When it comes to maintaining outdoor machinery, having a clear grasp of its various elements is crucial for optimal performance. Familiarity with the specific components enables users to diagnose issues efficiently and execute repairs with confidence. This knowledge not only extends the lifespan of the machinery but also enhances its overall functionality.

In this section, we will delve into a comprehensive overview of the intricate layout of essential components found in this particular model. By exploring the relationships and functions of each piece, operators can gain valuable insights that will aid in troubleshooting and maintenance tasks.

Equipped with this information, users will be empowered to take informed steps towards better care and operation of their equipment. Whether you’re a seasoned professional or a newcomer, understanding the anatomy of your machine is key to maximizing its potential.

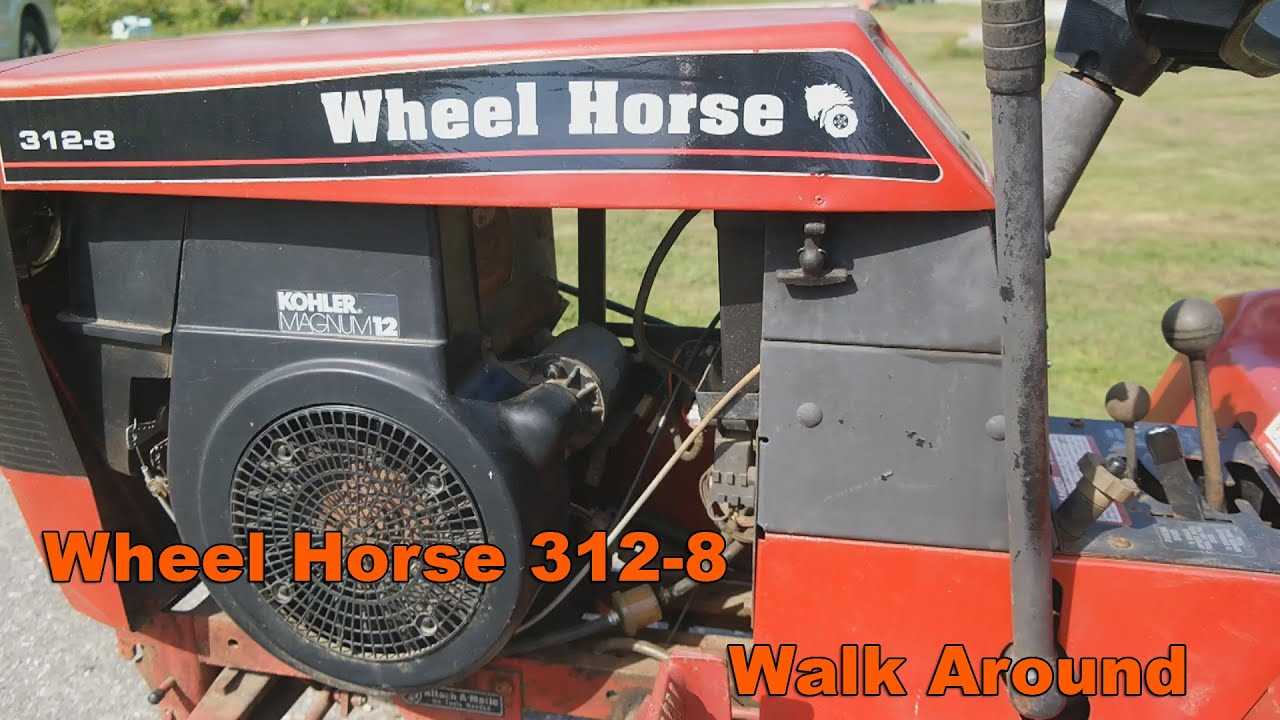

Understanding Wheel Horse 312-8

This section explores the essential aspects of a popular gardening and landscaping machine, focusing on its functionality, design, and maintenance. Knowledge of its components and operations enhances user experience and ensures optimal performance.

Key Features

- Robust construction for durability

- Versatile attachments for various tasks

- Efficient engine performance

Maintenance Tips

- Regularly check and change the oil

- Inspect belts and cables for wear

- Clean air filters to ensure proper airflow

Key Features of the 312-8 Model

This section highlights the remarkable attributes of a specific agricultural machine, showcasing its design and functionality. Each feature contributes to the overall performance and user experience, making it a preferred choice for many.

Robust Build Quality

Constructed with durability in mind, this model offers a strong chassis that withstands rigorous conditions. The use of high-quality materials ensures longevity and reliable operation in various environments.

Enhanced Maneuverability

Equipped with an efficient steering system, it allows for precise navigation in tight spaces. This ultimate feature is especially beneficial for users who operate in constrained areas, ensuring optimal productivity.

Common Issues with Wheel Horse Parts

Many users encounter frequent challenges when maintaining their outdoor machinery, often stemming from various components. Understanding these common problems can help in ensuring longevity and optimal performance of the equipment.

| Issue | Description |

|---|---|

| Wear and Tear | Components may deteriorate over time due to regular use, leading to reduced efficiency. |

| Alignment Problems | Improper alignment can cause undue strain, affecting the overall functionality of the machinery. |

| Corrosion | Exposure to moisture can lead to rust and degradation, impacting performance. |

| Fuel System Issues | Blockages or leaks in the fuel system can result in inefficient operation and starting difficulties. |

| Electrical Failures | Wiring problems or faulty connections can hinder functionality and safety. |

Locating the Parts Diagram Online

Finding detailed visual references for machinery components can significantly enhance maintenance and repair efforts. This section outlines effective strategies for uncovering these valuable resources on the internet.

Here are several approaches to consider:

- Utilize search engines: Enter specific terms related to your equipment, including model numbers and related keywords.

- Visit manufacturer websites: Most companies provide downloadable resources, including schematics and assembly guides.

- Explore online forums and communities: Engaging with enthusiasts can lead to shared documents and personal insights.

- Check parts retailers: Many online stores feature comprehensive catalogs that include visual aids for identification.

- Consult social media groups: Platforms like Facebook or Reddit often have dedicated groups for equipment owners.

Using these methods, you can efficiently locate the necessary visual references to aid in your repair and maintenance tasks.

Essential Tools for Repairing 312-8

Effective maintenance and repair require a selection of specialized equipment. Having the right tools on hand not only makes the process smoother but also ensures precision and efficiency. This section outlines the essential instruments that can aid in the upkeep and restoration of your machine.

Basic Tools

Starting with fundamental implements, a well-equipped toolbox is crucial. These items facilitate various tasks, from simple adjustments to complex repairs. Here are the must-have tools:

| Tool | Purpose |

|---|---|

| Socket Set | For loosening and tightening bolts |

| Wrenches | Essential for gripping and turning fasteners |

| Philips and Flathead Screwdrivers | Used for various screws in the assembly |

| Pliers | Helpful for gripping, twisting, and cutting |

| Torque Wrench | Ensures bolts are tightened to the correct specifications |

Advanced Tools

For more complex tasks, additional instruments may be necessary. These advanced tools can significantly aid in diagnosing and resolving issues:

| Tool | Purpose |

|---|---|

| Multimeter | Used for testing electrical components |

| Fuel Pressure Gauge | Measures fuel system pressure |

| Compression Tester | Evaluates engine cylinder compression |

| Diagnostic Scanner | Identifies error codes and system malfunctions |

| Impact Wrench | Facilitates quick loosening of stubborn bolts |

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your machinery requires a proactive approach to care and upkeep. By implementing consistent maintenance routines, you can extend the lifespan of your equipment significantly.

- Regularly check and change the fluids to prevent overheating and wear.

- Inspect belts and hoses for signs of wear and replace them as needed.

- Keep the equipment clean to avoid debris buildup that can cause damage.

- Sharpen and maintain blades to enhance performance and reduce strain on the engine.

- Store the machinery in a sheltered area to protect it from harsh weather conditions.

By following these guidelines, you can help ensure that your equipment remains in optimal condition for many years to come.

Aftermarket vs. OEM Parts Comparison

When it comes to maintenance and repairs, the choice between original components and alternative options can significantly impact performance, durability, and cost. Understanding the differences between these two categories is essential for making informed decisions that align with individual needs and budget constraints.

Quality and Performance

One of the primary considerations when comparing original and alternative components is quality. Here are some key points to consider:

- OEM Components: Typically manufactured by the original equipment manufacturer, these parts meet specific standards and specifications, ensuring compatibility and reliability.

- Aftermarket Components: Produced by third-party companies, these options can vary widely in quality. While some may match or exceed OEM standards, others may fall short.

Cost Considerations

Pricing is another crucial factor that influences choice:

- OEM Components: Generally, these are more expensive due to brand reputation and guaranteed quality.

- Aftermarket Components: Often more budget-friendly, these alternatives can provide cost savings, but it’s essential to assess the potential trade-offs in quality.

Ultimately, the decision should reflect an evaluation of performance requirements, budget limitations, and long-term maintenance goals. Careful consideration of these factors will help ensure optimal outcomes in any repair or maintenance situation.

Step-by-Step Guide to Assembly

This section provides a clear and concise method for putting together essential components of your machinery. Following these steps will ensure that each element is properly aligned and securely fastened for optimal performance.

- Gather all necessary components and tools.

- Begin with the base unit and position it on a stable surface.

- Attach the first assembly piece, ensuring it aligns with the designated slots.

- Secure the piece using appropriate fasteners.

- Proceed to the next component, following the same alignment and fastening procedure.

- Continue until all parts are connected as per the instruction manual.

- Double-check each connection for tightness and stability.

Once assembly is complete, perform a final inspection to confirm that everything functions as intended.

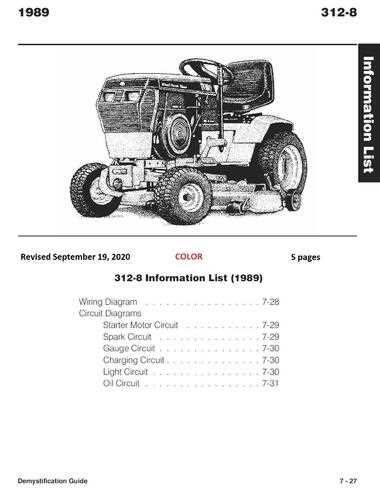

Identifying Parts in the Diagram

Understanding the components within a visual representation is crucial for effective maintenance and repairs. This section will guide you through recognizing and interpreting each element, ensuring you can efficiently navigate the layout and utilize it for your needs.

Breaking Down the Components

Each segment of the visual layout serves a specific function. By categorizing these elements, you can quickly pinpoint which are necessary for your tasks. Pay attention to labels and symbols, as they provide valuable information.

Utilizing Reference Guides

Consulting additional resources can enhance your comprehension of the visual aid. Reference guides often include detailed descriptions and contextual information that can enrich your understanding of the components and their roles.

Frequently Asked Questions About 312-8

This section aims to address common inquiries regarding a specific model that enthusiasts and users often encounter. From operational tips to maintenance advice, the following answers will help clarify various aspects of ownership and functionality.

General Information

Many users wonder about the typical features and specifications of this model. Understanding these elements can enhance the overall experience and ensure effective use.

| Question | Answer |

|---|---|

| What are the main specifications of this model? | This model is known for its robust engine, versatile functionality, and user-friendly design, making it suitable for a variety of tasks. |

| How can I maintain it properly? | Regular checks on oil levels, tire pressure, and overall wear and tear are essential for optimal performance. |

Common Issues

Users frequently encounter specific challenges that can arise during operation. Addressing these problems early can prevent further complications.

| Issue | Solution |

|---|---|

| Difficulty starting | Check the battery charge and ensure the fuel system is functioning correctly. |

| Overheating | Inspect the cooling system for blockages and ensure proper coolant levels are maintained. |

How to Order Replacement Parts

When the need arises for new components to restore functionality, it is crucial to follow a systematic approach. This ensures that the correct items are procured efficiently, minimizing downtime and maintaining performance.

First, identify the specific components required by consulting relevant documentation or service manuals. This step helps you understand the necessary specifications and compatible options.

Next, research reputable suppliers or manufacturers. Consider their reliability, customer reviews, and availability of the desired items. Utilize online platforms or local dealers to compare prices and options.

Finally, once you have gathered all necessary information, place your order. Ensure that you provide accurate details regarding the components, including any serial numbers or specifications to avoid discrepancies.

By following these steps, you can streamline the process of acquiring essential items for maintenance or repair, ultimately enhancing the longevity and efficiency of your equipment.

Upgrading Your Wheel Horse Equipment

Enhancing your outdoor machinery can significantly improve performance, efficiency, and longevity. This section explores various options for elevating your equipment, ensuring it meets your needs and expectations. By investing in upgrades, you can achieve a more reliable and effective experience in your gardening and landscaping tasks.

Benefits of Upgrading

- Improved Efficiency: Modern components can enhance fuel efficiency and reduce operational costs.

- Increased Durability: Upgrading to higher-quality materials can extend the lifespan of your machinery.

- Enhanced Performance: New technology can lead to better power output and smoother operation.

- Customization Options: Tailor your equipment to suit specific tasks and personal preferences.

Key Areas for Improvement

- Engine Enhancements: Consider options such as tuning kits or performance filters.

- Attachment Upgrades: Explore various implements that can expand functionality, like snow blowers or tillers.

- Comfort Features: Add ergonomic seats or steering upgrades to improve user experience.

- Safety Enhancements: Invest in better lighting or safety guards to ensure secure operation.

Upgrading your equipment is not just about performance; it’s also about enhancing your overall experience. By making informed choices, you can transform your outdoor tasks into a more enjoyable endeavor.

Community Resources and Support Groups

Accessing local resources and connecting with supportive networks can significantly enhance one’s experience in navigating challenges. These groups provide invaluable information, share experiences, and foster a sense of belonging, enabling individuals to gain insights and practical advice. By engaging with others facing similar situations, participants can cultivate relationships that offer both emotional and practical support.

Local organizations often host workshops, meetings, and online forums, making it easier to connect with others. These gatherings serve as a platform for exchanging knowledge and learning about tools that can help in various circumstances. In addition, many communities offer specialized resources that cater to specific needs, ensuring that everyone can find the help they require.

Joining a support group can also lead to valuable mentorship opportunities, where more experienced members provide guidance to those just beginning their journey. As individuals delve deeper into these networks, they often discover additional avenues for assistance, creating a robust foundation of support that extends beyond initial contacts.