When it comes to maintaining and ensuring the smooth operation of mechanical systems, recognizing the arrangement and functionality of various elements is essential. A clear understanding of how different units interact within a system can prevent issues and enhance overall performance. This guide provides a detailed exploration of key components and their interconnections.

By familiarizing yourself with the structure of various elements, you can better grasp how each section contributes to the system’s functionality. Whether you are troubleshooting or conducting routine maintenance, knowing the placement and role of each element will make the process more efficient and effective.

This resource aims to break down the complexities, offering insights into how each segment works in harmony with others, helping to extend the lifespan of the system and avoid unnecessary repairs. With this knowledge, you can confidently approach any maintenance or setup task with a comprehensive understanding of the internal workings.

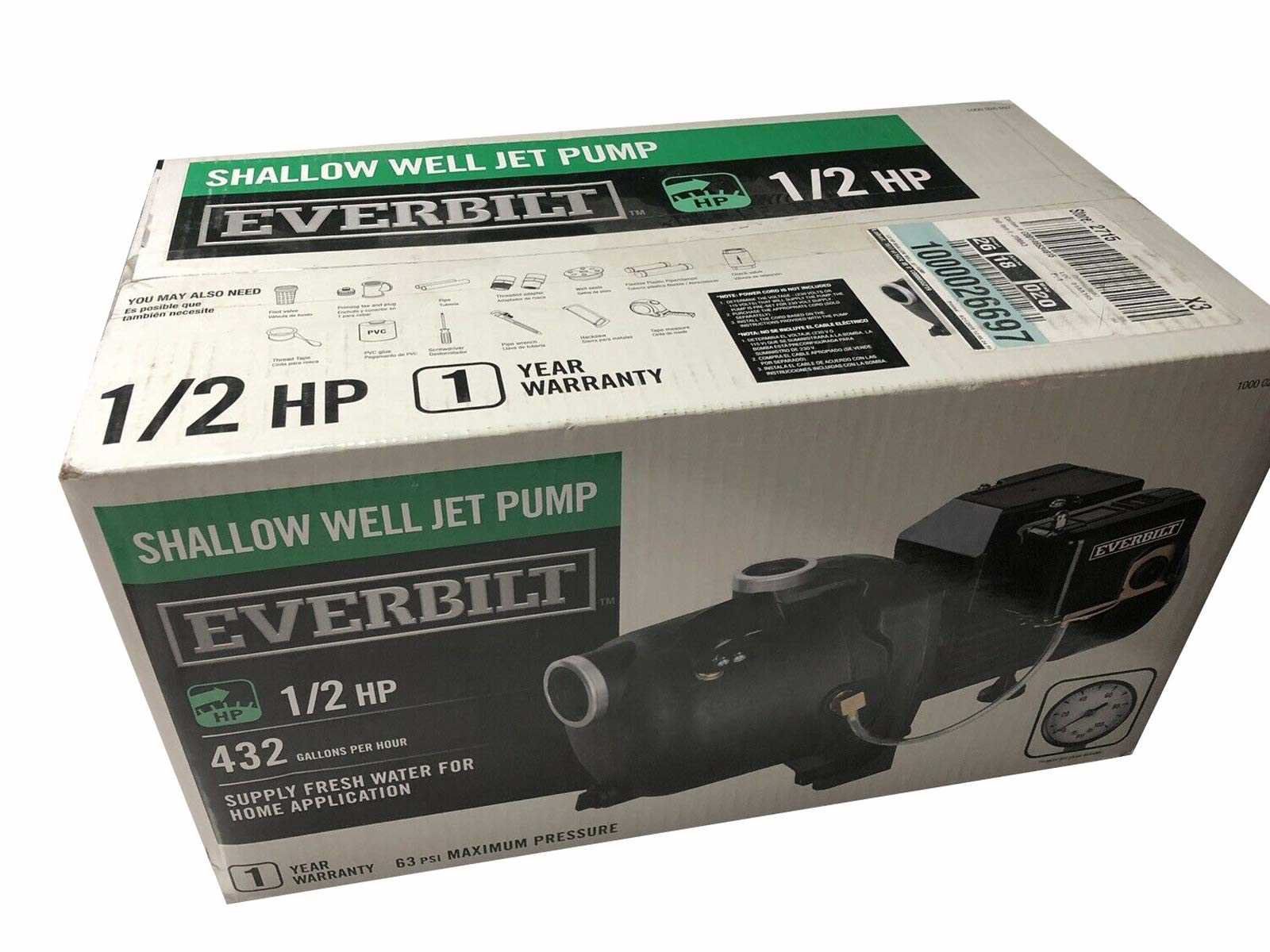

Understanding the Everbilt Pump Structure

The inner workings of this device are composed of several interconnected elements, each playing a crucial role in maintaining functionality. By exploring how these components fit together, you can gain a deeper understanding of how the mechanism operates efficiently. This knowledge can help in identifying potential issues and performing maintenance tasks with greater precision.

The Core Elements are designed to work in harmony, ensuring smooth movement and fluid transfer. These include a main driving force that initiates the motion, guiding liquid through a series of channels and control points. Each section has been optimized for durability and efficiency.

Fluid Dynamics within the structure rely on the coordinated effort of various channels and chambers. The movement of liquid is carefully regulated to prevent any disruptions in flow, ensuring steady performance even under pressure. Each segment is engineered to support the overall process, contributing to a balanced system.

In conclusion, understanding the way this apparatus functions not only enhances your ability to use it effectively but also equips you with the knowledge needed to troubleshoot and maintain its long-term performance.

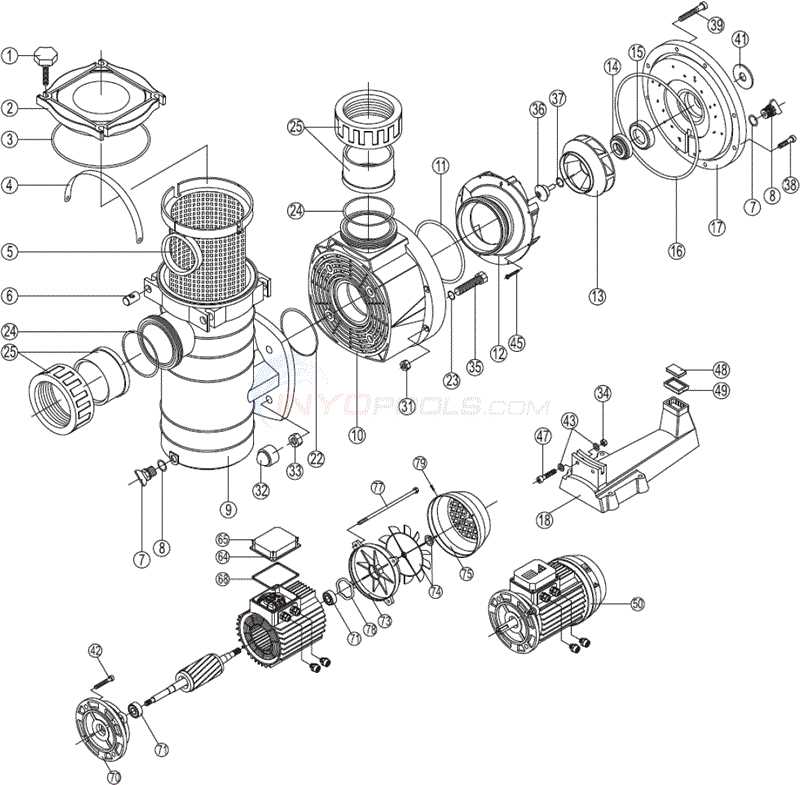

Key Components of Everbilt Pumps

Understanding the core elements of these devices is essential for efficient functionality and maintenance. Each system consists of multiple interconnected elements, each playing a critical role in ensuring optimal operation. Below, we break down the major components that work together to provide smooth performance.

Main Structural Elements

The primary body of the system houses several critical pieces that contribute to its overall efficiency. These include the casing, which protects the internal workings, and various internal sections designed to control the flow and pressure. Each of these parts is built to withstand long-term use and environmental factors.

Operational Mechanisms

Inside the device, mechanical systems work to move fluids effectively. These mechanisms include the driving unit and its connected moving parts, which help in generating the necessary force to propel liquids. Additionally, specialized regulators ensure that the operation remains steady, preventing disruptions and maintaining the correct flow throughout the system.

Exploring the Internal Mechanisms

The inner workings of this device are designed to perform efficiently and reliably over time. By examining the core components, we gain a deeper understanding of how the entire system functions in unison to deliver the expected performance. Each element within plays a crucial role in ensuring the proper operation, contributing to the overall longevity and functionality of the equipment.

Core Components and Their Roles

At the heart of the system lies a series of interconnected elements, each contributing to the smooth operation of the mechanism. These elements work together to create a consistent flow of movement, driven by intricate internal processes. The balance and coordination between these parts ensure that the system operates under various conditions without compromising its efficiency.

Performance and Efficiency

The design of the internal structure focuses on maximizing both performance and energy efficiency. By utilizing precision-engineered materials and strategic placement of each component, the system minimizes wear and tear while maintaining optimal functionality. This careful arrangement helps reduce the risk of malfunctions and prolongs the overall lifespan of the unit.

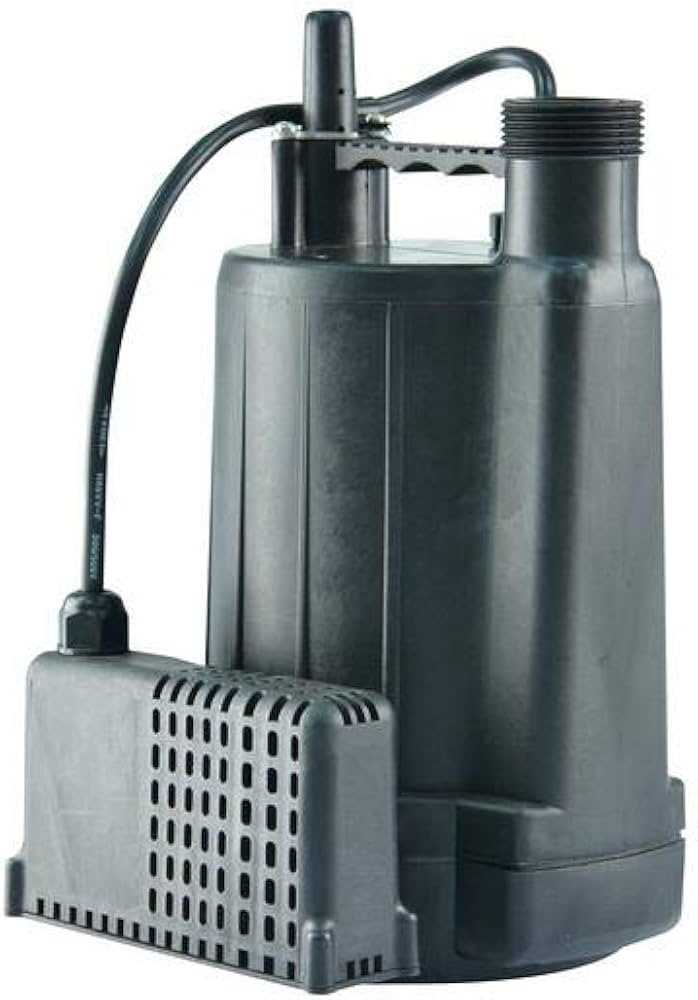

How Everbilt Pump Systems Operate

Understanding how water movement systems function helps to ensure their proper use and maintenance. These systems work by transferring liquid from one location to another efficiently, often relying on a motor-driven mechanism to facilitate the process. The overall operation is designed to manage the flow of water in a controlled and consistent manner, preventing overflow or damage to the system.

Key Components of Water Transfer Systems

Water transfer systems typically consist of several main elements, including a motor, impeller, and inlet/outlet connections. Each part works in harmony to move the liquid through the system. The motor provides the energy, while the impeller pushes the liquid along the designated path. The system’s design ensures smooth and reliable operation, suitable for various applications, including residential and industrial environments.

Flow Control and Efficiency

Effective flow control is crucial for these systems. By regulating the liquid’s speed and pressure, the system maintains a steady and efficient operation. Efficiency is enhanced by properly installed valves and sensors, which monitor the system’s performance and make necessary adjustments to prevent any potential issues. This ensures minimal energy consumption while maximizing output.

| Component | Function |

|---|---|

| Motor | Generates power to drive the system |

| Impeller | Moves liquid through the system |

| Valves | Control the flow and pressure of the liquid |

Identifying Essential Replacement Parts

Understanding the key components of your system is crucial for ensuring smooth operation and long-term functionality. When certain elements wear out or stop functioning correctly, identifying the right substitutes becomes essential to avoid any disruptions. This section will guide you through recognizing the most important items to replace and how to approach the task efficiently.

Commonly Worn Elements

- Seals and gaskets often experience wear due to constant pressure and exposure, making them a priority for regular inspection.

- Rotating mechanisms, which are subject to continuous movement, tend to degrade over time, requiring occasional swaps to maintain efficiency.

- Bearings and connectors are also susceptible to wear, as they endure the forces generated during operation.

Steps to Identify What Needs Replacement

- Inspect the system for any visible signs of leakage or unusual sounds, which might indicate failing components.

- Check the performance levels regularly–any drop in efficiency can be a sign that key elements need replacement.

- Consult the maintenance guide for part numbers and specifications to ensure the correct replacements are sourced.

Commonly Used Materials in Everbilt Pumps

In the realm of fluid management devices, the selection of materials plays a crucial role in ensuring durability, efficiency, and resistance to environmental factors. Various components are constructed from specific substances that enhance performance and longevity, contributing to the overall functionality of these systems.

Metal Components

Steel is often utilized for its strength and durability, making it ideal for high-pressure applications. Additionally, aluminum is favored for its lightweight properties and resistance to corrosion, which is essential in maintaining operational integrity in varying conditions.

Non-Metallic Materials

Various plastics and composite materials are also prevalent in the design of these devices. They offer excellent resistance to chemicals and environmental wear, ensuring reliability in various applications. Rubber is commonly used in seals and gaskets, providing essential protection against leaks and ensuring optimal performance.

Troubleshooting Everbilt Pump Malfunctions

Addressing issues with your water-moving device can be essential for maintaining its efficiency and longevity. Understanding common problems and their solutions will help ensure optimal performance and prevent future complications.

Identify Symptoms: Start by observing any irregular behavior. Unusual noises, insufficient flow, or leaks can indicate underlying issues that require attention.

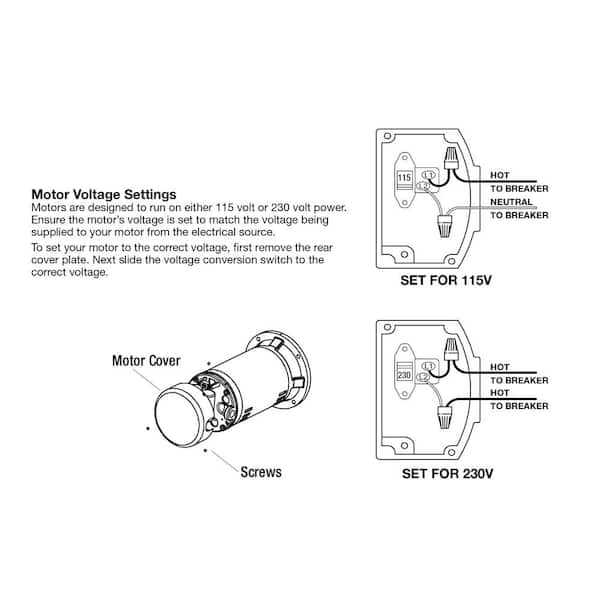

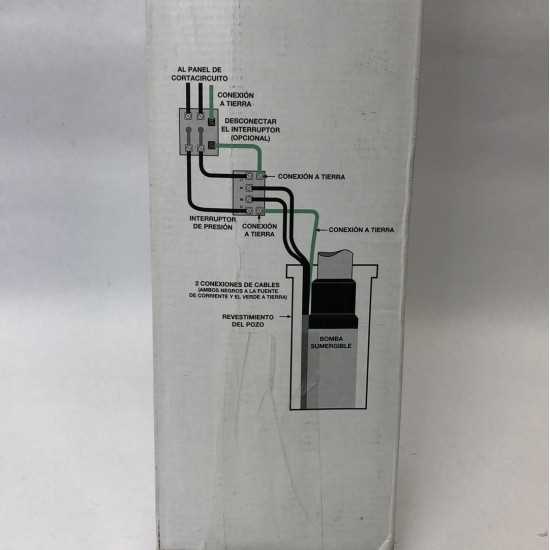

Check Power Supply: Ensure that the unit is properly connected to a power source. A faulty electrical connection may lead to operational failures. Inspect fuses and circuit breakers for any interruptions in service.

Inspect Mechanical Components: Examine the housing and other critical components for signs of wear or damage. A visual inspection can reveal cracks, corrosion, or loose connections that may hinder functionality.

Verify Fluid Levels: Low fluid levels can significantly impact performance. Confirm that the reservoir is adequately filled and that there are no obstructions in the intake line.

Look for Clogs: Blockages can occur in hoses or filters, leading to reduced efficiency. Regular cleaning of these components can help maintain smooth operation.

Consult Manufacturer’s Guidelines: Refer to the user manual for specific troubleshooting tips and maintenance schedules tailored to your model. Adhering to these recommendations can prolong the lifespan of your equipment.

Seek Professional Help: If issues persist after performing basic checks, consider reaching out to a qualified technician. Their expertise can provide valuable insights and repairs that ensure your device operates correctly.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the extended lifespan of your equipment. By adhering to specific maintenance practices, you can significantly enhance performance and prevent premature wear and tear. Implementing a consistent maintenance routine not only saves time and money but also improves reliability and efficiency in operation.

Routine Inspection

- Check for any signs of wear or damage on the exterior.

- Inspect all connections and seals for leaks or deterioration.

- Ensure that components are securely fastened and properly aligned.

Cleaning and Lubrication

- Clean all surfaces regularly to prevent dirt buildup.

- Use appropriate lubricants to maintain moving parts, ensuring smooth operation.

- Replace filters as needed to enhance airflow and efficiency.

Following these guidelines will contribute to optimal functionality and longevity, making your equipment more dependable over time.

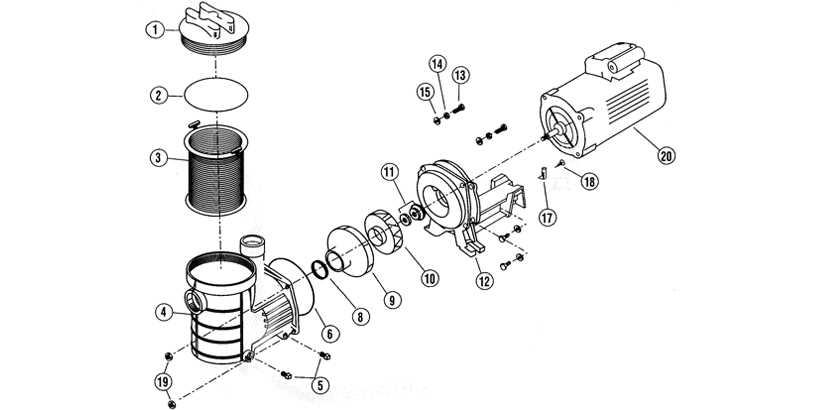

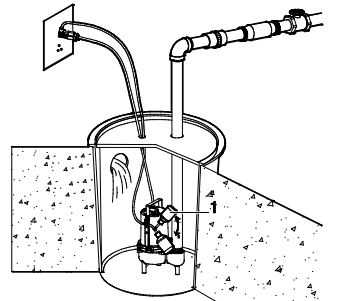

Assembly Guide for Everbilt Pumps

This section provides a comprehensive overview for the assembly of water-moving devices. Understanding the correct arrangement of components is crucial for optimal performance and longevity. This guide will outline the necessary steps and considerations for successful assembly.

Required Tools and Materials

- Wrench set

- Screwdriver set

- Sealant or gasket material

- Lubricant

- Safety goggles

- Work gloves

Step-by-Step Assembly Instructions

- Begin by laying out all components on a clean surface, ensuring that nothing is missing.

- Refer to the assembly guide for the correct configuration of parts.

- Attach the base to the housing, securing it with the appropriate fasteners.

- Install the motor, ensuring proper alignment with the drive shaft.

- Connect the intake and discharge fittings, applying sealant where necessary to prevent leaks.

- Check all connections and tighten as needed to ensure a secure assembly.

- Perform a final inspection before powering up the device.

Compatibility of Parts Across Models

Understanding the interchangeability of components between various units is essential for maintenance and repair. Many consumers benefit from knowing which elements can be substituted or shared across different designs, enhancing their ability to manage their equipment effectively. This section delves into how components can be matched across models, allowing for a smoother user experience and potential cost savings.

Key Factors Influencing Compatibility

- Design Specifications: Each model may have unique dimensions or functionalities that affect how components fit and operate together.

- Material Composition: The durability and performance of parts can vary based on the materials used, impacting compatibility.

- Manufacturing Updates: Changes in production processes over time can result in variations that may affect interchangeability.

Benefits of Component Compatibility

- Enhanced Availability: Users can access a wider range of replacement options.

- Cost Efficiency: Utilizing interchangeable components often reduces overall repair expenses.

- Simplified Maintenance: Streamlined access to parts can facilitate quicker repairs and minimize downtime.