Every floating craft possesses a unique configuration that plays a crucial role in its performance and stability on the water. This section delves into the various components that make up the foundational structure of these vessels, exploring how each element contributes to the overall functionality and efficiency.

From the underside to the framework, each segment is designed with precision to withstand the forces of nature. By comprehending the significance of these essential features, one can gain insight into the engineering marvels that enable safe and effective navigation across diverse aquatic environments.

Through a closer examination of the various segments, enthusiasts and professionals alike can appreciate the intricate craftsmanship involved in crafting a reliable and robust maritime vehicle. This knowledge not only enhances one’s understanding but also fosters a deeper respect for the art of maritime engineering.

The structure beneath the waterline is crucial for the overall performance and stability of a vessel. A comprehensive understanding of this framework helps enthusiasts and operators appreciate how various elements interact to ensure efficiency and safety. Each component contributes to buoyancy, maneuverability, and the longevity of the craft.

Key Elements of the Underwater Structure

Among the essential features of this submerged framework are those that support and protect the integrity of the entire vessel. Their design and positioning significantly influence navigation and operational capabilities.

Functionality and Importance

Understanding the role of each component enhances one’s ability to maintain and optimize performance. These features must be carefully considered during the design and construction phases, impacting everything from speed to handling in different conditions.

| Element | Description | Function |

|---|---|---|

| Keel | The central structural element that extends downward. | Provides stability and reduces sideways motion. |

| Rudder | A flat piece used to steer the vessel. | Controls direction and maneuverability. |

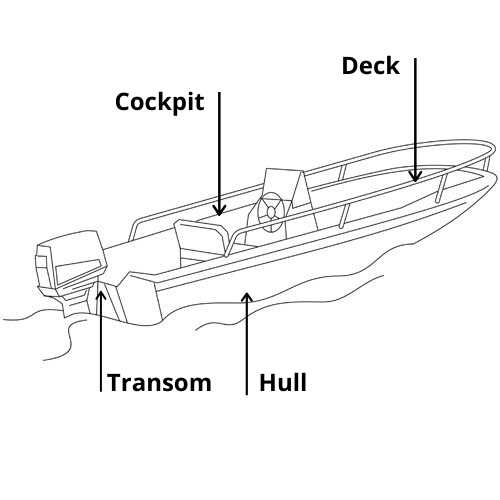

| Transom | The flat surface at the rear of the craft. | Supports the engine and helps in water displacement. |

| Bilge | The lowest part of the interior where water collects. | Facilitates drainage and prevents flooding. |

Overview of Boat Hull Types

This section provides insights into the various designs of watercraft bottoms, which play a crucial role in performance and stability on the water. Understanding these configurations is essential for selecting the right model for specific activities or conditions.

Common Designs

- Displacement: These structures are characterized by their ability to move through the water efficiently, ideal for cruising and long-distance travel.

- Planing: This type allows the vessel to rise above the water’s surface at high speeds, providing a smooth and fast ride, often used in sports and leisure activities.

- Catamaran: Featuring two parallel hulls, this design enhances stability and space, making it popular for recreational purposes.

Factors to Consider

- Purpose: The intended use of the vessel, such as fishing, racing, or leisure activities, influences the choice of design.

- Water Conditions: The type of water, whether calm or turbulent, can determine the most suitable configuration.

- Capacity: Assessing the required passenger and cargo space is vital for ensuring comfort and functionality.

Key Components of Hull Design

The structure and configuration of a marine vessel play a crucial role in its performance and stability. Understanding the fundamental elements that contribute to effective design can greatly enhance both functionality and safety on the water.

Essential Elements

- Shape: The contour significantly influences hydrodynamics and maneuverability.

- Material: Choices like fiberglass, aluminum, or wood affect durability and weight.

- Weight Distribution: Proper balance is vital for stability and performance.

- Transom: This rear section is critical for propulsion and water flow management.

- Keel: This structural feature provides stability and helps resist lateral forces.

Design Considerations

- Assessing intended use, such as leisure, fishing, or racing.

- Evaluating environmental conditions in which the vessel will operate.

- Incorporating safety features to prevent capsizing and enhance buoyancy.

- Optimizing for speed while maintaining control and comfort.

Functionality of the Hull Structure

The fundamental design of a vessel’s outer shell plays a crucial role in its overall performance and safety. This framework not only provides stability and buoyancy but also enhances maneuverability in various water conditions.

Key aspects of this structure include:

- Buoyancy: The framework ensures that the craft remains afloat by displacing an adequate amount of water.

- Stability: An efficient design minimizes tilting and enhances balance during movement.

- Hydrodynamics: A streamlined shape reduces resistance, allowing for smoother navigation through water.

- Durability: Constructed from resilient materials, it withstands harsh marine environments and impacts.

- Space Utilization: The structure often allows for the integration of various compartments for storage and equipment.

Each of these elements contributes significantly to the overall effectiveness of the vessel in achieving its intended purpose.

Materials Used in Hull Construction

The choice of materials for constructing the structure of a vessel is crucial to its performance and longevity. Various substances are utilized, each offering distinct advantages and characteristics. Understanding these options allows for informed decisions tailored to specific requirements, such as durability, weight, and environmental resistance.

| Material | Characteristics | Advantages |

|---|---|---|

| Fiberglass | Lightweight, corrosion-resistant, and strong | Low maintenance, affordable, and versatile |

| Aluminum | Strong, lightweight, and resistant to corrosion | Durable, easy to repair, and recyclable |

| Wood | Aesthetic appeal, good insulation properties | Natural look, strong when properly maintained |

| Steel | Heavy, very strong, and durable | Resistant to impact, ideal for larger vessels |

| Composites | Combines various materials for enhanced properties | Customizable, lightweight, and strong |

Importance of Hull Shape

The configuration of a vessel’s exterior plays a crucial role in its overall performance and efficiency. The design influences various factors, including speed, stability, and maneuverability, which are essential for effective navigation across different water conditions.

A well-thought-out form can enhance hydrodynamics, reducing drag and allowing for smoother movement through waves. Streamlined profiles facilitate faster travel, while broader sections contribute to stability, especially in turbulent environments. Moreover, the shape affects how a craft interacts with the elements, providing resilience against harsh weather and ensuring safety for those on board.

Ultimately, the significance of an optimized design extends beyond mere aesthetics; it is fundamental to achieving superior performance and a satisfying experience on the water. Understanding the implications of design choices is essential for anyone involved in crafting or selecting a vessel.

Common Hull Accessories and Additions

Enhancing the functionality and efficiency of marine vessels often involves integrating various supplementary elements. These additions can significantly improve performance, safety, and comfort, catering to the diverse needs of enthusiasts and professionals alike.

Essential Additions

Numerous accessories play a crucial role in optimizing the experience on the water. These components not only contribute to the overall aesthetic but also enhance the vessel’s capabilities. Here are some commonly utilized items:

| Accessory | Purpose |

|---|---|

| Anchor | Stabilizes the vessel in place during rest. |

| Fenders | Protects the sides from damage during docking. |

| Cleats | Secures lines for mooring and docking. |

| Navigation Lights | Ensures visibility and safety during nighttime navigation. |

| Bimini Top | Provides shade and protection from sun exposure. |

Advanced Features

For those seeking to elevate their maritime experience, more advanced options are available. These enhancements can contribute to both comfort and efficiency, making outings more enjoyable. Some notable additions include:

| Feature | Benefit |

|---|---|

| Livewell | Keeps bait or catch alive for extended periods. |

| Sound System | Enhances enjoyment during leisure activities on the water. |

| Swim Platform | Facilitates easy access to and from the water. |

| Solar Panels | Provides renewable energy for onboard systems. |

| Fish Finder | Assists in locating fish for a successful outing. |

Hull Maintenance and Repair Tips

Regular upkeep and timely restoration are essential for ensuring the longevity and performance of your watercraft. Proper care not only enhances the aesthetic appeal but also guarantees safety during navigation. Implementing a systematic approach to maintenance can prevent minor issues from escalating into significant problems.

Inspect for Damage: Periodically examine the exterior for any signs of wear or deterioration. Look for cracks, blisters, or any irregularities that could compromise the integrity of the structure.

Clean and Protect: Keeping the surface clean from debris and marine growth is crucial. Utilize appropriate cleaning agents and tools to avoid damaging the finish. Applying a protective coating can also safeguard against harsh elements.

Repair Promptly: Address any identified issues immediately. Delaying repairs can lead to further damage, which may require more extensive and costly interventions in the future.

Check Fastenings: Regularly inspect and tighten all fittings, screws, and joints to ensure everything remains secure. This practice helps maintain the overall stability and reliability.

Consult Professionals: For complex repairs or maintenance tasks, consider seeking the expertise of professionals. Their knowledge and experience can provide valuable insights and ensure that all work is performed to a high standard.

Impact of Hull on Performance

The structure beneath the waterline plays a crucial role in determining how efficiently a vessel moves through different aquatic environments. Its design significantly influences various factors such as speed, stability, and maneuverability. Understanding the interplay between the shape and materials used in construction can provide insights into optimizing overall performance.

Different configurations affect resistance faced while navigating, influencing fuel consumption and speed capabilities. A streamlined profile reduces drag, allowing for smoother transitions through the water, while a broader base enhances stability during rough conditions. Moreover, the choice of materials contributes to weight distribution, which can either improve or hinder handling characteristics.

In summary, the foundational design elements fundamentally impact operational efficiency. A well-engineered structure enhances not only the speed but also the safety and comfort of occupants. Continuous advancements in materials and design methodologies promise further improvements in performance metrics.

Safety Features in Hull Design

The structure of any watercraft plays a crucial role in ensuring the safety of its occupants. A well-thought-out design enhances stability, durability, and resilience against various maritime challenges. Innovative engineering approaches contribute to minimizing risks and maximizing protection during navigation.

One key aspect of safety in the design of vessels is the incorporation of floatation systems. These systems help maintain buoyancy, preventing capsizing in adverse conditions. Additionally, the use of high-quality materials ensures that the exterior can withstand impacts, reducing the likelihood of structural failure.

Another important feature is the configuration of the underwater section. A streamlined shape allows for smoother movement through water, reducing drag and enhancing maneuverability. This design choice not only improves efficiency but also helps in navigating challenging environments more safely.

Furthermore, integrated safety measures such as reinforced edges and safety rails contribute to the overall security of the vessel. These elements provide extra protection for passengers and crew, significantly lowering the risk of accidents during boarding and disembarkation.

Evolution of Hull Designs Over Time

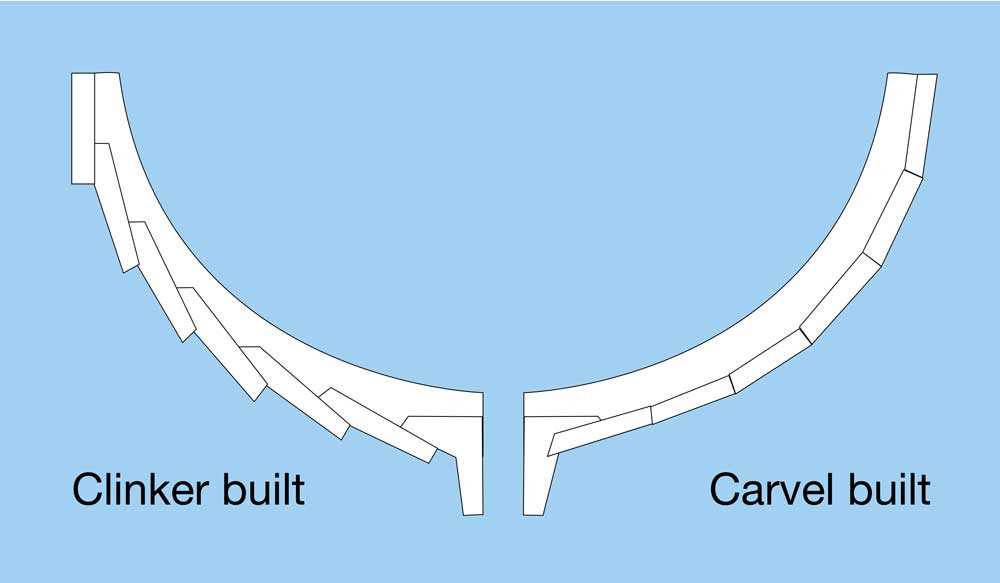

The development of watercraft structures has undergone significant transformation throughout history, reflecting changes in technology, materials, and the demands of navigation. Early vessels were often simple, utilitarian forms, designed primarily for functionality. As societies advanced, so too did the intricacies of their floating constructions, leading to innovations that enhanced performance, stability, and aesthetic appeal.

In ancient times, primitive designs utilized readily available materials, such as wood and reeds, resulting in craft that were both lightweight and versatile. With the advent of metalworking, stronger and more durable structures emerged, allowing for larger vessels capable of carrying greater loads. During the Age of Exploration, the need for improved seaworthiness spurred advancements in design, such as the incorporation of a deeper keel for better stability and navigation in rough waters.

As industrialization progressed, the introduction of steam power and iron construction further revolutionized floating vehicle designs. The focus shifted towards efficiency and speed, leading to the creation of sleek, streamlined forms. Modern engineering techniques have now enabled the use of advanced materials like fiberglass and carbon fiber, resulting in lighter and more robust vessels that can adapt to various water conditions.

Today, the evolution of watercraft shapes continues, with an emphasis on sustainability and innovation. Designers now explore eco-friendly options while maintaining high performance, illustrating a commitment to harmonizing tradition with contemporary demands.

Innovations in Hull Technology

Advancements in marine design have revolutionized the structure that supports vessels, enhancing performance and durability. These innovations reflect a commitment to improving safety, efficiency, and environmental sustainability in watercraft engineering.

- Composite Materials: The introduction of lightweight composite substances has significantly reduced overall weight, improving speed and fuel efficiency.

- Hydrodynamic Shapes: New forms have been developed to minimize water resistance, allowing for smoother navigation and better handling in various conditions.

- Self-Repairing Coatings: Innovative coatings that can autonomously repair small abrasions have been designed, prolonging the lifespan of the structure and reducing maintenance costs.

- Eco-Friendly Solutions: The use of sustainable materials and processes is becoming more prevalent, aimed at reducing the ecological impact of marine activities.

- Advanced Manufacturing Techniques: Techniques such as 3D printing allow for customized designs, enhancing the versatility and adaptability of the marine framework.

These developments not only enhance performance but also pave the way for a more sustainable future in maritime operations. As technology continues to evolve, the maritime industry is likely to witness even more groundbreaking changes in the structures that define modern vessels.

Environmental Considerations for Hulls

When designing and constructing the lower structure of watercraft, it is essential to prioritize ecological sustainability. The materials and methods employed in production can significantly impact marine ecosystems and overall water quality. Understanding these effects helps in choosing eco-friendly options that minimize environmental harm.

One of the key aspects to consider is the choice of materials. Traditional substances can leach harmful chemicals into the water, adversely affecting aquatic life. Opting for sustainable alternatives can reduce these negative effects. Moreover, the manufacturing process itself should be evaluated for its carbon footprint and waste generation.

| Material | Environmental Impact | Sustainable Alternatives |

|---|---|---|

| Fiberglass | Leaches toxins | Bamboo composites |

| Aluminum | Energy-intensive production | Recycled aluminum |

| Wood | Deforestation concerns | Sustainable timber |

Additionally, maintenance practices play a vital role in reducing environmental impact. Regular inspections and timely repairs can prolong the lifespan of the structure, thereby minimizing the need for replacements. Implementing non-toxic cleaning solutions also contributes to preserving water quality.