For enthusiasts and professionals alike, the intricate mechanisms behind brewing appliances can often be both fascinating and overwhelming. A comprehensive overview of these devices can enhance your appreciation and operational skills. This section aims to illuminate the essential components that contribute to the optimal functioning of your coffee-making system.

Exploring the intricate layout of your equipment not only aids in maintenance but also allows for troubleshooting and upgrades. By grasping the relationship between various elements, you can ensure that every cup brewed meets your ultimate expectations.

Whether you’re a seasoned barista or a casual coffee drinker, having a clear understanding of your device’s internal framework is invaluable. This knowledge empowers you to delve deeper into the art of brewing, ultimately enhancing your overall experience.

Understanding Bunn BX-B Components

The functionality of a coffee maker relies heavily on its various elements, each playing a crucial role in the brewing process. Recognizing these components can enhance your experience and enable effective maintenance, ensuring your machine operates at peak performance.

Key Elements: The primary components include the water reservoir, heating element, and brew basket. The reservoir stores the water needed for brewing, while the heating element is responsible for bringing the water to the optimal temperature. The brew basket holds the coffee grounds and allows for the extraction of flavor during the brewing cycle.

Maintenance and Care: Understanding the layout of these elements is essential for troubleshooting and maintenance. Regular cleaning and proper handling can prevent issues such as clogs or malfunctions, prolonging the life of your machine and ensuring a consistently rich cup of coffee.

In summary, familiarizing yourself with the integral components of your coffee maker will not only improve your brewing experience but also empower you to perform basic maintenance with confidence.

Key Features of Bunn BX-B Model

This exceptional brewing device is designed to enhance the coffee-making experience, providing efficiency and quality in every cup. Its innovative features cater to both casual users and coffee enthusiasts, ensuring a reliable performance with each brew.

One standout characteristic is its rapid brewing capability, allowing users to enjoy freshly brewed coffee in a fraction of the time compared to traditional methods. The built-in heating element maintains optimal water temperature, ensuring that every brew extracts the full flavor profile of the coffee grounds.

The user-friendly interface simplifies the brewing process, making it accessible to everyone. With precise measurements and customizable settings, users can easily adjust brewing strength to suit their preferences. Additionally, the durable construction promises longevity, making it a worthwhile investment for any coffee lover.

Another notable aspect is the large capacity, which allows for multiple servings in a single cycle, perfect for gatherings or busy mornings. The sleek design adds an aesthetic appeal to any kitchen, combining functionality with style.

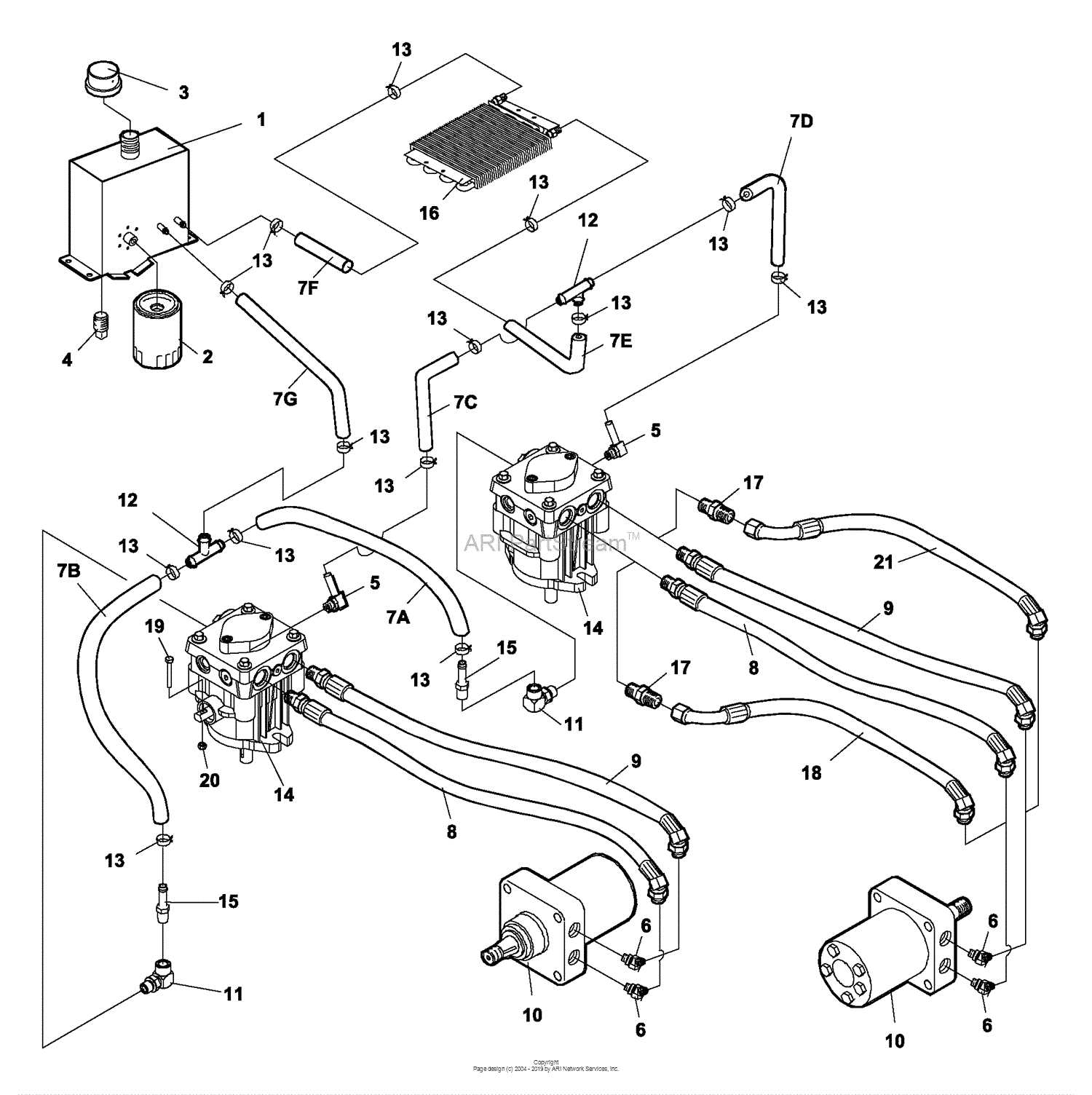

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the intricacies of machinery and equipment. These illustrations serve as essential tools for both technicians and users, offering clarity on the arrangement and functionality of various elements. By breaking down complex systems into manageable sections, they facilitate maintenance, repairs, and overall comprehension of how devices operate.

Enhancing Understanding

Clear visual guides help individuals quickly identify specific components and their interactions within a system. This not only aids in troubleshooting but also fosters a deeper grasp of the machinery’s overall design. When users can easily locate and comprehend each part, they are more equipped to address issues effectively, ensuring smoother operation.

Streamlining Maintenance

Accurate visual representations contribute significantly to efficient upkeep. Technicians can refer to these guides to determine what is needed for repairs or replacements, reducing downtime and improving productivity. With a clear view of how each element fits together, maintenance tasks become less daunting, allowing for quicker resolutions and extending the lifespan of the equipment.

How to Read Bunn BX-B Diagram

Understanding technical illustrations can seem daunting, but breaking down the components into manageable parts makes the process more approachable. These visual representations serve as guides, showcasing the relationships and functionalities of various elements within a system. By familiarizing yourself with the layout and symbols used, you can effectively navigate the information presented.

Begin by identifying the key sections, often labeled for clarity. Each area will typically highlight specific features or assemblies, making it easier to locate what you need. Pay attention to the legends or notes that provide additional context; they often explain the function of each element. This foundational knowledge allows you to delve deeper into the complexities of the system.

As you explore further, take note of any interconnected parts. Arrows or lines may indicate how components interact or where they are positioned within the overall assembly. This insight is crucial for troubleshooting or replacement tasks, as it reveals the ultimate path of operation and assembly.

Lastly, practice makes perfect. The more you engage with these visual resources, the more intuitive they become. Over time, you’ll build confidence in interpreting the information, enabling you to address issues or perform maintenance efficiently.

Common Issues with Bunn BX-B Parts

Every brewing machine can encounter specific challenges over time, impacting performance and user experience. Understanding these prevalent problems helps users maintain optimal functionality and enhance longevity. From minor glitches to more significant malfunctions, recognizing these issues can lead to timely resolutions.

Frequent Malfunctions

Several typical complications arise, often stemming from wear and tear or improper usage. Addressing these matters promptly can prevent further damage and ensure consistent brewing quality.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Leakage | Worn seals, loose connections | Check seals, tighten connections |

| Inconsistent Temperature | Faulty thermostat, mineral buildup | Calibrate thermostat, descale regularly |

| Delayed Brewing | Clogged filters, insufficient water | Clean filters, ensure proper water levels |

Maintenance Tips

Regular maintenance is crucial in preventing these common challenges. Routine checks and prompt interventions will enhance the machine’s reliability and overall performance.

Where to Find Replacement Parts

Locating components for your brewing equipment can be a straightforward process if you know where to look. Various sources cater to the needs of enthusiasts and professionals alike, ensuring that you can maintain optimal performance in your machines. Here are some reliable avenues to explore when seeking out necessary items.

| Source | Description |

|---|---|

| Manufacturer’s Website | The official site often has a dedicated section for accessories and components, providing authentic options directly from the source. |

| Online Retailers | Popular e-commerce platforms frequently stock a wide variety of equipment essentials, allowing for easy comparison of prices and availability. |

| Local Supply Stores | Brick-and-mortar establishments may carry key items or can order them for you, providing a personal touch to your shopping experience. |

| Specialty Forums | Online communities focused on brewing often share leads on where to find rare or hard-to-get components, including recommendations from experienced users. |

| Second-Hand Marketplaces | Websites dedicated to used goods can offer great deals on gently used components, allowing you to save money while obtaining what you need. |

Step-by-Step Maintenance Tips

Regular upkeep of your brewing equipment ensures optimal performance and longevity. By following a systematic approach, you can prevent common issues and enhance the quality of your beverages.

Daily Maintenance

- Clean the brewing components to remove any residue.

- Check water levels and refill as necessary.

- Inspect the power supply and connections for safety.

Weekly Maintenance

- Descale the machine to prevent mineral buildup.

- Examine seals and gaskets for wear and replace if needed.

- Test functionality of all buttons and controls.

Upgrading Bunn BX-B Components

Enhancing the efficiency and functionality of your coffee brewing equipment can significantly improve the overall experience. By focusing on specific elements within the system, users can achieve better performance, increased durability, and a more satisfying final product. This section will explore various options for upgrading key components, ensuring that your setup operates at its best.

Key Components for Enhancement

When considering upgrades, it’s essential to identify which elements can benefit from modernization. Below are some critical areas to focus on:

| Component | Upgrade Options | Benefits |

|---|---|---|

| Heating Element | High-efficiency units | Faster heating times, energy savings |

| Water Reservoir | Larger capacity models | Less frequent refilling, consistent brewing |

| Filter Basket | Stainless steel alternatives | Durability, improved flavor extraction |

| Control Module | Digital interface upgrades | Enhanced precision, programmable settings |

Installation Considerations

Proper installation is crucial for maximizing the benefits of any upgrades. Ensure compatibility with existing equipment and follow manufacturer guidelines closely. Additionally, consulting a professional can help avoid potential issues and guarantee optimal performance from your enhanced setup.

Comparing Bunn Models and Diagrams

When exploring various models of commercial brewing equipment, understanding the unique configurations and components is essential. Each version has specific features that cater to different brewing preferences and operational needs. By analyzing these variations, users can identify which design aligns best with their requirements.

Key Differences in Design

Models vary significantly in their structure and functionality. Some are tailored for high-volume settings, while others focus on efficiency and ease of use. Examining these distinctions allows for a more informed selection process, ensuring optimal performance in any environment.

Benefits of Visual References

Utilizing visual references enhances comprehension of each model’s intricacies. Diagrams serve as valuable tools for identifying components and understanding assembly or maintenance procedures. This visual approach ultimately aids in maximizing the lifespan and efficiency of the equipment.

Frequently Asked Questions About Parts

This section aims to address common inquiries regarding components and their functionality. Whether you are seeking replacement items or simply looking to enhance your knowledge, the following questions and answers will provide clarity on various aspects related to these essential elements.

What should I consider when replacing components?

When looking to replace any item, it is crucial to ensure compatibility with your existing setup. Check for specifications such as size, type, and performance ratings. Additionally, consider the quality of materials, as durable options can significantly enhance the longevity and efficiency of your equipment.

How can I maintain the longevity of my equipment?

Regular maintenance is key to prolonging the life of your machinery. Cleaning components regularly, avoiding overuse, and promptly addressing any signs of wear will contribute to optimal performance. It’s also beneficial to consult the manufacturer’s guidelines for specific care instructions.

Customer Reviews and Experiences

This section highlights the insights and feedback from users who have interacted with a specific beverage-making machine. Their experiences provide valuable perspectives on performance, usability, and overall satisfaction.

Many customers appreciate the machine’s efficiency and brewing quality, noting the following points:

- Consistency in brewing temperature and flavor.

- Ease of use and intuitive controls.

- Durability and long-lasting components.

However, some users have encountered challenges:

- Initial setup can be somewhat complex.

- Cleaning and maintenance require attention to detail.

- Occasional issues with specific accessories not functioning as expected.

Overall, customer feedback reflects a mix of appreciation for quality alongside some areas for improvement, ultimately guiding potential buyers in their decision-making process.