion systems, prioritizing safety is essential. Understanding the inherent risks and adopting appropriate measures can prevent accidents and ensure a smooth working process.

Personal Protective Equipment (PPE) is crucial. Always wear gloves, goggles, and a life jacket if you’re near water. This equipment helps shield you from potential injuries and hazards associated with the components.

Before beginning any task, ensure that the system is deactivated and disconnected from its power source. This precaution helps avoid accidental activation, which can lead to serious injuries. Additionally, verify that all parts are securely fastened and in good condition to prevent unexpected failures during maintenance.

Maintain a clean and organized workspace. Clutter can lead to distractions and increase the risk of accidents. Keep tools and components neatly arranged, and dispose of any debris or waste materials promptly.

Familiarize yourself with the operation manual for the specific system you are working on. Understanding the design and functionality of the equipment will enhance your ability to perform maintenance safely and effectively.

Lastly, never hesitate to seek assistance or guidance from a professional if you encounter difficulties or are unsure about any aspect of the task. Teamwork and proper communication can greatly enhance safety and efficiency in any repair or maintenance endeavor.

Upgrading Jet Pump Performance Parts

Enhancing the efficiency of propulsion systems can significantly improve watercraft performance. By focusing on specific components, enthusiasts can achieve faster speeds, better handling, and increased fuel efficiency. This section explores various upgrades that can lead to a more dynamic experience on the water.

| Component | Upgrade Options | Benefits |

|---|---|---|

| Impeller | High-performance designs | Improved thrust and acceleration |

| Nozzle | Adjustable or larger diameter | Enhanced steering and maneuverability |

| Wear Ring | Aftermarket materials | Increased durability and reduced cavitation |

| Intake Grate | Performance grates | Better water flow and reduced drag |

Understanding Jet Pump Efficiency

Efficiency in water propulsion systems is crucial for optimizing performance and enhancing overall experience on the water. This concept revolves around the effectiveness of converting mechanical energy into thrust, which directly influences speed and maneuverability.

Several factors contribute to this efficiency, including the design of the components, the quality of materials used, and the overall configuration of the system. Hydrodynamics plays a vital role, as the shape and arrangement of elements can significantly impact how water is drawn in and expelled.

Moreover, maintenance is essential for sustaining optimal operation. Regular checks and servicing help to identify wear and tear, which can hinder performance. Understanding these dynamics enables users to make informed decisions regarding upgrades and repairs, ultimately leading to a more enjoyable and efficient ride.

Common Myths about Jet Pumps

There are numerous misconceptions surrounding the operation and maintenance of watercraft propulsion systems. Understanding these myths is crucial for ensuring optimal performance and longevity of your vessel. This section will clarify some prevalent inaccuracies that can lead to confusion among users.

| Myth | Reality |

|---|---|

| They are not efficient in shallow water. | In fact, many systems are designed to operate effectively in shallow conditions, making them versatile for various environments. |

| Regular maintenance isn’t necessary. | Contrary to this belief, consistent upkeep is essential to prevent wear and ensure smooth operation. |

| They are complicated to repair. | With the right resources and guidance, repairs can often be straightforward and manageable for most owners. |

| All models are the same. | Different designs and technologies result in varying performance characteristics, tailored for specific needs and conditions. |

Resources for Jet Pump Diagrams

This section provides valuable references for understanding the intricate components of water propulsion systems. Accessing detailed illustrations can greatly enhance maintenance and repair efforts, ensuring optimal performance and longevity.

| Resource Type | Description | Link |

|---|---|---|

| Manufacturer Manuals | Official documentation from producers detailing assembly and function. | View Manuals |

| Online Forums | Community-driven platforms where enthusiasts share insights and diagrams. | Join Forums |

| Tutorial Videos | Visual guides demonstrating assembly and disassembly processes. | Watch Videos |

| Technical Blogs | Articles offering detailed analysis and visual aids for understanding systems. | Read Blogs |