Exploring the intricate world of aquatic propulsion systems reveals a complex interplay of elements that contribute to efficient performance. A comprehensive grasp of these components is essential for enthusiasts and technicians alike, enabling them to troubleshoot and enhance their machinery.

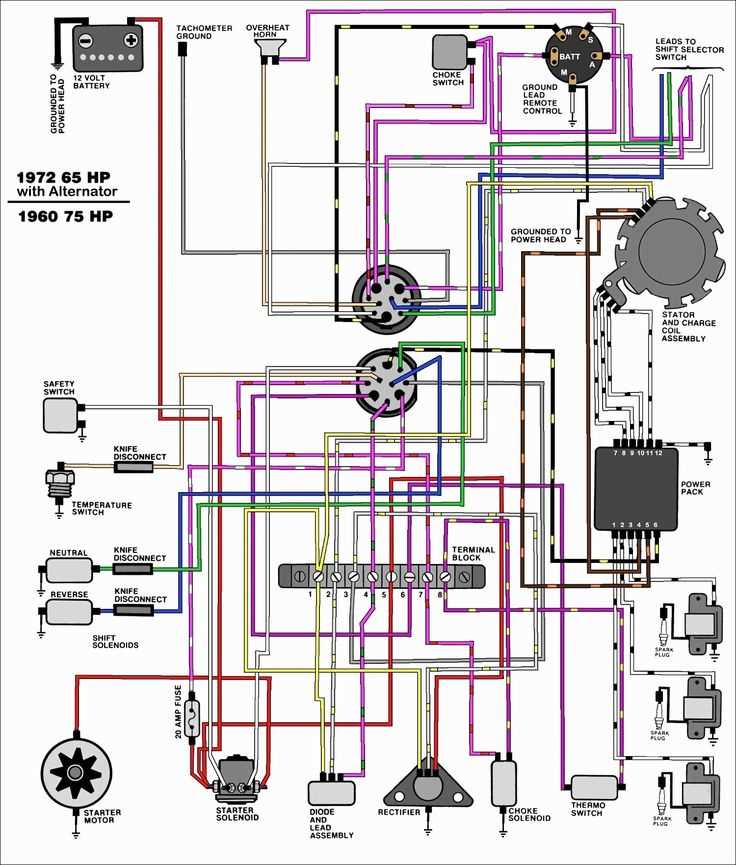

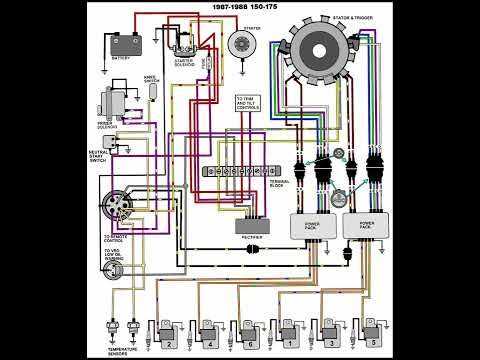

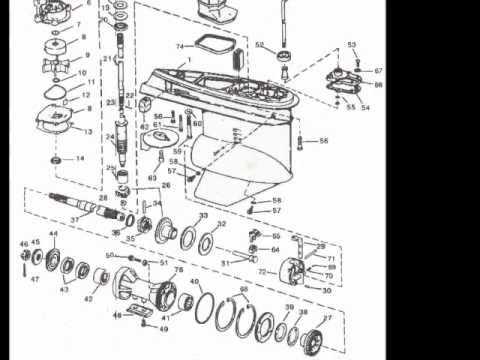

In this section, we will delve into various illustrations and schematics that elucidate the configuration of crucial elements. These visual aids serve as an ultimate reference, providing clarity and insight into the assembly and functioning of the system.

Whether you are an experienced operator or a newcomer, familiarizing yourself with these detailed representations will significantly enhance your understanding of how each part interacts within the assembly. Armed with this knowledge, you can confidently maintain and optimize your equipment for optimal results.

Understanding Johnson Boat Motors

The intricate machinery behind watercraft propulsion plays a vital role in ensuring smooth navigation and reliable performance. Familiarity with these mechanisms is essential for enthusiasts and professionals alike, as it enhances maintenance and troubleshooting skills. Grasping the components and their functions is key to optimizing the overall experience on the water.

One of the most important aspects of these propulsion systems is the relationship between the various elements that contribute to efficient operation. Each unit comprises a variety of mechanisms that work in harmony to convert fuel into kinetic energy, enabling swift movement across water surfaces.

Understanding these elements allows for better care and upkeep, ultimately prolonging the lifespan of the equipment. Regular inspection and knowledge of how each segment interacts can prevent minor issues from escalating into major problems, ensuring that adventures on the water remain enjoyable and trouble-free.

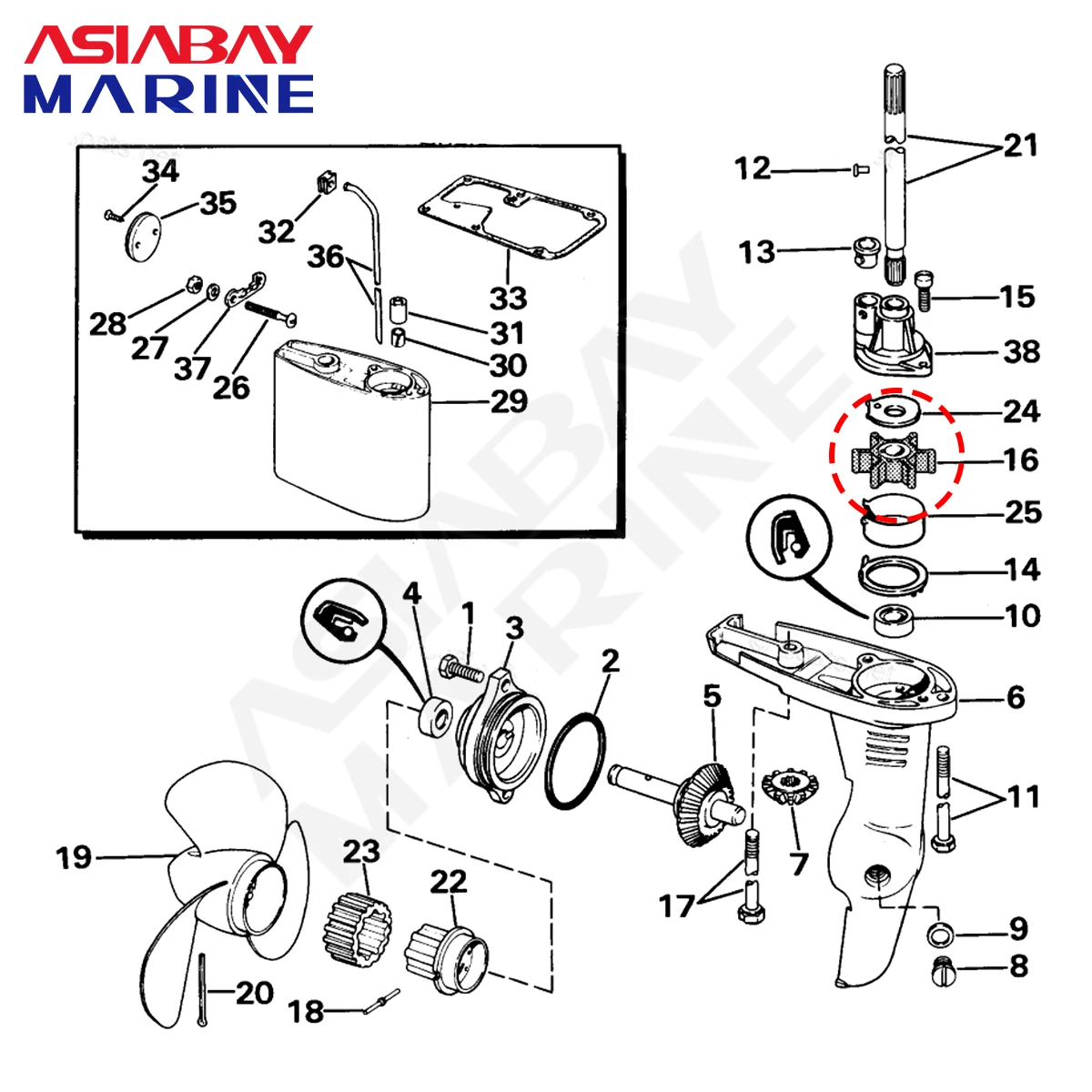

Components of Johnson Outboard Motors

This section explores the essential elements that contribute to the efficient functioning of marine propulsion systems. Understanding these components is crucial for maintenance and optimization, ensuring seamless operation on the water.

Key Elements

The primary constituents include the engine, fuel system, cooling mechanism, and transmission. Each of these plays a vital role in the overall performance and durability of the unit.

Table of Main Components

| Component | Description |

|---|---|

| Engine | Converts fuel into mechanical energy for propulsion. |

| Fuel System | Delivers fuel to the engine for optimal performance. |

| Cooling System | Regulates temperature to prevent overheating. |

| Transmission | Transfers power from the engine to the propeller. |

Importance of Motor Diagrams

Understanding the layout and functionality of various components is crucial for effective maintenance and repair. Visual representations provide clarity and streamline the process of troubleshooting, ensuring that users can quickly identify issues and implement solutions.

Facilitating Repairs

Illustrations serve as valuable references, guiding individuals through intricate assemblies. They enhance comprehension, allowing for a more efficient approach to restoring functionality.

Enhancing Learning

For those new to machinery, visual aids are indispensable. They transform complex information into manageable insights, fostering a deeper grasp of how different elements interact within the system.

Common Parts in Johnson Motors

Understanding the essential components of watercraft engines is crucial for maintenance and repair. These elements work together to ensure optimal performance and reliability. Familiarity with these crucial pieces can aid in troubleshooting and replacement efforts.

Key Components

Piston: This is a fundamental element that helps convert fuel into mechanical energy. Its movement drives the crankshaft, which ultimately powers the craft.

Crankshaft: Serving as the core of the engine’s operation, this piece transforms linear motion into rotational force, enabling the propulsion system to function effectively.

Supporting Elements

Fuel Pump: Vital for delivering the necessary fuel to the engine, this component ensures a consistent supply for optimal combustion.

Ignition System: This system ignites the fuel-air mixture, initiating the combustion process. It plays a pivotal role in the engine’s starting and overall performance.

How to Read Motor Diagrams

Understanding technical illustrations is essential for effective maintenance and repair. These visuals provide crucial insights into component relationships and operational mechanisms.

To interpret these illustrations effectively, follow these steps:

- Familiarize Yourself with Symbols:

- Identify common symbols used for different components.

- Refer to a legend if available, as it explains specific symbols.

- Analyze the Layout:

- Observe the overall structure to grasp how parts interact.

- Look for pathways indicating flow or connections.

- Follow the Sequence:

- Trace the order of operations as shown in the illustration.

- Note any cycles or repeated processes for clarity.

- Consult Additional Resources:

- Seek manuals or guides that complement the visual.

- Engage with online forums for insights from experienced users.

By mastering these techniques, you will delve into the intricacies of the mechanics and enhance your troubleshooting skills, leading to ultimate efficiency in repairs.

Locating Replacement Parts Easily

Finding suitable components for your watercraft can often feel daunting, but with the right approach, the process can be streamlined significantly. Understanding where to search and which resources to utilize is essential for ensuring that you acquire the correct items without unnecessary hassle.

Online Resources: The internet offers a wealth of information, including specialized websites dedicated to marine equipment. Utilizing these platforms can help you quickly identify the specific items you need. Look for forums, customer reviews, and user experiences that can guide you in making informed choices.

Local Suppliers: Visiting local dealers or retailers can provide immediate access to the essentials. Engaging with knowledgeable staff can also lead to helpful recommendations and insights into which alternatives may work best for your situation.

Manufacturer Manuals: Referencing documentation from the manufacturer can be invaluable. These manuals often contain detailed listings and schematics that clarify what is required, making it easier to identify compatible replacements.

Networking: Connecting with fellow enthusiasts or professionals in the field can open up new avenues for sourcing. Sharing experiences and recommendations can lead to discovering reliable vendors and quality items that may not be widely advertised.

By leveraging these strategies, you can enhance your efficiency in locating necessary components, ensuring your vessel remains in optimal condition for all your adventures.

Maintenance Tips for Outboard Motors

Regular upkeep is essential for ensuring optimal performance and longevity of your aquatic engine. Adopting a systematic approach to maintenance can prevent costly repairs and enhance reliability during your adventures on the water. By following a few key practices, you can keep your equipment running smoothly and efficiently.

Essential Maintenance Practices

Routine checks and servicing can make a significant difference. Consider implementing the following actions as part of your maintenance schedule:

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 100 hours or annually | Replace with fresh lubricant to ensure engine health. |

| Fuel System Inspection | Before each season | Check for clogs or contamination in lines and filters. |

| Battery Maintenance | Monthly | Inspect terminals and charge as needed. |

| Propeller Check | Before each outing | Look for damage and ensure it’s securely attached. |

Storage and Winterization Tips

Proper storage is crucial for preserving your equipment during off-seasons. Follow these tips to protect your engine:

- Drain the fuel system to avoid stale gas issues.

- Store in a dry, sheltered location to prevent rust and corrosion.

- Cover with a breathable material to keep dust and moisture out.

Identifying Common Issues

Understanding the typical challenges that can arise in aquatic propulsion systems is essential for effective maintenance and performance optimization. By recognizing these prevalent problems, users can ensure a smoother experience and prolong the lifespan of their equipment.

One frequent issue is inadequate power output, which may stem from various factors such as fuel quality or ignition system failures. Users should examine fuel lines and filters to ensure there are no blockages or leaks.

Another common concern is overheating, often caused by insufficient coolant flow or a malfunctioning cooling system. Regularly checking the intake for debris can help prevent this issue and maintain optimal operating temperatures.

Additionally, erratic operation or unusual noises can indicate underlying mechanical problems. Users are advised to conduct periodic inspections of moving components and ensure that they are properly lubricated.

By being vigilant and addressing these issues promptly, users can enhance the reliability and efficiency of their aquatic propulsion systems.

Tools Needed for Repairs

To effectively undertake maintenance and restoration tasks, having the right equipment is crucial. The selection of tools can greatly influence the efficiency and outcome of your repair efforts.

- Wrenches: Essential for loosening and tightening fasteners.

- Screwdrivers: Vital for various types of screws, providing versatility in handling components.

- Pliers: Useful for gripping, twisting, and cutting wires or other materials.

- Socket Set: Offers a range of sizes for optimal compatibility with nuts and bolts.

- Torque Wrench: Ensures precise tightening to manufacturer specifications.

Additional tools may include a multi-meter for electrical diagnostics, a clean-up kit for maintenance, and safety gear to protect yourself during repairs.

Where to Find Diagrams Online

Accessing visual guides for machinery components can greatly enhance repair and maintenance efforts. Numerous online resources cater to enthusiasts and professionals alike, offering detailed illustrations that simplify the understanding of assembly and functionality.

Specialized Websites

Several platforms specialize in technical resources, providing extensive libraries of visual references. These sites often feature searchable databases, allowing users to easily locate specific schematics related to their equipment.

Community Forums and Resources

Engaging with online communities can also yield valuable insights. Many forums include user-contributed content, where members share their own illustrations and repair experiences, creating a collaborative environment for knowledge exchange.

Exploring Aftermarket Part Options

When it comes to enhancing the performance and reliability of your aquatic vehicle, considering alternatives to original components can be a valuable strategy. Aftermarket offerings often provide cost-effective solutions, improved specifications, and unique features that may not be available from the original manufacturer. This section delves into the benefits and considerations associated with selecting these alternatives.

Benefits of Aftermarket Components

Opting for alternatives can lead to significant advantages, including:

| Advantage | Description |

|---|---|

| Cost Savings | Many alternatives are priced lower than OEM options, making maintenance more affordable. |

| Enhanced Performance | Some alternatives may offer improved durability or efficiency, enhancing overall performance. |

| Wider Selection | A greater variety of options allows for customization tailored to individual preferences. |

Considerations When Choosing Alternatives

While there are clear benefits, it’s crucial to assess a few factors before making a decision:

| Factor | Importance |

|---|---|

| Quality Assurance | Ensure that the alternatives meet industry standards for safety and performance. |

| Compatibility | Verify that the selected components fit seamlessly with your existing setup. |

| Warranty Considerations | Review warranty policies to understand any potential impacts on coverage. |

Safety Precautions for Motor Work

Engaging in mechanical tasks requires a strong commitment to safety to prevent accidents and injuries. Following essential guidelines can ensure a secure working environment, protecting both the technician and the equipment involved.

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and hearing protection.

- Ensure the workspace is well-ventilated to avoid inhaling harmful fumes.

- Disconnect power sources before starting any repair work to prevent accidental activation.

- Keep the work area organized and free from clutter to reduce the risk of tripping or accidents.

By implementing these safety measures, you can significantly minimize hazards while working on mechanical systems.