The world of marine elevation systems is vast, comprising various elements that work in harmony to ensure seamless functionality. Whether for recreational or commercial use, a comprehensive understanding of these systems is vital for optimal performance and maintenance. This section aims to delve into the intricacies of these essential mechanisms, offering insights into their design and operational principles.

Every aspect of these elevation systems plays a crucial role in their effectiveness and longevity. From the mechanical structures that support movement to the intricate control mechanisms that regulate operation, recognizing each component’s function can significantly enhance user experience. By breaking down the individual elements, one can better appreciate the engineering marvels that facilitate watercraft management.

In the following sections, we will explore the specific elements involved in these systems, highlighting their interconnections and the importance of proper maintenance. This knowledge not only fosters a deeper appreciation for the technology but also empowers users to make informed decisions regarding repairs and upgrades, ultimately leading to improved reliability and efficiency.

Understanding Shorestation Boat Lift Systems

Effective aquatic platforms are essential for maintaining and enhancing watercraft safety and accessibility. This section explores the critical components and operational principles behind these systems, emphasizing their importance for preserving vehicles from water damage and facilitating ease of use.

At the core of these systems lies a combination of mechanical and hydraulic elements that work together to raise and lower the vessels seamlessly. Users can benefit from knowing the key functions and interactions of these components, ensuring a smoother experience when managing their marine vehicles.

| Component | Description |

|---|---|

| Frame | The structural backbone providing stability and support. |

| Hoisting Mechanism | A device designed to elevate and lower the marine vehicle efficiently. |

| Pulleys | Wheels that guide the ropes or cables, reducing friction during operation. |

| Winch | A mechanical device that provides the necessary force to raise or lower the platform. |

| Hydraulic Cylinder | A crucial component that utilizes fluid pressure to enable lifting actions. |

Understanding the functionality and arrangement of these elements empowers users to optimize the usage of their aquatic systems. Proper maintenance and awareness of each component’s role are vital for longevity and performance.

Key Components of Boat Lifts

The functionality of a marine elevation system relies on several essential elements working in harmony. These crucial components ensure that vessels can be raised or lowered efficiently and safely, providing a seamless experience for users. Understanding these elements is vital for anyone looking to operate or maintain such a system.

One of the primary features includes the framework, which serves as the backbone of the entire setup. This structure supports the weight of the vessel and the associated mechanisms. Complementing this is the hoisting mechanism, responsible for the elevation process, utilizing cables or pulleys to maneuver the craft smoothly.

Additionally, a reliable power source is indispensable, whether it’s hydraulic, electric, or manual. Each type has its advantages, allowing for varying degrees of control and efficiency. Furthermore, control systems play a pivotal role, enabling users to operate the elevation mechanism with precision and ease.

Finally, safety features such as limit switches and emergency stops are critical for preventing accidents and ensuring secure operations. Together, these integral components form a cohesive unit that enhances the overall functionality and safety of the marine elevation process.

Importance of Maintenance in Boat Lifts

Proper upkeep of marine equipment is essential for ensuring optimal performance and longevity. Regular attention to these systems not only enhances functionality but also prevents unexpected failures that can lead to costly repairs and safety hazards. Consistent maintenance fosters reliability and efficiency, ultimately safeguarding the investment made in such essential apparatus.

Benefits of Routine Upkeep

Conducting frequent inspections and maintenance checks provides numerous advantages. These practices help identify wear and tear early on, allowing for timely interventions. Additionally, a well-maintained system promotes smoother operations, reducing the likelihood of malfunction during critical moments.

Key Maintenance Practices

| Maintenance Activity | Description | Frequency |

|---|---|---|

| Inspection of Components | Regularly check for signs of corrosion, damage, or wear in critical components. | Monthly |

| Lubrication | Apply appropriate lubricants to moving parts to reduce friction and wear. | Quarterly |

| Electrical System Check | Examine electrical connections and control systems for proper function. | Bi-Annually |

| Cleaning | Remove debris and contaminants that may affect performance. | As Needed |

In summary, maintaining marine apparatus is vital for ensuring reliable operation and safety. By implementing regular checks and adhering to best practices, users can maximize the efficiency and lifespan of their equipment.

Types of Shorestation Boat Lifts

The variety of available options for elevating watercraft offers distinct advantages tailored to specific needs and environments. Understanding these different categories is crucial for making informed decisions when selecting a system for aquatic storage or maintenance. Each type is designed with unique functionalities and features, catering to various user requirements and preferences.

Floating Systems: These models utilize buoyancy to elevate the vessel above the waterline, ensuring stability and ease of access. They are ideal for fluctuating water levels and are often simple to install and remove. Their design provides flexibility, accommodating various sizes and weights.

Vertical Systems: This style employs a vertical mechanism to raise the craft directly from the water, making it a popular choice for limited spaces. It offers efficient operation and minimizes the footprint required on the shoreline. The lifting process is straightforward, allowing for quick retrieval and storage.

Cradle Systems: Designed to securely support the hull, cradle configurations distribute weight evenly, providing enhanced stability during storage. They are particularly suitable for larger vessels and can be customized to fit specific shapes and sizes. These structures often come with additional features for protective storage.

Drive-On Options: These systems allow users to simply drive their watercraft onto a platform, making the docking process incredibly convenient. Ideal for recreational users, they facilitate effortless entry and exit, saving time and effort. This type is particularly favored for its ease of use.

Understanding the various types of systems available enhances the decision-making process, ensuring that users select the best option for their needs. Each category offers unique benefits, contributing to a more efficient and enjoyable experience on the water.

How to Read Parts Diagrams

Understanding schematic representations is essential for anyone involved in maintenance or assembly tasks. These visual aids provide a clear view of components and their relationships, making it easier to identify and source necessary items. A solid grasp of these illustrations not only enhances efficiency but also minimizes the risk of errors during repairs or construction.

When examining these visuals, start by familiarizing yourself with the various symbols and notations used. Each mark or icon has a specific meaning, often indicating size, shape, or function. Pay attention to the legend or key, which explains these symbols and offers crucial context for interpretation.

Next, observe the layout and organization of the visual representation. Components are usually arranged logically, guiding the viewer from one element to another. Identifying groupings can help in understanding how different parts interact and contribute to the overall system. Note any connections or pathways indicated by lines, which often represent physical or functional links between items.

It’s also important to check for any numerical references that may correlate with a list of items or specifications. These numbers typically serve as unique identifiers, allowing for easy cross-referencing when ordering or sourcing components. Take your time to analyze these references carefully to ensure accuracy.

Lastly, practice is key. The more you engage with these types of illustrations, the more adept you will become at quickly extracting the necessary information. As you gain confidence, you’ll find that these representations can significantly streamline your workflow and enhance your overall understanding of the assembly or maintenance process.

Common Issues with Boat Lift Parts

Maintaining marine equipment requires attention to various components that play crucial roles in its functionality. Regular wear and tear can lead to a variety of challenges that may impede performance and safety. Understanding these common complications is essential for ensuring longevity and reliable operation.

One frequent concern is corrosion, which affects metal components exposed to moisture and saltwater. This deterioration can weaken structural integrity, making timely inspections vital. Additionally, wear on moving elements can result in decreased efficiency, necessitating lubrication and adjustments to maintain optimal function.

Another issue arises from misalignment during installation or use, which can cause undue stress on the mechanisms involved. Over time, this misalignment may lead to further complications, including increased energy consumption and potential breakdowns. Regular alignment checks are crucial for preventing such issues.

Furthermore, electrical components may experience failures due to exposure to harsh environmental conditions. Faulty wiring or connections can disrupt operations, requiring immediate attention to prevent larger problems. Implementing protective measures can mitigate these risks and enhance the reliability of the system.

In conclusion, addressing these common challenges proactively can help ensure the smooth operation of marine equipment. Routine maintenance, timely repairs, and vigilance are key factors in sustaining performance and extending the life of these essential systems.

Materials Used in Boat Lift Construction

The construction of lifting mechanisms for aquatic vehicles involves a variety of materials that contribute to their functionality and durability. Each component plays a crucial role in ensuring safety and efficiency while operating in marine environments. The choice of materials is influenced by factors such as corrosion resistance, strength, and weight, which are essential for the longevity and reliability of these systems.

Commonly Utilized Materials

Among the most frequently employed materials are stainless steel and aluminum. Stainless steel is renowned for its excellent resistance to rust and corrosion, making it ideal for environments exposed to moisture and saltwater. Its strength allows for the construction of robust frames and supports. On the other hand, aluminum is lightweight yet strong, facilitating ease of installation and transportation, while also resisting corrosion effectively.

Other Essential Components

In addition to metals, various synthetic materials are used to enhance performance. Polyethylene, for example, is a popular choice for floats due to its buoyancy and resistance to chemicals. Additionally, composite materials can offer improved strength-to-weight ratios and flexibility in design, enabling manufacturers to create innovative solutions tailored to specific needs.

In conclusion, the selection of materials in the construction of lifting systems is critical to achieving optimal performance and durability. By understanding the properties of each material, manufacturers can design systems that withstand the rigors of aquatic environments while ensuring user safety.

Installation Tips for Boat Lifts

When setting up a system for elevating your watercraft, attention to detail is essential for ensuring a smooth and efficient operation. Proper installation not only enhances functionality but also prolongs the lifespan of your equipment. Here are some valuable recommendations to consider during the installation process.

Preparation and Planning

- Research local regulations to ensure compliance with safety standards and environmental guidelines.

- Assess the area for installation, considering factors such as water depth, soil conditions, and proximity to power sources.

- Create a detailed plan that outlines the installation process, including required tools and materials.

Installation Steps

- Begin by assembling all necessary components, ensuring everything is in good condition.

- Securely anchor the system to prevent movement caused by water currents or wind.

- Carefully follow the manufacturer’s instructions for positioning and connecting components.

- Test the system multiple times to confirm it operates smoothly before regular use.

By adhering to these guidelines, you can ensure a successful setup that meets your needs and enhances your experience on the water.

Identifying Replacement Parts Effectively

When it comes to maintaining complex machinery, pinpointing the appropriate components for replacement is essential. An organized approach can save time and ensure optimal functionality. Understanding the intricacies of the system, including the various elements involved, can significantly enhance the process of finding suitable substitutes.

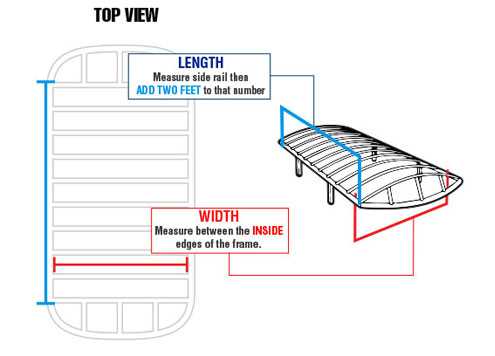

One effective method is to utilize comprehensive reference materials that outline the specific components used in the machinery. These resources often include visual aids and detailed descriptions that facilitate the identification of necessary items. Additionally, consulting the manufacturer’s documentation can provide insights into compatibility and specifications.

| Identification Method | Description | Benefits |

|---|---|---|

| Manufacturer’s Manual | A detailed guide provided by the producer, listing components and specifications. | Ensures compatibility and provides insights into installation procedures. |

| Visual Reference | Diagrams or photographs that showcase the components and their placements. | Enhances understanding of the assembly and facilitates quicker identification. |

| Online Resources | Websites and forums dedicated to equipment maintenance and repair. | Offers community support and shared experiences that can aid in troubleshooting. |

By utilizing a combination of these strategies, one can streamline the process of identifying and acquiring the necessary components. This proactive approach not only minimizes downtime but also contributes to the longevity and efficiency of the machinery.

Safety Features of Boat Lifts

The design and functionality of lifting mechanisms for watercraft have greatly evolved, with an emphasis on ensuring user safety and operational reliability. These systems incorporate various protective features that safeguard both the vessel and its users during the handling process. Understanding these attributes is crucial for maintaining optimal performance and preventing accidents.

Emergency Stop Mechanism: One of the key components in any handling system is the emergency stop feature. This allows operators to quickly halt operations in case of an unexpected situation, minimizing the risk of injury or damage. Quick access to this mechanism is vital for immediate response during emergencies.

Load Monitoring Systems: Advanced load monitoring technologies provide real-time data about the weight being handled. By preventing overload conditions, these systems ensure that the lifting apparatus operates within safe limits, thereby reducing the likelihood of mechanical failure.

Safety Barriers: Physical barriers are often installed around the operational area to protect users from accidental falls or collisions. These barriers create a safer environment, especially in busy marine facilities, where numerous activities occur simultaneously.

Regular Maintenance Checks: A proactive maintenance schedule is essential for the longevity and safety of handling systems. Routine inspections help identify potential issues before they escalate, ensuring that all safety features are functioning as intended.

Investing in advanced safety features not only enhances the operational efficiency of handling mechanisms but also provides peace of mind to users, allowing them to focus on enjoying their time on the water.

Upgrading Your Boat Lift System

Enhancing your aquatic transport elevation system can significantly improve its performance, efficiency, and longevity. With advancements in technology and materials, it is essential to consider modernizing various components to ensure optimal functionality. This upgrade process not only elevates the user experience but also addresses any wear and tear that may have accumulated over time.

When contemplating an upgrade, evaluate the existing configuration for potential improvements. Incorporating new mechanisms can enhance reliability, while the introduction of advanced materials can increase resilience against environmental factors. Upgrading motors and controls can lead to smoother operations and increased safety.

Additionally, consider integrating smart technology for monitoring and control, which provides real-time data on performance metrics. This modern approach allows for proactive maintenance, ensuring that any issues are addressed before they escalate. Implementing such innovations will not only streamline operations but also reduce long-term maintenance costs.

Ultimately, a well-planned upgrade can transform your elevation system into a more efficient and user-friendly solution, adapting to the evolving needs of maritime activities. Investing in such enhancements is a step toward maximizing functionality and enhancing overall satisfaction with your aquatic ventures.

Frequently Asked Questions on Boat Lifts

This section addresses common inquiries regarding the mechanisms designed for elevating and lowering watercraft. These systems play a crucial role in the maintenance and accessibility of vessels. Understanding their functionality, installation, and care can greatly enhance the user experience and ensure safety on the water.

1. What is the purpose of these elevation systems?

These systems are primarily used to securely raise watercraft out of the water, providing protection from the elements, facilitating repairs, and making launching and retrieval more convenient.

2. How do I determine the right model for my needs?

Choosing the appropriate mechanism depends on factors such as the size and weight of your vessel, the type of environment it will be used in, and your specific accessibility requirements.

3. What maintenance is required for optimal operation?

Regular inspections are essential. Ensure that all components are clean and free of debris, lubricate moving parts, and check for any signs of wear or corrosion to maintain functionality and extend the lifespan of the equipment.

4. Can I install one of these systems myself?

While some individuals may have the skills to install the equipment independently, it is advisable to consult a professional to ensure proper setup and compliance with local regulations.

5. Are there any safety considerations to keep in mind?

Absolutely. Always follow the manufacturer’s guidelines for operation, ensure that the system is rated for the weight of your vessel, and be mindful of weather conditions that may affect stability and safety.

Resources for Boat Lift Owners

For individuals who own a platform for elevating watercraft, access to reliable resources is essential for maintaining and optimizing their equipment. Various tools, guides, and expert advice can assist in ensuring safe and efficient operation. This section provides a collection of valuable information and resources tailored specifically for enthusiasts and operators in this domain.

Here are some useful resources to enhance your knowledge and maintenance practices:

| Resource Type | Description | Link |

|---|---|---|

| Maintenance Guides | Comprehensive manuals detailing upkeep and troubleshooting techniques. | Visit |

| Online Forums | Communities where owners share experiences and solutions to common issues. | Visit |

| Video Tutorials | Visual aids demonstrating installation and repair processes. | Visit |

| Expert Consultations | Access to professionals for personalized guidance and advice. | Visit |

| Parts Suppliers | Trusted vendors for acquiring components and accessories needed for maintenance. | Visit |