In the world of heavy-duty vehicles, ensuring optimal performance and safety is paramount. A thorough grasp of the intricate elements that contribute to the stopping mechanism is essential for both operators and enthusiasts alike. This knowledge not only enhances safety but also aids in the maintenance and troubleshooting processes.

Essential systems play a crucial role in the operation of large transport vehicles. By examining these systems, one can appreciate how they work together to facilitate smooth and controlled halting. Understanding these crucial elements empowers users to make informed decisions regarding repairs and upgrades.

Furthermore, delving into the intricacies of these mechanisms reveals the ultimate importance of proper maintenance. Regular checks and replacements can significantly extend the lifespan of these components, ensuring that vehicles remain reliable and efficient throughout their operational life.

Understanding Semi-Trailer Brake Systems

The effective functioning of large transport vehicles relies heavily on their stopping mechanisms. These systems are crucial for safety and performance, ensuring that operators can control their vehicles under various conditions. A solid grasp of these mechanisms is essential for maintenance and operation.

Key Components of the Stopping Mechanism

At the heart of the stopping system are several key components that work in harmony. Each element, from the hydraulic system to the actuators, plays a vital role in providing the necessary force to halt movement. Understanding how these parts interact allows for better diagnostics and troubleshooting.

Maintenance for Optimal Performance

Regular upkeep is essential to ensure these systems function effectively. Neglecting routine inspections can lead to severe consequences, affecting both safety and efficiency. By focusing on preventive measures, operators can enhance the longevity and reliability of the entire system.

Components of Brake Systems

The efficiency of a stopping mechanism relies on various critical elements working together seamlessly. Each component plays a vital role in ensuring safety and performance in a vehicle’s operation.

- Actuator: Transforms input from the driver into a physical response.

- Calipers: Houses the friction material and applies pressure to the discs.

- Discs: Provides the surface for friction to slow down the wheels.

- Friction Material: Enhances grip and control during deceleration.

- Hydraulic Lines: Transmit force from the actuator to the calipers.

Understanding these elements allows for better maintenance and enhances overall vehicle performance.

Importance of Brake Maintenance

Ensuring the reliability of stopping mechanisms is crucial for the safety and efficiency of any vehicle. Regular upkeep not only prolongs the lifespan of these components but also significantly reduces the risk of failures that could lead to accidents. A well-maintained system contributes to optimal performance, enhancing overall driving experience and confidence on the road.

Neglecting maintenance can result in wear and tear, ultimately compromising the effectiveness of these critical systems. Over time, components may deteriorate, leading to diminished responsiveness and increased stopping distances. Addressing issues promptly is essential to avoid costly repairs and ensure the safety of all road users.

Furthermore, consistent inspections and servicing can help identify potential problems before they escalate, providing peace of mind for drivers and passengers alike. Implementing a routine maintenance schedule is not just a recommendation; it is a necessary practice that promotes safety, reliability, and longevity in vehicles.

Common Brake Failure Signs

Identifying issues with stopping mechanisms early can prevent serious incidents and enhance safety. Awareness of specific symptoms can guide vehicle owners in recognizing potential failures before they escalate.

Visual Indicators

- Fluid leaks under the vehicle

- Worn or damaged components visible through inspection

- Uneven wear on stopping surfaces

Performance Issues

- Unresponsive or spongy pedal feel

- Grinding or squeaking noises during operation

- Vibrations felt while engaging the system

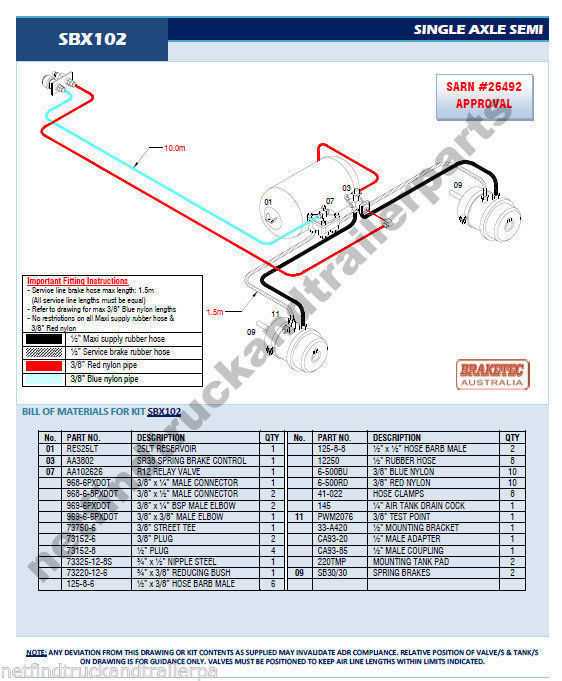

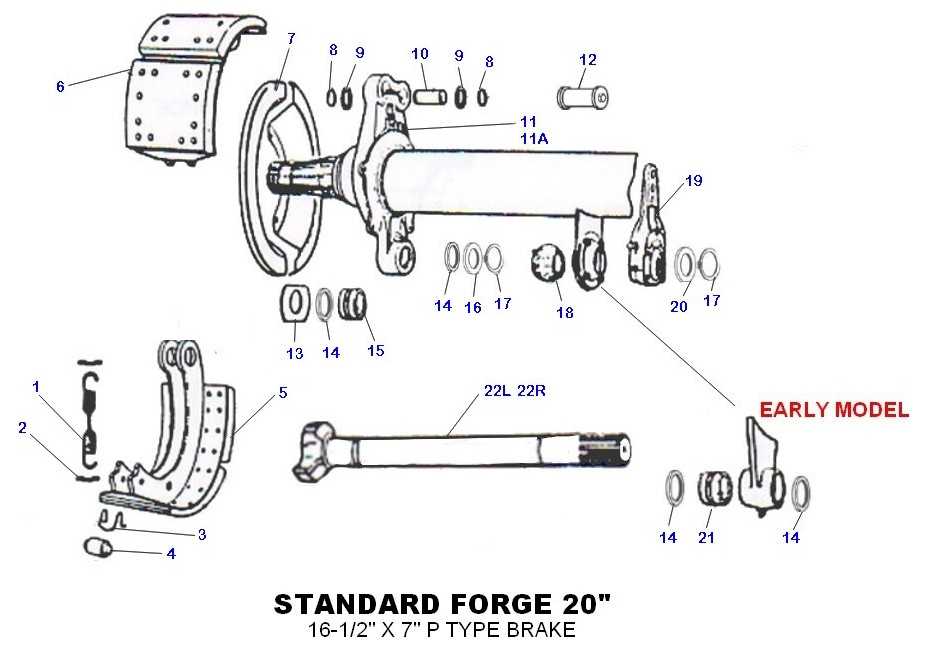

Brake Parts Diagram Explained

This section focuses on the essential components involved in the stopping mechanism of large vehicles. Understanding the layout and function of each element is crucial for maintenance and safety, ensuring optimal performance during operation.

Key Components Overview

The assembly consists of various elements, each playing a vital role in the overall functionality. Familiarity with these components aids in identifying issues and implementing effective solutions.

| Component | Function |

|---|---|

| Actuator | Initiates the stopping process. |

| Pads | Provide friction against the surface. |

| Rotors | Disperse heat and sustain pressure. |

| Lines | Transport hydraulic fluid. |

Importance of Regular Inspection

Routine checks of these elements are vital for preventing malfunction and ensuring safety. Neglect can lead to severe consequences, emphasizing the need for diligence in upkeep.

Types of Brake Mechanisms

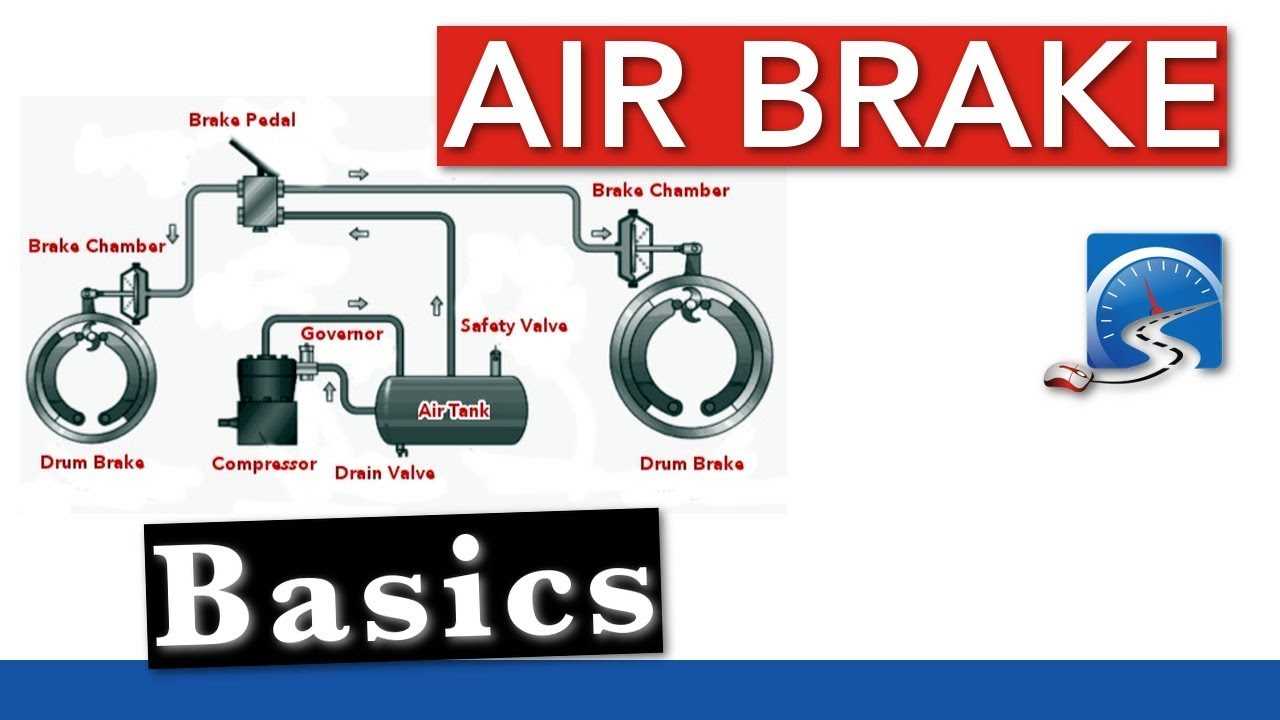

Understanding the various systems that bring vehicles to a halt is essential for optimizing safety and performance. Different approaches utilize distinct principles of operation, catering to specific requirements and conditions encountered during travel. This section explores the main types of these mechanisms and their functionalities.

Disc and Drum Systems

Among the most common mechanisms are disc and drum systems, each with unique characteristics that influence their efficiency and application. Disc systems are known for their superior heat dissipation, while drum systems excel in compactness and cost-effectiveness.

| Type | Advantages | Disadvantages |

|---|---|---|

| Disc | Better cooling, consistent performance | Higher cost, more exposed to debris |

| Drum | Compact design, lower manufacturing cost | Poor heat dissipation, potential for fade |

Hydraulic and Pneumatic Systems

Another classification focuses on the application of pressure. Hydraulic systems utilize fluid to amplify force, providing a responsive feel. Conversely, pneumatic systems rely on compressed air, often seen in larger vehicles for enhanced power delivery.

| Type | Application | Features |

|---|---|---|

| Hydraulic | Passenger vehicles | Responsive, precise control |

| Pneumatic | Commercial vehicles | Powerful, suitable for heavy loads |

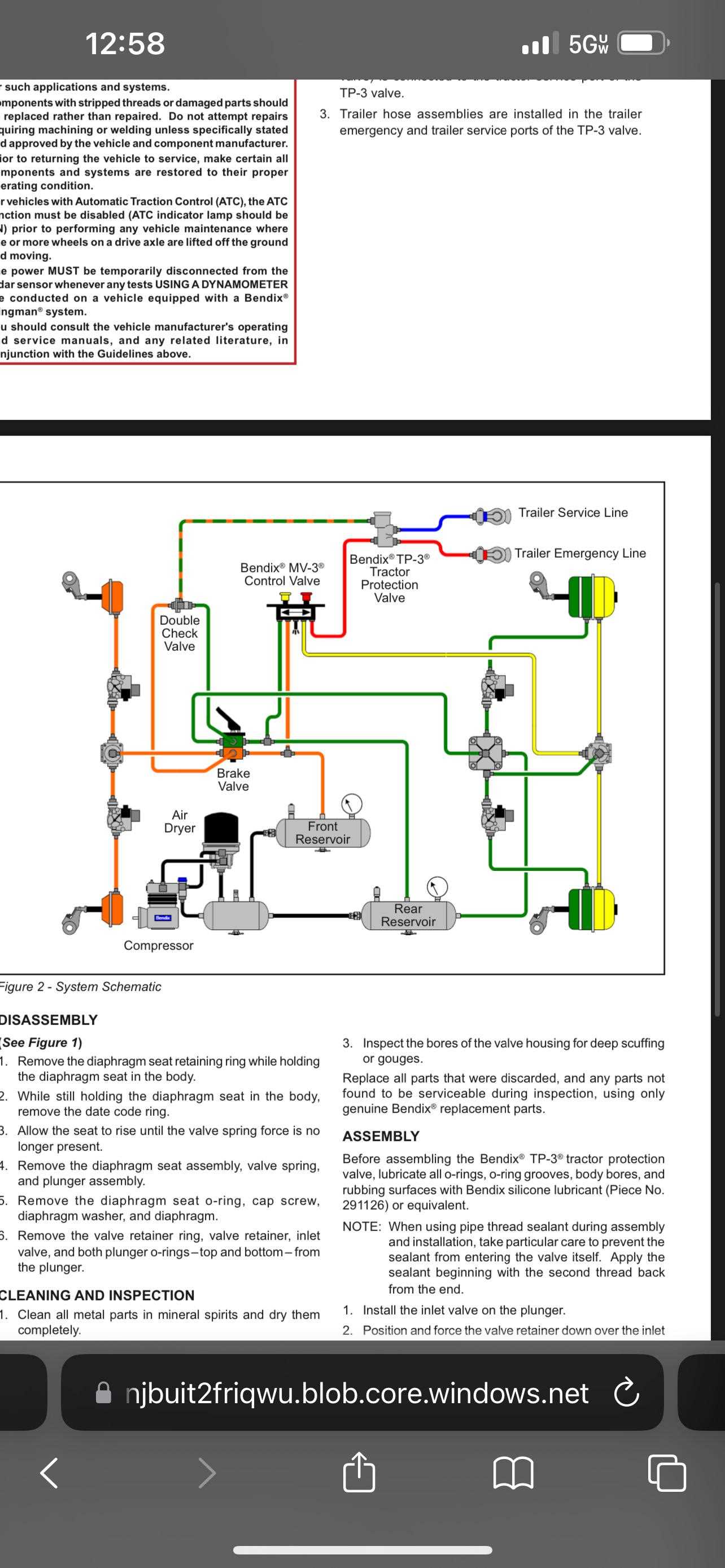

How to Read Brake Diagrams

Understanding technical illustrations can be essential for effective maintenance and repair. These visuals often contain crucial information regarding components and their interconnections. Familiarity with symbols and layouts will enable you to quickly identify elements and their functions, ensuring efficient troubleshooting.

Key Components and Symbols

To interpret illustrations accurately, one must first recognize common symbols. Each element in the visual may represent specific mechanisms or features. Familiarity with these icons is critical for grasping the overall design and functionality.

| Symbol | Description |

|---|---|

| Circle | Indicates a connection point or junction. |

| Arrow | Shows direction of flow or movement. |

| Square | Represents a component, such as a valve or cylinder. |

Interpreting the Layout

Once you recognize symbols, the next step is to analyze the overall layout. Pay attention to how components are arranged and linked. This arrangement can provide insights into operational sequences and potential points of failure, enhancing your diagnostic skills.

Brake Adjustment Techniques

Proper calibration of stopping mechanisms is essential for optimal vehicle performance and safety. This section explores effective methods to ensure components function efficiently, enhancing responsiveness and prolonging lifespan.

- Regular Inspection: Frequently check for wear and tear, ensuring that all elements are in good condition.

- Manual Adjustment: Utilize tools to modify the tension or position of components as needed.

- Automated Systems: Implement advanced technologies that automatically adjust settings based on performance metrics.

By applying these techniques, drivers can achieve the ultimate reliability and efficiency in their vehicles.

Safety Standards for Trailers

Ensuring the well-being of all road users requires adherence to specific guidelines and regulations concerning large transport vehicles. These standards are designed to mitigate risks and enhance the reliability of the equipment, ultimately safeguarding both the cargo and those who operate or encounter these vehicles on the road.

Regulatory Compliance

To maintain safety, various governing bodies establish regulations that must be followed by manufacturers and operators. Compliance with these rules not only promotes safe usage but also fosters public trust in the transportation industry. Regular inspections and certifications are critical components of this compliance process, ensuring that vehicles meet the necessary safety criteria before they are allowed on the roads.

Technological Innovations

Advancements in technology play a vital role in improving the safety of large transport equipment. Innovations such as advanced monitoring systems, automated safety features, and enhanced braking technologies are being integrated to minimize the likelihood of accidents. These improvements not only enhance performance but also provide greater peace of mind for operators and the public alike.

Upgrading Brake Components

Enhancing the stopping mechanisms of heavy-duty vehicles is crucial for improving safety and performance. Upgrades can lead to better responsiveness, reduced wear, and increased durability. By selecting high-quality components, operators can ensure optimal functionality under various driving conditions.

One of the primary considerations when upgrading is the selection of materials. Options like carbon-ceramic and performance-enhanced metals provide greater strength and heat resistance, which can significantly affect performance. Additionally, newer technologies often offer improved designs that enhance air circulation and cooling efficiency.

Another aspect to focus on is the compatibility of upgraded components with existing systems. Proper fitment ensures that new elements work harmoniously with the vehicle’s overall architecture, avoiding potential malfunctions or premature wear. Consulting with professionals or referring to manufacturer guidelines can facilitate a seamless upgrade process.

Moreover, regular maintenance and inspections post-upgrade are vital. Monitoring the condition of new components helps in identifying any issues early on, ensuring that the improvements translate into long-term benefits. Investing in better stopping technology ultimately contributes to enhanced safety and operational efficiency on the road.

DIY Brake Repairs: A Guide

Understanding the mechanisms that ensure your vehicle stops effectively is crucial for every enthusiast. This guide aims to empower you with the knowledge to tackle maintenance tasks, enhancing both safety and performance. From identifying common issues to performing straightforward fixes, you’ll gain confidence in handling repairs yourself.

Start with Safety: Before diving into any maintenance, ensure you have the right tools and safety gear. This includes gloves, goggles, and a sturdy jack to secure your vehicle while you work.

Identifying Issues: Regular inspection is key. Look for signs of wear such as unusual noises or diminished responsiveness. Keeping an eye on these indicators will help you address problems before they escalate.

Step-by-Step Process: Begin with removing the necessary components to access the system. Carefully examine for any damaged or worn elements. Follow manufacturer guidelines for replacements and reassembly, ensuring everything is tightened to specifications.

Test and Adjust: After reassembly, it’s vital to conduct a test. Drive at low speeds to confirm that everything operates smoothly. Make adjustments as needed to ensure optimal functionality.

Professional Brake Service Options

When it comes to ensuring optimal safety and performance of heavy-duty vehicles, specialized maintenance services are crucial. These offerings provide thorough inspections and repairs to critical systems, enhancing reliability and longevity. Engaging with experienced technicians can make a significant difference in maintaining vehicle efficiency.

| Service Type | Description |

|---|---|

| System Inspection | Comprehensive checks of components to identify wear and potential failures. |

| Component Replacement | Installation of new elements to restore optimal functionality and safety. |

| Adjustment Services | Fine-tuning of mechanisms to ensure proper operation and responsiveness. |

| Fluid Changes | Replacement of essential liquids to prevent overheating and ensure smooth operation. |

| Diagnostic Services | Advanced tools used to detect issues and provide accurate solutions. |