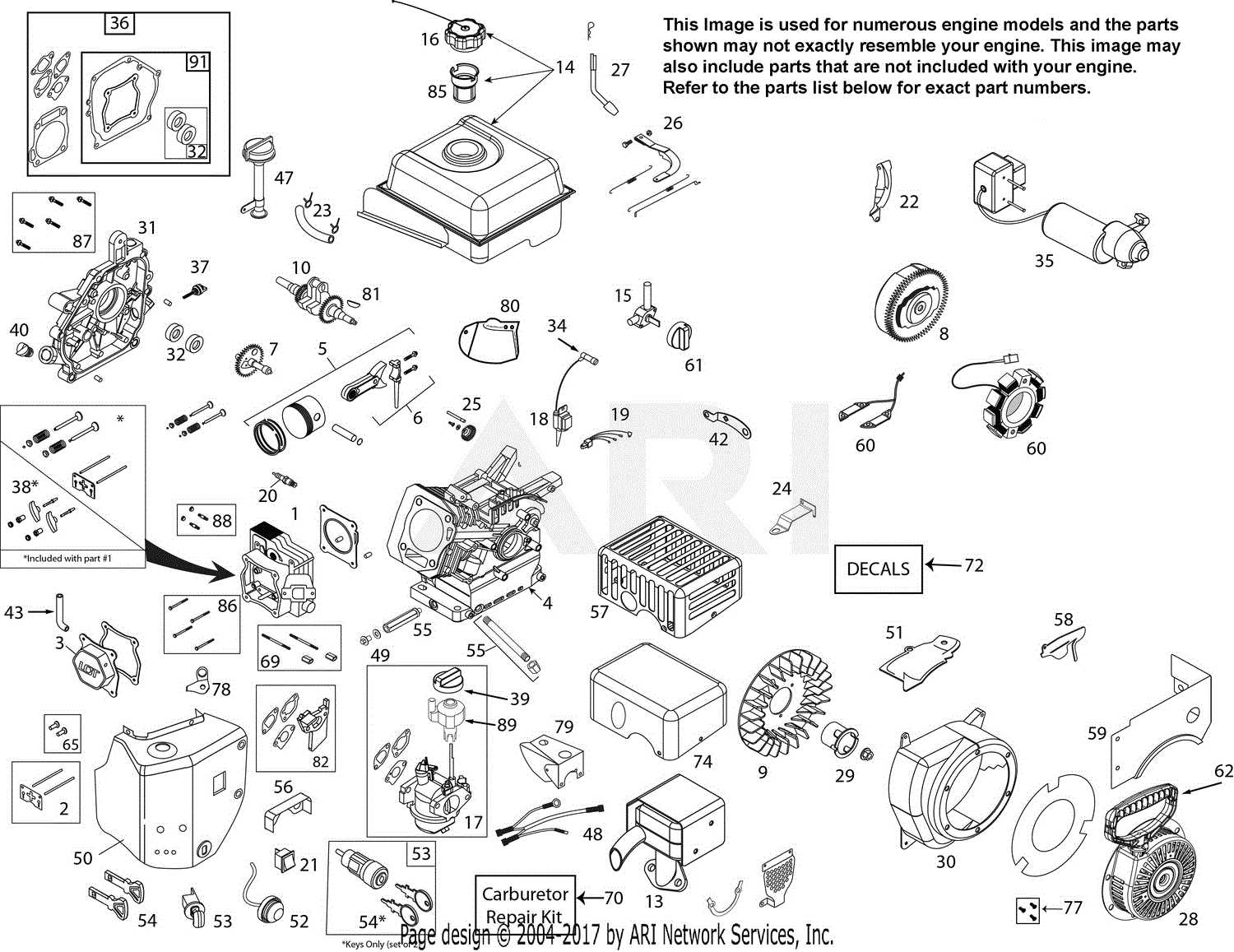

In the world of outdoor machinery, comprehending the various elements that contribute to its functionality is essential. A thorough exploration of the intricate system ensures that users can maintain and repair their devices effectively. Identifying each component allows for informed decisions regarding upkeep and enhancements.

By examining a comprehensive representation of these components, operators can gain valuable insights into how their machinery operates. Recognizing the role of each section fosters a deeper appreciation and understanding of the overall mechanics involved. Knowledge of these elements is vital for achieving optimal performance.

Moreover, a detailed view of these individual parts empowers users to troubleshoot issues swiftly and accurately. Whether it’s routine maintenance or unexpected repairs, familiarity with the structure facilitates efficient resolutions. A proactive approach to understanding these components can significantly extend the lifespan of the equipment.

Ariens Snow Blower Parts Overview

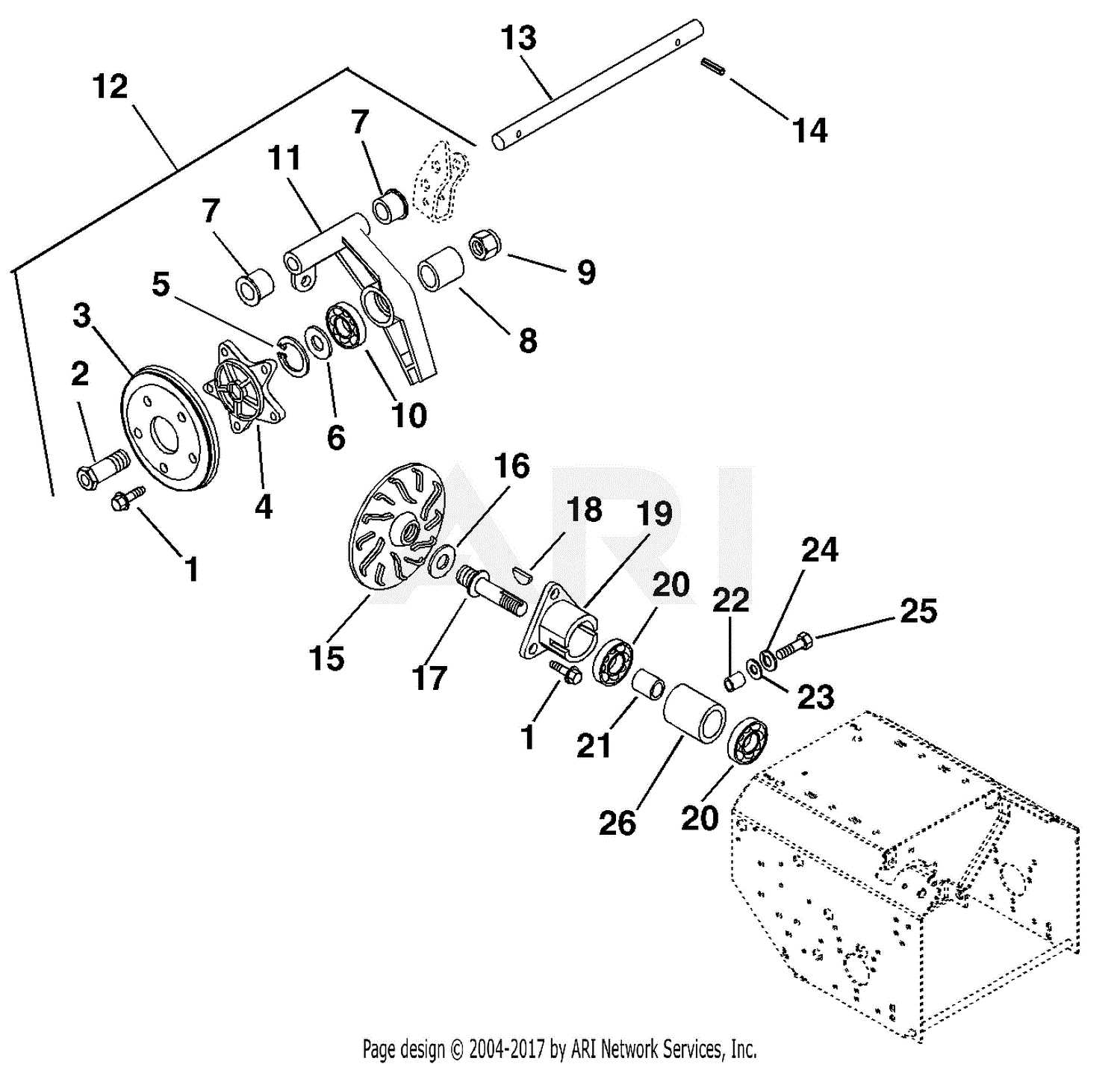

The functionality of this type of winter equipment depends heavily on a variety of interconnected elements, each playing a crucial role in its performance. These components are designed to ensure smooth operation, reliable clearing of icy surfaces, and ease of use even in the harshest conditions.

Key systems include mechanisms for propulsion, which help the unit navigate different surfaces, and the engine, which delivers the necessary power. Additionally, specialized features are responsible for gathering and throwing material, making the machine efficient in removing heavy layers. Regular maintenance of all these elements is essential for long-lasting performance and dependability.

Essential Components of Snow Blowers

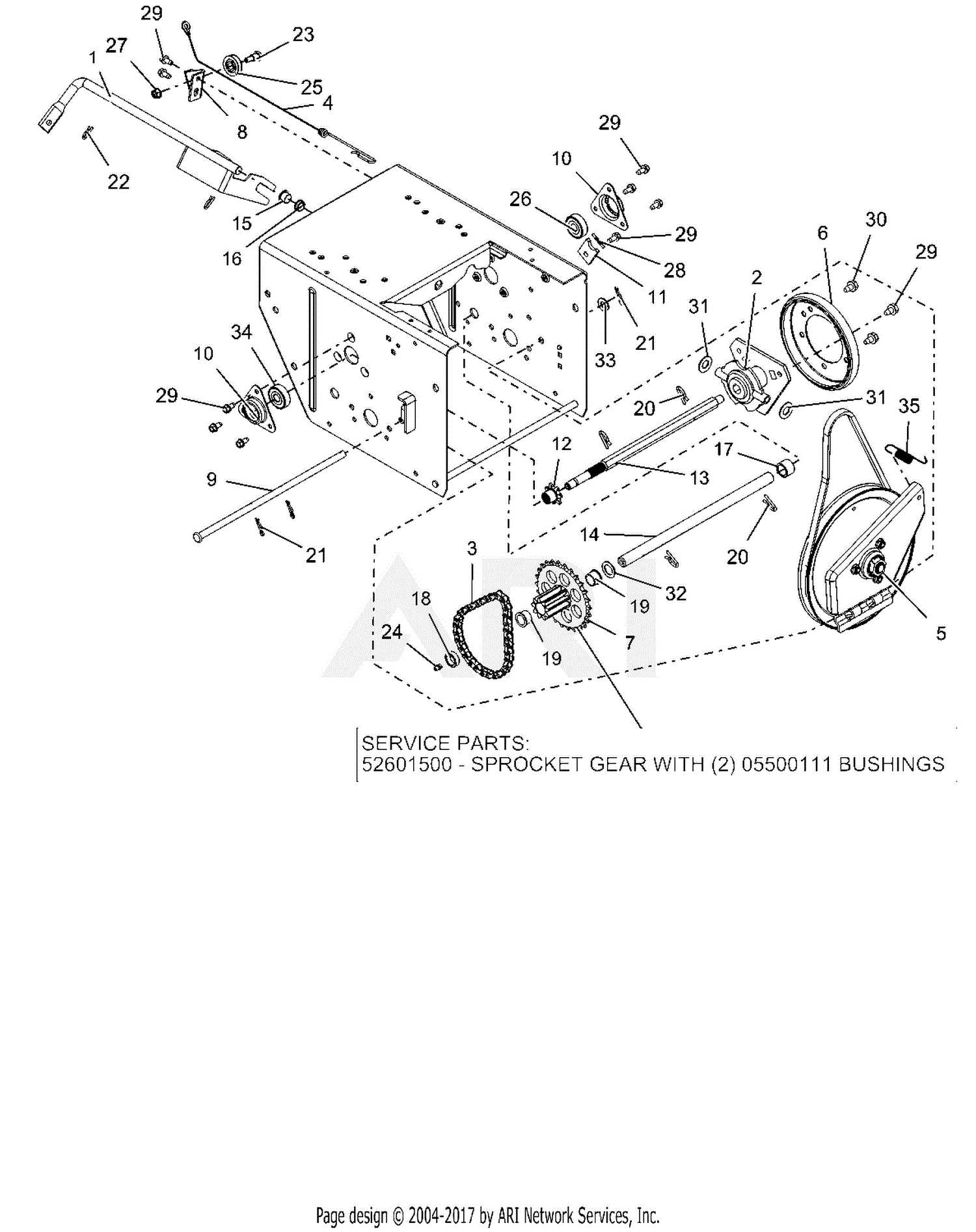

Machines designed for clearing pathways and driveways in winter conditions rely on several key mechanisms to ensure efficient operation. These core components work together to deliver the power and precision needed for removing heavy buildup and maintaining clear access areas. Understanding these elements can help identify potential issues and maintain equipment in optimal condition.

Power Source and Transmission

The engine provides the necessary force for the machine’s operation, often available in gas-powered or electric variations. Coupled with a robust transmission system, this ensures smooth control over the device’s speed and movement, enabling adjustments depending on the terrain and type of accumulation being cleared.

Auger and Impeller

The rotating blade at the front of the machine serves to break down and gather material, while the impeller assists in expelling the debris through the chute. These two components work in tandem to provide effective clearing, ensuring that material is collected and directed away from the area being worked on.

| Component | Function | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine | Powers the entire system | |||||||||||||||||||||

| Transmission | Controls speed and movement | |||||||||||||||||||||

| Auger | Collects and cuts through material |

| Issue | Potential Cause | Solution | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Failure to start | Old fuel or blocked filter | Replace fuel, clean or change filter | ||||||||||||

| Decreased efficiency | Clogged air passages | Clean air passages, check for blockages |

| Accessory | Description | Benefits |

|---|---|---|

| Skid Shoes | Replaceable shoes that protect the base and adjust the height of the equipment. | Enhanced durability and customized height settings for different surfaces. |

| Drift Cutters | Blades that help cut through heavy, piled snow. | Improved cutting ability for tough snow conditions. |

| Headlight Kit | Illumination accessories for low-visibility operations. | Increased safety and visibility during early mornings or late evenings. |

Conclusion

Incorporating these enhancements not only elevates performance but also enriches the overall user experience. By investing in the right accessories, users can enjoy enhanced efficiency and a more satisfying operation.

Finding Genuine Ariens Parts Online

Locating authentic components for outdoor equipment can significantly enhance performance and longevity. When seeking reliable replacements, it’s crucial to ensure that the sources you choose provide high-quality items that meet the specific requirements of your machine.

Identifying Reliable Sources

Start by exploring well-established online retailers that specialize in outdoor machinery. These vendors often have a comprehensive inventory, ensuring that you find the necessary components easily. Reading customer reviews can also provide insights into the quality of the products offered and the level of service provided.

Using Manufacturer Resources

Utilizing official manufacturer websites can be advantageous when searching for genuine components. Many manufacturers offer online catalogs or reference guides that help identify compatible replacements. Additionally, customer service representatives can assist with any queries, ensuring that you acquire the correct items for your equipment.

In summary, sourcing authentic components from reputable suppliers not only guarantees better performance but also extends the lifespan of your outdoor machinery. Prioritize quality and reliability in your search for replacements.

Comparing Different Model Diagrams

When assessing various machine configurations, it is essential to examine the specific layouts and components of each model. This analysis can reveal distinct features, efficiencies, and design variations that contribute to performance. Understanding these differences aids users in making informed decisions regarding maintenance and upgrades.

Key Features and Components

Each model showcases unique attributes, often tailored to different user needs. For instance, the arrangement of essential elements can significantly impact functionality and ease of use. Identifying these characteristics allows operators to select models that align with their requirements, ensuring optimal performance in various conditions.

Maintenance and Upgrades

Recognizing the structural differences among models is crucial for effective upkeep. Components that are easily accessible facilitate routine maintenance tasks, enhancing the longevity of the machine. Furthermore, understanding compatibility with new upgrades ensures users can enhance their equipment without significant overhauls.

Safety Precautions When Repairing

Ensuring safety during maintenance tasks is paramount to prevent accidents and injuries. Proper precautions should be taken to create a secure working environment. Familiarizing oneself with equipment and tools is essential before commencing any repair work.

Wear Appropriate Gear

Always utilize suitable protective equipment. This includes gloves, goggles, and non-slip footwear. These items help shield against potential hazards such as sharp edges or moving components. Adequate attire can significantly reduce the risk of injury.

Maintain a Clean Workspace

A tidy work area contributes to safety. Remove any unnecessary objects that may obstruct movement or create tripping hazards. Keeping tools organized and within reach minimizes distractions and enhances focus. This practice ensures a more efficient and secure repair process.