In the realm of woodworking and craftsmanship, the functionality of cutting equipment heavily relies on the intricate arrangement of its individual elements. Recognizing how each component interacts and contributes to overall performance is essential for both efficient operation and effective maintenance. A well-structured layout provides invaluable insight into the mechanics of these powerful devices, ensuring users can maximize their capabilities.

For enthusiasts and professionals alike, a clear representation of the assembly can demystify complex machinery. By exploring the various segments involved, one can appreciate the engineering that facilitates precision and reliability in each task. This knowledge not only enhances user experience but also promotes safety and longevity of the equipment.

Whether you are troubleshooting issues or performing routine maintenance, familiarizing yourself with the intricate relationships between the components will empower you to tackle challenges with confidence. Understanding the visual guide to the arrangement allows for informed decisions, ensuring your tools operate at their best.

Understanding Bosch Table Saw Components

Grasping the intricacies of various elements in cutting machinery is essential for optimal performance and maintenance. Each component plays a crucial role in ensuring precision and safety, making it vital for users to familiarize themselves with these essential features.

Main Features

Core components contribute to the functionality and efficiency of the equipment. Knowing how these elements interact enhances the user experience and fosters better care.

| Component | Description |

|---|---|

| Blade | The main tool for cutting, available in various sizes and tooth configurations. |

| Fence | A guide that ensures straight cuts by holding the material in place. |

| Motor | Powers the equipment, crucial for driving the blade at the required speed. |

Maintenance Tips

Regular inspection of each element ensures longevity and reliability. Users should prioritize cleaning and lubricating moving parts to maintain smooth operation.

Essential Parts of Bosch Table Saws

Understanding the critical components of a cutting tool is vital for effective operation and maintenance. Each element plays a significant role in ensuring precision and efficiency during various tasks. This section highlights the core elements that contribute to the overall functionality and performance.

Blade: The cutting edge is central to achieving clean and accurate cuts. Selecting the right blade type and size enhances versatility for different materials.

Motor: The powerhouse of the equipment, responsible for driving the blade. A robust motor is essential for handling various workloads with ease.

Fence: This guiding mechanism ensures straight cuts and stability, providing the user with confidence in their measurements.

Table Surface: A flat and durable workspace supports the material being cut, facilitating smooth movement and preventing binding.

Guard: Safety is paramount. The protective feature shields users from accidental contact with the blade while allowing for unobstructed visibility during operation.

Adjustment Mechanisms: These components allow users to modify settings for different cutting depths and angles, enhancing the tool’s adaptability.

By familiarizing oneself with these crucial elements, users can optimize their experience and ensure longevity of their cutting tools.

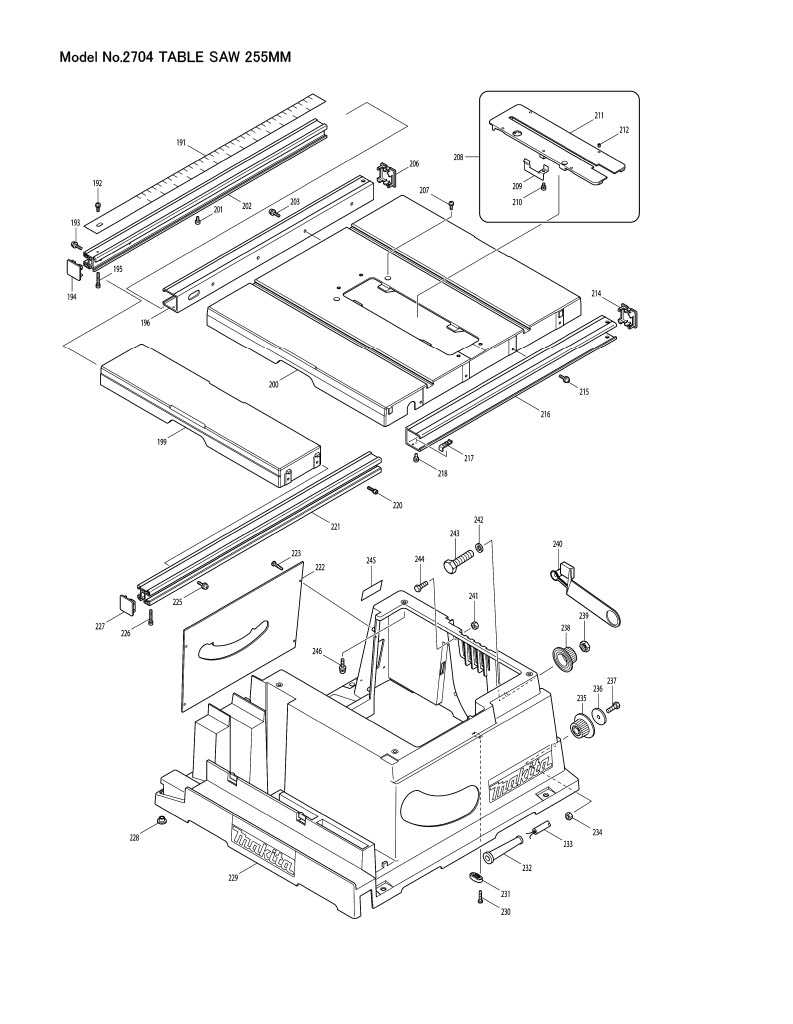

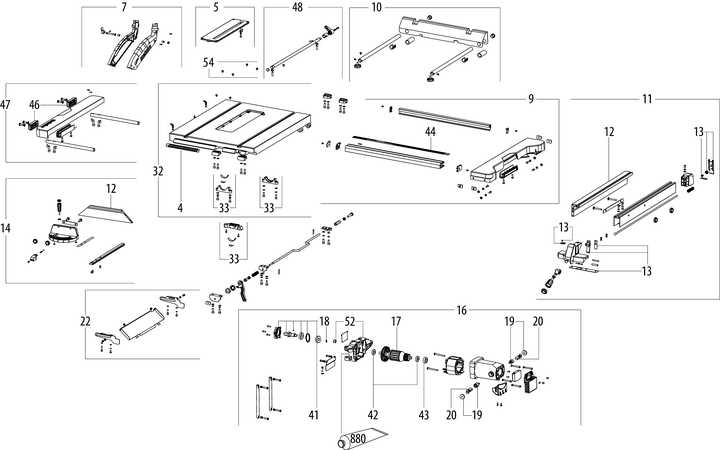

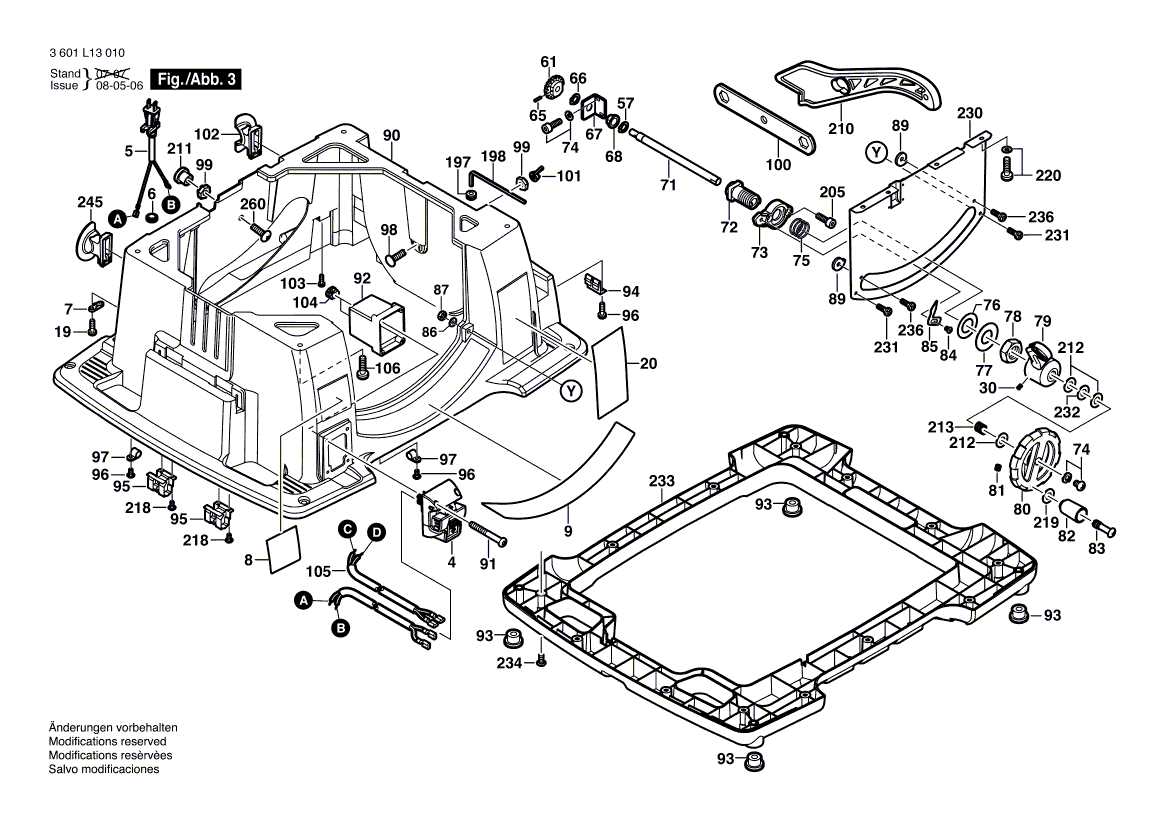

How to Read Parts Diagrams

Understanding assembly illustrations is essential for effective maintenance and repair of various machinery. These visual representations provide a clear overview of components, their relationships, and how they fit together. Familiarizing yourself with these drawings can greatly enhance your ability to identify and replace parts as needed.

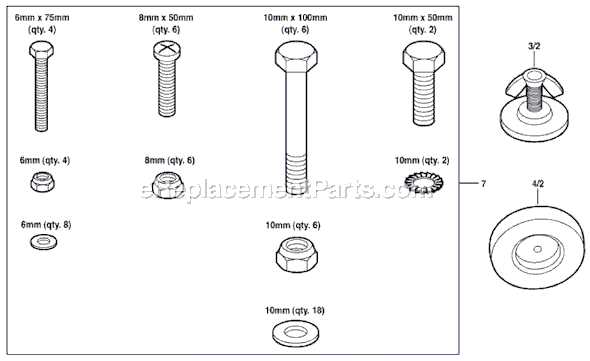

Components and Symbols

Each illustration contains numerous symbols and labels that correspond to specific elements. Familiarize yourself with these symbols to quickly identify the parts you need. Typically, you will find numbered references that align with a parts list, making it easier to locate the required components for repairs or upgrades.

Interpreting Relationships

Beyond individual parts, understanding how they interact is crucial. Look for lines and arrows that indicate connections or movements between elements. This context will aid you in grasping the overall function of the machinery and anticipating potential issues that may arise from wear or damage.

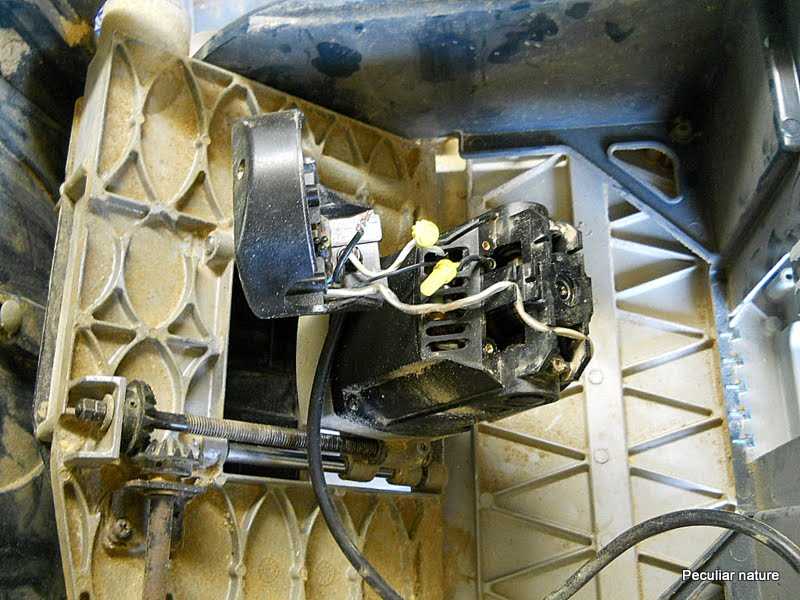

Common Issues with Table Saw Parts

Many users encounter challenges with their cutting machines, which can affect performance and safety. Understanding these frequent complications is essential for effective maintenance and operation.

1. Worn Components

Over time, certain elements may degrade due to extensive use. Commonly affected items include:

- Blades: Dull edges can lead to poor cuts and increased effort.

- Bearings: Friction may increase, causing noise and reduced efficiency.

- Belts: Signs of wear can lead to slipping or improper functioning.

2. Misalignment Issues

Proper alignment is crucial for optimal performance. Misalignment can result from:

- Improper installation of components.

- Frequent adjustments without recalibration.

- Wear over time that affects the positioning of key parts.

Replacement Parts for Bosch Models

Maintaining your equipment in optimal condition is essential for achieving the best results in your projects. Understanding the various components that may need replacement over time ensures that your machine operates smoothly and efficiently. This section provides an overview of essential items that may require substitution for continued high performance.

Common Components for Replacement

- Blades

- Belts

- Switches

- Motors

- Fences

Finding the Right Replacement

When seeking replacements, it is vital to refer to the specific model’s specifications to ensure compatibility. Always opt for original equipment to maintain quality and performance. Online retailers, local dealers, and service centers can be reliable sources for acquiring these items.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular attention and care. By implementing effective upkeep practices, you can enhance performance and extend the lifespan of your tools. This section outlines essential strategies for maintaining your machinery in optimal condition.

Regular Cleaning

Keep your tools free from dust and debris. Accumulation can lead to operational issues and decreased efficiency. Use appropriate cleaning agents and brushes to ensure all surfaces are maintained.

Lubrication and Inspection

Frequent lubrication of moving components is crucial. Regularly inspect for wear and tear, replacing any damaged parts promptly to prevent further deterioration.

| Maintenance Task | Frequency |

|---|---|

| Clean surfaces | After each use |

| Lubricate components | Monthly |

| Inspect for damage | Weekly |

| Replace worn parts | As needed |

Upgrading Bosch Table Saw Features

Enhancing the functionality of your woodworking equipment can significantly improve performance and precision. By integrating advanced components and technology, users can transform their setup into a more efficient tool for various projects. Whether you’re looking for increased power, better safety mechanisms, or improved versatility, there are several options available to elevate your experience.

| Feature | Description |

|---|---|

| Laser Guide | Incorporating a laser guide aids in achieving accurate cuts by projecting a line onto the material. |

| Upgraded Motor | Replacing the motor with a higher horsepower version enhances cutting speed and efficiency. |

| Dust Collection System | Adding a robust dust collection mechanism helps maintain a clean workspace and improves visibility. |

| Digital Display | Installing a digital readout allows for precise measurement and adjustments, facilitating better accuracy. |

| Enhanced Fencing | Upgrading to a high-quality fence system ensures better stability and easier adjustments for various materials. |

Comparing Different Bosch Models

When evaluating various models from a renowned manufacturer, it’s essential to consider their features, specifications, and intended uses. Each variant offers unique capabilities that cater to diverse user needs, making it crucial to understand the distinctions for informed decision-making.

Key Features to Consider

- Power and Performance

- Portability and Weight

- Cutting Capacity

- Safety Features

- Ease of Use

Popular Models Overview

-

Model A

Designed for professionals, this variant boasts a robust motor, allowing for heavy-duty tasks. It offers advanced safety mechanisms and precise cutting capabilities.

-

Model B

A more compact option, ideal for DIY enthusiasts. It combines portability with decent power, making it suitable for various home projects.

-

Model C

This entry-level choice caters to beginners, featuring simplified controls and safety features that enhance user confidence during operation.

Tools Needed for Part Replacement

Replacing components in your equipment requires the right set of tools to ensure efficiency and precision. Having the appropriate instruments not only simplifies the process but also minimizes the risk of damage to the machine or its new elements.

Essential Tools

Start with basic hand tools such as screwdrivers, pliers, and wrenches. A set of hex keys is also vital for accessing hard-to-reach fasteners. Additionally, a multimeter can be beneficial for checking electrical connections.

Safety Equipment

Don’t overlook safety gear like gloves and goggles. These items protect against debris and sharp edges, ensuring a safe working environment while you delve into your repairs.

Safety Measures During Repairs

Ensuring safety during maintenance tasks is crucial to prevent accidents and injuries. Proper precautions not only protect the individual performing the work but also help preserve the integrity of the equipment involved. A clear understanding of safety protocols is essential before undertaking any repair activities.

Personal Protective Equipment

Always wear appropriate personal protective gear, including safety goggles to shield your eyes from debris, gloves to protect your hands, and ear protection if the operation involves loud machinery. These items are vital for minimizing risks and ensuring a safer working environment.

Workspace Organization

Maintain a clean and organized workspace to avoid hazards. Ensure that tools are easily accessible and that there are no trip hazards in the vicinity. Proper lighting is also important, as it enhances visibility and reduces the likelihood of accidents during repairs. Regularly check for any potential hazards and address them promptly.

Where to Purchase Bosch Parts

Finding high-quality components for your equipment is essential for maintaining performance and longevity. There are several reliable sources where you can obtain these necessary items, ensuring you get the best value for your investment.

Consider the following options when searching for components:

- Official Retailers: Authorized dealers often carry a complete range of items and can provide expert assistance.

- Online Marketplaces: Websites like Amazon or eBay can be excellent resources for finding both new and used components, often at competitive prices.

- Local Hardware Stores: Many community-based stores stock a variety of items and can offer personalized service.

- Specialty Websites: Numerous sites focus specifically on tools and equipment, providing a wide selection of items and often detailed specifications.

Always ensure to verify the authenticity of the source and check for customer reviews to avoid counterfeit products.

Resources for Bosch Table Saw Users

For enthusiasts and professionals alike, having access to the right resources is essential for maximizing the functionality and lifespan of your woodworking equipment. This section provides valuable information, including support, manuals, and community forums, to enhance your experience and ensure your tools operate at peak performance.

| Resource Type | Description | Link |

|---|---|---|

| User Manual | A comprehensive guide detailing features, setup, and maintenance tips. | Download Manual |

| Replacement Components | Access to a variety of components for repair and upgrades. | View Components |

| Community Forums | Join discussions with fellow users to share tips and troubleshooting advice. | Visit Forums |

| Video Tutorials | Step-by-step videos demonstrating techniques and maintenance procedures. | Watch Tutorials |