In the realm of agricultural machinery, the intricacies of its components play a vital role in ensuring optimal performance. Familiarizing oneself with these elements not only enhances functionality but also aids in effective maintenance.

By exploring the various segments of this essential machinery, users can gain insights into the structure and arrangement of its critical parts. This knowledge empowers operators to make informed decisions regarding repairs and enhancements.

Utilizing comprehensive visuals to illustrate these components serves as an invaluable resource. It enables individuals to grasp the ultimate configuration of machinery, fostering a deeper understanding of its operation and care.

Understanding New Holland 258 Rake

This section explores the mechanics and functionalities of a widely used agricultural tool, designed to efficiently gather and manage crop residues. Its robust construction and innovative design contribute to its effectiveness in various farming operations.

Key features include:

- Durable framework that withstands rigorous field conditions.

- Adjustable mechanisms for optimal performance across different terrains.

- Efficient gathering technology that minimizes crop loss.

To fully appreciate this implement, it is essential to understand its components and how they interact. The main elements consist of:

- Frame: Provides structural integrity and stability.

- Gathering Wheels: These rotate to collect and align material for easy transport.

- Adjustment Levers: Allow for customization of height and angle for varying crop types.

Overall, familiarity with this essential farming apparatus enhances operational efficiency and productivity in agricultural tasks.

Importance of Maintenance for Rakes

Regular upkeep is essential for ensuring optimal performance and longevity of agricultural equipment. Proper care not only enhances efficiency but also minimizes unexpected breakdowns, ultimately leading to better productivity during crucial farming seasons.

Benefits of Routine Care

- Prolongs the lifespan of equipment.

- Enhances operational efficiency.

- Reduces repair costs over time.

- Increases safety for operators and workers.

Key Maintenance Practices

- Regularly inspect components for wear and tear.

- Lubricate moving parts to prevent friction.

- Ensure proper adjustments to maintain functionality.

- Clean equipment after use to prevent debris buildup.

Consistent maintenance habits are crucial for optimal agricultural operations, fostering not only better yields but also a safer working environment.

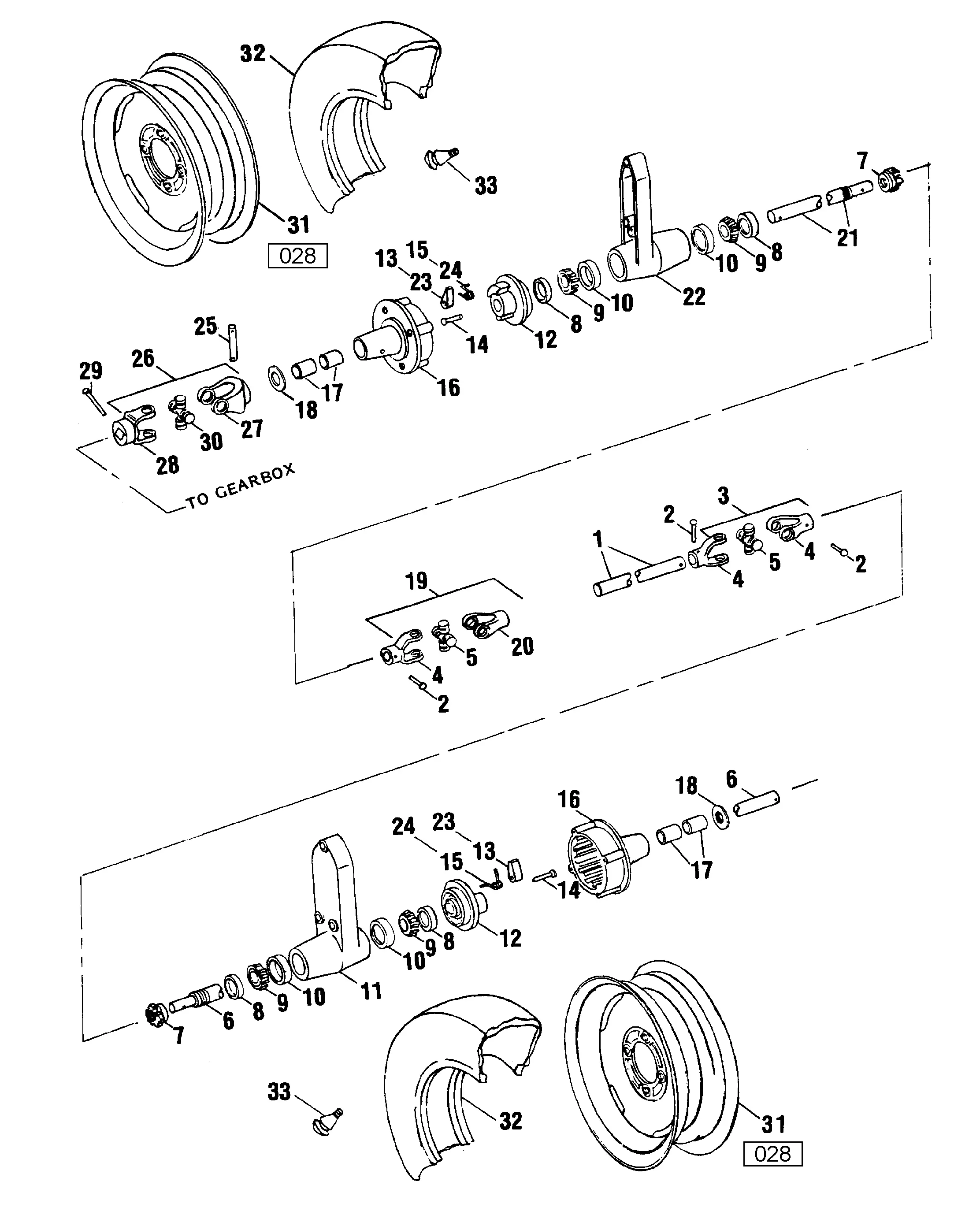

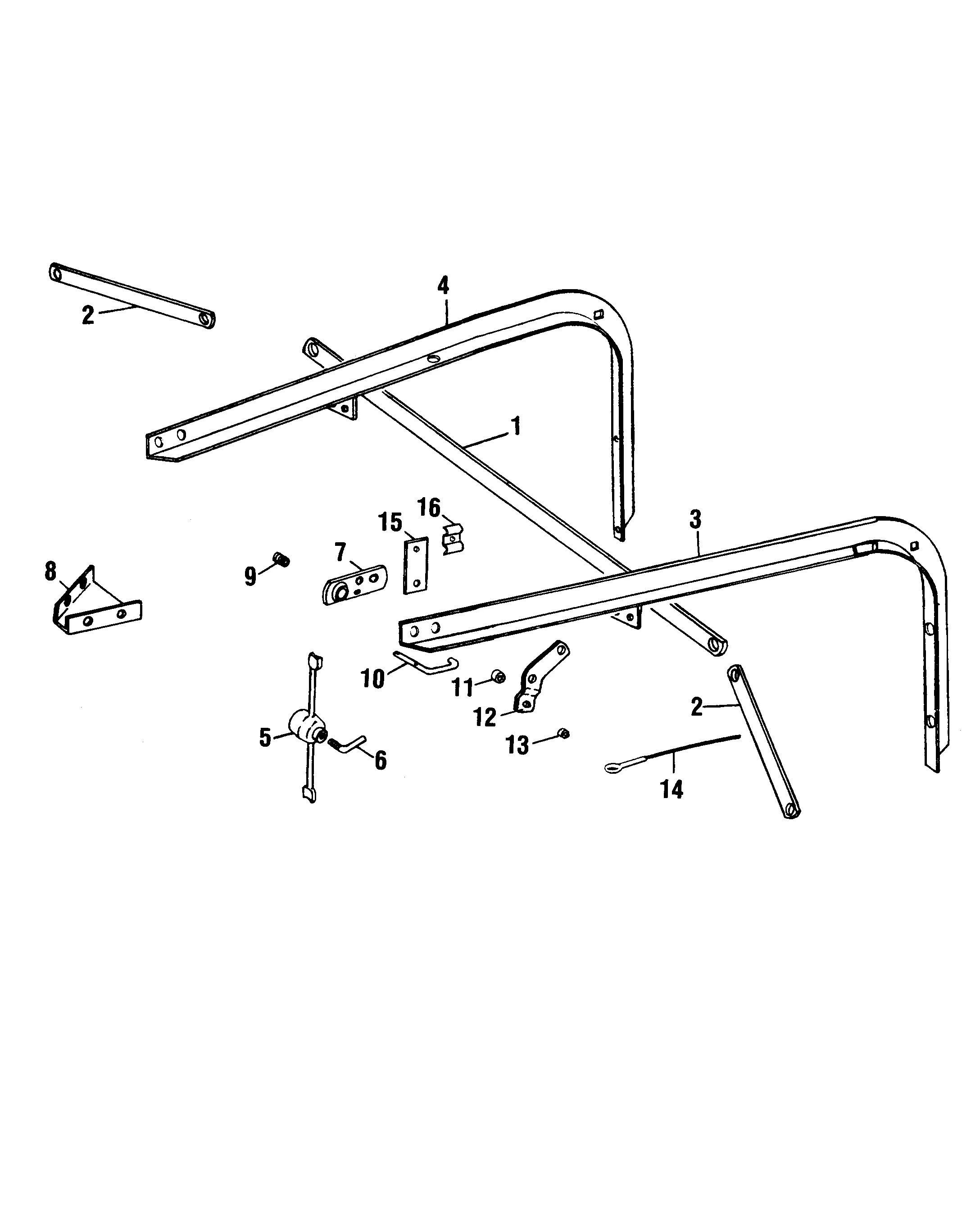

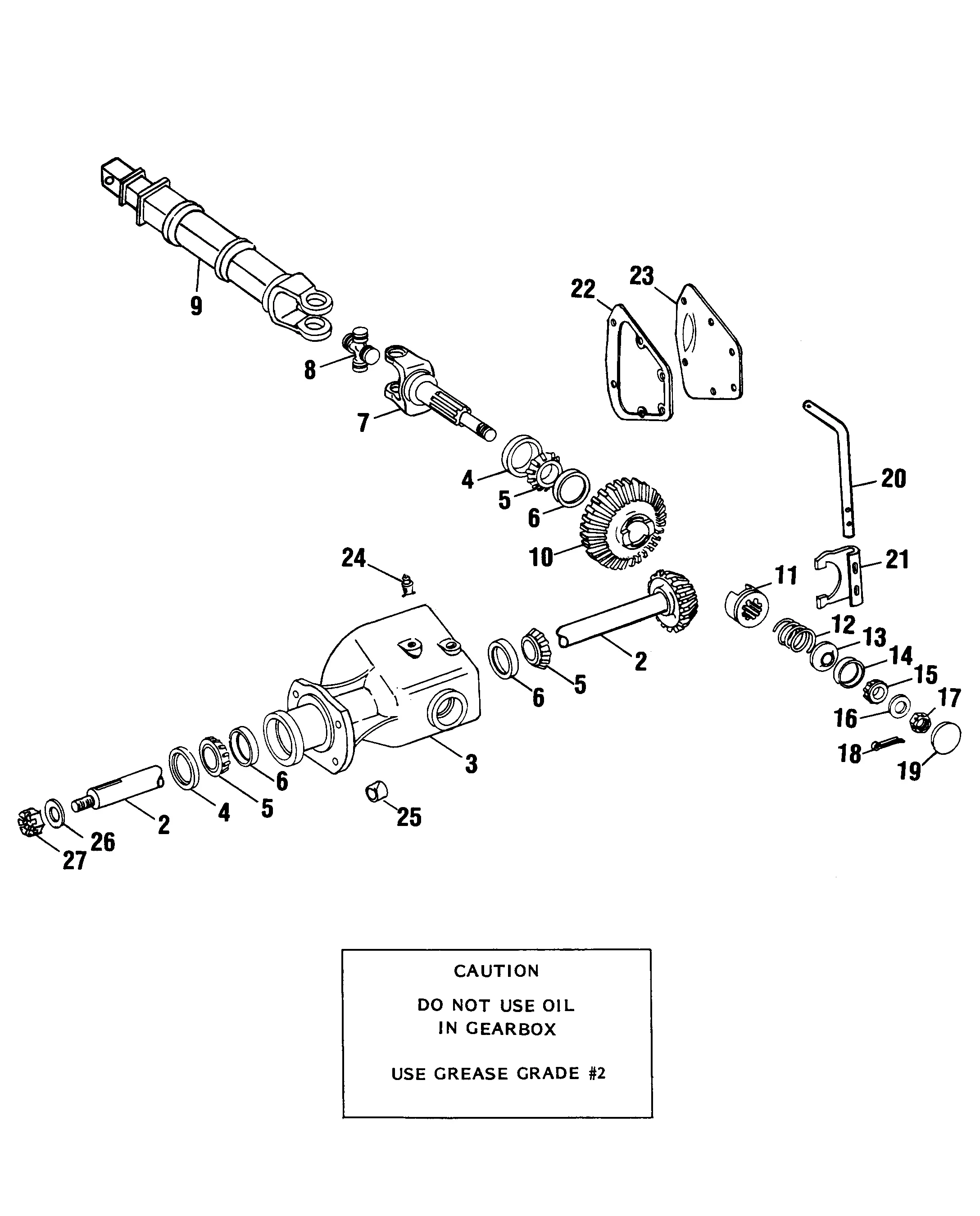

Key Components of the 258 Rake

This section provides an overview of essential elements that contribute to the functionality and efficiency of this agricultural implement. Understanding these components is vital for effective maintenance and optimal performance during use.

Essential Elements

The primary components include various mechanical parts that facilitate the gathering and handling of hay or similar materials. Each part plays a critical role in ensuring that the equipment operates smoothly and effectively, making it crucial for users to be familiar with their functions.

Functionality and Maintenance

Proper care and regular inspection of these components can significantly enhance the longevity of the implement. Familiarity with each part’s role will help in troubleshooting and repairs, ensuring that the equipment remains in peak condition.

| Component | Description |

|---|---|

| Frame | Provides structural support and stability during operation. |

| Tines | Curved metal pieces that collect and lift material from the ground. |

| Wheel Assembly | Enables mobility and maneuverability across fields. |

| Gearbox | Facilitates power transfer from the tractor to the implement. |

| Lift Mechanism | Controls the raising and lowering of the gathering system. |

Common Issues with Rake Parts

When maintaining agricultural machinery, mechanical components often face wear and tear due to regular use. Understanding common issues with these elements can help prevent breakdowns and extend the lifespan of the equipment. Timely identification of problems allows for efficient repairs, ensuring smooth operation during harvest season.

Wear and Tear on Mechanical Components

One of the most frequent problems involves the natural degradation of metal and moving parts. Over time, repeated friction can cause surfaces to wear down, leading to inefficiency. Regular lubrication and monitoring can help mitigate this issue.

Misalignment and Loose Fittings

Another common challenge is the misalignment of rotating or moving parts, which can occur due to vibrations during use. Loose bolts and connections may also contribute to malfunction. Periodic inspections are crucial for preventing these issues from escalating.

Finding Replacement Parts Efficiently

Efficiently locating spare components for any machinery can be a time-sensitive and essential task. Whether it’s for maintaining equipment or enhancing its performance, identifying the right components is crucial for minimizing downtime and ensuring smooth operations. Proper research and organization are key to streamlining this process.

Organizing Information

Start by gathering all available documentation and resources related to the specific model or equipment. This might include user manuals, maintenance guides, or product catalogs. A well-organized system for tracking these documents can save time and help quickly pinpoint the necessary parts.

Using Online Resources

The internet offers numerous platforms where parts can be sourced. Many manufacturers and third-party suppliers have comprehensive online databases where you can search by model number, serial code, or part description. These platforms often provide detailed breakdowns and lists that can help ensure compatibility.

- Check official manufacturer websites for verified parts lists.

- Explore online marketplaces for competitive pricing.

- Consult forums or expert communities for advice on replacements.

With careful preparation and the right tools, finding the necessary components can be straightforward, helping to keep your equipment in top working order.

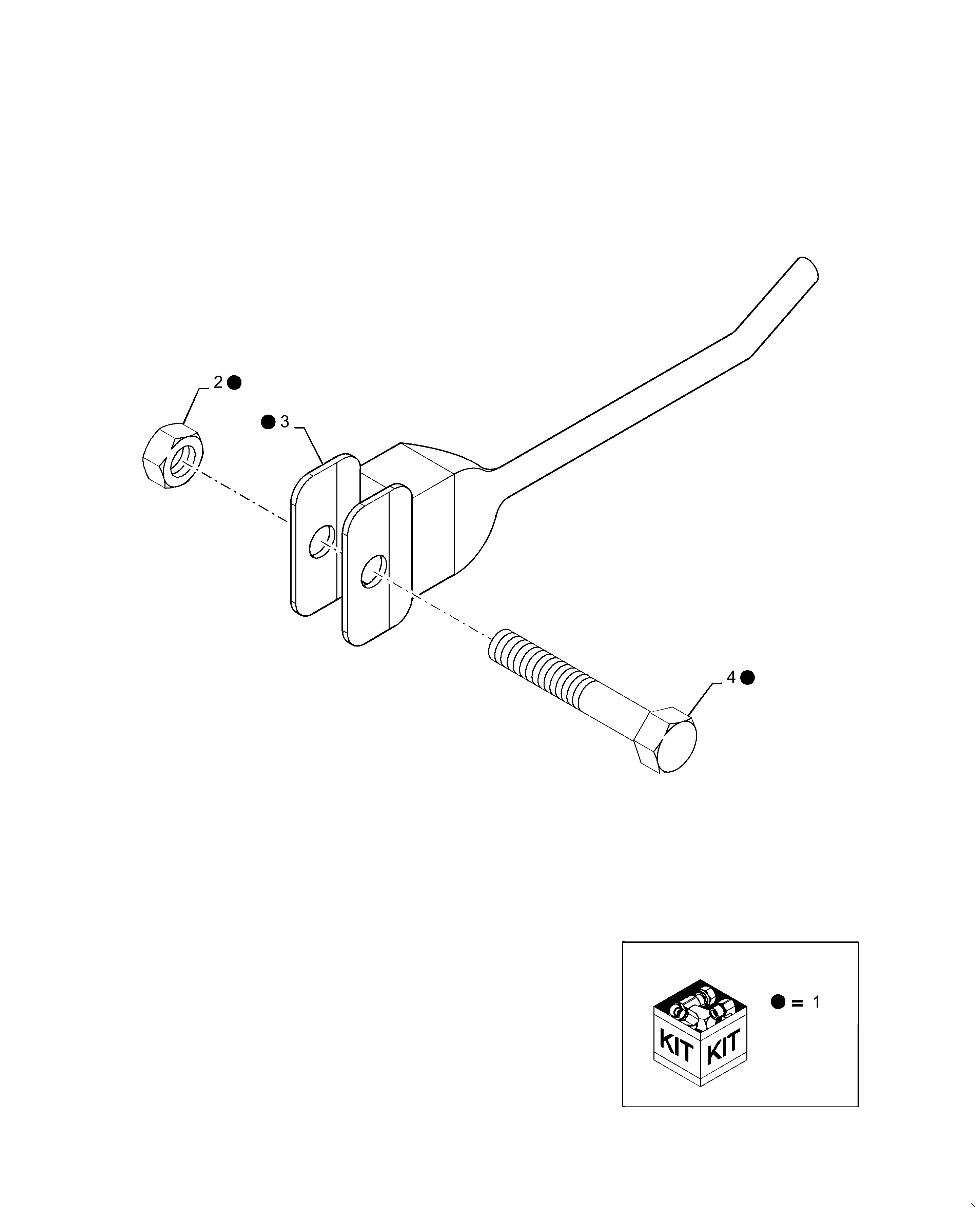

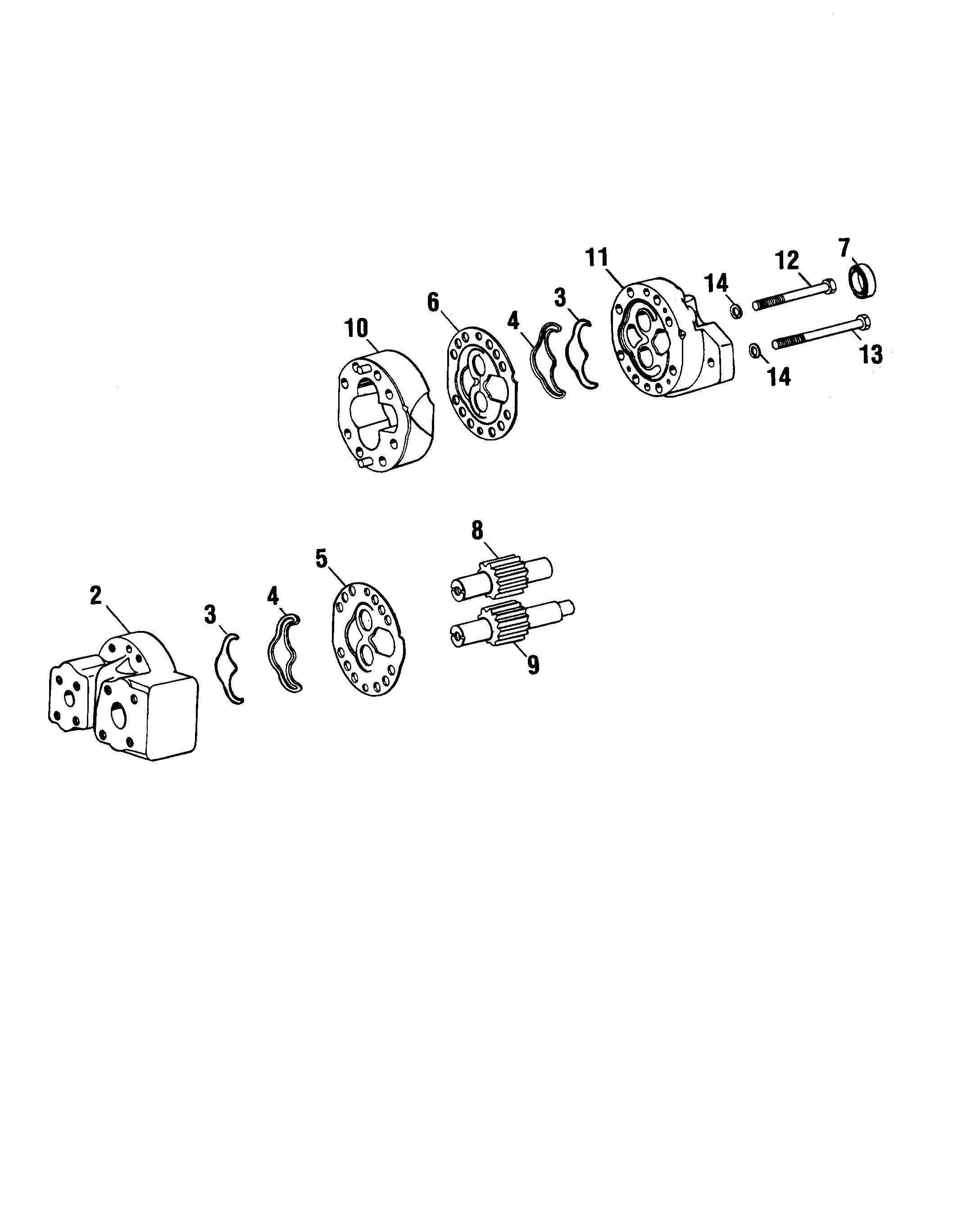

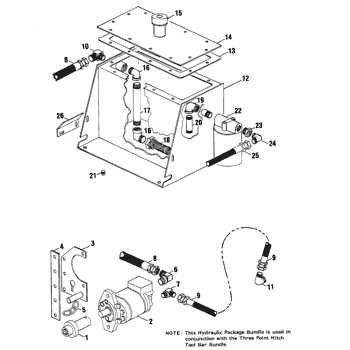

Diagram Interpretation for Rake Repairs

Understanding mechanical schematics is crucial for anyone involved in equipment maintenance. These visual guides help to identify components, their connections, and the overall structure of the machinery, allowing for efficient troubleshooting and repairs. The ability to interpret these diagrams accurately can significantly reduce downtime and improve the longevity of the equipment.

When reviewing a schematic, pay close attention to the labeling and positioning of each part. The diagram is typically divided into sections, with each component clearly marked to indicate its function and relationship to other elements. Having a clear grasp of these relationships ensures proper handling during repairs or replacements.

| Component | Description | Function |

|---|---|---|

| Gear Assembly | A set of interlocking gears | Responsible for transmitting motion |

| Spring Mechanism | A coil spring attached to the frame | Provides tension for smoother operation |

| Axle | The central shaft connecting the wheels | Ensures balanced movement during use |

Best Practices for Rake Assembly

Proper assembly of a field tool is crucial for ensuring optimal performance and long-term durability. Following correct steps during installation helps to prevent unnecessary wear and ensures the equipment functions efficiently in different conditions. In this section, we will discuss key practices that enhance the assembly process, focusing on component alignment, securing connections, and maintaining balance.

Ensuring Correct Component Alignment

When assembling your tool, it’s essential to make sure that all moving and fixed parts are aligned accurately. Misalignment can lead to uneven operation, which may cause mechanical issues over time. Before tightening any bolts, double-check that the elements are positioned according to the specifications, ensuring smooth motion and proper spacing between critical components.

- Check the position of all adjustable elements before finalizing the setup.

- Make sure to use a level or measuring tools to guarantee symmetry across moving parts.

- Avoid overtightening, as this can warp or misalign parts, causing unnecessary strain on the assembly.

Securing Connections and Fasteners

Fasteners play a pivotal role in holding the system together under load. It’s important to not only select the right hardware but also to follow the recommended tightening sequences and

Tools Needed for Rake Maintenance

Maintaining your equipment ensures longevity and optimal performance. To achieve this, having the right set of tools is crucial. Regular upkeep prevents wear and tear and minimizes the risk of more extensive damage.

Basic Hand Tools

For routine adjustments, basic hand tools such as wrenches, screwdrivers, and pliers are essential. These tools allow you to tighten loose parts and ensure everything is securely fastened.

Specialized Equipment

In addition to common tools, specialized equipment like grease guns for lubrication and torque wrenches for precise adjustments are important. Regular lubrication and correct torque settings help maintain smooth operation.

Enhancing Performance of Your Rake

Proper maintenance and thoughtful adjustments can significantly improve the efficiency and durability of your agricultural equipment. By focusing on key areas such as lubrication, alignment, and tension control, you can optimize functionality and reduce the risk of breakdowns during operation.

Regular Lubrication and Inspection

Keeping your equipment well-lubricated is essential for smooth operation and longevity. Regularly check all moving parts for signs of wear or rust, and apply the appropriate lubricants to minimize friction. This practice not only extends the life of the components but also ensures more consistent performance.

Adjusting Alignment and Tension

Ensuring that all mechanical elements are properly aligned can prevent uneven wear and improve overall efficiency. Periodically check the tension settings of critical components, making adjustments as necessary to maintain optimal operation. Overly tight or loose settings can affect functionality and lead to premature wear, so finding the right balance is key to maintaining performance.

Cost-Effective Solutions for Part Replacement

When maintaining agricultural equipment, finding affordable alternatives for component replacement can greatly reduce operational costs. Regular wear and tear can affect the efficiency of machinery, but identifying budget-friendly options for essential parts can ensure smooth operation without compromising quality. It is crucial to evaluate both original and aftermarket options, as well as to consider the availability of refurbished components.

Aftermarket alternatives provide a viable solution for many machines, offering comparable quality at lower prices. These components are typically designed to meet the specifications of the original, ensuring compatibility and reliability.

Another approach is to source refurbished or reconditioned parts, which can be a more economical option without sacrificing performance. These parts are inspected and restored to optimal condition, making them a cost-effective choice for those looking to extend the life of their equipment.

By carefully considering these solutions, operators can minimize downtime and expenses, keeping machinery running efficiently while staying within budget.

Resources for New Holland Rake Owners

Finding the right tools and guides for your equipment is essential to ensure smooth operation and efficient performance. There are numerous sources available that provide detailed information on maintenance, repair, and enhancements for your farming machinery. These resources can assist in identifying components, understanding assembly processes, and finding solutions to common issues.

| Resource Type | Description |

|---|---|

| Owner Manuals | Comprehensive guides covering the basic use, safety instructions, and troubleshooting steps for your machine. |

| Spare Parts Catalogs | These catalogs help identify necessary components for repairs and replacements, ensuring compatibility with your machinery model. |

| Online Forums | Communities of users and experts where you can exchange tips, ask questions, and get advice on specific issues. |

| Video Tutorials | Step-by-step visual guides to assist with hands-on repairs, adjustments, and improvements. |