Exploring the intricate components of a cutting instrument can enhance both its maintenance and performance. Familiarity with its inner workings allows users to optimize efficiency and longevity. This section aims to provide a comprehensive overview of the essential elements that make up such a device.

By delving into the specifics of its construction, one can gain valuable insights into functionality and potential upgrades. An ultimate understanding of how these pieces interact with each other can empower users to troubleshoot issues effectively and enhance their crafting experience.

Whether you are a novice or a seasoned expert, knowing the layout and purpose of each segment is crucial. This knowledge not only supports effective operation but also encourages a deeper appreciation for the craftsmanship involved in these tools.

Understanding the Bosch 4000 Table Saw

This section aims to explore the intricacies and functionalities of a well-regarded woodworking tool, focusing on its components and mechanisms. Gaining insight into its design and operational features will ultimately enhance the user’s experience and efficiency during projects.

Equipped with a powerful motor, this machinery provides the necessary strength to handle various materials. The thoughtful engineering ensures precision cuts, making it an ideal choice for both hobbyists and professionals. Users can delve into its adjustable features, which cater to a range of cutting needs, enhancing versatility.

Furthermore, understanding the assembly and maintenance of this equipment is crucial for longevity and optimal performance. Each element plays a vital role in achieving desired outcomes, underscoring the importance of familiarization with the tool’s structure.

Key Features of the Bosch 4000

This model stands out for its exceptional blend of precision, power, and versatility, making it an ideal choice for both professionals and hobbyists. Its innovative design and advanced technology enhance user experience and safety, ensuring that every cut is clean and accurate.

Precision and Performance

- High-torque motor providing consistent power for various materials.

- Accurate cutting capabilities for precise measurements and angles.

- Enhanced stability features to minimize vibration during operation.

User-Friendly Design

- Intuitive controls for easy adjustments and settings.

- Lightweight and portable design for convenient transport.

- Integrated safety features to protect users during operation.

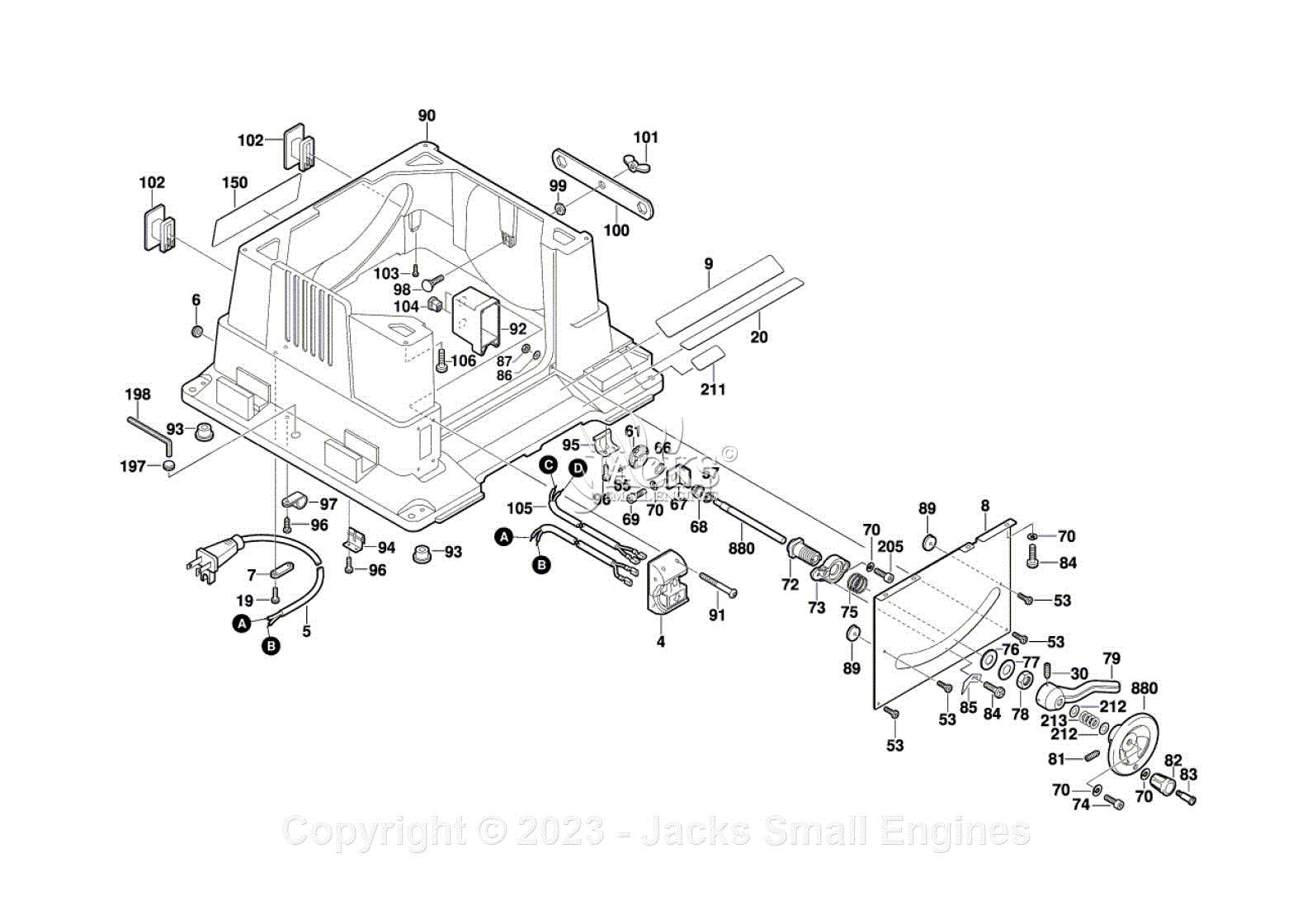

Identifying Essential Parts and Components

Understanding the fundamental elements and mechanisms of a cutting device is crucial for effective operation and maintenance. Familiarity with these components enhances user experience and ensures safety during use. This section will delve into the key elements that make up such equipment, outlining their functions and significance.

| Component | Description |

|---|---|

| Blade | The primary cutting instrument that determines the precision and quality of cuts. |

| Fence | A guide that helps in making straight cuts and maintaining accurate measurements. |

| Table | The flat surface that supports the material being cut, allowing for stability and control. |

| Motor | The power source that drives the cutting blade, influencing speed and efficiency. |

| Guard | A safety feature designed to protect the user from accidental contact with the blade. |

| Base | The foundational structure that provides stability and support for the entire unit. |

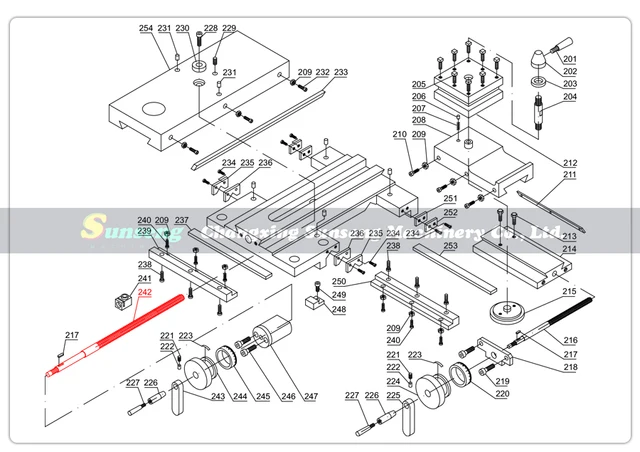

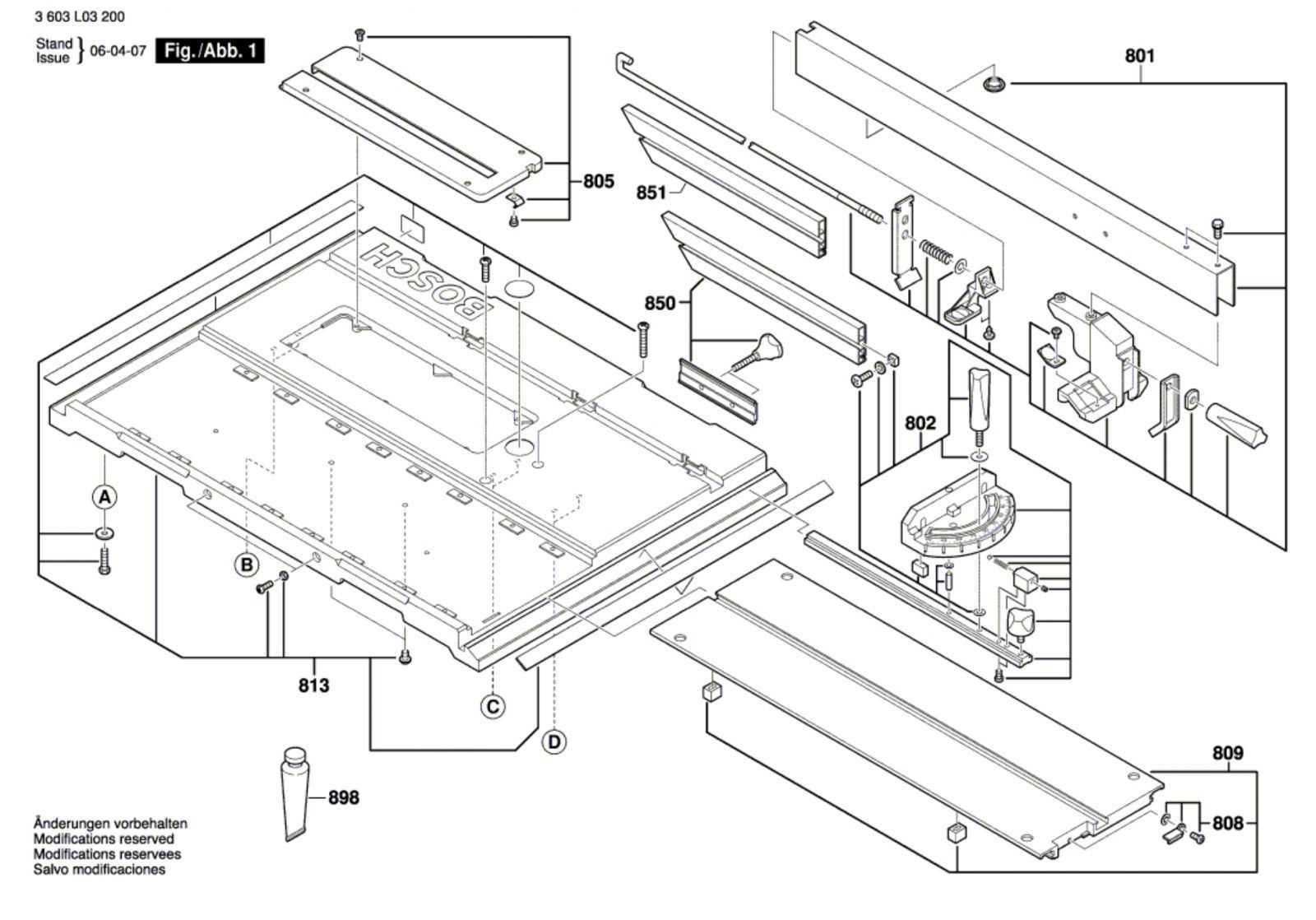

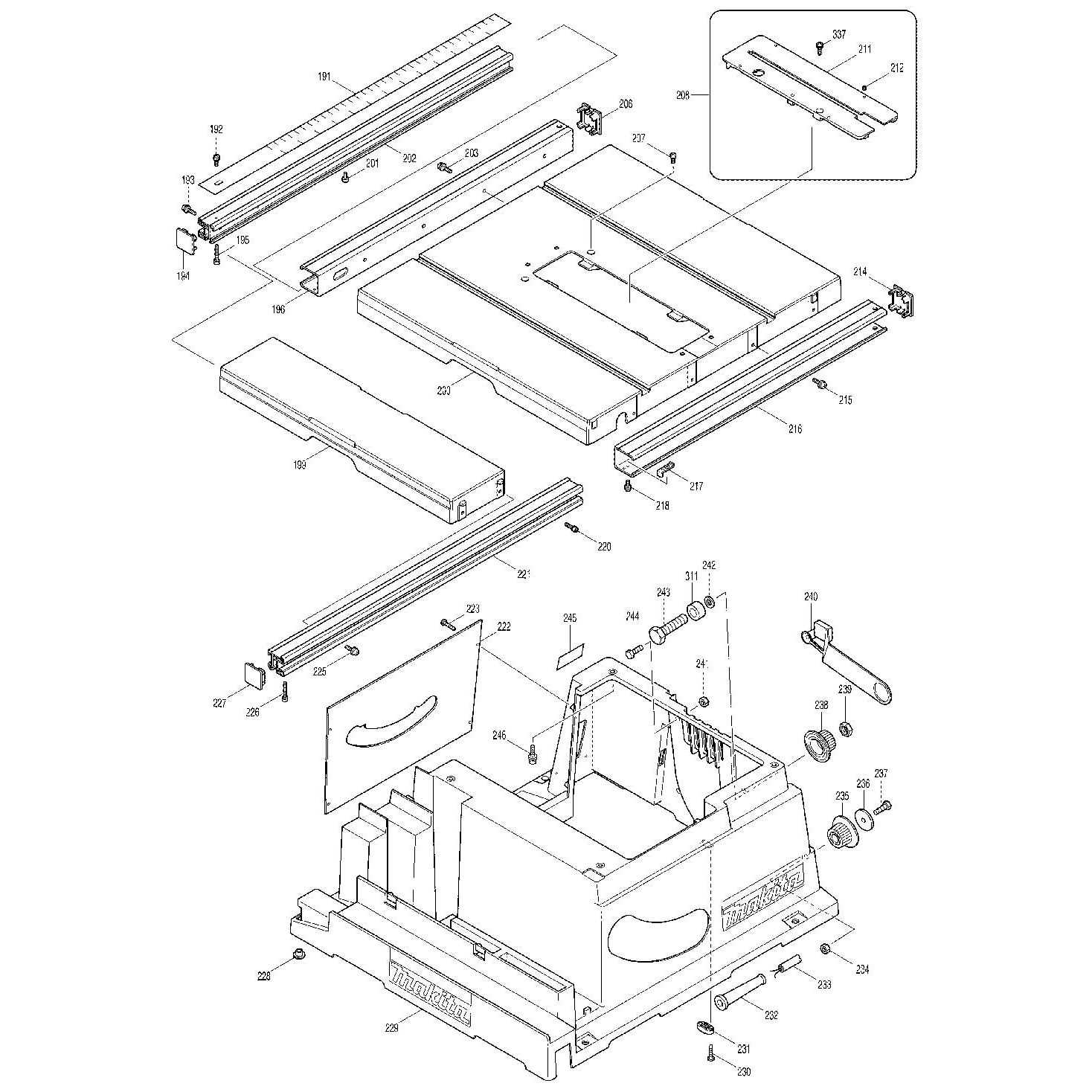

How to Read Parts Diagrams

Understanding illustrations that display component layouts is essential for effective maintenance and repair. These visual representations serve as guides, enabling users to identify and locate various elements within a device or machinery. Grasping how to interpret these visuals can simplify troubleshooting and replacement tasks.

To effectively read these illustrations, consider the following steps:

- Familiarize Yourself with Symbols: Different shapes and icons often represent specific components. Take time to learn what each symbol signifies.

- Identify the Layout: Observe the arrangement of components. This can provide insight into how parts interact with each other.

- Check for Labels: Many illustrations include labels or numbers corresponding to a list of parts. Make sure to reference this for clarity.

- Look for Key Details: Pay attention to any additional notes or arrows that indicate the orientation or assembly of parts.

- Use a Reference Guide: Having a manual or guide handy can help clarify any uncertainties about the components depicted.

By following these guidelines, you’ll enhance your ability to navigate component illustrations, making repairs and maintenance more straightforward and efficient.

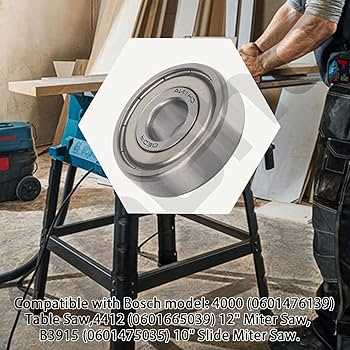

Common Replacement Parts for Maintenance

Regular upkeep of your cutting equipment ensures optimal performance and extends its lifespan. Understanding the most frequently replaced components can help you keep your machine in excellent working condition. Whether you’re a hobbyist or a professional, knowing these essential elements can save time and enhance efficiency during projects.

Blades

The cutting edge of any tool is vital for precision. Replacing dull or damaged blades is crucial for achieving clean cuts and maintaining safety. High-quality blades are available in various materials and designs, allowing you to select the one that best fits your specific tasks.

Motor Brushes

Motor brushes play a significant role in the operation of your device. Over time, these components wear down and can cause reduced power or efficiency. Regularly checking and replacing them can prevent unnecessary disruptions and ensure smooth functionality.

Where to Find Original Bosch Parts

Finding authentic components for your machinery is essential for maintaining optimal performance and safety. Quality replacements ensure that your equipment functions as intended and can help prolong its lifespan. Here are some reliable sources to obtain genuine replacements.

- Official Manufacturer Website: Start by visiting the official website of the manufacturer. They often have a dedicated section for spare components, where you can search for your specific model.

- Authorized Retailers: Look for retailers who are authorized to sell the manufacturer’s products. These stores typically stock original components and can provide guidance on compatibility.

- Local Service Centers: Reach out to local service centers that specialize in equipment repair. They can often order original parts directly from the manufacturer.

- Online Marketplaces: Utilize reputable online marketplaces that feature genuine products. Always check seller ratings and reviews to ensure authenticity.

- Industry Trade Shows: Attend trade shows related to your equipment. Exhibitors often showcase their products, and you might find vendors offering original components.

By exploring these avenues, you can ensure that you acquire authentic replacements, keeping your machinery in peak condition.

Exploring Aftermarket Alternatives

In the realm of woodworking equipment, the availability of aftermarket options has become increasingly popular among enthusiasts and professionals alike. These alternatives provide a range of choices that can enhance functionality, improve durability, or simply offer cost-effective solutions. Understanding the landscape of these options is essential for anyone looking to optimize their tools.

Benefits of Aftermarket Options

- Cost-Effectiveness: Many aftermarket components are available at lower prices compared to original manufacturer items, allowing users to save money.

- Enhanced Performance: Certain aftermarket products are designed to outperform their originals, providing better efficiency and precision.

- Wider Selection: Users can choose from a diverse array of styles and materials, catering to specific needs and preferences.

Considerations When Choosing Alternatives

- Compatibility: Ensure that the alternative fits your equipment properly to avoid operational issues.

- Quality: Research manufacturers and read reviews to gauge the reliability of aftermarket products.

- Warranty: Check if the aftermarket item offers a warranty or guarantee to protect your investment.

By exploring these alternatives, users can make informed decisions that enhance their woodworking experience while potentially reducing costs.

Troubleshooting Common Issues

Addressing frequent challenges with woodworking machinery can enhance both performance and safety. Recognizing symptoms and understanding potential causes allows users to implement effective solutions, ensuring a smoother operation and longer lifespan of the equipment.

Inconsistent Cutting Performance

If you notice uneven cuts or difficulty in achieving the desired depth, check the alignment of the blade and the stability of the work surface. Ensuring that the blade is sharp and properly installed can significantly improve cutting accuracy.

Electrical Problems

Electrical malfunctions may manifest as failure to start or unexpected shutdowns. Inspect the power cord and outlet for any damage. Additionally, ensure that all safety switches are engaged correctly, as these can inhibit operation if not properly set.

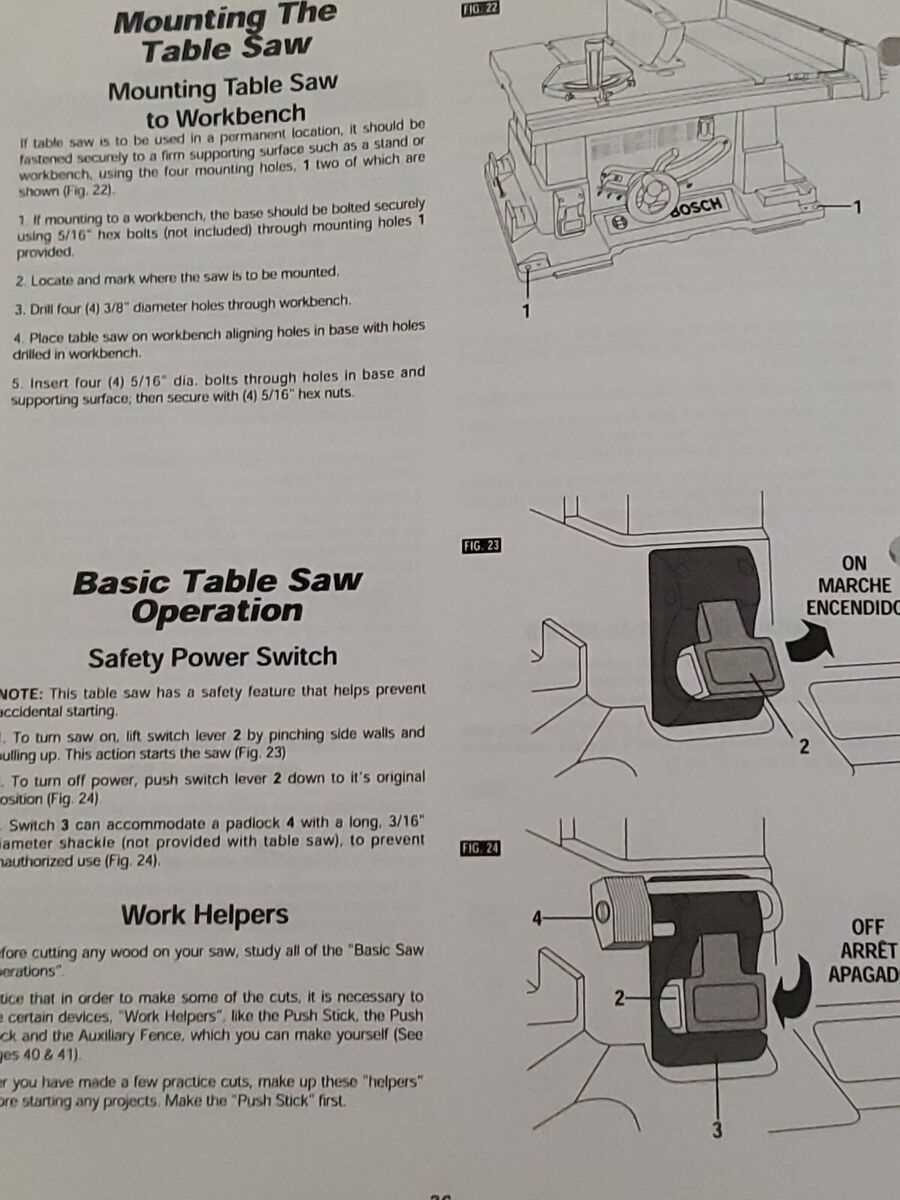

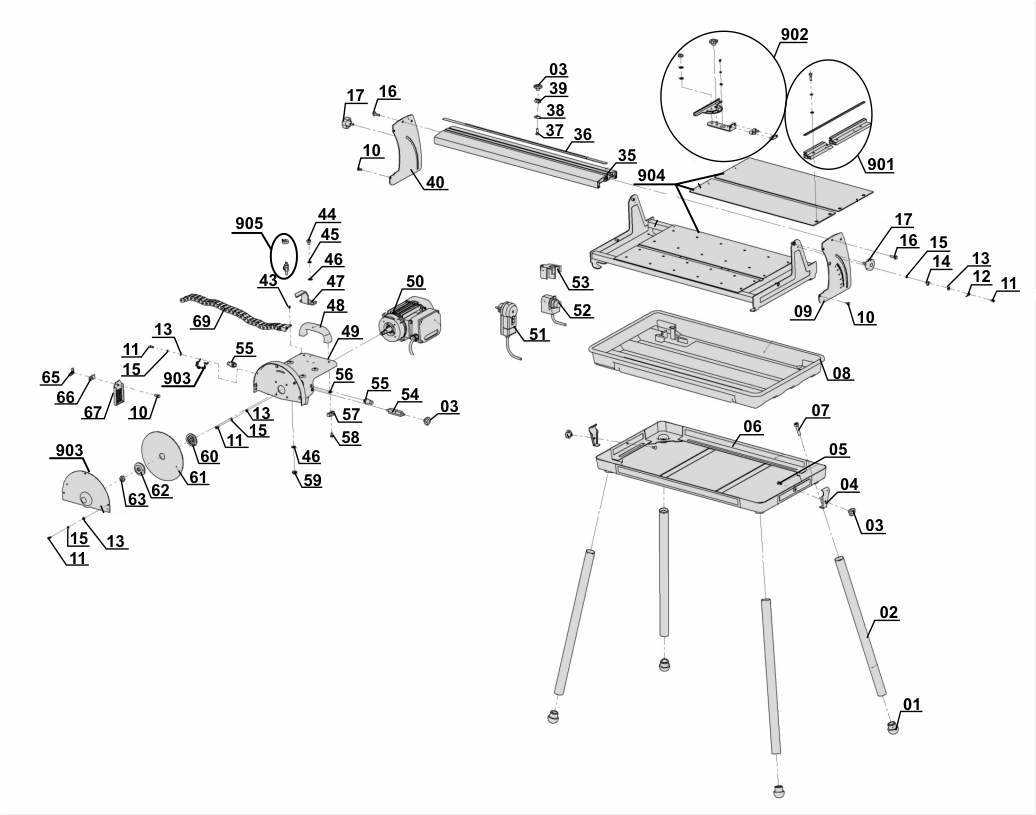

Step-by-Step Assembly Guide

Building your equipment can be an exciting yet challenging endeavor. This guide provides a clear, structured approach to help you assemble your device efficiently and safely. Following each step will ensure that you achieve optimal performance and longevity from your machine.

- Gather Your Tools and Components

Before starting, ensure you have all necessary tools and components on hand. This includes:

- Screwdrivers

- Wrenches

- Safety goggles

- Work gloves

- Read the Instruction Manual

Familiarize yourself with the manual provided. It contains vital information about assembly procedures and safety precautions.

- Prepare Your Workspace

Create a clean, organized workspace. Ensure there’s adequate lighting and room to maneuver.

- Begin with the Base Assembly

Start by assembling the base structure. Follow these steps:

- Align the base components as shown in the manual.

- Secure using the appropriate screws and tools.

- Attach the Main Components

Once the base is secure, proceed to attach the main components. This typically includes:

- Motor housing

- Control panel

- Support arms

- Install Safety Features

Safety features are crucial. Ensure that:

- Emergency stops are functioning.

- Protective covers are properly fitted.

- Final Checks and Testing

After assembly, conduct a thorough inspection. Check for:

- Loose screws

- Correct alignment

- Proper functioning of all parts

Once satisfied, power up the machine for a test run to ensure everything operates smoothly.

lessCopy code

By following these systematic steps, you will successfully assemble your device, ready for a variety of tasks ahead.

Safety Precautions for Operation

Ensuring a safe working environment is paramount when utilizing power equipment. Adhering to specific safety guidelines not only protects the operator but also promotes efficiency and longevity of the machinery. Understanding potential hazards and implementing preventive measures is crucial for a successful operation.

General Guidelines

Before commencing work, familiarize yourself with the equipment’s manual and safety features. Always wear appropriate personal protective equipment (PPE), including goggles, hearing protection, and dust masks. Keep the workspace clean and organized to avoid accidents.

Operational Safety Tips

During operation, maintain a firm stance and ensure proper footing. Avoid wearing loose clothing or accessories that could get caught in moving parts. Never bypass safety guards and keep hands away from cutting areas at all times.

| Precaution | Description |

|---|---|

| Personal Protective Equipment | Use goggles, gloves, and masks as needed. |

| Workspace Organization | Keep the area tidy to prevent slips and falls. |

| Attention to Operation | Stay focused and avoid distractions while working. |

Upgrading Your Bosch Table Saw

Enhancing your cutting tool can significantly improve your woodworking experience. By investing in better components and features, you can achieve greater precision, safety, and efficiency in your projects. Upgrading not only revitalizes your equipment but also allows you to tackle more complex tasks with confidence.

Improving Precision and Performance

One of the first areas to consider for enhancement is the cutting mechanism. Upgrading to high-quality blades can lead to cleaner cuts and reduce the amount of effort required during operation. Additionally, incorporating a digital measuring system can help ensure accuracy, making your work more consistent and professional.

Enhancing Safety Features

Safety should always be a top priority. Adding features like riving knives and improved blade guards can greatly reduce the risk of accidents. Furthermore, installing a better dust collection system will not only keep your workspace clean but also improve visibility and reduce respiratory hazards.

Maintaining Longevity of Your Tool

Ensuring the durability and efficiency of your equipment requires consistent care and attention. Proper maintenance not only extends the life of your device but also enhances its performance, making every project smoother and more enjoyable. By following a few key practices, you can protect your investment and avoid costly repairs or replacements.

Regular cleaning is essential to prevent the accumulation of dust and debris, which can hinder functionality. After each use, take a moment to wipe down surfaces and remove any buildup that could affect the operation. Additionally, keeping moving parts lubricated is crucial for maintaining smooth performance and reducing wear over time.

Checking and tightening screws and fasteners periodically helps to ensure that everything remains secure. Loose components can lead to misalignment and potential damage, so addressing these issues promptly can save time and trouble in the long run. Furthermore, storing your equipment in a dry, climate-controlled environment protects it from rust and corrosion, further extending its lifespan.

Lastly, following the manufacturer’s guidelines for servicing and parts replacement will keep your device running optimally. Regular inspections and timely updates will prevent minor issues from escalating into major problems, allowing you to enjoy your tool for years to come.