In the realm of garden maintenance, the efficient functioning of essential equipment hinges on a clear understanding of its various components. This knowledge not only enhances performance but also aids in troubleshooting issues when they arise. By familiarizing oneself with the intricate makeup of these devices, users can ensure optimal operation and prolong the lifespan of their tools.

The significance of each element cannot be overstated, as even the smallest component plays a crucial role in the overall efficiency of the machine. Whether it’s about the airflow dynamics or the power source, recognizing how each piece interacts with others forms the backbone of effective usage. Enthusiasts and professionals alike can benefit from a detailed exploration of these mechanisms.

For those seeking to optimize their gardening experience, a comprehensive visual guide illustrating the various sections and functionalities of the equipment can be invaluable. Such resources serve as a roadmap, simplifying maintenance and repairs while empowering users with the confidence to tackle tasks head-on. Embracing this knowledge transforms the way one approaches garden care, paving the way for a more productive and enjoyable experience.

Poulan Leaf Blower Overview

This section provides an insight into a popular outdoor tool designed for managing yard debris efficiently. With a focus on performance and ease of use, it caters to both casual gardeners and dedicated landscapers. Understanding the features and components is essential for maximizing its capabilities.

Key Features

Equipped with powerful engines and ergonomic designs, these devices facilitate effortless cleanup. The incorporation of advanced technology enhances airflow control, allowing users to tackle various tasks with precision.

Maintenance Tips

Regular upkeep is vital for optimal functionality. Ensuring that all components are clean and well-lubricated will extend the lifespan and improve efficiency. Consulting the user manual can provide specific guidance tailored to your model, making it easier to manage any potential issues.

Understanding Leaf Blower Components

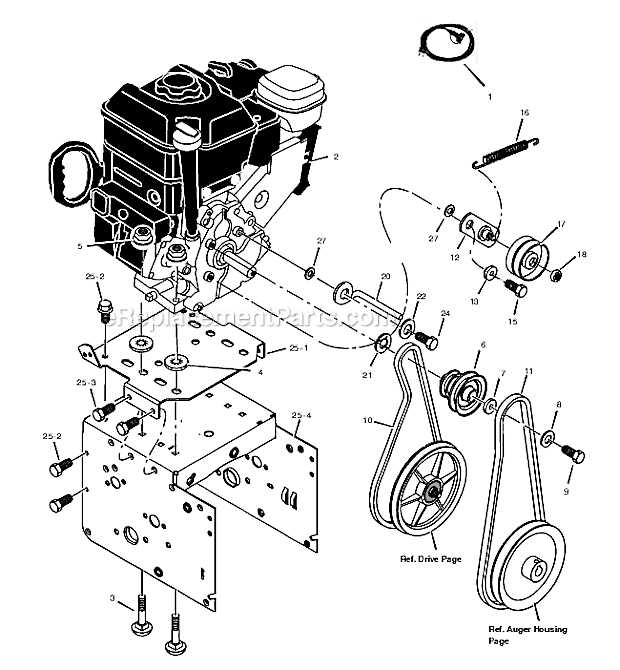

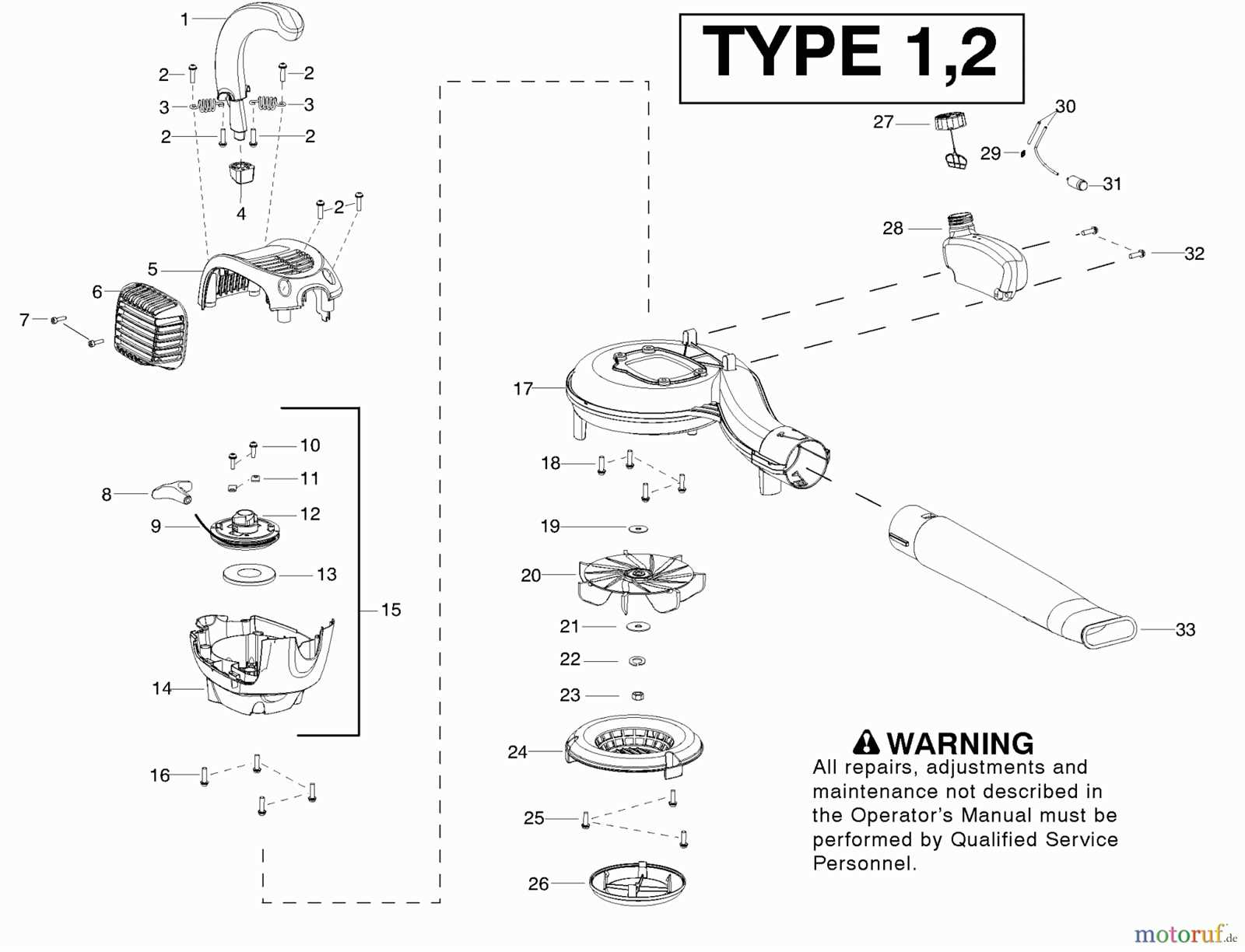

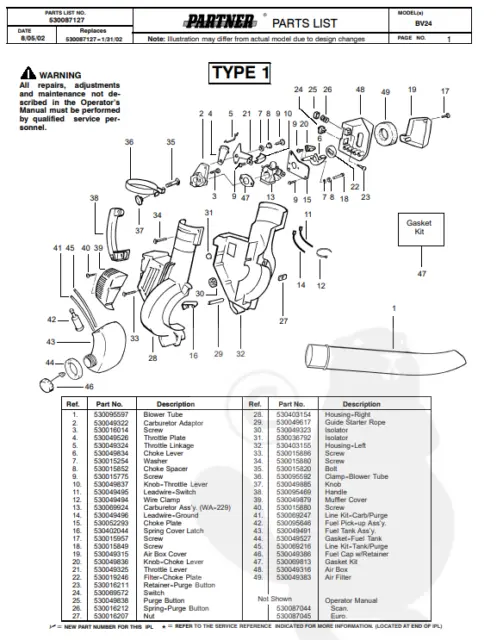

The efficiency of garden tools relies heavily on their various elements working in harmony. Each component plays a crucial role, contributing to the overall functionality and performance. A clear comprehension of these individual parts allows users to maintain their devices effectively and troubleshoot issues with ease.

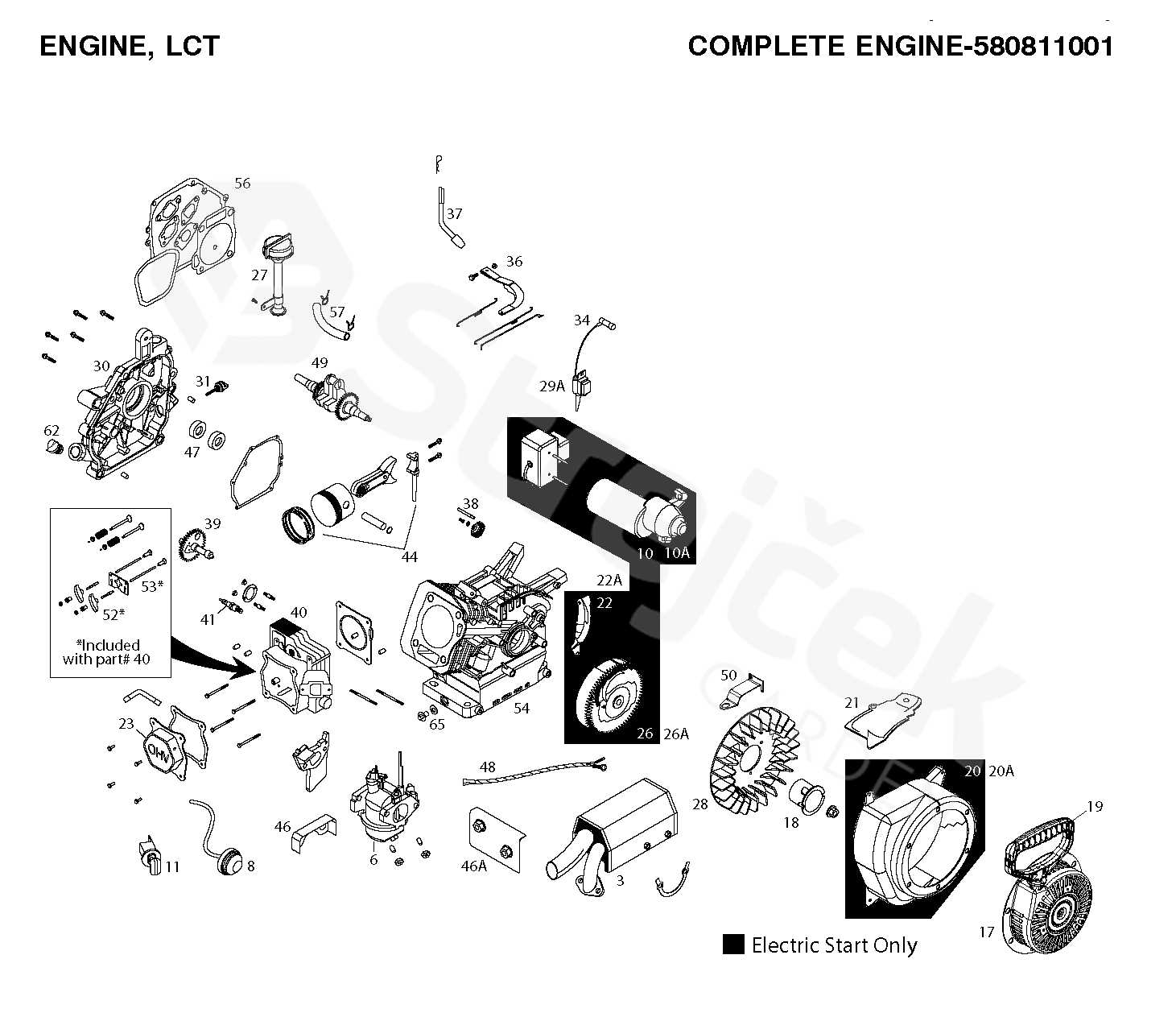

Power Source: The engine serves as the heart of the machine, providing the necessary energy for operation. Understanding the different types–electric or gas–can help users select the right tool for their needs.

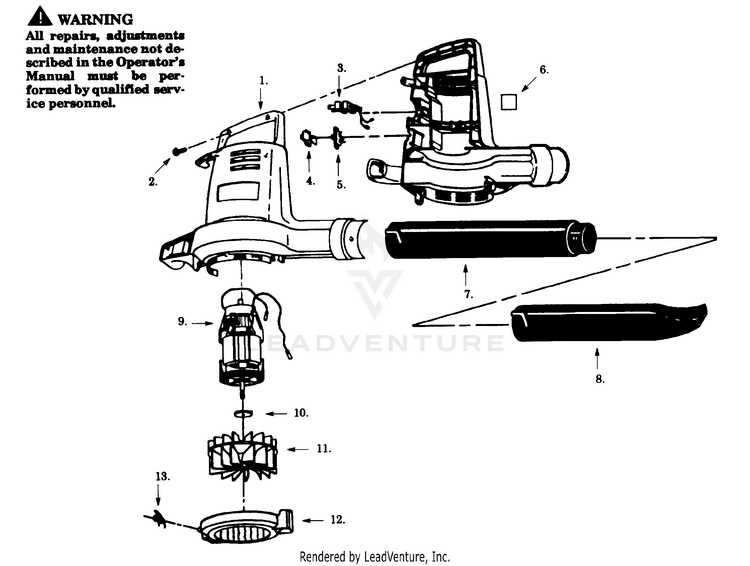

Fan Assembly: This part generates the airflow required to move debris. The design and size of the fan greatly influence the velocity and volume of air produced, making it a vital factor in performance.

Housing: The outer shell protects internal components while providing structural integrity. It also plays a role in user comfort, with ergonomic designs reducing fatigue during use.

Controls: These elements allow for user interaction, enabling adjustments to speed and direction. Familiarity with the control layout enhances operational efficiency and safety.

By delving into these components, users can achieve the ultimate understanding necessary for optimal usage and maintenance of their equipment.

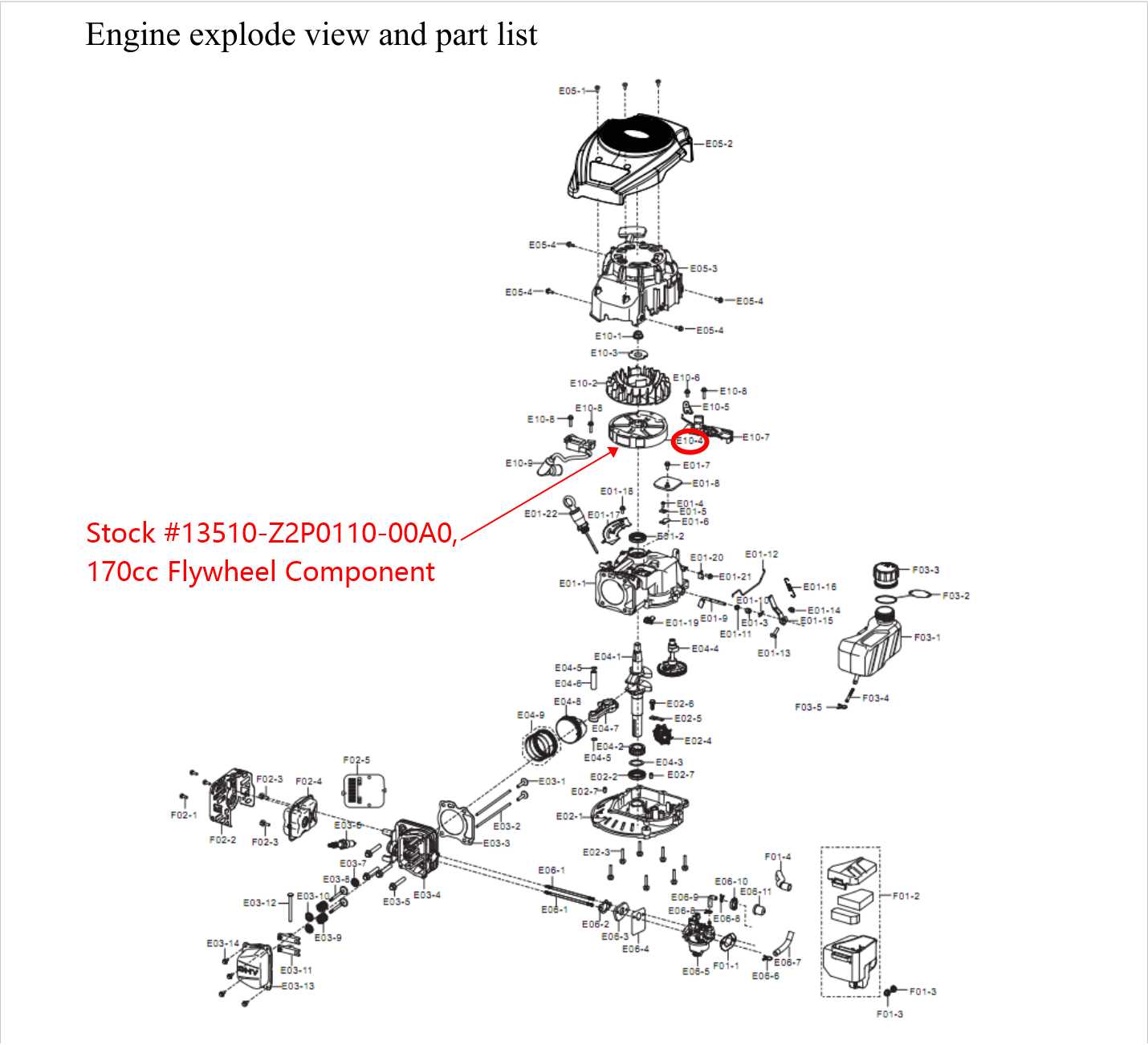

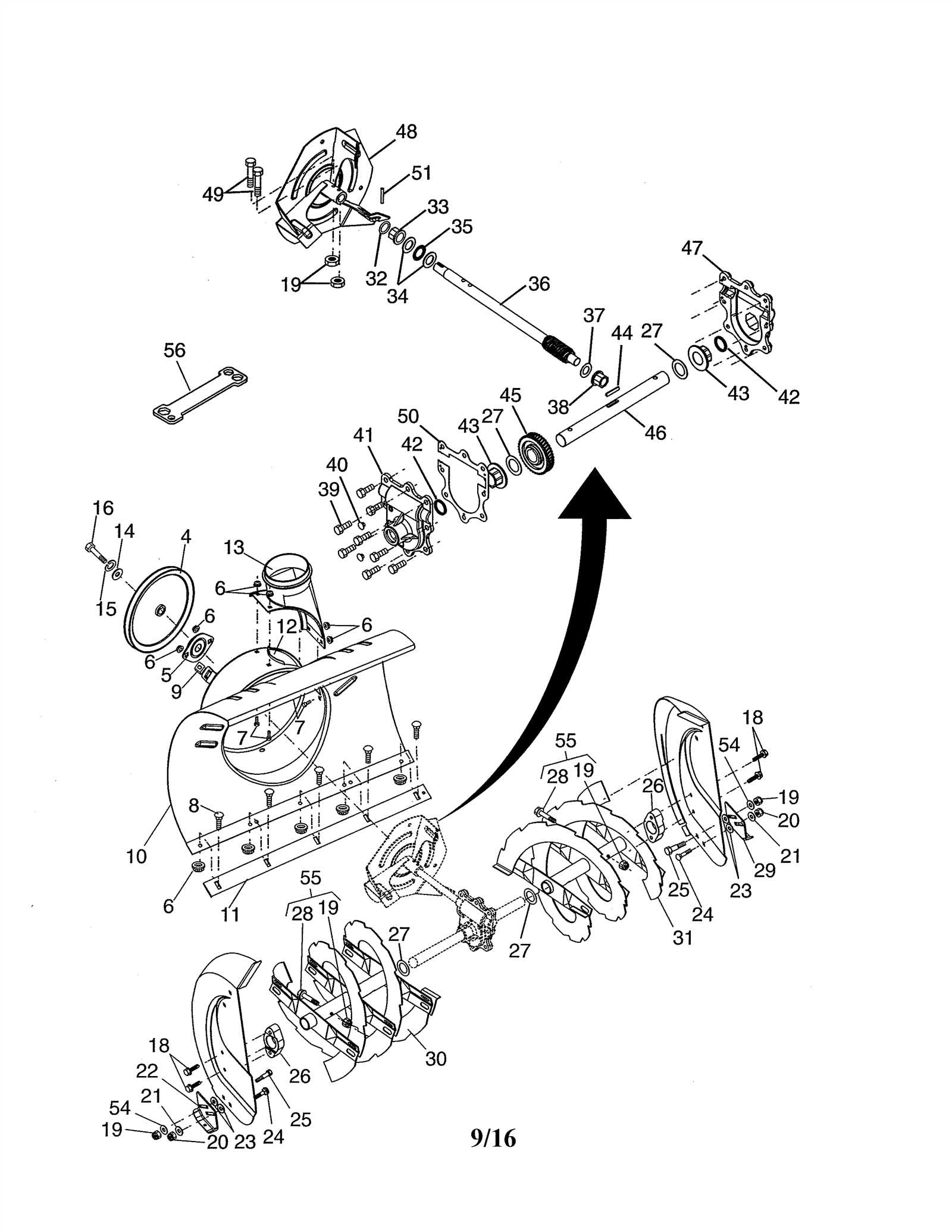

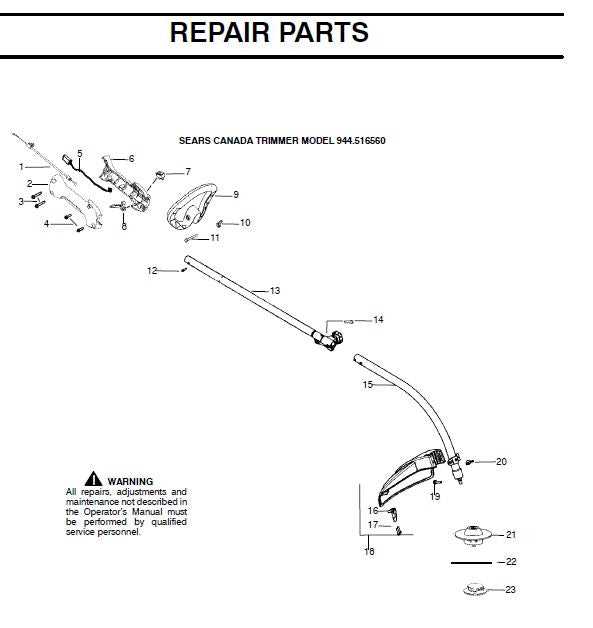

Importance of Diagram for Repairs

Understanding the layout and components of equipment is crucial for effective maintenance and repair. A visual representation serves as a guide, making it easier to identify and address issues efficiently.

Benefits of Visual Guides

- Enhances clarity in identifying components.

- Simplifies the assembly and disassembly process.

- Reduces the risk of errors during repairs.

How to Use Visual Aids Effectively

- Refer to the illustration before starting any repair work.

- Cross-check each part against the guide to ensure accuracy.

- Keep the visual aid accessible for quick reference.

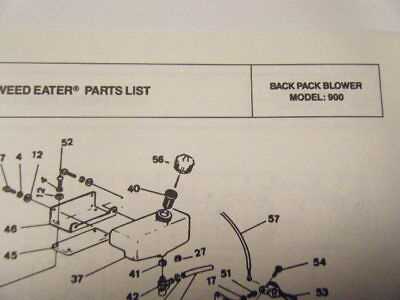

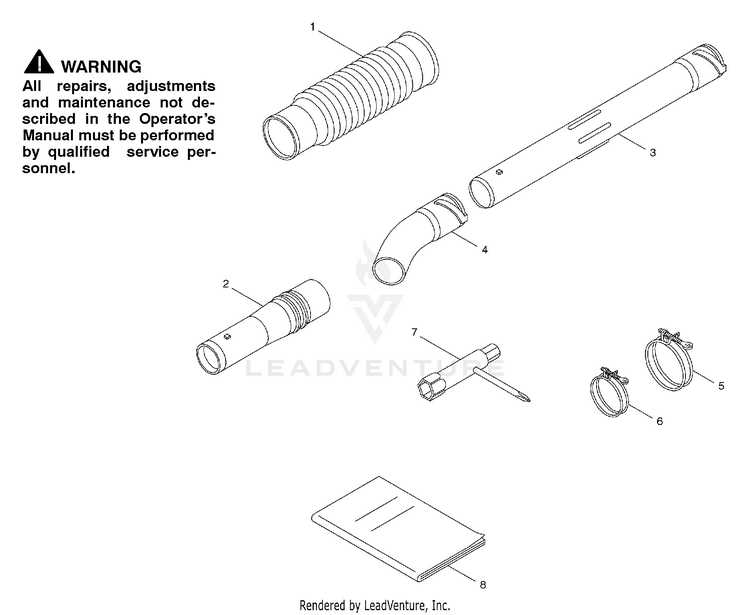

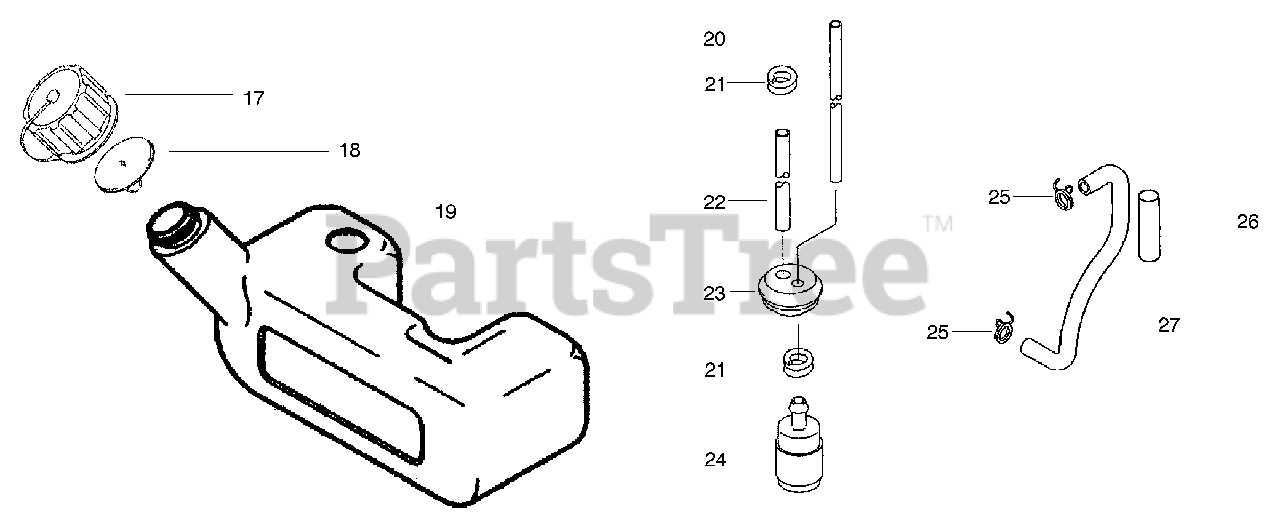

Common Parts of Poulan Leaf Blowers

Understanding the various components of outdoor equipment is essential for effective maintenance and troubleshooting. Each section plays a critical role in ensuring the machinery operates smoothly and efficiently. Below are the primary elements typically found in these types of devices.

Essential Components

- Engine: The heart of the machine, providing the necessary power for operation.

- Fuel Tank: Holds the mixture required for the engine, crucial for performance.

- Air Filter: Prevents dirt and debris from entering the engine, enhancing longevity.

- Fan Wheel: Generates airflow, directing it through the nozzle.

- Nozzle: The end attachment that controls the direction and speed of the air.

Additional Elements

- Throttle Control: Regulates engine speed, allowing for variable output.

- Starter Rope: Initiates the engine’s operation with a manual pull.

- Chassis: The frame that houses and supports all components.

- Vibration Dampeners: Reduce operator fatigue by minimizing vibrations during use.

Familiarizing oneself with these essential elements not only aids in effective maintenance but also enhances overall user experience. Proper understanding ensures that any issues can be quickly identified and resolved.

How to Access the Parts Diagram

Understanding the assembly and components of your equipment is essential for effective maintenance and repair. Accessing a visual representation of these elements can greatly simplify the process. Here’s how you can find and utilize this resource effectively.

- Visit the Manufacturer’s Website:

- Go to the official site of the brand.

- Look for a section dedicated to support or resources.

- Search for User Manuals:

- Locate the manuals specific to your model.

- These often include detailed illustrations and lists of components.

- Utilize Online Forums:

- Join community forums where enthusiasts discuss various models.

- Ask for assistance in finding visual aids related to your equipment.

- Check Retailer Websites:

- Visit sites that sell your equipment or its accessories.

- Look for resources or links to diagrams provided by the retailer.

By following these steps, you can easily access the necessary illustrations to help you understand the intricacies of your equipment, ensuring you can perform maintenance and repairs efficiently.

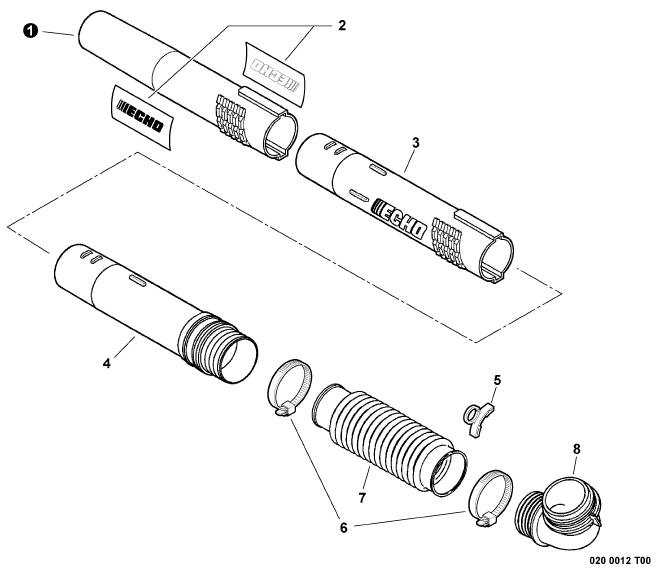

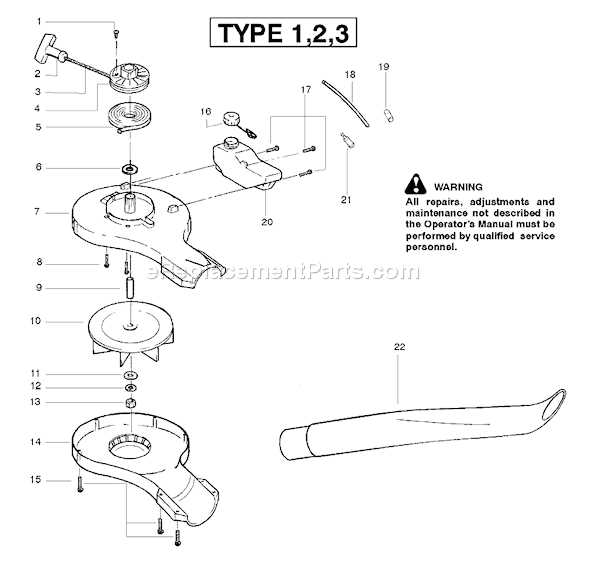

Identifying Key Components Visually

Understanding the various elements of your device is essential for effective maintenance and repair. Recognizing these components through visual references allows for quicker identification of issues and enhances your troubleshooting skills. By familiarizing yourself with each part, you can ensure optimal performance and longevity.

Main Body Elements

The primary structure of your equipment is crucial, as it houses essential mechanisms. Focus on distinguishing the outer casing, intake areas, and attachment points, which facilitate operation and connectivity to other parts.

Additional tools and attachments play a significant role in functionality. Examine items like tubes, nozzles, and motors, as they directly influence performance. Understanding their shapes and placements can aid in recognizing compatibility and potential upgrades.

Tips for Maintaining Leaf Blower Parts

Proper upkeep of outdoor equipment is essential for optimal performance and longevity. Regular attention to various components ensures efficiency and can prevent costly repairs. By following a few simple guidelines, users can enhance the reliability of their machines and extend their lifespan.

1. Clean Regularly: Keep the exterior and interior free of debris. A clean machine operates more efficiently and prevents overheating. After each use, wipe down the surfaces and check for any buildup that may affect performance.

2. Inspect Components: Regularly examine essential elements like the air filter, fuel lines, and spark plug. Replacing worn or damaged parts promptly will maintain functionality and prevent breakdowns.

3. Check Fuel Quality: Always use fresh fuel and store it correctly. Stale fuel can lead to engine issues and decreased efficiency. Consider using fuel stabilizers if fuel will be stored for an extended period.

4. Lubricate Moving Parts: Apply lubricant to any moving components as recommended by the manufacturer. Proper lubrication reduces friction and wear, ensuring smooth operation.

5. Store Properly: When not in use, store the equipment in a dry, sheltered location. Cover it to protect against dust and moisture, which can cause corrosion or damage.

6. Follow Manufacturer’s Guidelines: Always refer to the user manual for specific maintenance recommendations. Adhering to these guidelines will help users avoid common pitfalls and ensure that the machine remains in peak condition.

Where to Find Replacement Parts

When maintaining your outdoor equipment, sourcing high-quality components is crucial for optimal performance. Various avenues exist for locating suitable replacements, ensuring that your tools remain functional and efficient.

Online Retailers

Many online platforms offer a vast selection of components. These sites typically provide detailed specifications, allowing you to identify the exact match for your needs.

Local Hardware Stores

Your nearby hardware stores can be valuable resources. They often carry a range of components, and staff can assist in finding the right item for your equipment.

| Source | Advantages |

|---|---|

| Online Retailers | Wide selection, competitive prices, convenience |

| Local Hardware Stores | Immediate availability, personal assistance, support local business |

Tools Needed for Disassembly

To effectively dismantle the device, it’s essential to gather the right tools beforehand. Having the appropriate instruments not only ensures safety but also streamlines the process, allowing for a smoother workflow.

- Philips screwdriver

- Flathead screwdriver

- Socket wrench set

- Pliers

- Torque wrench

- Wire cutters

- Safety goggles

Once equipped with these tools, you will be prepared to delve into the assembly with confidence and efficiency.

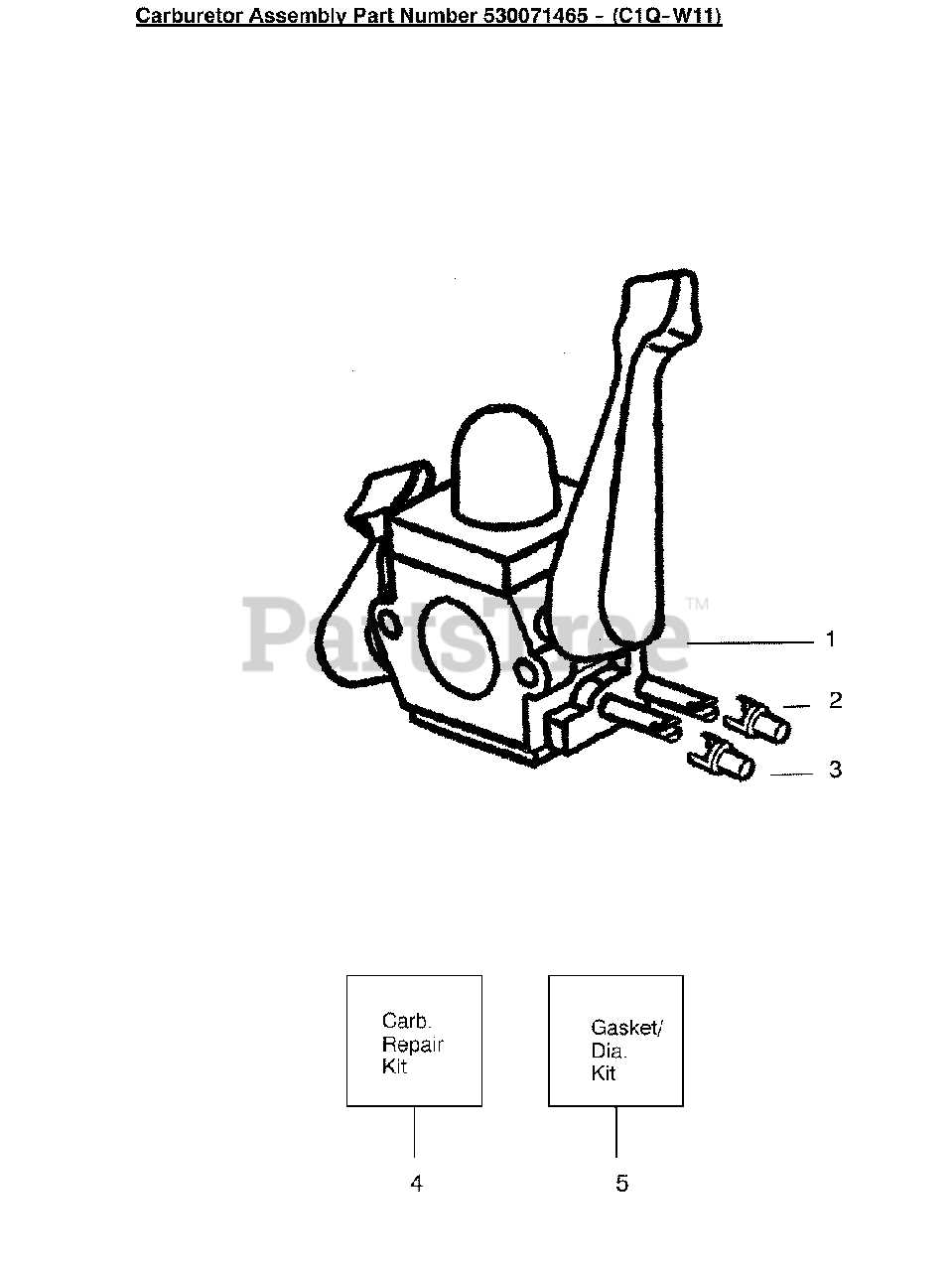

Steps for Replacing Worn Parts

Maintaining equipment is essential for optimal performance and longevity. When components become damaged or inefficient, timely replacement is crucial to ensure smooth operation. This section outlines the necessary steps to effectively swap out these worn elements.

1. Gather Necessary Tools and Supplies: Before starting, assemble all required tools such as screwdrivers, wrenches, and replacement components. Having everything on hand will streamline the process.

2. Power Down the Equipment: Always ensure the machine is turned off and disconnected from any power source. This step is vital for safety to prevent accidental activation during the procedure.

3. Remove the Housing: Using appropriate tools, carefully take off the outer casing to access the internal mechanisms. Be cautious not to damage any clips or screws that hold the assembly together.

4. Identify Worn Components: Examine the internal parts for signs of wear or damage. Look for cracks, fraying, or any irregularities that indicate a need for replacement.

5. Replace the Components: Carefully remove the identified elements, noting their arrangement for accurate reinstallation. Insert the new components, ensuring they fit securely and align correctly.

6. Reassemble the Equipment: Once replacements are in place, reattach the outer housing. Double-check that all screws and clips are securely fastened to prevent any issues during operation.

7. Test the Equipment: Finally, reconnect to the power source and conduct a test run. Monitor for any unusual noises or performance issues, ensuring everything functions as expected.

By following these steps, you can efficiently replace worn components and maintain the efficiency of your equipment.

Common Issues and Troubleshooting Tips

Maintaining outdoor equipment can sometimes lead to unexpected challenges. Identifying and resolving common problems is essential for optimal performance. This section outlines frequent issues users encounter and provides practical solutions to ensure your device operates smoothly.

Frequent Problems

One of the most typical concerns involves starting difficulties. Users may find that their equipment fails to ignite, often due to fuel-related issues or spark plug malfunctions. Additionally, inconsistent power output can result from blockages in the air intake or exhaust systems, affecting overall efficiency. Regular inspection of these areas is crucial to avoid further complications.

Troubleshooting Techniques

To address starting issues, first check the fuel quality and ensure the tank is filled with fresh fuel. Inspect the spark plug for signs of wear or damage, replacing it if necessary. For power fluctuations, examine the air filter and clean or replace it to eliminate any debris obstructing airflow. Keeping your device well-maintained can significantly extend its lifespan and enhance performance.

Enhancing Performance with Quality Parts

Improving efficiency in garden tools often hinges on the components used in their construction. High-quality materials can significantly influence the overall functionality and lifespan of these machines.

- Durability: Robust elements withstand wear and tear, ensuring long-term use.

- Efficiency: Superior parts enhance performance, optimizing energy consumption.

- Compatibility: Selecting the right components ensures seamless operation with existing machinery.

Investing in premium components offers several advantages:

- Improved airflow and power output.

- Reduced maintenance needs and costs.

- Increased reliability during use.

Ultimately, quality components elevate performance, leading to a more satisfying experience for users. By choosing wisely, you can transform your equipment into an efficient powerhouse.